ii

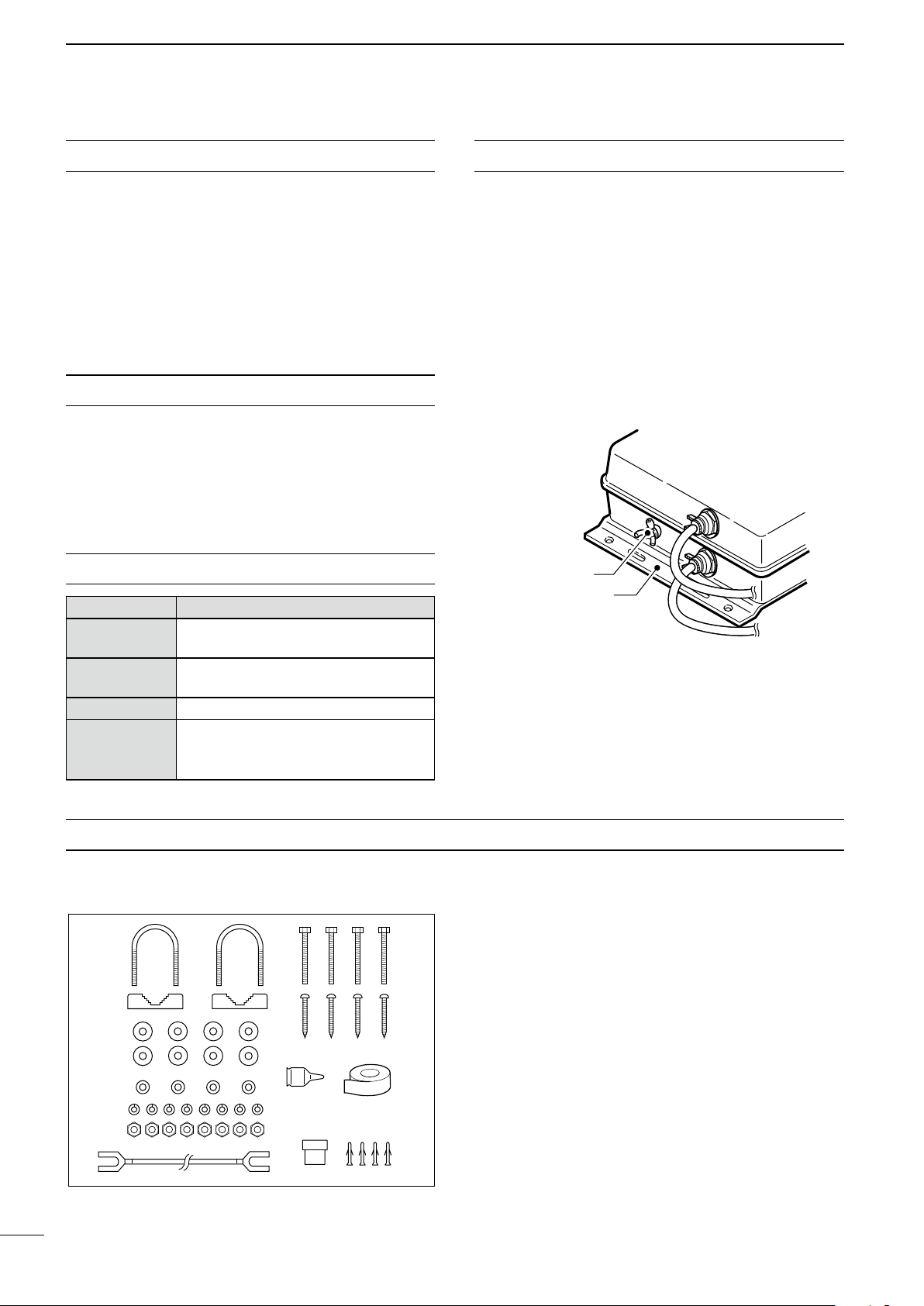

MISCELLANEOUS ITEMS

The following parts are additionally required for instal-

lation, but are not supplied with the AT-141.

Purchase these parts locally.

qAWG 14 × 4 conductor shielded cable

•IcomoffersanoptionalOPC-1465controlcable.

Length: 10 m

w50 Ωcoaxial cable

eTwo PL-259 connectors

FEATURES

Weather resistant

The AT-141 is housed in a durable, completely

weather resistant ASA case, with a rubber gasket. The

antenna tuner can be conveniently installed near the

antenna element.

Matches all bands

The AT-141 matches all frequencies on the HF marine

band. For example, the tuner matches a 7 m long-wire

antenna across 1.6–30 MHz.

Full automatic tuning

Just push the [TUNE] key on the transceiver, and the

AT-141 immediately tunes for a minimum SWR on any

frequency in the HF marine band.

HF operation on any size ship

The AT-141 allows HF operation where antenna ele-

ment length is restricted due to space.

Simple installation

Installation is simple. Just connect the control and an-

tenna cables. You never need to open the cover.

