IGS MBG-N5.5 User manual

OPERATION AND

MAINTENANCE MANUAL

Version 2

April 2019

This Operation and Maintenance Manual is for use with the IGS Microbubble

Generator (MBG) and provides the necessary information to successfully install

and operate the unit in accordance with manufacturers direction.

The MBG unit consists off

Full metal casing with vents

Priming pump

Main cavitation pump specifically designed to purpose

Cavitation cylinder and pressure gauge

On board electrical control enclosure

Actuators to assist in control of unit for bubble generation

Suction hose that connects foot valve to inlet

Suction Hose that connects foot valve to primer pump

Foot valve in cage

High pressure delivery hose with diffuser

Model Reference

The model reference for this product is

IGS MBG-N5.5

Positioning Requirements

The IGS Microbubble Generator is designed to sit above the water level of the

water body to be aerated. Both suction and delivery hoses need to downwards

to the water. Under no circumstances should these hoses be raised above the

unit itself - e.g., over the top of a tank. To do so reduces the efficacy of aeration

substantially.

MBG Enclosure:

The model is as shown to the left. The

stainless-steel cabinet that houses pumps,

electricals and controls is a rectangular box

type product with opening front doors. These

doors are opened to start/stop the operation of

the unit and to adjust for correct pressure.

Both sides of the enclosure have vents

positioned and the rear of the enclosure is

mainly a single sheet with cut outs at the

bottom to access plumbing. The base is open.

The unit is designed to operate in such a way

as to allow ventilation of heat out of the

enclosure and be able to successfully operate

outside in all weathers.

The product requires mechanical lifting equipment to place into position or shift

from one position to another. It is feasible to bolt the frame to a specifically

sized pallet to allow easy movement by forklift.

The unit shown above has protective coverings on the outside and the unit that

you receive may have some of this protection or it may be removed. Your unit

will have a IGS Water signage on it with contact phone numbers and web

details.

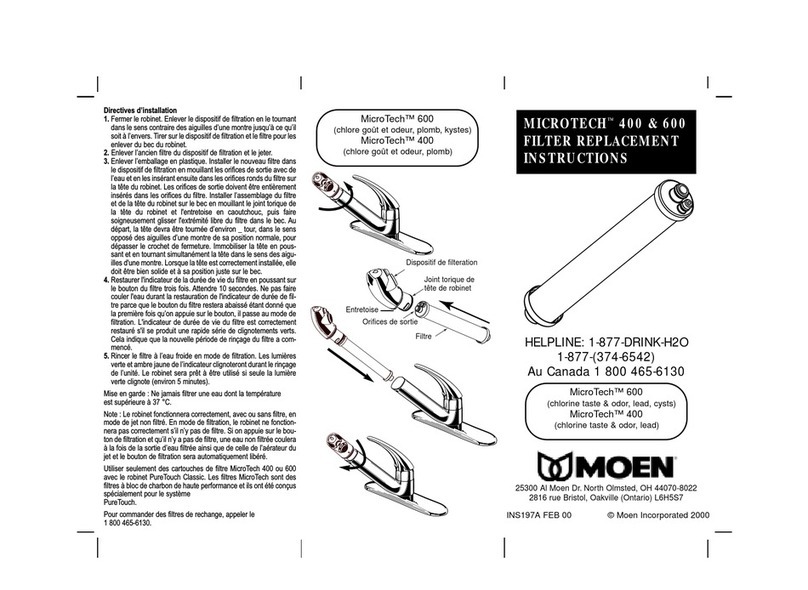

How to connect the delivery hose:

Note: It is recommended that the delivery hose is connected to the correct

fitting on the side of the unit prior to connecting the suction hose.

This is to allow easy tightening of the delivery hose without risk of damage to

the suction hose.

Always ensure the washer is inserted into the hose connection to prevent

leakage

Shown here is the delivery hose

connection. The delivery hose is a

high-pressure hose which is screwed

onto the connection found at the left-

hand side of the unit in the lower left

corner.

Connection is a simple thread

connection. Insert the washer to

prevent leaks, screw connect the

fitting to the tread on the pipe from

the unit and tighten with a suitable

tool.

