2.0 Descripon

This Full Body Harness (FBH) comprises the Body Wear component of your Personal Fall Arrest System (PFAS).

This manual will discuss the various connecon points with their specic applicaon. When properly worn and

ulized, a FallTech® FBH will allow the user to work safely and comfortably. A FBH is part of a PFAS requiring a

properly rated anchorage and anchorage connector that uses a compable connecng device

appropriate for the fall protecon applicaon.

2.1 Maximum Harness Rang: The FallTech® FBHs are ANSI Z359.11, CSA Z259.10, and OSHA compliant. ANSI

user capacity is 310 lbs.(140.6 kg) including clothing, tools, etc., CSA user capacity is 350 lbs.(160 kg) including

clothing, tools, etc., and OSHA rated capacity is 425lbs (192.8 kg) including clothing, tools, etc.

FallTech® Full Body Harnesses are available in a wide variety of conguraons to address the specic needs in

most workplaces. The suitability of a Full Body Harness for a specic applicaon is determined primarily by the

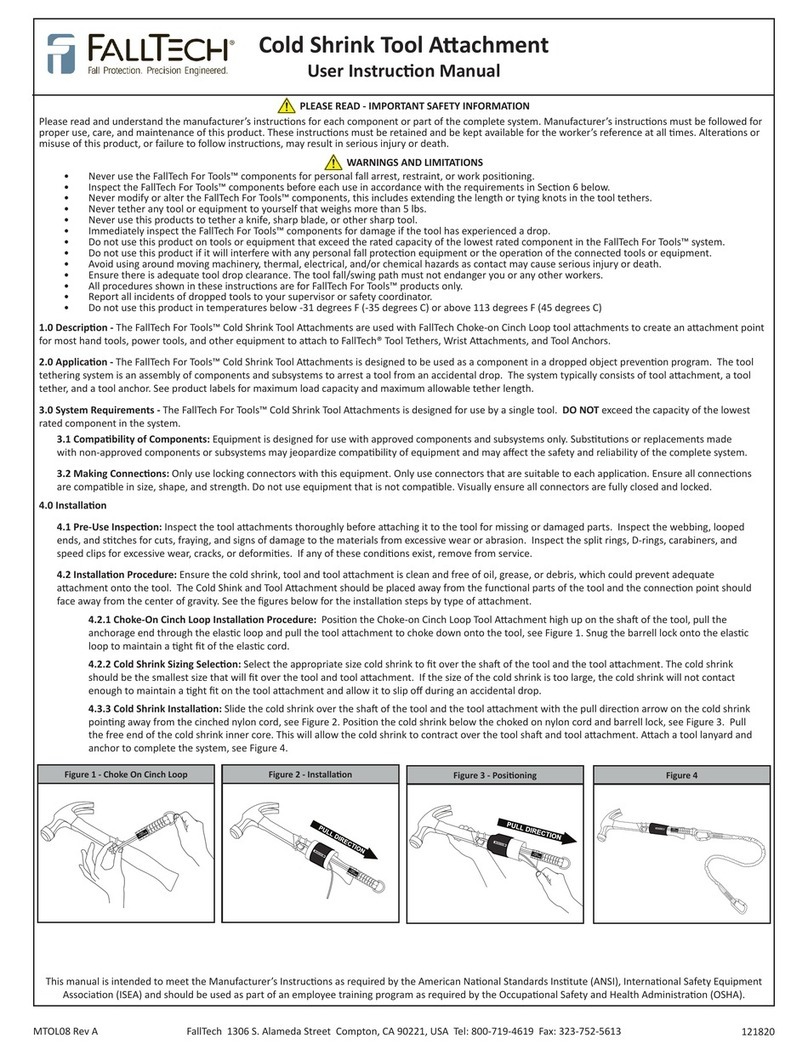

type and locaon of the D-ring or D-rings on the FBH. See Figure 1 for a summary of the approved applicaons for

each D-ring located on a FBH.

If you have quesons about whether this product is suitable for your applicaon, please consult a competent

person or contact FallTech® for further advice.

Figure 1 - Harness Connecon Points

CSA

Class Applicaon Pictogram Explanaon

Class A Fall Arrest

The dorsal D-ring is the aachment point is located on the back of your full

body harness (FBH). It is to be used for fall arrest or restraint only,

connecng devices for these applicaons include Energy Absorbing

Lanyards, Self-Retracng Lifelines, and Restraint lanyards.

Class P Work

Posioning

Work posioning D-rings are located adjacent to each hip, the intended

use is with a posioning lanyard when posioning on a vercal surface (e.g.

tower applicaons, rebar tying, etc.). This system is a primary system and

should always be used in conjuncon with a fall arrest system.

Class E Rescue

Located on each shoulder of the FBH, these D-rings are intended for

conned space entry and retrieval. They can also be used in other rescue

applicaons where limited access is an issue.

Class D Decent May be located at the sternal posion of the harness or have one or two

D-rings located below the waist (e.g. bosun’s chair).

Class L Ladder

Climbing

Harnesses with a sternal D-ring can be aached to a vercal ladder

climbing system. The sternum locaon can be used in conjuncon with a

ladder climbing device which allows for no more than a 9-inch (22.5 cm)

connecon.

3.0 Applicaon

3.1 Purpose: The FallTech® FBH is designed for use as a component in a PFAS, to provide a combinaon of worker

mobility and fall protecon as required for inspecon work, general construcon, maintenance work, oil

producon, conned space work, or any applicaon where fall protecon is required.

3.2 Personal Fall Arrest System: A PFAS is typically composed of an anchorage and a FBH, with an energy

absorbing connecng device, i.e., an EAL, an SRD, or a Fall Arrester Connecng Subsystem (FACSS), aached to the

dorsal D-ring of properly ed and adjusted FBH. All uses and applicaons of a FBH with this equipment requires

the FBH to be properly ed and adjusted to the user. Failure to properly t the FBH to the user could result in

serious injury or death.

NOTE: PFAS components used in conjuncon with this FBH should comply with ANSI Z359/CSA Z259 and

applicable OSHA regulaons.

3.3 Applicaon Limits: Take acon to avoid moving machinery, sharp edges, abrasive surfaces, and thermal,

electrical and chemical hazards as contact may cause damage to fall protecon equipment, or serious injury, or

death.

3.4 Approved Applicaons: Figure 1 is a summary of the approved applicaons for each D-ring locaon on the

FBH. This list is not all-inclusive, but is intended to ancipate the most common applicaons in which this product

may be used. If you have quesons about whether this product is suitable for your parcular applicaon, please

consult a competent person or contact FallTech®.

MFBH04 Rev A 121219

4