CANopen encoder

2

Contents

1 Preliminary note � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�1 Symbols used� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�2 Warning signs used � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

2 Safety instructions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

3 General information � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

3�1 Absolute encoders � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

3�2 CANopen technology � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

3�2�1 Certification of CANopen products� � � � � � � � � � � � � � � � � � � � � � � � � � � 5

3�3 References � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

3�3�1 Abbreviations � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

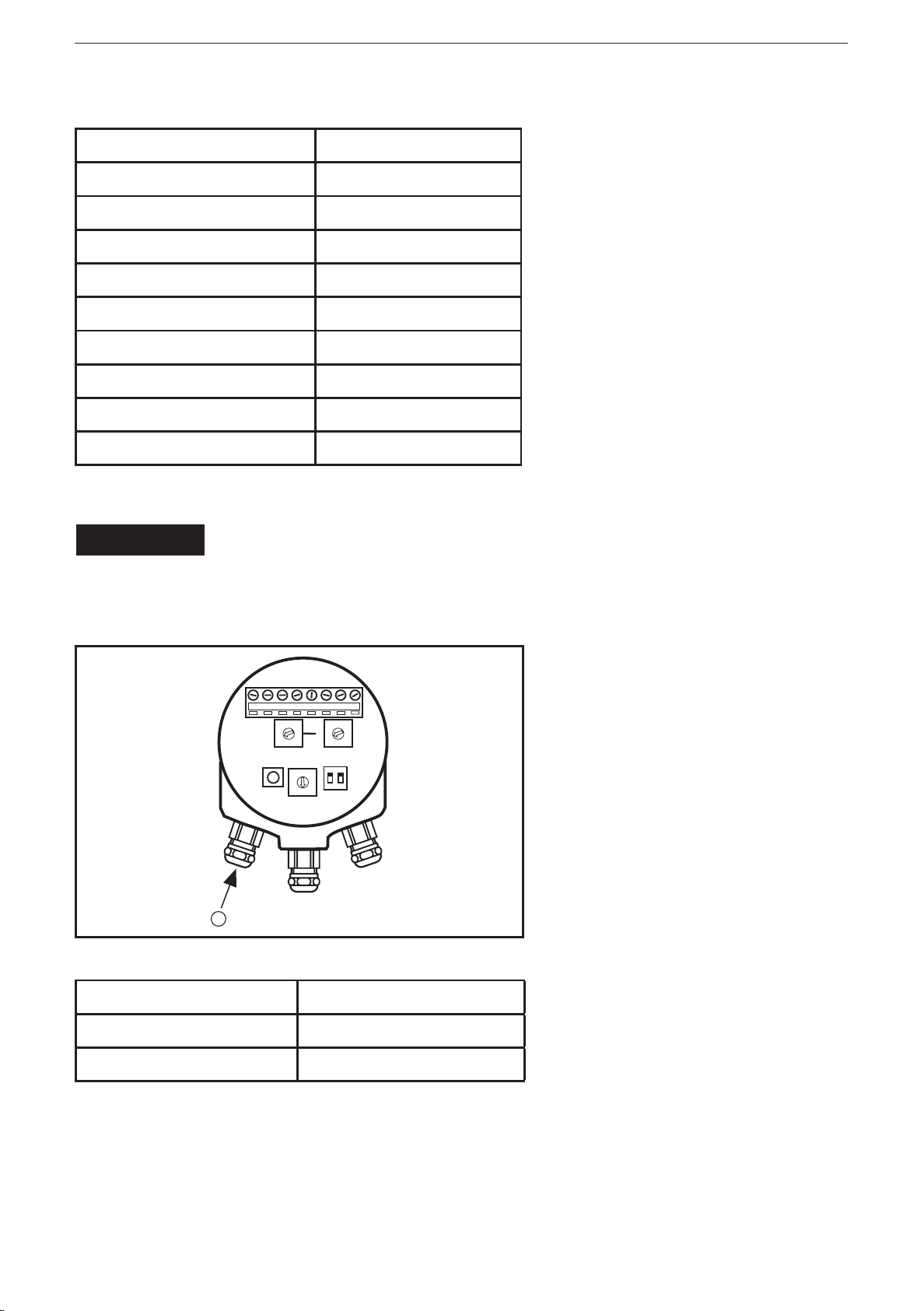

4 Installation of the encoder� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

4�1 Settings of the encoder � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

4�2 Node address � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�3 Bus termination � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