You only need to tighten to a normal tightness for this type of fitting. There is

no set tension required for this connection. If, when the unit is operating, this

connection leaks, check for tightness. If unit continues to leak, then shut down

and remove the delivery hose and check for damage to the seal. If seal is

damaged, replace seal and reconnect.

How to connect to the water source:

The water source for the product will generally be the same water that has

oxygen delivered back to it, although not always. For example, if the product is

used in an aquaculture sea cage, the water source will be the ocean water beside

the unit. If in a land-based prawn farm, it will normally be water drawn from

the prawn pond. If used in agriculture irrigation, water would normally be

drawn from the irrigation supply channel or head ditch and may be delivered

into a head ditch or direct to field.

Connection of the suction lines requires the connection of two hoses –one hose

to the priming pump and the other to the main inlet

Shown at left is the foot valve connected and

lying on the bottom of a tank.

At the top of the picture, you can see there are

two clear hoses connected to the foot valve.

Connect these two hoses to the foot valve with

the larger hose connected to the applicable

piping and the smaller hose connected to the

smaller pipe.

Secure both hoses with the supplied clamps

and tighten to a normal tightness for this type

of fitting. There is no need to overtighten

either of these connections.

The other end of the larger hose is connected

to the fitting found on the lower left side of

the unit and inside the unit. Feed the hose

though the hole provided. This connection is

in front of the discharge connection and is

easy to recognise as it is a push on fitting and

not screwed on.

As with the foot valve, use the supplied clamp

to tighten the connection. Normal tightness is

sufficient and there is no need to overtighten.

The smaller suction hose is connected to the

primer pump as shown here. Feed this hose

through the hole provided on the left-hand

side of the unit and connect as shown in the

photo to the left.

As with the other clamps tighten as needed

without over-tightening.

Have the orange valve fully open:

If this valve is included in your unit, ensure

it is fully open during operation. This

ensures the valve does not throttle the water

flow in any way. The photo at left shows

the valve partially closed –make sure this

remains fully open during operation.

Connection of electrical power lead:

The orange power lead shown at left at the bottom

of the electrical board needs to be connected by an

authorised electrician and has enough length to

allow you to connect to a three-phase electricity

supply.

If additional length is required if the unit is relocated

this can be achieved using a three-phase extension,

making sure that any connection is kept out of water

that may be around the unit.

Connection is simple and if in doubt seek the advice

of an electrician.

Once the above connections are made with the unit in a stable upright position

you will be ready to turn the unit on and commence the production of

microbubbles, which will in turn break down to nanobubbles. Double check all

connections at this point.

Lower the foot valve with the two hoses connected into the water source.

Make sure that the cage is suspended in such a way it can operate without

obstruction or is sitting comfortably on the base of the water source if a tank.

To start the MBG:

On the front of the electrical box is a switch. To switch one way is to start the

unit automatically, and to switch the other is manual. This switch has a sticker

showing which way is which.

Turn the switch to automatic, after ensuring that the foot valve is in water.

Primer pump starts first:

At left is the primer pump. You will hear this pump

start and it will prime the main pump which will not

start immediately. Do not worry if the main pump

does not immediately start as it will come on line

once priming is complete.

This primer pump has a dual purpose –one is to

prime the main pump at start-up, and the other is to

prime the main pump during operation as required.

This process is automated and requires no operator

intervention once the switch is turned on.

It can take a short time for the primer pump to fully prime the system and you

just need to wait for this to happen.

Main pump will then start:

Shown at left is the main pump within the system.

This pump is behind and to the right of the blue

primer pump and is named Leo on the top of the

pump.

This pump will start automatically once the system

is primed and it is correct for it to start. No operator

action is required to have this pump start once the

switch is turned on.

This pump is in continual running whilst the system

is in use.

Should it stop operating check the water supply is still OK and start again. If the

pump still does not work the electrical supply will need to be checked. If the

electrical supply is found OK, then contact IGS for further assistance.

Actuators:

These actuators are critical for the

operation of the system. The actuator on

the right has a tap below it (behind the

wiring), which brings air in from the side

(blue open plug) and has a set screw

adjustment on the top.

There is no need to adjust the left-hand

actuator. Take care as this actuator does

get hot. You will not need to adjust the

right-hand actuator, only the air valve.

