Tipping Trailers 5

Operator Manual

TILTING THE TRAILER BODY (continued)

Connect the remote control lead to the socket on the side of the

pump. * (fig 6) Insert the key into the isolator switch and turn

clockwise through 90 degrees to switch on.

After checking that the rear of the trailer is clear, operate the ‘up

arrow’ button on the remote control to tip the trailer body.

As the load starts to move, release the button and operate again in

short bursts to release the load slowly. It may be necessary to move

the trailer forward before the full load has been released to avoid the

load coming in contact with the rear of the trailer. Lower the body

slightly to hold the load back before moving the trailer forward.

To lower the body, operate the ‘down arrow’ button until the body is

in the required position. To return the trailer bed to the horizontal

position, ensure that the area between the body and chassis is clear

of obstructions and lower fully. To ensure that the body cannot be

accidentally raised, disconnect the remote control lead plug from the

socket (a straight pull).

During normal operation the ‘Green’ LED lamp on the remote control

will be lit. If the ‘Red’ LED lamp lights it will indicate that the battery

charge is low - i.e. below 9V. See also page 8 - battery indicators.

Turn the isolator key anti-clockwise through 90 degrees to switch off,

and remove the key.

Manual Operation (back-up system to the electrical pump)

Operation

Check that the rear of the trailer is clear.

Check that the manual release valve is closed and insert the handle

into the socket. After checking that the rear of the trailer is clear,

operate the manual pump lever to tip the trailer body.

To lower the body, check that the area between the body and chassis

is clear of obstructions and open the valve slowly. Control the rate of

descent by opening and closing the valve as required.

* Users should note that the remote control unit supplied is generally

splash-proof, although it is not fully waterproof. It should never be

submerged and should be removed from the trailer when not in use

to avoid damage and possible erratic operation.

If a control unit has been accidentally submerged or is otherwise

damaged it should be taken out of service until it can be fully checked

or ideally replaced with a new unit.

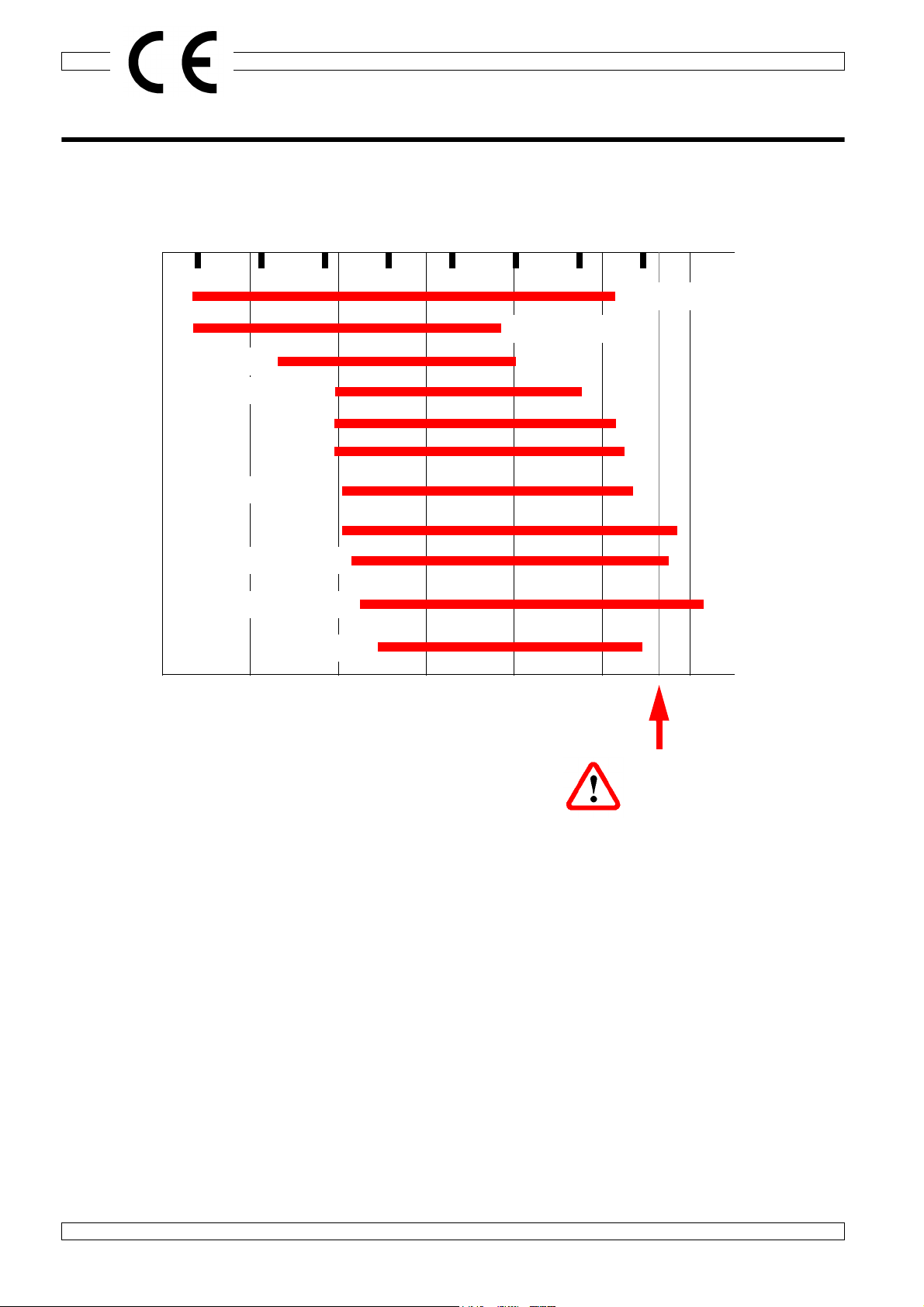

Fig.8

Fig.6

Fig.7

Fig.9

Fig.5

Slide pump handle into receiver

Behind front pump plate

Red & Green

LED Lamps

Up

Down

Manual operating handle

Manual release valve

Pump handle socket

Oil reservoir waterproof

filler cap Pump

Electrical remote

control connector

Isolator switch

and key