45 memories for shorter tuning time

To decrease the tune-up time, the AT-141 automati-

cally stores the matching conditions for up to 45 fre-

quencies. Retuning a memorized frequency takes ap-

proximately 1 second.

Super capacitor for memory backup

Even if the AT-141 is not used for approximately 1

week, the built-in super capacitor backs up the con-

tents of the 45 memories.

Low power tune up

The AT-141 emits low output power during tuning. This

feature reduces the possibility of causing interference

to other stations.

Tuner Through function

The Tuner Through function is built into the AT-141.

This function helps improve receiver gain, depending

on the antenna element length used, and the operat-

ing frequency.

FOREWORD ………………………………………… ii

IMPORTANT…………………………………………… ii

EXPLICIT DEFINITIONS …………………………… ii

PRECAUTIONS ……………………………………… ii

SUPPLIED ACCESSORIES ………………………… ii

MISCELLANEOUS ITEMS………………………… iii

FEATURES ………………………………………… iii

TABLE OF CONTENTS …………………………… iii

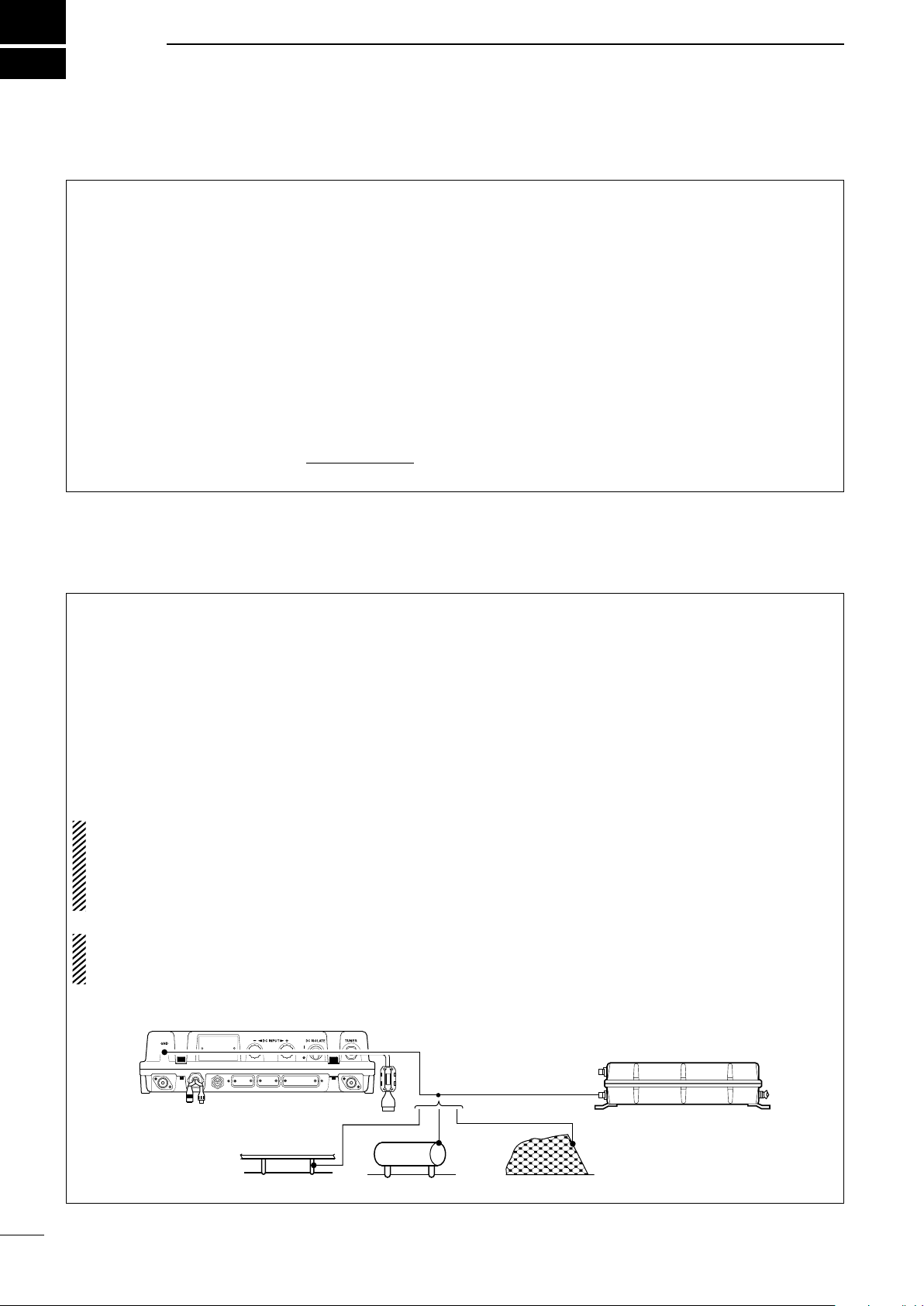

1 SYSTEM INSTALLATION ………………………… 1

Five Critical Points for a successful HF■

installation���������������� 1

Vessel ground connection■�������� 1

Antenna and tuners■������������ 2

The importance of grounding■������� 2

2 ANTENNA SYSTEM ……………………………… 3

Antenna for ship■������������� 3

Coaxial cable■�������������� 4

Ground and counterpoise■��������� 4

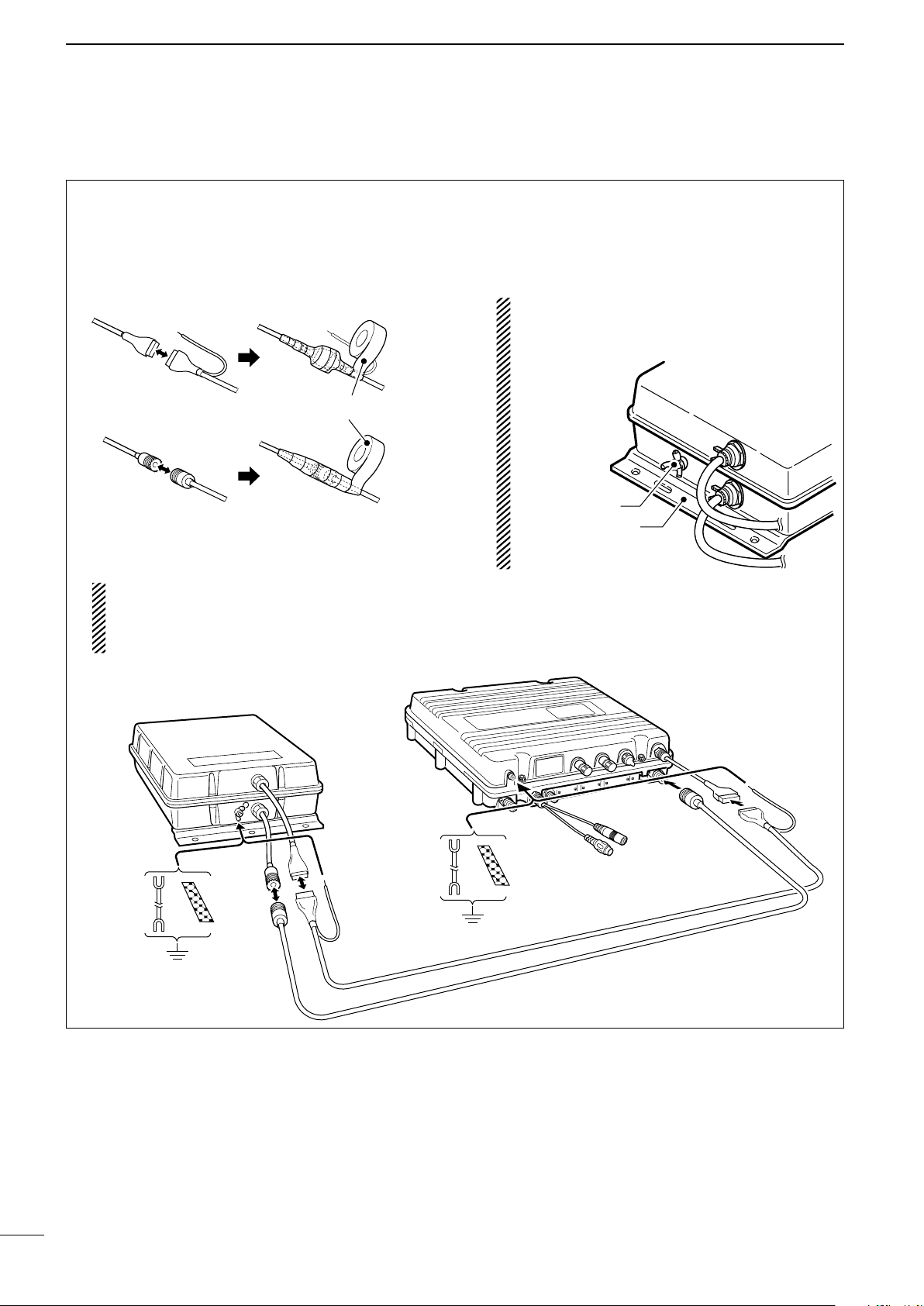

3 INSTALLATIONS ………………………………… 5

Installation outline■������������ 5

Control cable■�������������� 5

PL-259 connector■������������ 5

Waterproofing the antenna connection■��� 6

Mounting■���������������� 6

Cable connections■������������ 7

4 CONTROL CABLE SIGNALS …………………… 8

Terminal information■����������� 8

Unit description■������������� 9

Specifications■�������������� 9

5 UNIT DESCRIPTION AND SPECIFICATIONS … 9

6 INSTALLATION EXAMPLE …………………… 10

TABLE OF CONTENTS