Image Diagnostics 1000F Series Product manual

D000-479 REV J MAY-2018 Image Diagnostics, Inc. Page 1

idi

Manufacturer of Quality Medical Products

Image Diagnostics, Inc.

IDI 1000F Series Monitor Suspension System

Model IDI 1000F-1 thru 1000F-6

With Adapter to CAS 8000 Rails

Installation and Maintenance Guide

Installation and Maintenance Guide for IDI 1000F Series Suspension System for use

with CAS 8000 Rails

D000-479 REV J MAY-2018 Image Diagnostics, Inc. Page 2

The text of this manual was originally written, approved and published by the

manufacturer in English.

The information in this manual is subject to change without notice.

CONTENTS

SECTION TITLE

A………………………….. INTRODUCTION, PRODUCT DATA, AND

OPERATION

B………………………….. SYMBOLS

C………………………….. GENERAL SAFETY

D………………………….. SAFETY HAZARDS

E………………………….. INSTALLATION

F………………………….. CLEANING

G………………………….. MAINTENANCE

H………………………….. CUSTOMER SUPPORT

I………………………….. DISPOSAL GUIDELINES

J………………………….. APPROVALS

Installation and Maintenance Guide for IDI 1000F Series Suspension System for use

with CAS 8000 Rails

D000-479 REV J MAY-2018 Image Diagnostics, Inc. Page 3

A. INTRODUCTION

The IDI 1000F Flat Panel Suspension System transports monitors used in

medical imaging procedures. The system features a counterbalanced arm with

vertical travel and internal cable routing. A dual-axis flat panel monitor mount

permits independent panel mounting and positioning. This mobile package

includes clip-mounted ceiling rails.

PRODUCT DATA

Package Includes:

Mobile gantry and counterbalanced swing arm with 42" sweep radius, 25"

vertical travel and +180o rotation

Anodized aluminum ceiling rails with Easymount clip system

Flat panel array with +180o rotation

Array includes display panel mounts with +10o tilt

Complete installation package; meter box mounts, all mounting hardware and

cable management components; brackets, covers and 25' "flexhaust" hose

OPERATION

The monitors are moved along the overhead rails, positioned vertically, and

rotated manually using the handle.

Installation and Maintenance Guide for IDI 1000F Series Suspension System for use

with CAS 8000 Rails

D000-479 REV J MAY-2018 Image Diagnostics, Inc. Page 4

B. SYMBOLS

Attention, consult accompanying documents.

Failure to follow these instructions can cause accidents

resulting in serious injury to patient, user, and damage to

equipment.

Caution, risk of electrical shock

Protective Ground

This is the common tie point between the AC monitor

cord grounds, frame ground, and service (main) ground.

Alternating Current

Weight Limit

Recycle

Some of the materials can be recycled rather than discarded.

Installation and Maintenance Guide for IDI 1000F Series Suspension System for use

with CAS 8000 Rails

D000-479 REV J MAY-2018 Image Diagnostics, Inc. Page 5

C. GENERAL SAFETY

Attention, consult accompanying documents.

Failure to follow these instructions can cause accidents

resulting in serious injury to patient, user, and damage to

equipment.

Only qualified persons may install, operate or maintain this equipment.

Installation of this unit must adhere to applicable codes and authorities having

any jurisdiction over this installation. The customer's architect or engineer is

responsible for assuring that the structural support plans comply with all

applicable codes and regulations.

The unit should be used only in rooms that comply with state, federal and local

recommendations concerning electrical safety when used in medical installations. All

electrical connections shall be done by licensed/approved electrician per national

electric codes.

CAUTION: •Always switch off mains before

performing nonelectrical tests or

maintenance.

•Many positions exist where

equipment or patient collision may

occur. Care must be exercised during

equipment positioning to avoid a

patient or equipment collision.

Changes and additions to the equipment may be performed only by an authorized

representative. These changes must conform to regulations and accepted standards of

good practice. To prevent defeat of the built-in safety mechanisms, changes must be

submitted in writing to the manufacturer for review.

Use only parts specified by Image Diagnostics, Inc. when repairing or servicing this

equipment.

This equipment is intended to only be used with Image Diagnostics, Inc. rails.

Installation and Maintenance Guide for IDI 1000F Series Suspension System for use

with CAS 8000 Rails

D000-479 REV J MAY-2018 Image Diagnostics, Inc. Page 6

D. SAFETY HAZARDS

Installers and Operators using this equipment should understand the safety issues

and operating instructions provided.

Comments and questions regarding safety should be addressed to:

Customer Support

Image Diagnostics, Inc.

310 AUTHORITY DRIVE

FITCHBURG, MA 01420

USA

Or call IDI at (978)829-0009 or send fax to (978)829-0027

Or call IDI Toll Free at (877)304-5434

SAFETY HAZARDS ALERTS

Alert

Circumstances for use

DANGER

Indicates an imminentlyhazardous situation which, if

not avoided, will result in death or serious injury.

WARNING

Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury

or equipment damage.

Installation and Maintenance Guide for IDI 1000F Series Suspension System for use

with CAS 8000 Rails

D000-479 REV J MAY-2018 Image Diagnostics, Inc. Page 7

E. INSTALLATION

UNPACK

No special handling is required for unpacking this equipment at the site.