Cavitation cylinder:

The cavitation cylinder is a critical operational

component of the product for the creation of

microbubbles. It is found at the rear of the unit on

the left-hand side, under the electrical enclosure.

On the top of this cylinder is a pressure gauge

which will need to be checked in operation, with

adjustments made on the air intake actuator.

No other operator input is required for this cylinder.

Use of pressure gauge on top of cylinder:

This pressure gauge needs to show an

operating pressure of 0.7 for the unit

to be creating microbubbles at the

highest efficiency.

In start-up operation the pressure will

read anywhere either side of 0.7. An

operator needs to adjust the air flow

to achieve a 0.7 reading on this

gauge. No other action is required

for this cylinder or gauge except to

check the pressure now and then.

Note: to adjust the pressure you need to adjust the air intake actuator.

Adjusting the air intake actuator:

The air intake actuator is the right-hand side

actuator which has the blue open plug injected

in the right-hand side of the pipe above the

actuator.

To adjust the pressure in the cylinder, open

the red handle tap that can be seen behind the

wiring at the front of the actuator. Open this

tap fully by pushing it toward the bottom of

the unit until it is in a vertical position.

Next turn the set screw at the top of the pipe

shown here and adjust by raising or lowering

the screw until the pressure on the gauge is

showing 0.7.

Once achieved, then tighten the lock nut by screwing down until tight against

the base, but not that tight to cause damage to the screw or locknut.

Allow the unit to run for up to five minutes with regular checks on the pressure

gauge. Once you are comfortable the pressure is constant at 0.7 on the gauge

then the adjustment is complete.

How to know if the unit is producing microbubbles:

Look for white clouding in the water body

assuming it is clear enough to see this as

shown in the tank at our R&D centre. You

will see this milky clouding occurring in the

water.

These microbubbles will clear once the unit

is turned off as they break to nanobubbles

and both remain in the water as a ‘bank of

air’ for some considerable time.

Maintenance:

The Microbubble Generator is designed to operate with minimal operator action

and should continue to produce microbubbles consistently once stared until

switched off.

Regular checks that need to be conducted are:

Foot Valve Cage:

Ensure the foot valve cage is not blocked by a build-up of rubbish. If this cage

cannot be seen, turn the MBG off at the power source, raise the cage and check.

If blocked or partially blocked clean the cage off with a water jet, brush, rag or

similar. Once clean insert back in the water and restart machine.

Note: After each restart check the pressure on the cylinder gauge and adjust as

necessary.

IGS recommends a log of cleaning frequency is kept assisting in knowing how

often this needs to be cleaned. Each water body has different amounts of

organics and particles in it and as such there is no set procedure. Dirty water

will require more frequent cleaning than cleaner water. Common sense needs to

be applied to the cleaning regime to ensure long term operation of the product in

situ.

Pressure Gauge Check:

Checking of the pressure gauge to show a reading of 0.7 should happen every

couple of hours if possible or daily as a minimum to ensure the unit is creating

microbubbles at its optimum capacity.

If it is noticed this tends to change check the lock nut has not worked loose. If

it has, readjust, and retighten the lock nut. Also check the foot valve cage is

clean.

General Check:

A general check of the overall unit should be conducted each day. Look for

loose connection on the suction pipe and tighten the clamps as necessary.

Check for leakage at the delivery pipe and tighten if necessary.

Check power lead connection for damage and tight connections.

Check all electrical leads and connections contained within the unit are not

showing signs of damage. If damage is noticed contact an authorised electrician

for repair to damaged parts.

