2

Contents

1 Preliminary note...................................................................................................4

1.1 Symbols used ................................................................................................4

1.2 Warnings used...............................................................................................4

2 Safety instructions ...............................................................................................5

3 Functions and features ........................................................................................6

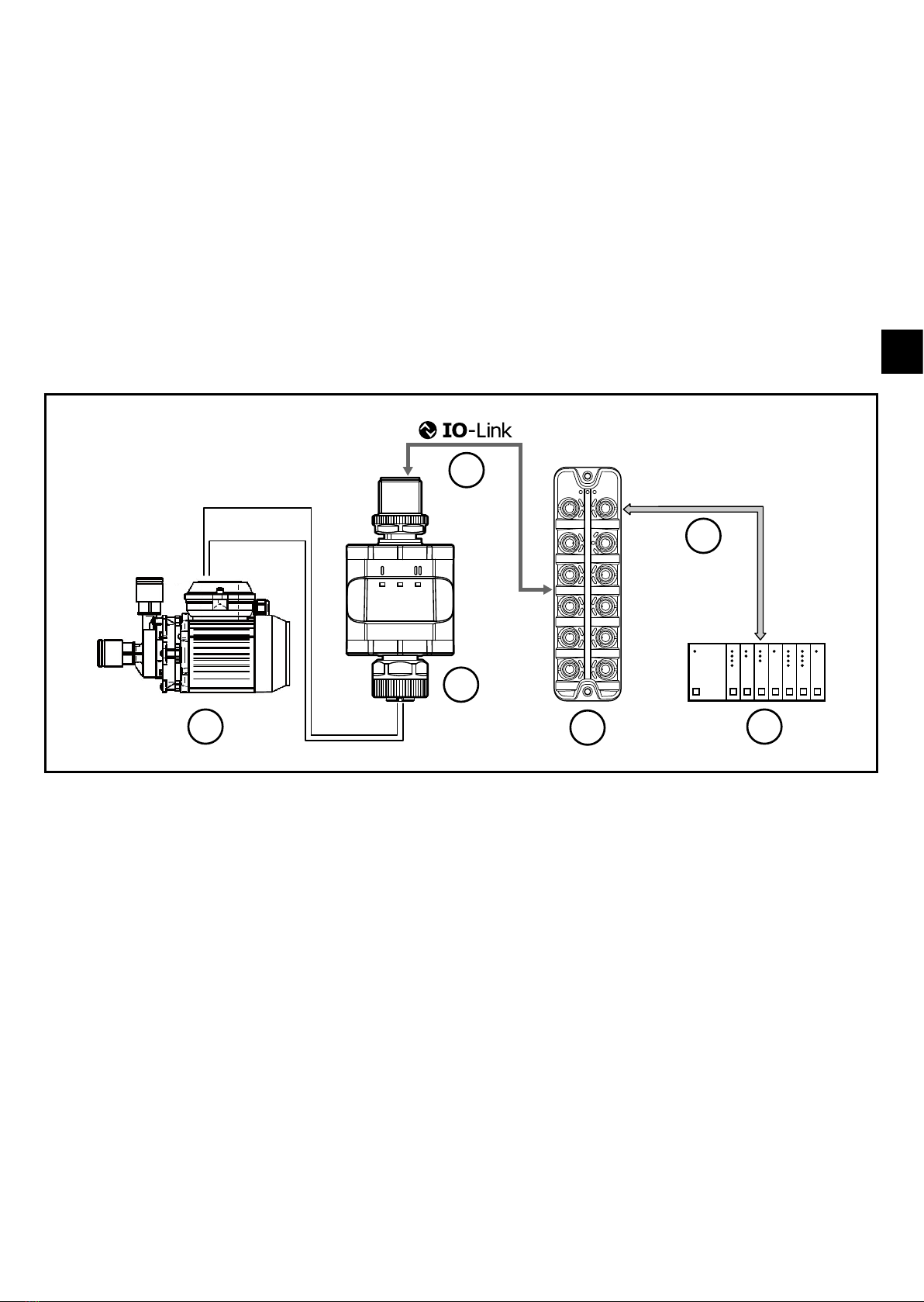

3.1 Block diagram................................................................................................6

3.2 General application and functionality.............................................................6