Conventional shipping materials are used.

Recycle or disposal of shipping material per local regulations

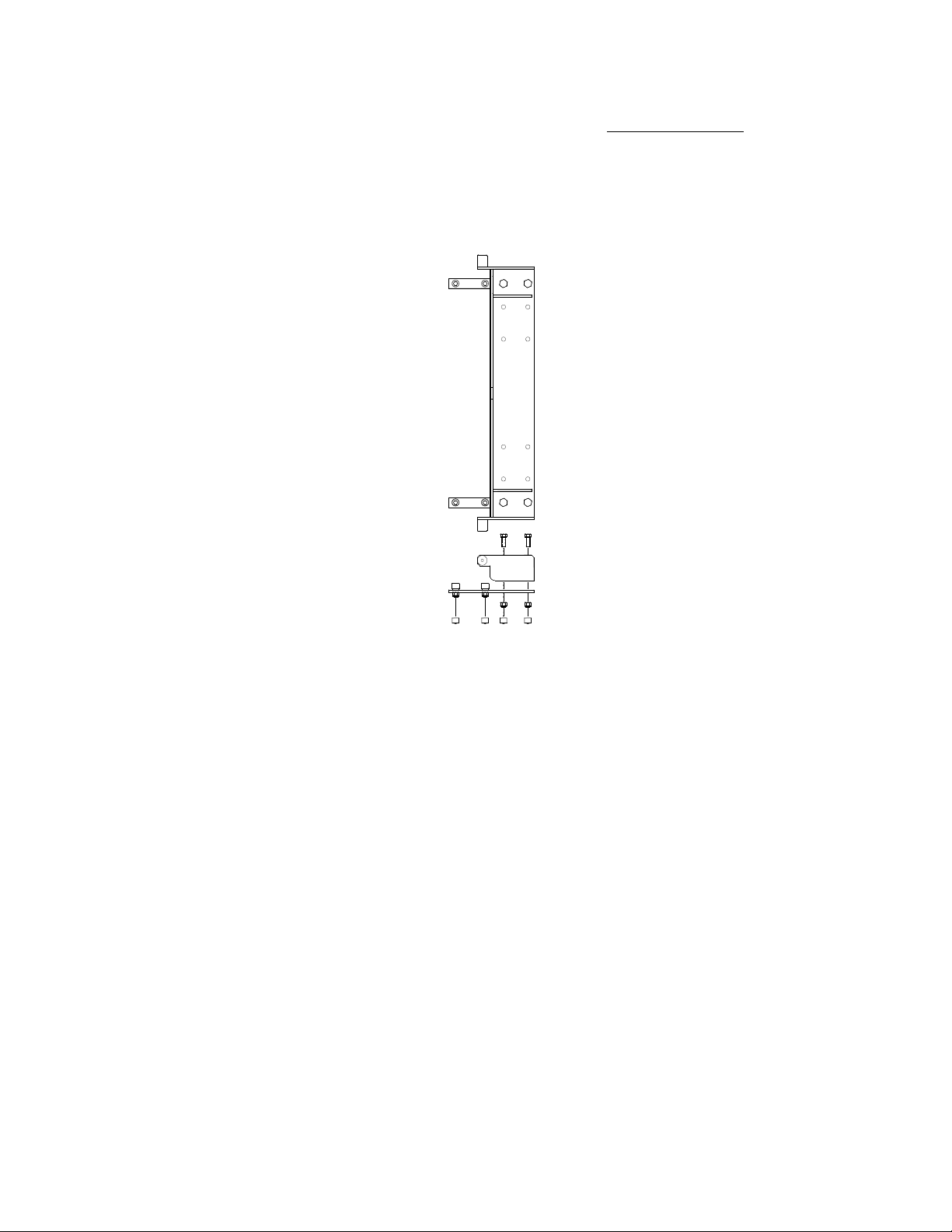

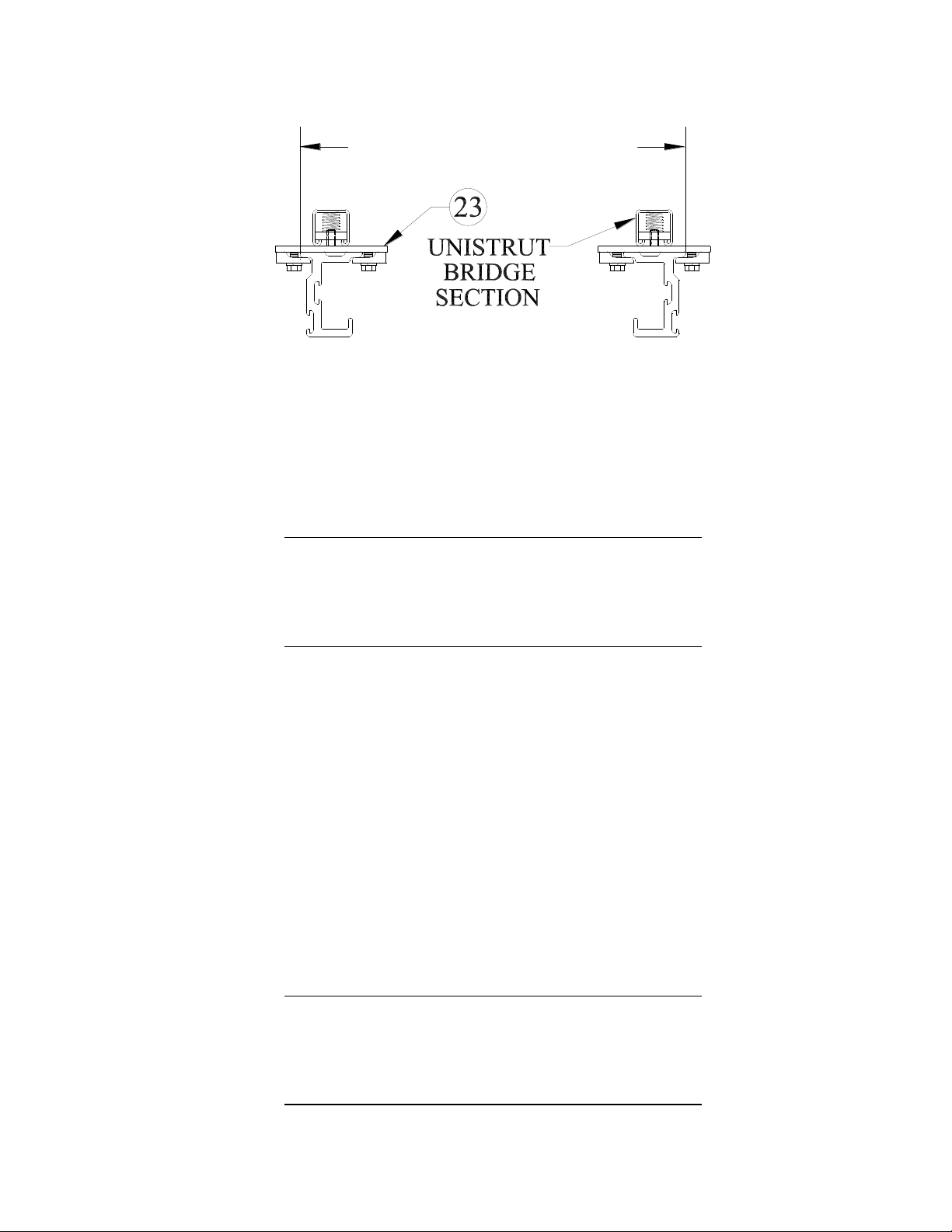

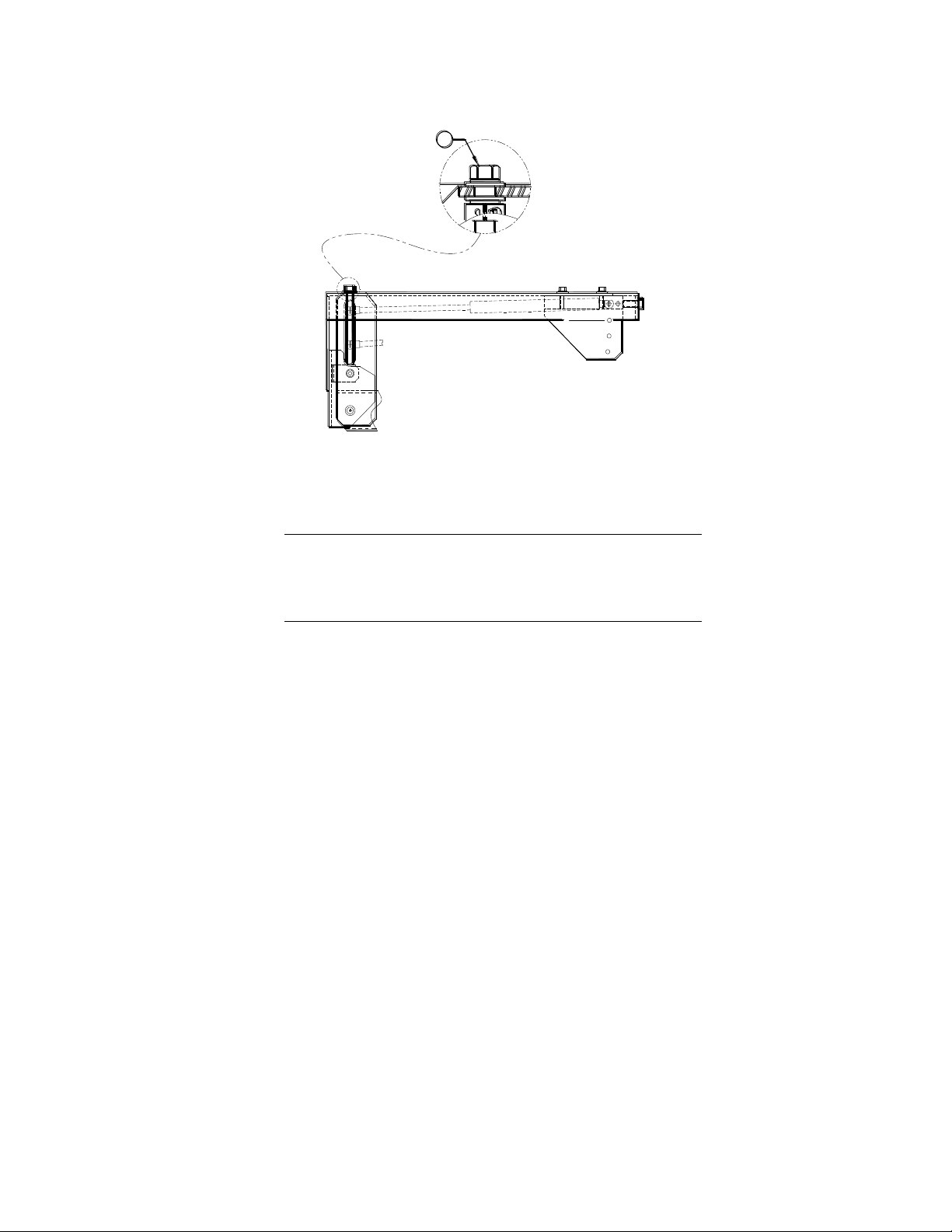

BUILD TRANSVERSE BRIDGE (Refer to Adapter Assembly Drawing)

1. Please note the X/Y ceiling carriage assembly consists of two rail adapter

subassemblies, two unistrut braces and two transverse rails. It is important to

note the two adapters are not identical; the "guide" adapter can be identified by

the thicker wheels and greater wheel offset, (left adapter in drawing below, note

2). The guide adapter will be fitted with a pair of guide wheel bars later on this

assembly.

2. The bridge assembly can be accomplished in position on the longitudinal rails

on the ceiling (recommended) or on the floor and then end loaded into the

longitudinal rails with a Hi-Jack if there is sufficient room between longitudinal

rail ends and any walls or obstructions. To assemble the bridge structure in place

you must first slide each adapter subassemblies onto the left and right

longitudinal rails. If you have sufficient space between the longitudinal rails and

the wall you can simply end load each adapter. If you do not have adequate

space at the end of the longitudinal rails, you may need to remove the center

wheel subassembly so that you can install the adapters by "rolling" them in from

the inside of the "C" section. See figure below.

3. To side load adapters into longitudinal rails, you must loosen (preferably) or