Wipe down unit occasionally in general cleaning

Table of contents

Popular Water Filtration System manuals by other brands

Lincoln Electric

Lincoln Electric Mobiflex 400-MS instruction manual

STAUFF

STAUFF SMFS-U-030 instruction manual

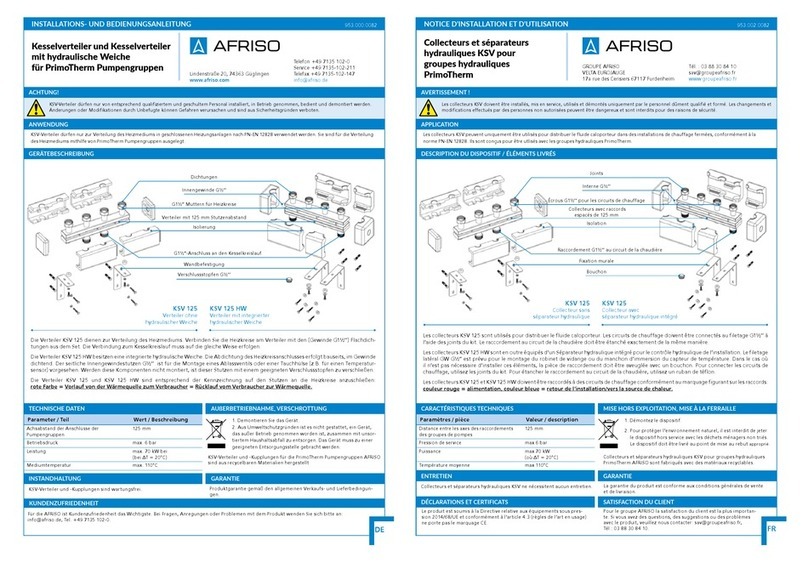

AFRISO

AFRISO PrimoTherm KSV 125 instruction manual

Atlas Filtri

Atlas Filtri HYDRA M Installation, use and maintenance manual

Dynabrade

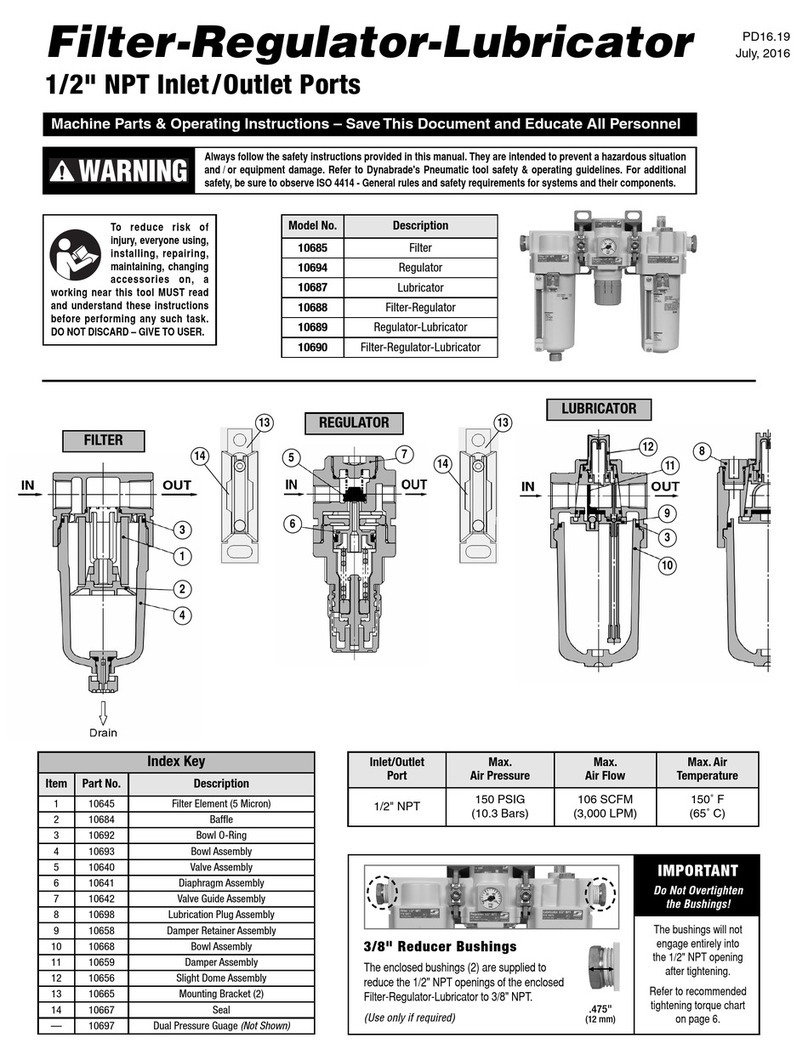

Dynabrade 10685 Machine Parts & Operating Instructions

Midea

Midea MRO1744N manual