DP1222 Converter 2 x 0...10 V / IO-Link

2

Contents

1 Preliminary note ............................................................. 3

1.1 Symbols used.......................................................... 3

1.2 Warnings used ......................................................... 3

2 Safety instructions............................................................ 4

3 Intended use................................................................ 5

4 Function ................................................................... 6

4.1 Operating modes ....................................................... 6

4.2 Application as an IO-Link device............................................ 6

4.2.1 General information.................................................. 6

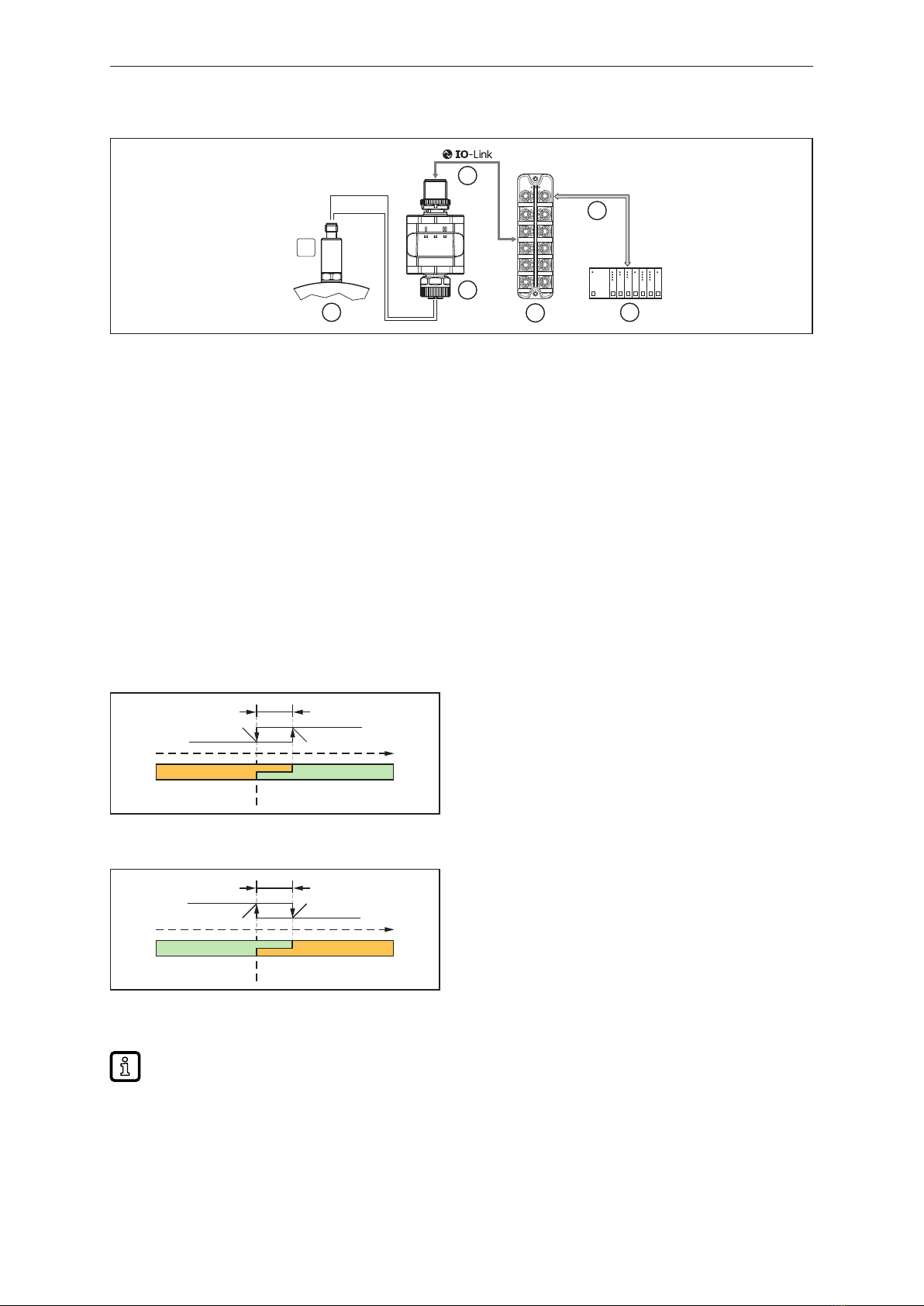

4.2.2 Application example ................................................. 7

4.2.3 IO Device Description (IODD).......................................... 7

4.3 Function diagrams....................................................... 7

4.3.1 Single point mode................................................... 7

4.3.2 Window mode...................................................... 8

4.3.3 Two point mode .................................................... 8

4.3.4 Deactivated mode................................................... 8

5 Installation.................................................................. 10

6 Electrical connection.......................................................... 11

6.1 Mounting the connector................................................... 12

6.2 Removing the connector.................................................. 12

6.3 Cable length........................................................... 12

7 Operating and display elements................................................. 13

7.1 LEDs................................................................. 13

7.1.1 Visualisation of the voltage value at the input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8 Parameter setting............................................................ 14

8.1 Parameters via IO-Link................................................... 14

8.1.1 Application-specific tag............................................... 14

8.1.2 Function Tag....................................................... 14

8.1.3 Location Tag....................................................... 14

8.1.4 internal_temperature – operating temperature microcontroller . . . . . . . . . . . . . . . . . 14

8.1.5 operation_hours – operating hours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

8.1.6 ModE ─ switch point mode............................................ 14

8.1.7 LoGc ─ switch point logic ............................................. 14

8.1.8 SP1 ─ switch point 1................................................. 15

8.1.9 SP2 ─ switch point 2................................................. 15

8.1.10 HyS ─ switch points hysteresis......................................... 15

8.1.11 Mean filter......................................................... 15

9 Operation .................................................................. 16

10 Troubleshooting ............................................................. 17

11 Maintenance, repair and disposal................................................ 18

12 Factory settings.............................................................. 19