remove the wheel mounts (items 6 & 7) from the rail adapter carriages (item 2)

by removing the mounting hardware (items 21, 22 & 31). If you have removed

the two center wheel mount subassemblies position them on the rails as you

rotate each adapter into place and align the wheel stud and mounting plate to

the adapter. Once the adapters have been loaded into the rails tighten or

reinstall hardware (with LOCTITE #242 or equivalent) while applying

upward pressure on the wheel to maintain contact with the top of the

longitudinal rails.

Installation and Maintenance Guide for IDI 1000F Series Suspension System for use

with CAS 8000 Rails

D000-479 REV J MAY-2018 Image Diagnostics, Inc. Page 8

GUIDE (left view) and STANDARD

RAIL ADAPTER SUBASSEMBLIES

Installation and Maintenance Guide for IDI 1000F Series Suspension System for use

with CAS 8000 Rails

D000-479 REV J MAY-2018 Image Diagnostics, Inc. Page 9

4. Next, mount the two guide bars (item 27) to the guide rail adapter carriage

subassembly using screws (item 33) and locknuts (item 16) as shown below.

Slip white covers (item 36) over the total of eight locknuts associated with the

two guide bars.

MOUNT GUIDE BARS

INSTALL BRIDGE STRUTS (Refer to Adapter Assembly Drawing)

1. Attach the two bridge support plates (item 23) to the two bridge struts (item 1)

using flathead screws (item 24) and strut nuts (item 19). Center the plates on the

struts.

2. Attach the two pieces of painted unistrut that make up the bridge (item 1)