4�4 Baud rate switch� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

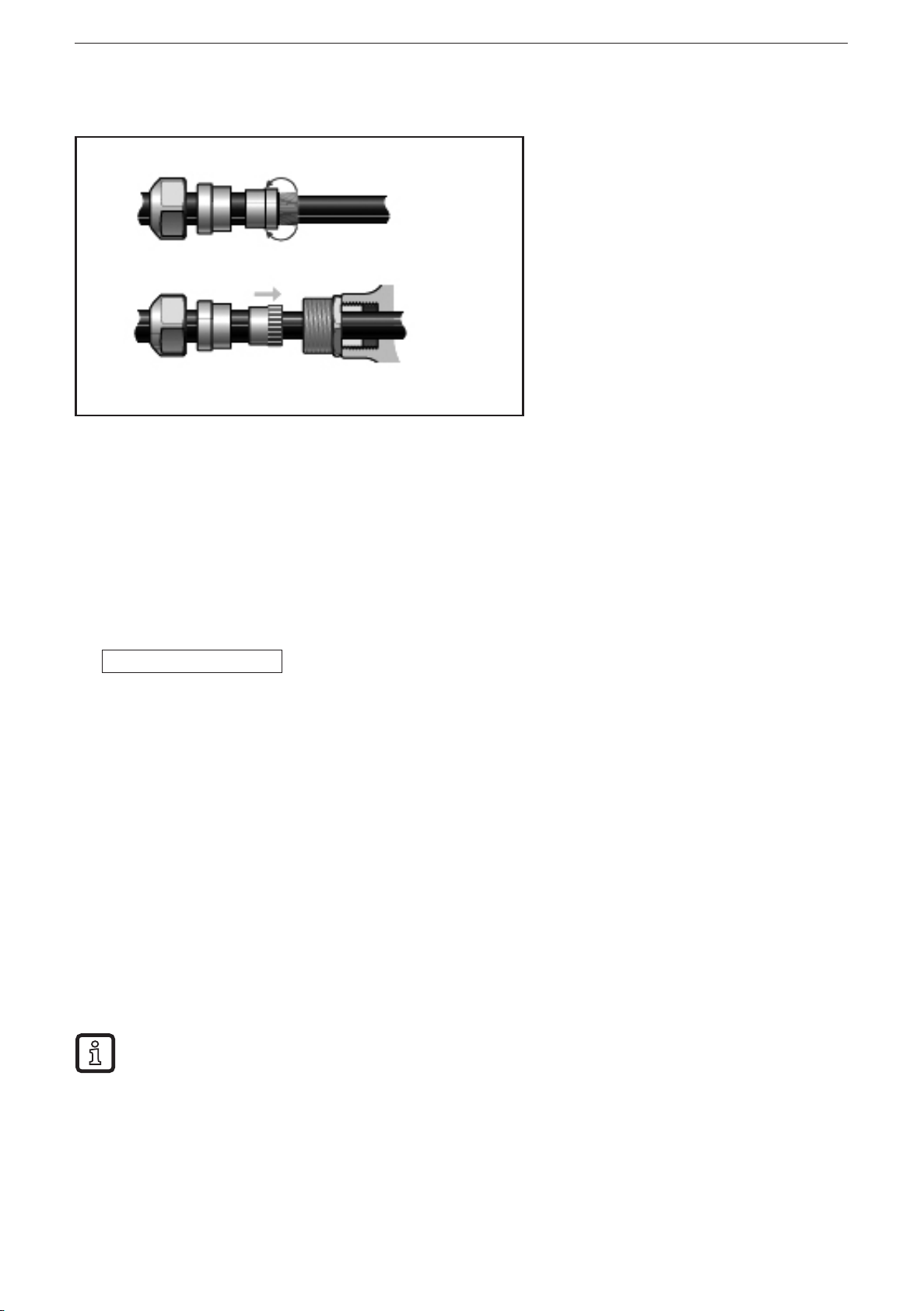

4�5 Electrical connection of the encoder � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

4�6 BUS lines � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

4�7 Shield � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

4�8 EDS file � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

4�9 Parameter setting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

4�10 LED display � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �11

4�10�1 Module LED � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �11

4�10�2 Status LED� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

5 Profile overview � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

6 Functionality of the encoder � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

6�1 Basic functionality of the encoder� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

6�2 Default identifiers � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

6�3 Boot message � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

6�4 Operating parameters � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

6�5 Scaling function � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

6�5�1 Overview � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

6�5�2 Scaling formulas � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

6�6 Preset value � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

6�6�1 Overview � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

6�6�2 Calculation of the preset value� � � � � � � � � � � � � � � � � � � � � � � � � � � � � 17

6�7 Zero setting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

6�8 Speed and acceleration � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

6�9 PDO mapping� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 18

6�9�1 PDO configuration � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 19

6�9�2 PDO configuration example � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 20

6�10 Heartbeat � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21

6�11 IRT mode � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 21