iM3 Revolution 4DC-Mobile User manual

Table of contents

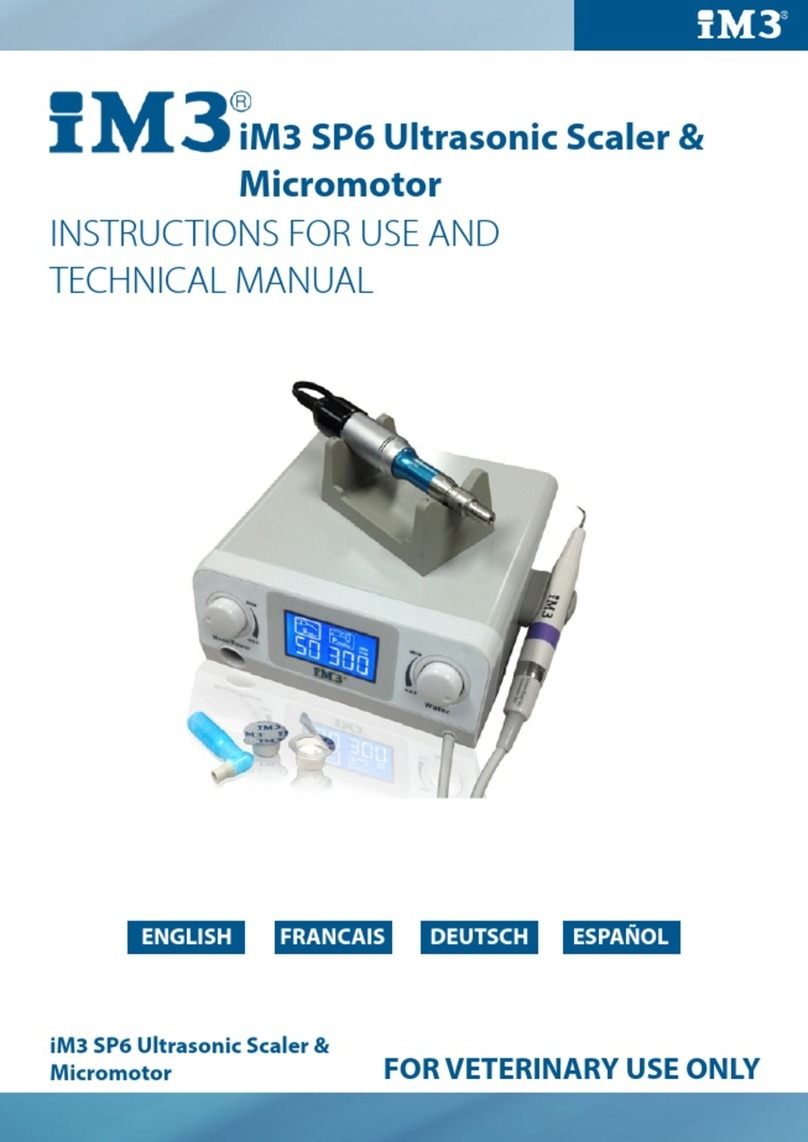

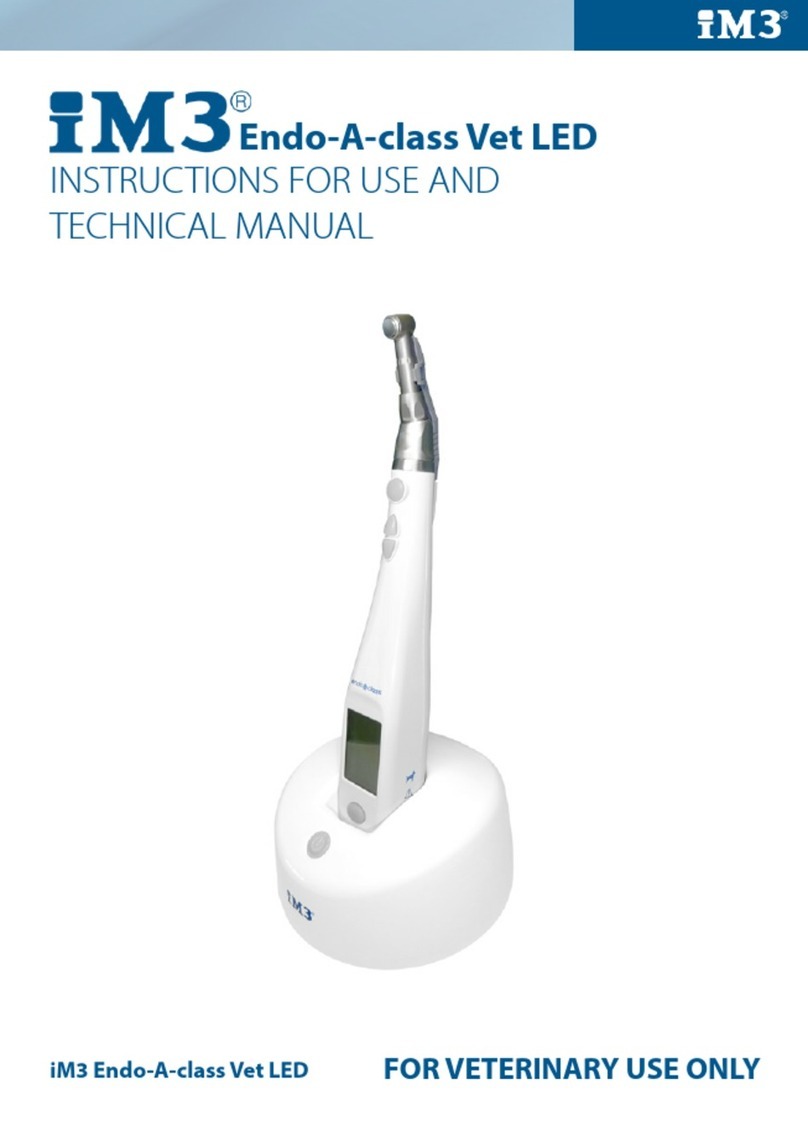

Other iM3 Dental Equipment manuals

Popular Dental Equipment manuals by other brands

Aseptico

Aseptico ADU-22 Operation and maintenance instruction manual

DentLight

DentLight FUSION-DOE Instructions for use

Bien Air

