2

Contents

1 Preliminary note���������������������������������������������������������������������������������������������������2

1�1 Symbols used �����������������������������������������������������������������������������������������������3

2 Safety instructions �����������������������������������������������������������������������������������������������3

3 Functions and features ����������������������������������������������������������������������������������������4

3�1 Application area ���������������������������������������������������������������������������������������������4

3�1�1 Device types �����������������������������������������������������������������������������������������4

3�1�2 Restriction of the application area �������������������������������������������������������5

4 Function���������������������������������������������������������������������������������������������������������������5

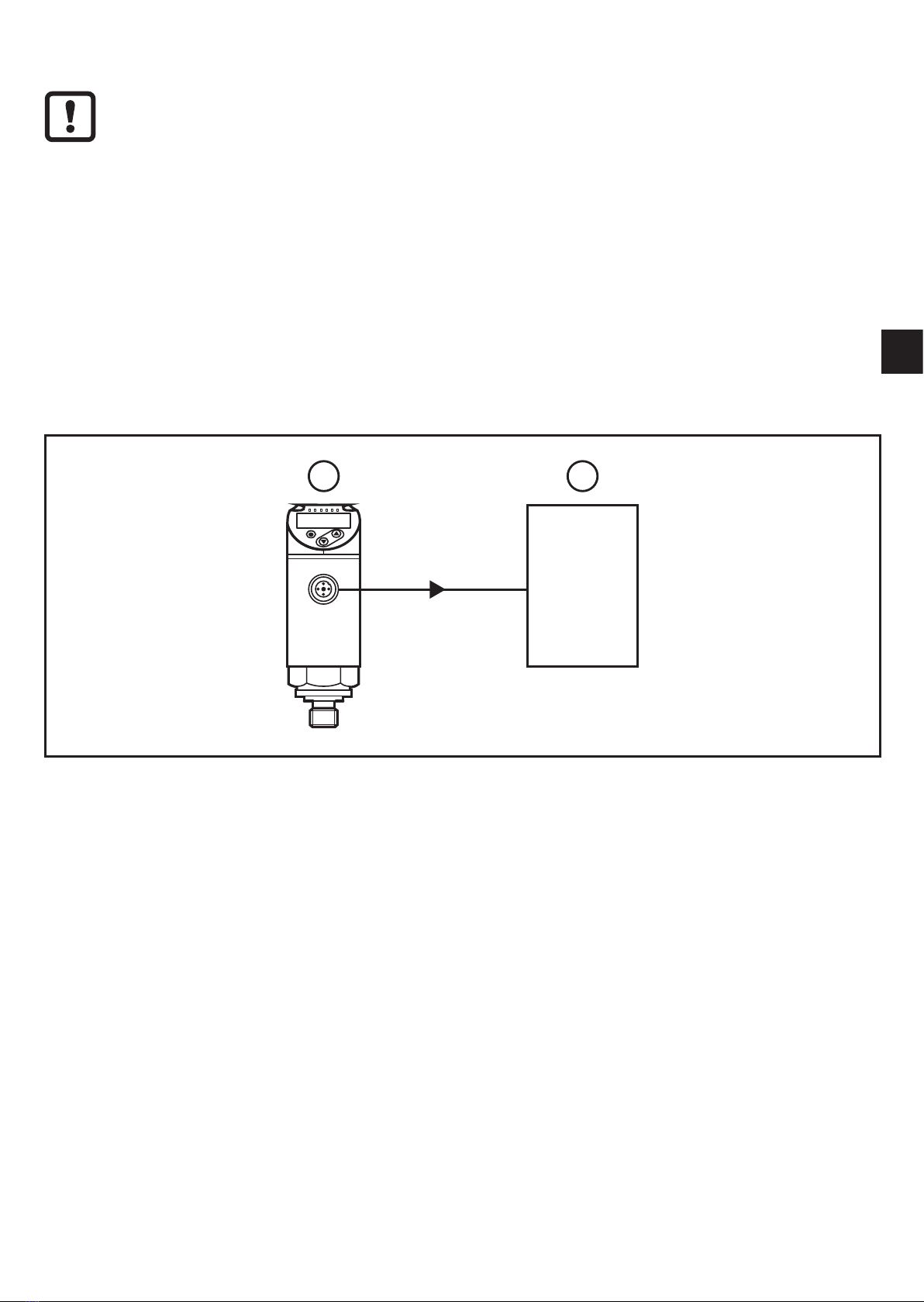

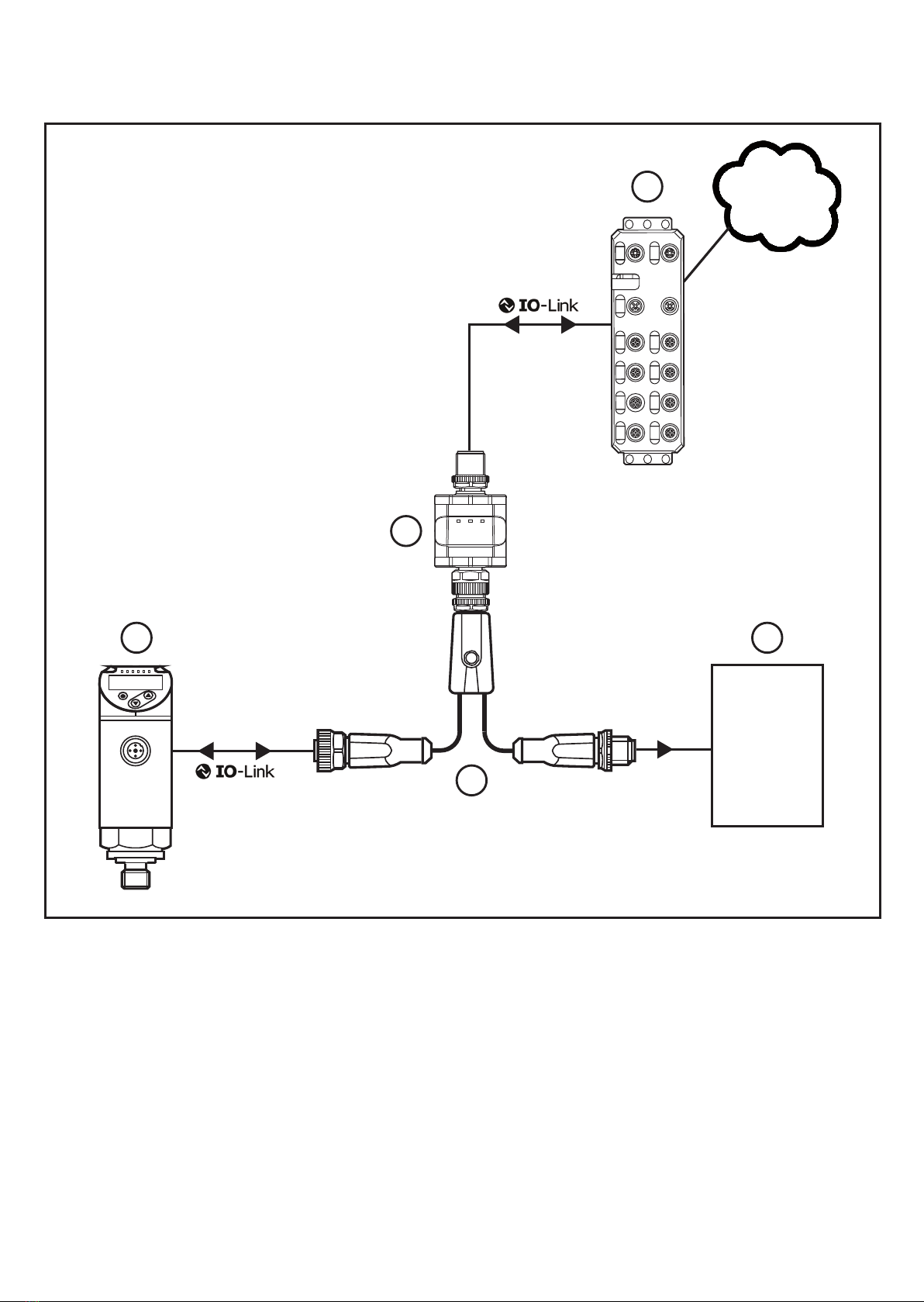

4�1 System integration�����������������������������������������������������������������������������������������5

4�2 Write protection against unauthorised access�����������������������������������������������7

4�3 IO-Link �����������������������������������������������������������������������������������������������������������7

5 Installation������������������������������������������������������������������������������������������������������������7

5�1 Installation location / installation environment �����������������������������������������������7