between the rail adapter carriage subassemblies using flathead screws (item 24)

and strut nuts (item 19). Use LOCTITE #242 on screws. Snug up hardware to

maintain required dimension and parallelism. Final tightening can be done after

final adjustments.

Installation and Maintenance Guide for IDI 1000F Series Suspension System for use

with CAS 8000 Rails

D000-479 REV J MAY-2018 Image Diagnostics, Inc. Page 10

MOUNT PLATES & STRUTS

3. Check bridge assembly carefully for both parallelism between components and

perpendicularity with the longitudinal rails. Verify the load bearing support

wheels on both sides of the adapter run true and as close as possible to the center

of the longitudinal rails. Once this check is complete tighten all flathead screws

(item 24).

4. Loosely attach rail clips (item 5) to the rail adapter carriage subassemblies (item

2) with hardware (items 14, 26, 15, 16).

5. Remove one outboard rail clip (item 5) from each corner of adapter carriages

and the bridge support plate (item 23). Place one rail (item 9), perpendicular to

the adapter carriages and hold in place. Replace rail clip (item 5), around the

rail flanges. Lightly tighten hardware. Attach the second rail in the same

manner.

6. Slide the rails back and forth to center them under the adapter carriages and to

align both ends. Make adjustments until the rails are spaced 17 1/8" (43.5cm)

apart at both ends. Tighten clip hardware in 16 places. Reference section view

AA shown in step 2, page 10.