3.3 Application as an IO-Link device ...................................................................7

3.3.1 General information ..............................................................................7

3.3.2 IO Device Description (IODD) ..............................................................7

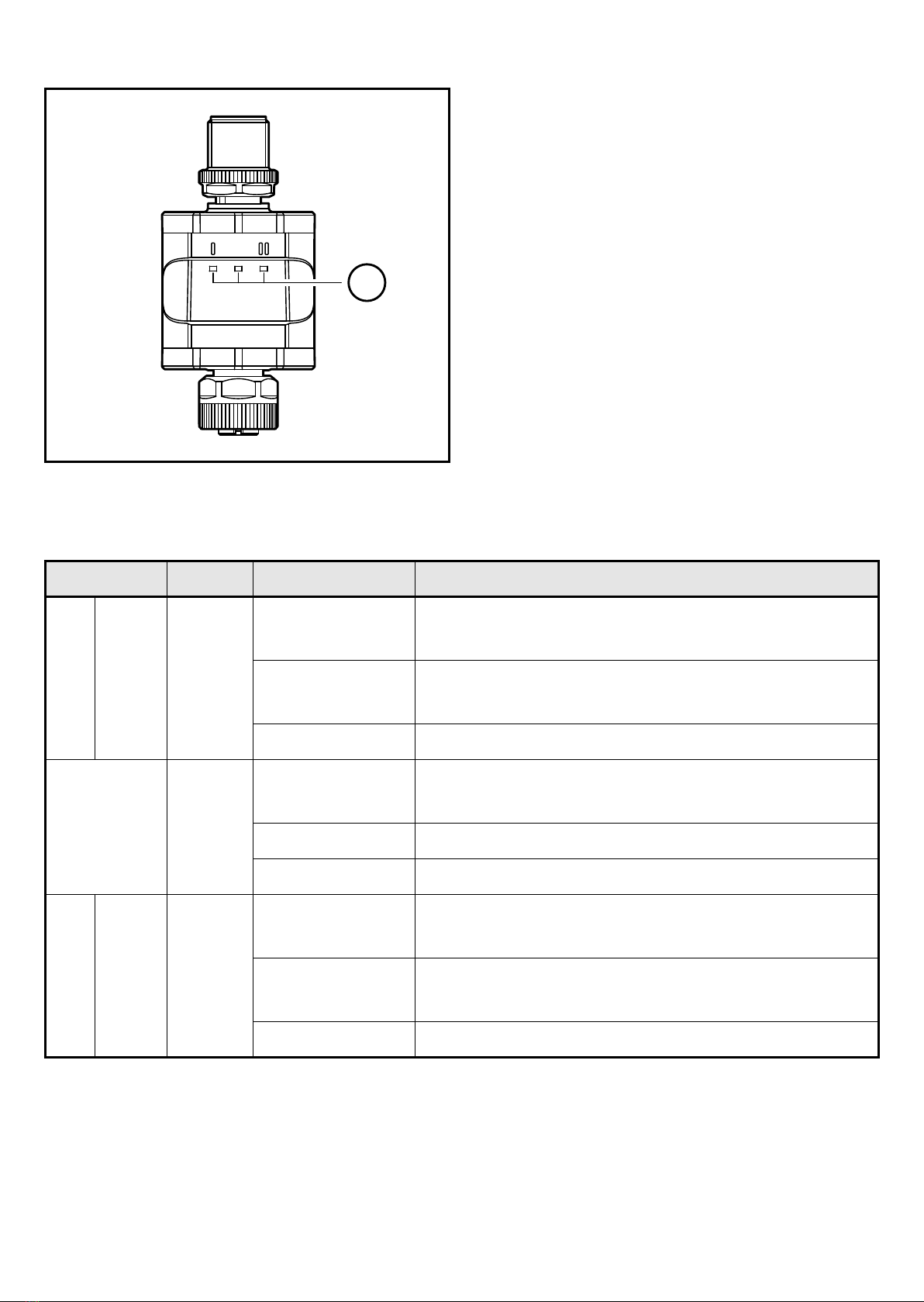

4 Operating and display elements ..........................................................................8

4.1 LEDs..............................................................................................................8

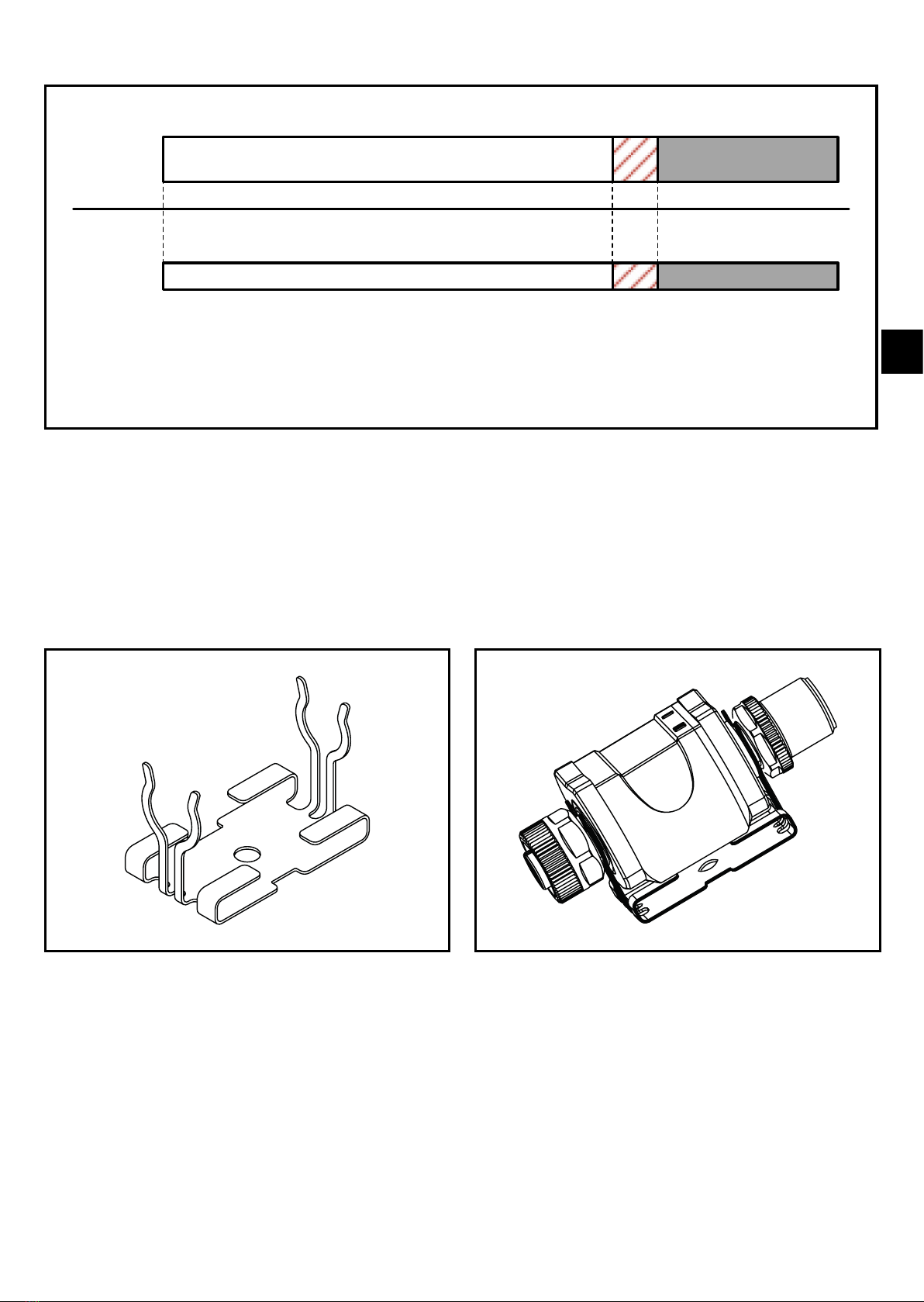

4.1.1 Visualisation of the voltage value at the output ...................................9

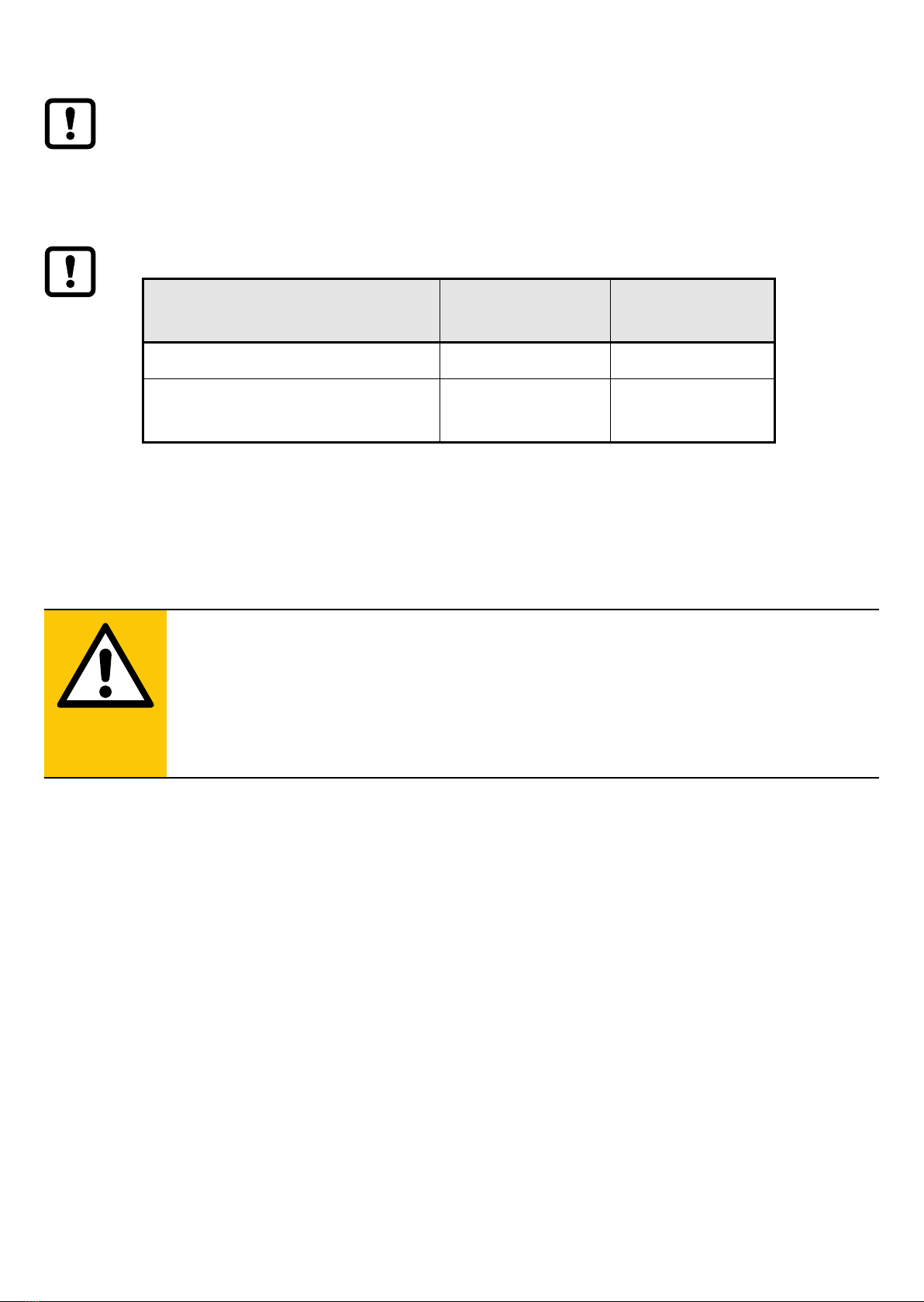

5 Installation............................................................................................................9

6 Electrical connection..........................................................................................10

6.1 Maximum length of the connection cables ..................................................12

7 Operation ..........................................................................................................12

8 Parameters ........................................................................................................12

8.1 Parameters via IO-Link................................................................................12

8.1.1 Application-specific tag .......................................................................12

8.1.2 Plant identification code......................................................................12

8.1.3 Location identification code ................................................................12

9 Parameter setting ..............................................................................................12

10 Scale drawing ..................................................................................................13

11 Technical data ..................................................................................................14

11.1 IO-Link device............................................................................................14

11.2 Approvals/standards ..................................................................................15

12 Troubleshooting ...............................................................................................15

13 Maintenance, repair and disposal....................................................................15