Bien Air OPTIMA INT user guide

EMS

EMS PIEZON 150 Operation instructions

Velopex

Velopex EXTRA X MK V user guide

Dentsply Sirona

Dentsply Sirona MAILLEFER Thermaprep B00THPR230VEU Instructions for use

Amanngirrbach

Amanngirrbach Ceramill Zolid Preshades instruction manual

Den-Mat

Den-Mat Sapphire plus Instructions for use

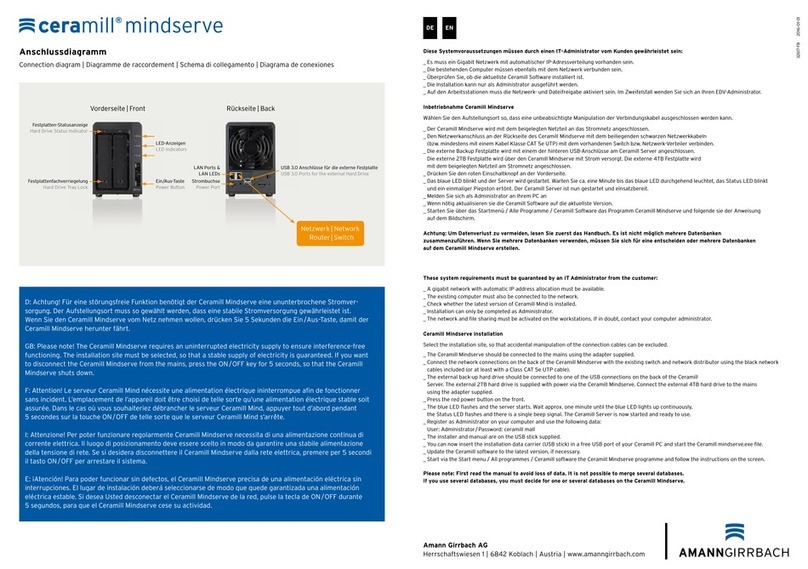