MOUNT PLATES & STRUTS (WIDE CARRIAGE)

A

A

Installation and Maintenance Guide for IDI 1000F Series Suspension System for use

with CAS 8000 Rails

D000-479 REV J MAY-2018 Image Diagnostics, Inc. Page 11

7. Attach clips to middle plates (item 23) installed in step 5 with hardware (item

14, 26, 15, 16). Using LOCTITE #242 and tighten securely.

NOTE: Center wheel (item 10) can be raised or lowered to adjust the space

(lash) between the adapters and the top of the rails. Loosen screws (item 21)

to move mounting plate (item 7) until wheel comes in contact with the surface

on the top of the rail.

WARNING! Failure to properly install this

bridge system and securely attach

all mounting hardware may result

in serious injury to patient, user,

and damage to equipment.

INSTALL RAIL END PLATE (Refer to End Plate Assembly Drawing)

1. Install one end plate (item 22) at the far end of the rails, making sure rubber

bumper (item 23) faces in towards the rails. Use LOCTITE #242 on all threads.

END-LOAD GANTRY (Refer to End Plate Assembly Drawing)

1. Remove shipping straps and packing material from carriage. Using Hi-Jack or

other suitable lift table, raise gantry (still attached to pallet) up and into the

rails. Adjust center wheels if necessary per figure on page 8. Make sure all

carriage wheels are engaged onto rails before lowering Hi-Jack. Remove

pallet and shipping bars from support unit.

WARNING! Remove plastic cover and remove

block of wood between gantry core

and arm. Failure todo so may result

in serious injury to user and damage

to equipment.

17 1/8 inches [43.5cm]

Installation and Maintenance Guide for IDI 1000F Series Suspension System for use

with CAS 8000 Rails

D000-479 REV J MAY-2018 Image Diagnostics, Inc. Page 12

2. Install the second end plate (item 22) at the near end of the rails, making sure

rubber bumper faces in towards the carriage. Use LOCTITE #242 on all

threads.

WARNING! Failure to install both rail end plates

may result in serious injury to user.

INSTALL MONITOR MOUNT (Refer to Monitor Mount Assembly Drawing)

NOTE TO INSTALLER: It is important that the load be balanced on the

monitor mount. Take into account any differences in size and weight of the

monitors.

1. Remove wireway cover (item 38).

2. Drop rotation bearing (item 50) into pivot plate (item 59).

3. Take the thicker thrust ring (item 20) and put around rotation bearing (item 50).

4. Place stainless-steel thrust ring (item 47) below the thicker thrust ring (item 20).

5. The six bolts (item 16) with lockwashers (item 29) go through rotation cap (item

43) and rotation bearing (item 50) into the pivot tube (item 43 in the Core

Assembly Drawing). Use LOCTITE #242 on hardware.

Installation and Maintenance Guide for IDI 1000F Series Suspension System for use

with CAS 8000 Rails

D000-479 REV J MAY-2018 Image Diagnostics, Inc. Page 13

6. Apply a very little amount of LOCTITE #242 to and insert the six setscrews

(item 24) into the six threaded holes on second rotation cap (item 43). Thread

the setscrews in until they contact the rotation cap (item 43). The setscrews

may be tightened or loosened later to adjust rotational resistance.

WARNING! Failure to securely attach hardware

may result in serious injury to

patient, user, and damage to

equipment.

INSTALL MONITOR (Refer to Monitor Mount Assembly Drawing)

Maximum weight of any individual monitor.

Maximum total weight of monitors.

1. To attach a monitor to the system, first remove a monitor mounting bracket

(item #30) by removing its mounting screw (item #21). Fasten the bracket to

the monitor (hardware not provided). Reinstall the bracket with the monitor.

WARNING! Failure to securely attach hardware

may result in serious injury to

patient, user, and damage to

equipment.

2. Monitors can be tilted and rotated.

3. If monitor tilt resistance is inadequate and it fails to stay in the desired position,

tighten bolt (item 21).

4. If monitor rotation resistance is inadequate and it fails to stay in the desired

position, tighten bolt (item 22).