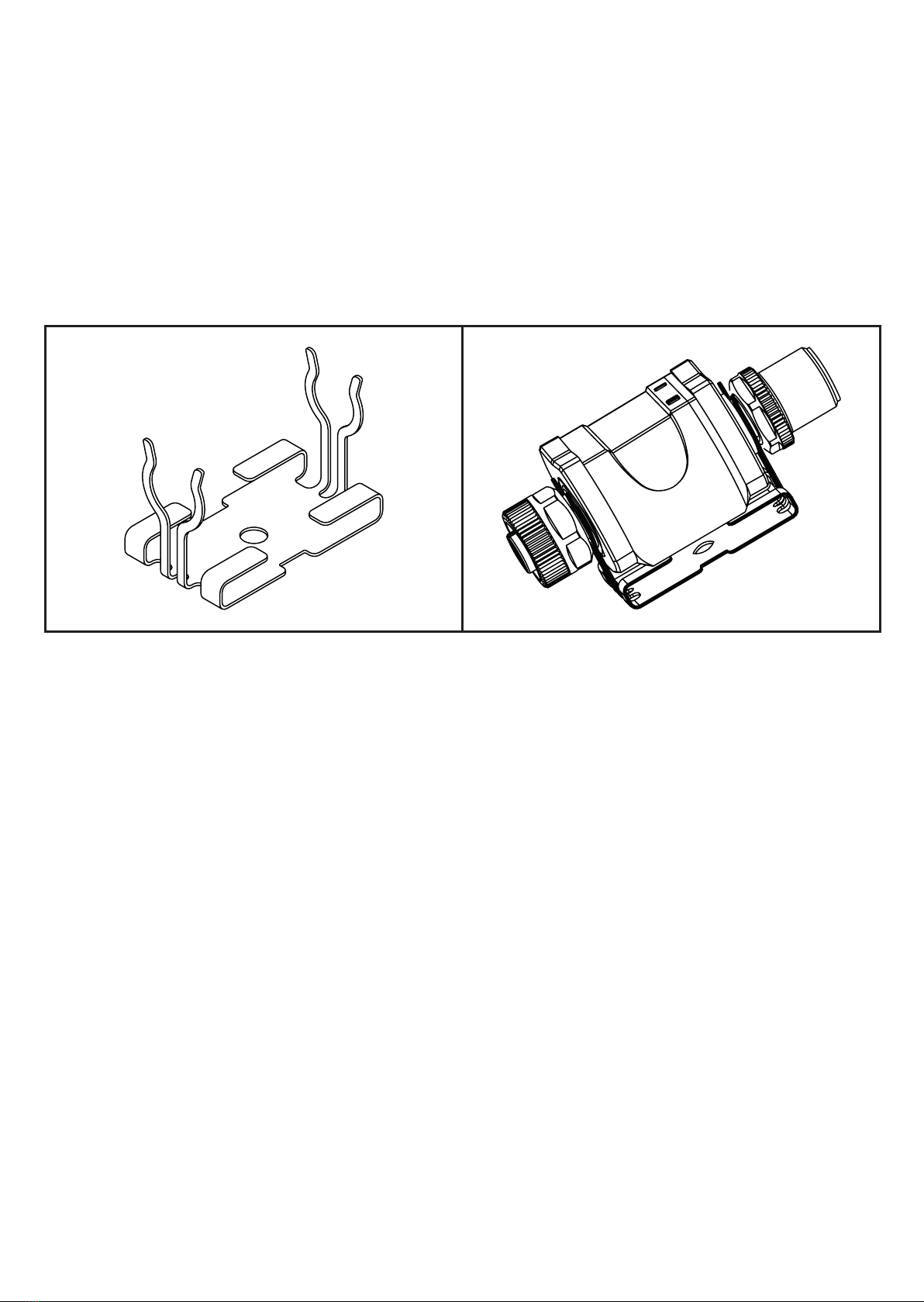

5�2 Installation procedure ������������������������������������������������������������������������������������8