Amanngirrbach

Amanngirrbach Ceramill mindserve Connection diagram

Amanngirrbach

Amanngirrbach Stemaer X3 operating instructions

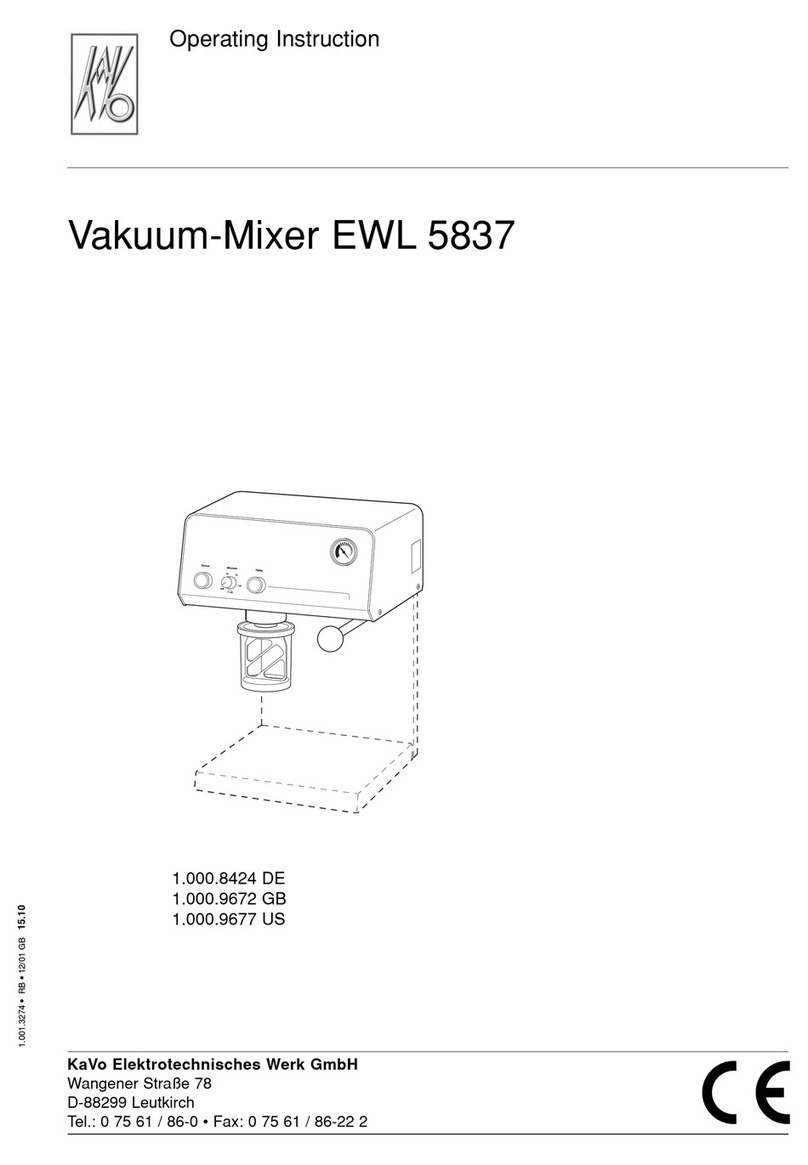

KaVo

KaVo EWL 5837 Operating instruction

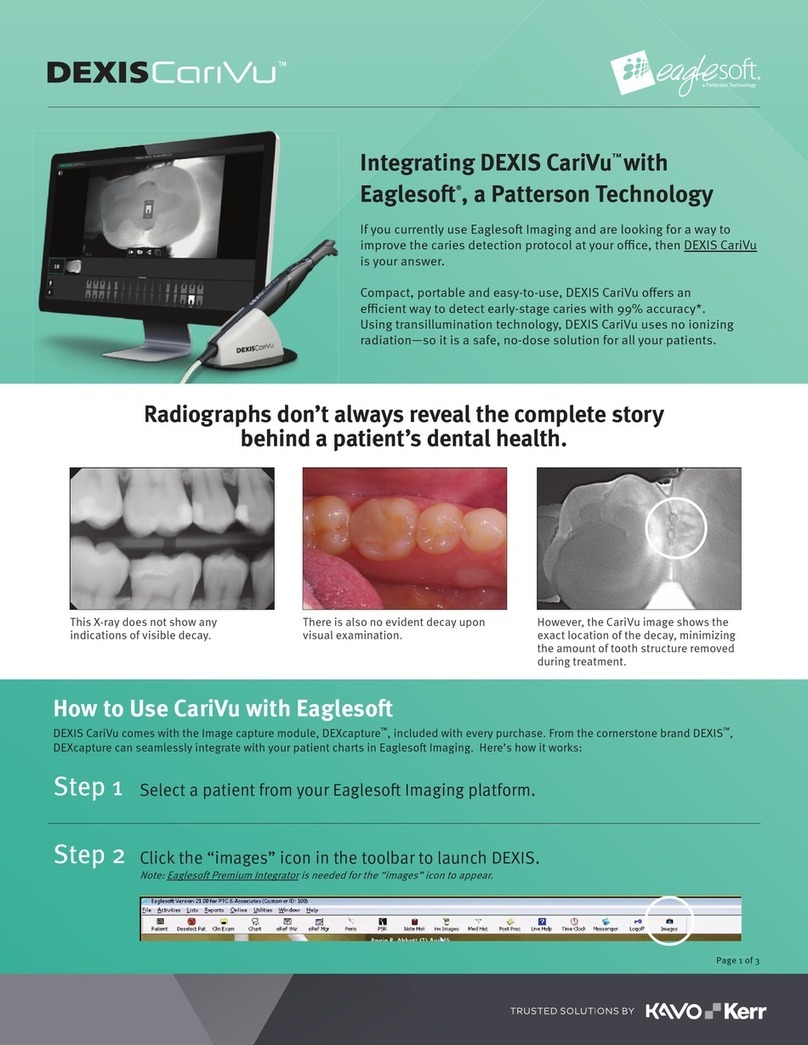

KaVo Kerr

KaVo Kerr DEXIS CariVu quick start guide

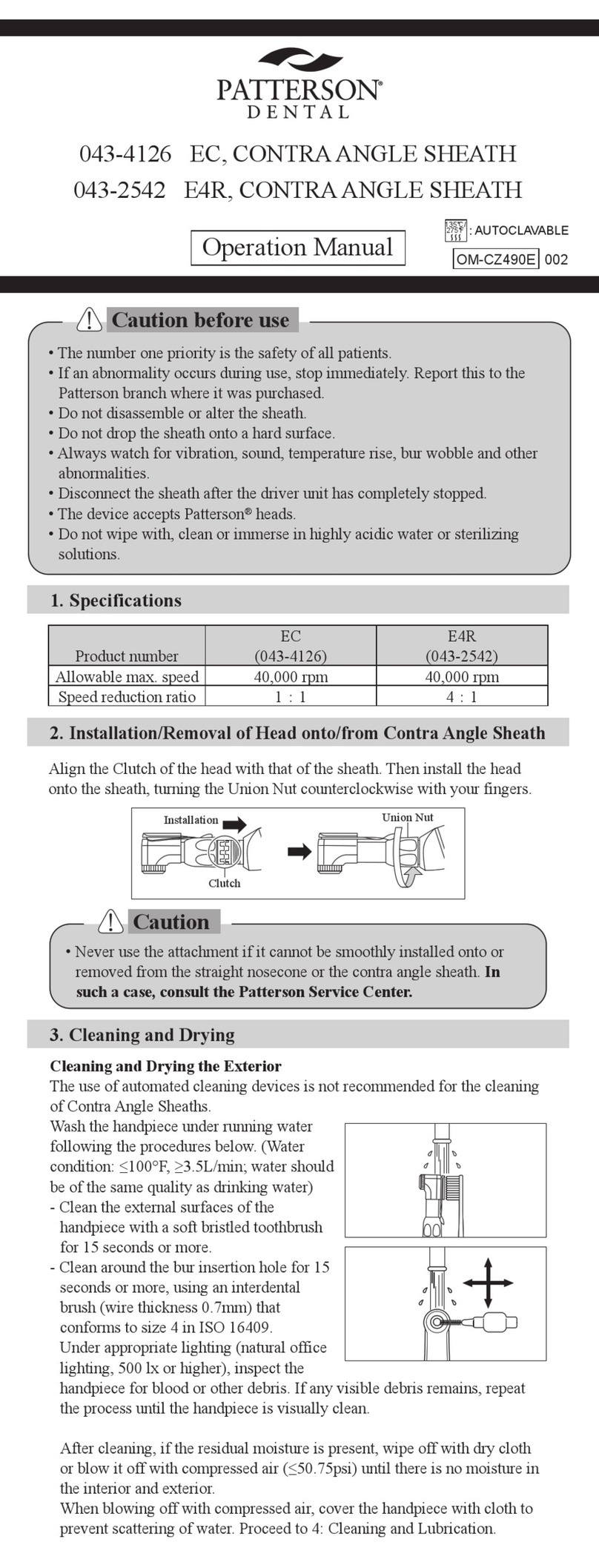

Patterson Medical

Patterson Medical EC quick start guide

Dentsply Sirona

Dentsply Sirona Essix Dual Laminate Plastic Directions for use

Instrumentarium

Instrumentarium Orthopantomograph OP200 D installation manual

vita

vita YZ Series Instructions for use

Acteon

Acteon X-MIND prime 3D ceph Service manual

Acteon

Acteon I-Surge user manual