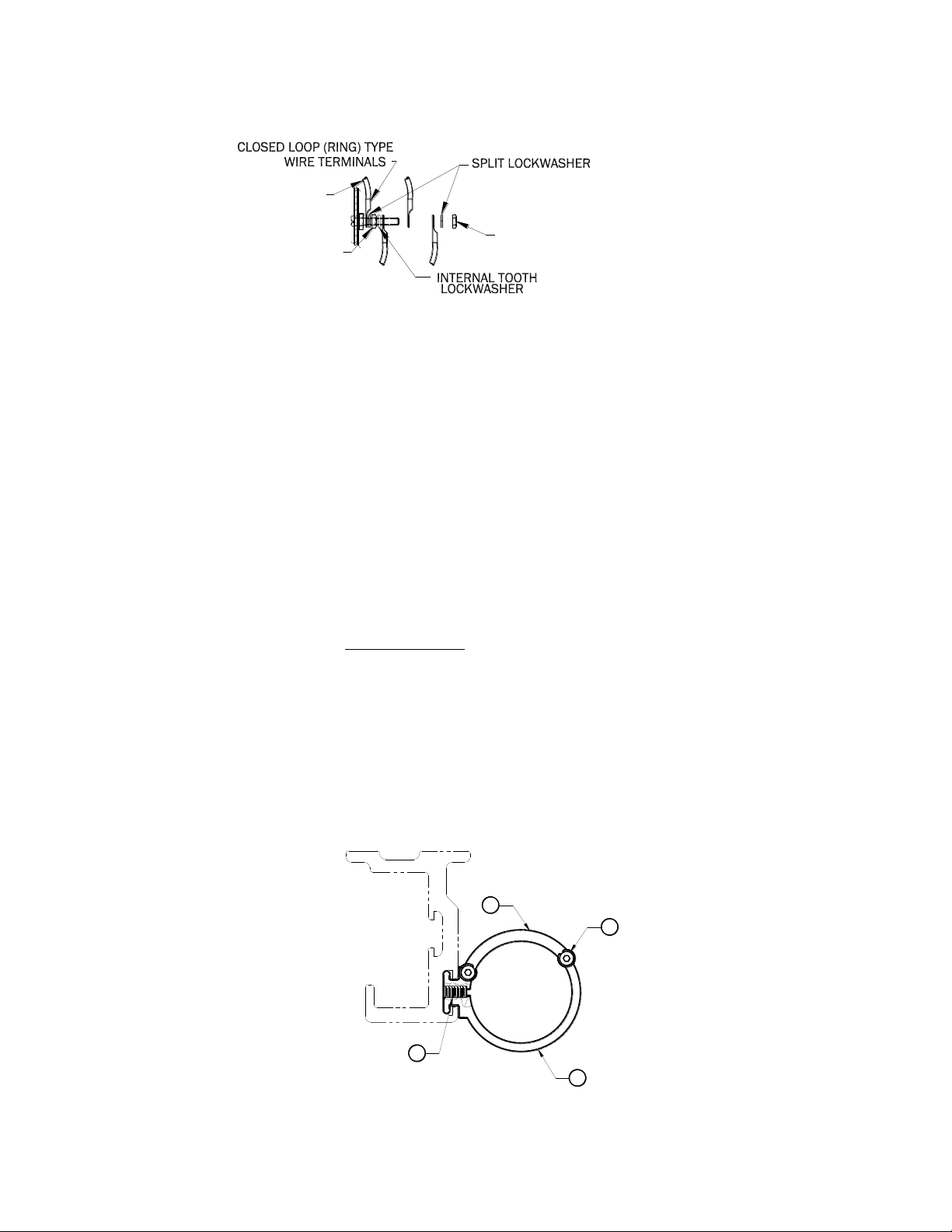

NOTE TO INSTALLER: Ground stud (item 27) has been provided to

properly ground monitors as a group. Terminal strip (item 31) has been

provided for distribution of line voltage to each monitor. Cut and strip each

monitor power cord to fit.

25 LBS

11 kg

44 kg

96 LBS

Installation and Maintenance Guide for IDI 1000F Series Suspension System for use

with CAS 8000 Rails

D000-479 REV J MAY-2018 Image Diagnostics, Inc. Page 14

SET ROTATIONAL LIMITS (Refer to Monitor Mount Assembly Drawing)

1. If desired, the stop pin (item 4) can be relocated to another of its four possible

mounting locations. Remove rotational cover (item 35) to access the stop pin

mounting screw (item 52).

ELECTRICAL CONNECTIONS

1. Colors of conductors in power supply cords shall be in accordance with IEC

publication 60227 (amendment #1) or with IEC publication 60245.

Wiring Color Codes:

International: brown (line), blue (neutral), green/yellow (ground)

North America: black (line), white (neutral), green/yellow (ground)

2. Cable tie mounting platforms are supplied near the terminal block for anchoring

the monitor cords and the wires from the mains. Use nylon cable ties. (Tying

the cord into a knot or tying the ends with string shall not be used for cord

anchorage).

3. Conductors of the power supply cord shall be arranged that the protective earth

conductor is not subject to strain as long as the phase conductors are in contact

with their terminals.

4. All power cords used for mains connection shall have double insulation.

Conduit provided for routing cables shall not be relied on for insulation.

FOUR POSSIBLE

STOP PIN

MOUNTING POSITIONS

Installation and Maintenance Guide for IDI 1000F Series Suspension System for use

with CAS 8000 Rails

D000-479 REV J MAY-2018 Image Diagnostics, Inc. Page 15

5. Connect all monitor ground wires and the service ground wire as shown in the

figure above. (The number of wires varies with the number of monitors

installed).

INSTALL STATIONARY CABLE HANDLING ASSEMBLY

(Refer to Stationary Cable Handling Kit Drawing)

1. Determine which rail end the stationary cable handling kit will be positioned.

If, at the far end of the rail, slide kit into rail track; slide kit into rail track

prior to positioning the mobile cable handling kit. If stationary kit is to be

positioned at the near end of rail, slide into rail after positioning mobile cable

handling kit. Stationary kit is typically mounted approximately 6 inches

(15cm) from rail end.

2. After applying LOCTITE #242 to threads, tighten the setscrew (item 4) to

secure in place.