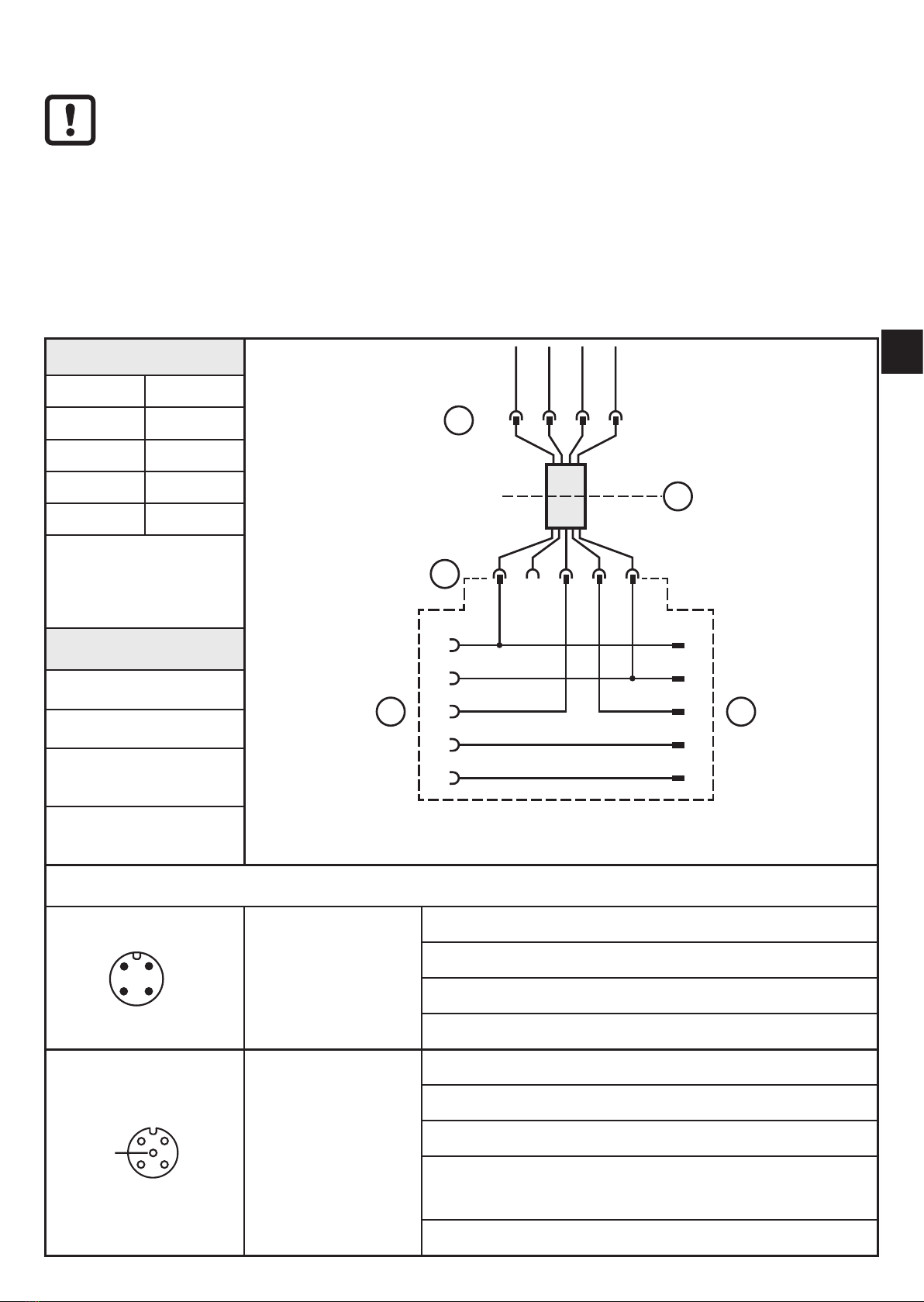

6 Electrical connection��������������������������������������������������������������������������������������������9

6�1 Electrical design of the output stage������������������������������������������������������������ 11

7 Display��������������������������������������������������������������������������������������������������������������� 11

8 Parameter setting ����������������������������������������������������������������������������������������������12

8�1 Parameters ��������������������������������������������������������������������������������������������������13

9 Operation�����������������������������������������������������������������������������������������������������������14

9�1 Operation and diagnostics display ��������������������������������������������������������������14

9�2 Delay times��������������������������������������������������������������������������������������������������15

10 Technical data and scale drawing��������������������������������������������������������������������15

11 Maintenance, repair and disposal ��������������������������������������������������������������������15

1 Preliminary note

Technical data, approvals, accessories and further information at

www�ifm�com