INDICE

USER pageINSTALLER page MAINTENANCE TECHNICIAN page

1 Installation Trio V2 ....................................5

1.1 Description of the device...........................5

1.2 Installation recommendations..................5

1.3 Packaging..................................................... 5

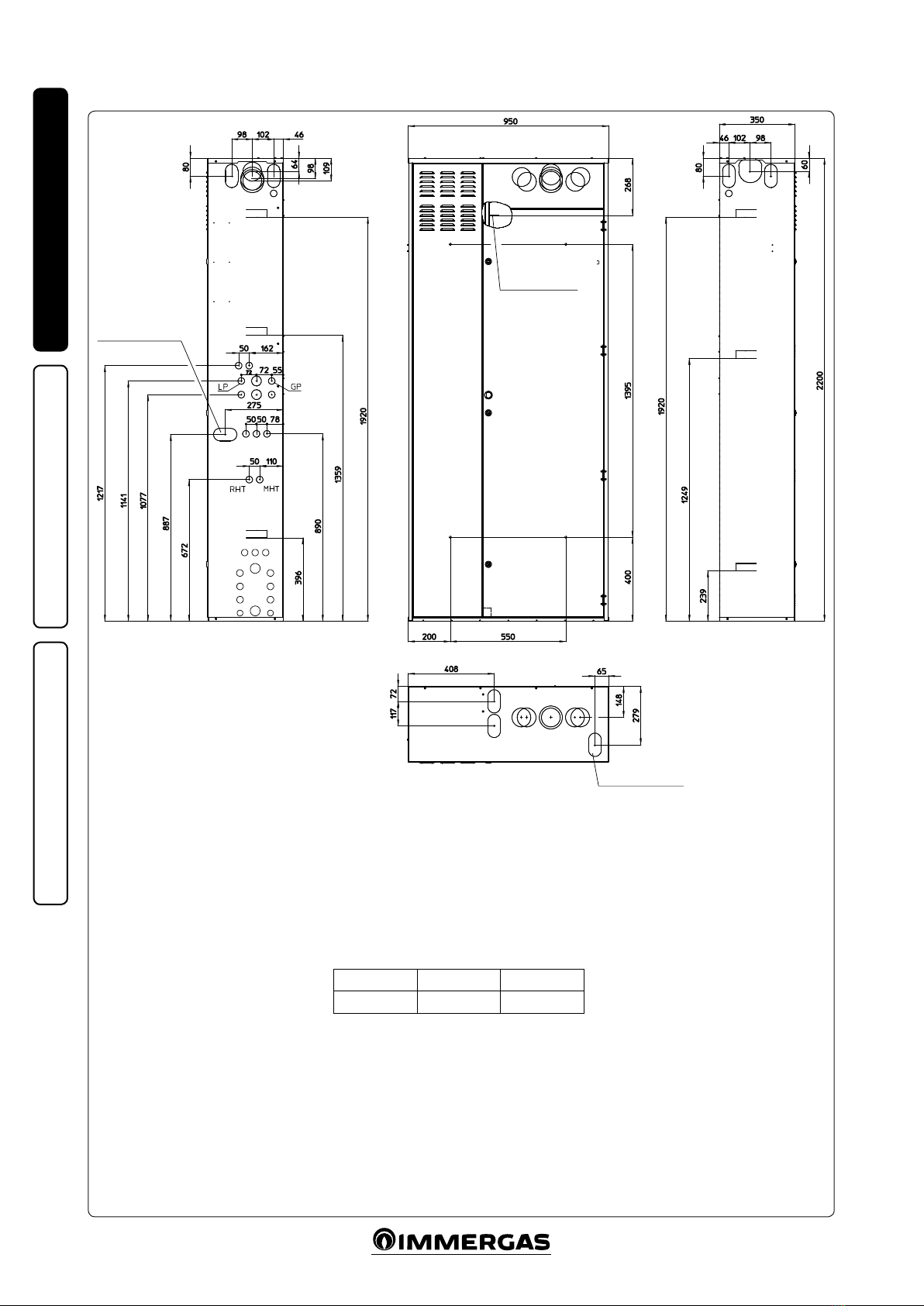

1.4 Overall dimensions.....................................6

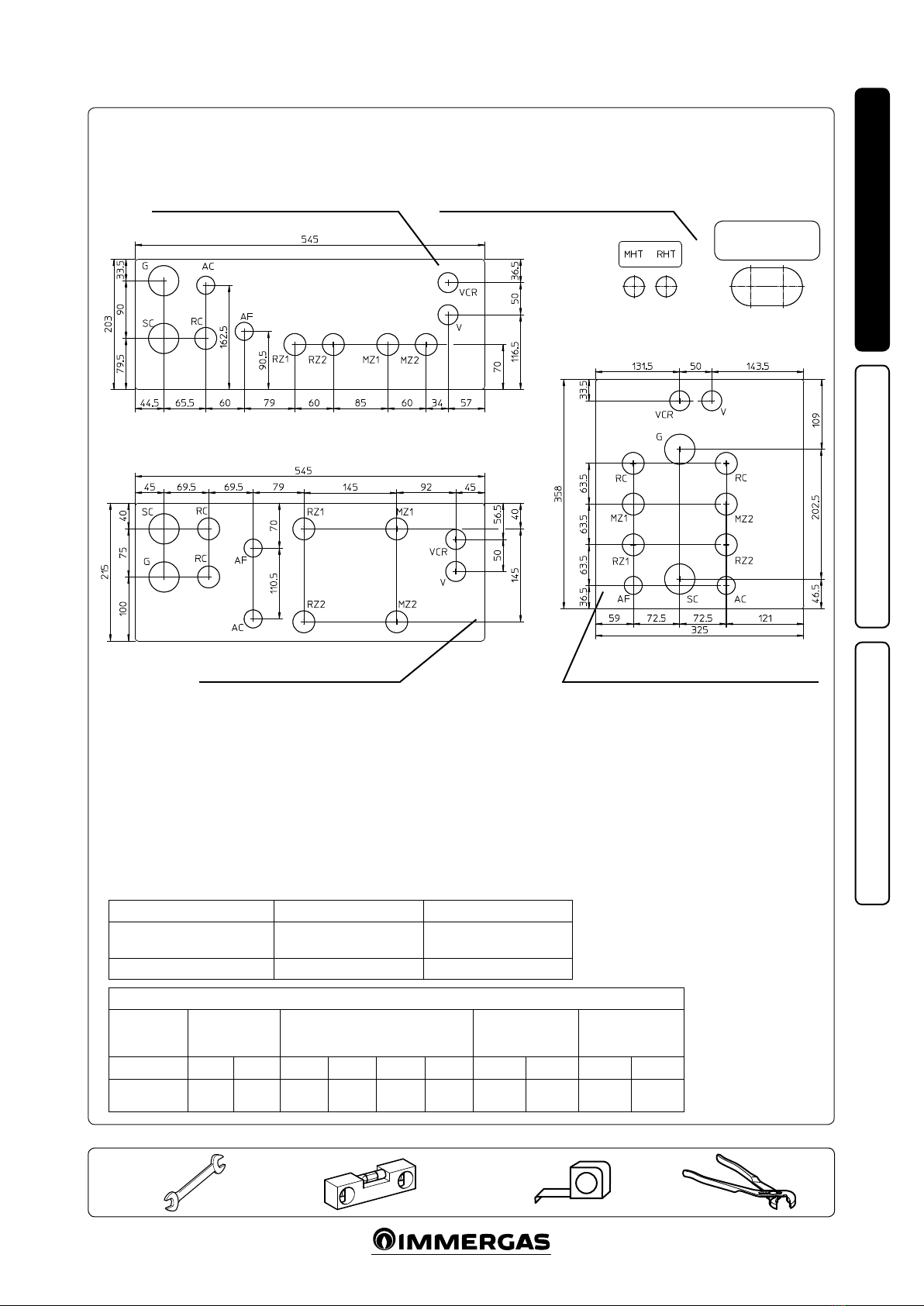

1.5 Connection template..................................7

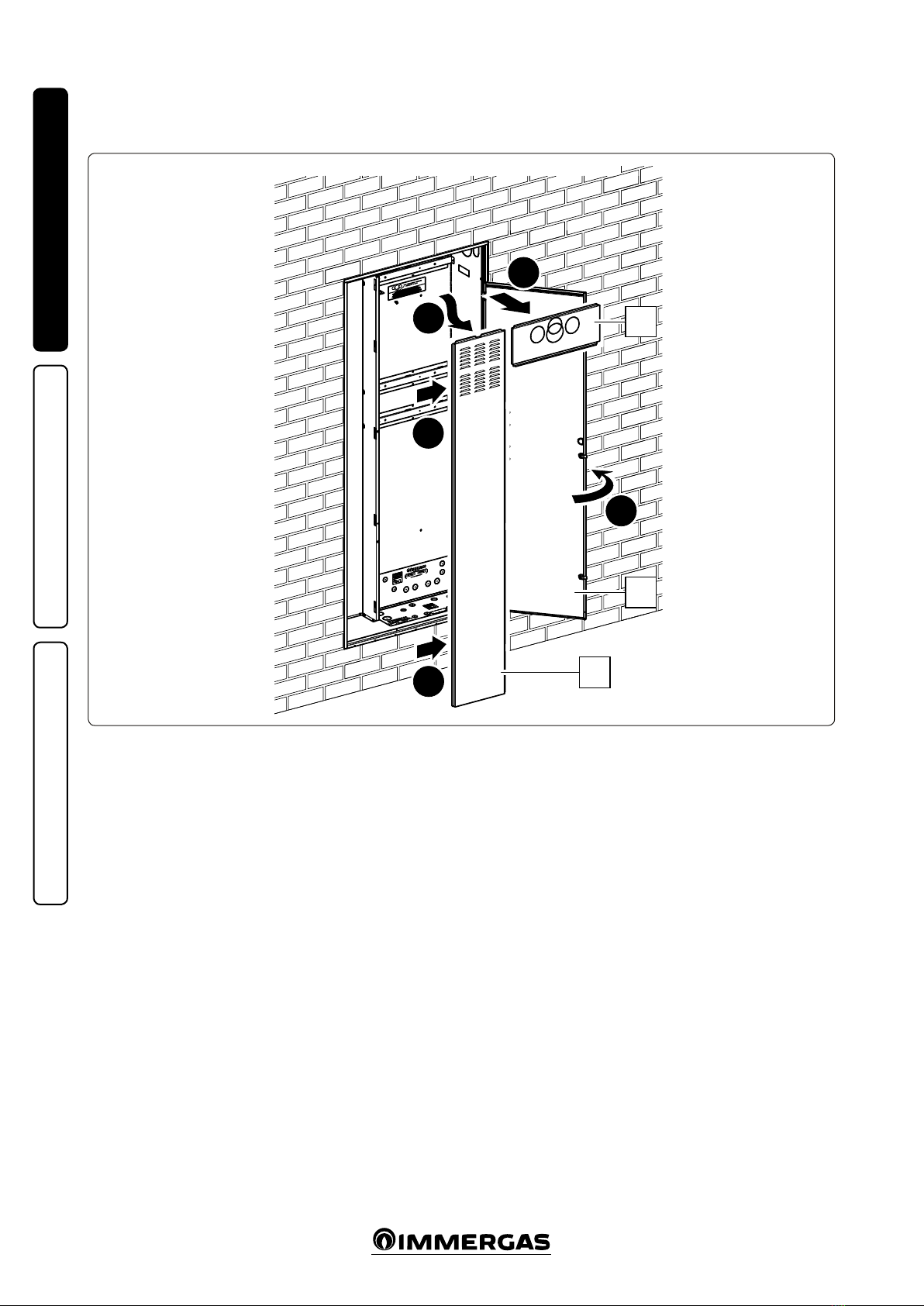

1.6 Installation...................................................9

1.7 Trio V2 (Base) wiring connection

diagram. .....................................................25

1.8 Remote panel main dimensions .............26

1.9 Remote panel installation operations.....26

1.10Gas connection (where the optional

boiler is present). ......................................27

1.11Hydraulic connection...............................27

1.12Safety valve drain......................................27