3. Remove retainer (item 2) by taking out the two mounting screws (item 3).

4. Place section of cable hose into clamp (item 1).

5. Reinstall retainer (item 2) screws (item 3).

4

2

1

2X3

(#10-32 HARDWARE)

NUT "B"

MAIN GROUND WIRE

FROM SERVICE

NUT "A"

under split lockwasher and nut "A".

First attach main ground wire

Attach all other ground wires

between nut "A", lockwashers,

and nut "B".

Installation and Maintenance Guide for IDI 1000F Series Suspension System for use

with CAS 8000 Rails

D000-479 REV J MAY-2018 Image Diagnostics, Inc. Page 16

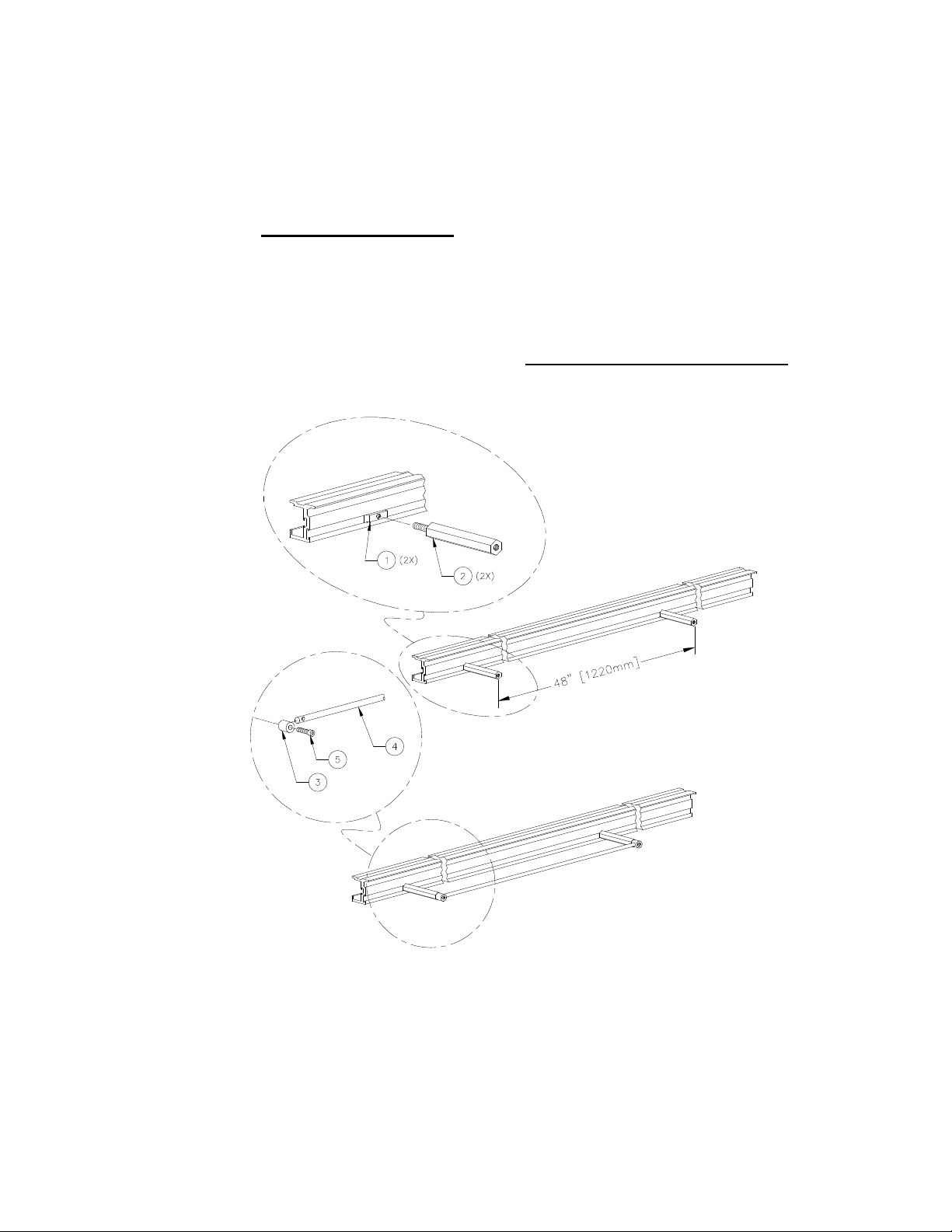

INSTALL MOBILE CABLE HANDLING ASSEMBLY (Refer to Cable Handling

Kit Assembly Drawing)

1. Slide nut plate of two hanger standoff assemblies (items 1&2) into rail track.

After applying LOCTITE #242 to the end that will be secured into the nutplate

(item 1), position standoffs approximately 48" (122cm) from each other. To

assure proper fit and positioning, temporarily assemble cable hanger shaft

(item 4) to standoffs. Place one shaft support (item 3) onto far end standoff.

Place the other shaft support to the second standoff, while temporarily

installing cable hanger shaft (item 4) into holes of shaft supports. Lightly

tighten socket head cap screws (item 5). Use LOCTITE #242 on hardware.

Installation and Maintenance Guide for IDI 1000F Series Suspension System for use

with CAS 8000 Rails

D000-479 REV J MAY-2018 Image Diagnostics, Inc. Page 17

2. Position shaft/cable handling subassemblies (items 1-5) to desired location on

rail. Without disrupting alignment, remove shaft and shaft supports. Torque

standoffs to ~35-50 inch pounds, 4.2-6.0(Nm). Use LOCTITE #242 on

hardware.

CAUTION! Over tightening the standoff will

weaken or break the set screw

connecting the standoff to the nut

plate causing attached components

to fall. DO NOT loosen or adjust the

exposed length of the setscrew on the

standoff.

3. Reattach shaft supports. Install one end of shaft to a shaft support. Tighten

socket head cap screw (item 5). Slide cable trolley assembly(s) onto cable

hanger shaft (item 4). Install free end of shaft into other shaft support. Tighten

second socket head cap screw (item 4). Use LOCTITE #242 on hardware.

DRESS CABLES (Refer to Gantry Core Assembly)

1. When the monitors have been properly installed, it is recommended that the

cables be brought through the pivot tube (item 43). 2" (5cm) flexaust (provided)

is to be attached to pivot tube and to be routed underneath the arm (item 51) via

the cable clamps (items 46, 50). Rotate entire system and bring to maximum

positions: the system should not drift from any position. If it does, check that

enough cable has been left to allow freedom of motion.

Installation and Maintenance Guide for IDI 1000F Series Suspension System for use

with CAS 8000 Rails

D000-479 REV J MAY-2018 Image Diagnostics, Inc. Page 18

36" [914mm]

HANDLING ASSEMBLY

MOBILE CABLE

48" [1220mm]

BETWEEN COMPONENTS

APPROX. LENGTH OF CABLE HOSE

*

[400mm]

15 3/4"

47" [1200mm]

*

LOCATIONS MAY REQUIRE SOME VARIATION

ACTUAL ROOM LAYOUT AND EQUIPMENT

CONFIGURATION

OPTIMUM CABLE HOSE

HANDLING ASSEMBLY

STATIONARY CABLE

*

BALANCE SYSTEM (Refer to Gantry Core Assembly)

Note: System balance has been set at factory based upon quoted monitor weight.

1. Note initial settings from Spring Data label (item 18). Substantial increases in

payload may require spring change.

2. Prior to adjustment - payload must be secure and arm horizontal. Fine

adjustment to compensate monitor counterbalance can be made by turning

adjustment screw (item 53). Rotate adjustment nut:

clockwise to increase capacity

counter clockwise to decrease capacity

Installation and Maintenance Guide for IDI 1000F Series Suspension System for use

with CAS 8000 Rails

D000-479 REV J MAY-2018 Image Diagnostics, Inc. Page 19

53

Yoke Balance Adjustment

WARNING! Yoke has been leveled at

manufacturers. Make adjustment

only if absolutely necessary to

compensate for an unbalanced load.

NOTE: Prior to yoke adjustment - payload must be secure and arm horizontal.

1. Fine adjustment, to compensate for yoke balance, can be made by turning the

link (item 48). Loosen threaded hex nut (item 24) at outboard rod end (item 10);

spin link until yoke is in a horizontal position; retighten hex nut.

MONITOR MOUNT ASSEMBLY ROTATION RESISTANCE

1. The setscrews (item 24) installed in step 6 of "INSTALL MONITOR MOUNT"

on page 12 can be loosened or tightened to adjust the rotation resistance of the

suspended monitor mount assembly.

2. Replace wireway cover (item 38) after making adjustment.

Installation and Maintenance Guide for IDI 1000F Series Suspension System for use

with CAS 8000 Rails

D000-479 REV J MAY-2018 Image Diagnostics, Inc. Page 20

F. CLEANING THE EQUIPMENT

No part of this unit is designed to be sterilized in an autoclave. Do not allow

water or other liquids to enter the equipment as this may cause short circuits or

corrosion. Clean parts with a clean cloth dampened with disinfectant or a mild

detergent solution. Do not use abrasives, solvents, sprays or corrosive cleaning

agents. Gently rub with a clean soft cloth to dry.

If room is to be disinfected by means of an atomizer, the equipment must be

covered with plastic or similar sheeting. The equipment must be turned off well

in advance of this procedure to prevent convection currents from drawing the

disinfectant mist into the equipment. After the mist disperses completely, the

sheeting may be removed and the equipment disinfected as described above.

G. MAINTENANCE

"Authorized Technician"

All maintenance procedures should be done by an experienced technician with

demonstrated knowledge and skills (electrical and mechanical) relative to this

type of equipment.

This individual must have access to this manual and the proper tools.

Daily Maintenance Checks:

1. Pre-Operational and Post-Operational Checks

Perform daily checks of the monitor suspension BEFORE and

AFTER operating the equipment.

CAUTION! If any abnormality is found in the

monitor suspension, stop using it. Post

a sign reading "DO NOT USE" so that

the system is not used by mistake.

2. Visual check

Before checking the operation, confirm the following:

•The monitor suspension is not tilted. Refer to the following figures.

•Although "A" in the following figure shows a gap, there is no gap at the

monitor frame rotation section.

•Monitors installed on the monitor suspension are not tilted.

This manual suits for next models

6

Table of contents

Other Image Diagnostics Protection Device manuals