1.13Condensate drain (where the optional

boiler is present). ......................................27

1.14Electrical connection................................27

1.15Room thermostats (Optional). ...............30

1.16Audax control panel. ................................30

1.17 Secondary zone remote control (optional)....30

1.18 Solar control unit installation (Optional).......31

1.19Antifreeze protection. ..............................33

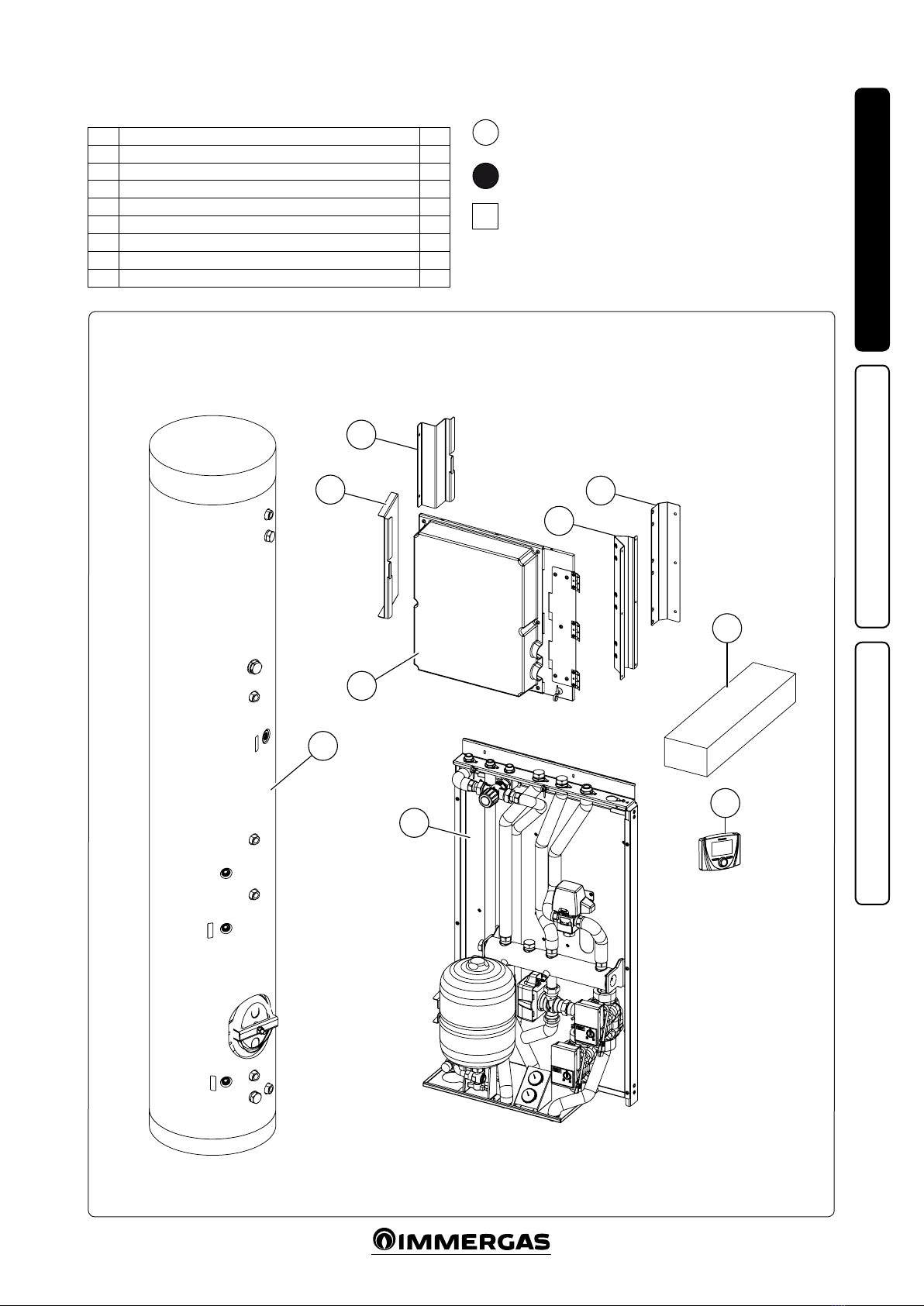

1.20Trio Base V2 main components..............34

1.21Main components Trio Base V2 with

integrated resistances (Optional)............35

1.22Main components Trio Combi V2 with

instantaneous boiler (Optional) .............36

1.23Main components Trio Combi V2 with

Victrix Omnia (Optional) .......................37

1.24Main components Trio Plus V2 with

Plus boiler (Optional) ..............................38

1.25Main components Trio Pro V2 with

Magis Pro (Optional)...............................39

1.26Main components solar heating system

coupling kit (Optional)............................40

1.27Trio Base V2 hydraulic diagram.............41

1.28Hydraulic diagram Trio Base V2 with

integrated resistances (Optional)............42

1.29Hydraulic diagram Trio Combi V2 with

instantaneous boiler (Optional) .............43

1.30Hydraulic diagram Trio Combi V2 with

Victrix Omnia (Optional) .......................44

1.31Hydraulic diagram Trio Combi Mono V2

with instantaneous boiler (Optional).....45

1.32Hydraulic diagram Trio Combi Mono V2

with Victrix Omnia (Optional)...............46

1.33Hydraulic diagram Trio Plus V2 with

Plus boiler (Optional). .............................47

1.34Hydraulic diagram Trio Pro V2 with

Magis Pro (Optional)...............................48

1.35Hydraulic diagram solar heating system

coupling kit (Optional)............................49

1.36Hydraulic diagram V2 DHW

(Domestic hot water) three-way priority

valve (Optional)........................................50

1.37Mixing valve. .............................................51

1.38Commissioning (Ignition).......................51

1.39Boiler commissioning (if present)..........51

1.40Gas system commissioning (where the

optional boiler is present)........................51

1.41Commissioning solar heating system

coupling kit (Optional)............................51

1.42Cooling / Central heating circuit / C.H.

circuit system lling. ................................51

1.43 Filling the solar circuit system (Optional)...52

1.44Sizing the systems.....................................52

1.45Kits available on request. .........................53

1.46Circulation pump (Trio)..........................53

1.47Circulation pump (solar thermal system

coupling kit). .............................................55

2 Instructions for use and maintenance....57

2.1 Cleaning and maintenance......................57

2.2 General warnings......................................57

2.3 Decommissioning.....................................57

2.4 Trio remote panel (main). .......................58

2.5 System use..................................................58

2.6 Comfort / Economy / Manual Operation. ....59

2.7 Operation with external probe................59

2.8 Clock and programs.................................59

2.9 Settings menu............................................60

2.10 DHW (Domestic hot water) set setting.... 63

2.11Fault and anomaly signals. ......................64

2.12 Use of the remote zone control (optional).....66

2.13Using the secondary zone Remote panel

(optional). ..................................................67

2.14Fault and anomaly signals. ......................69

3 Control and maintenance........................70

3.1 Trio V2 wiring diagram...........................71

3.2 Trio Mono V2 wiring diagram................72

3.3 System programming...............................73

3.4 Programming and use of the zone

remote panel..............................................79

3.5 External temperature probe (Optional).... 80

3.6 Programming the remote zone control

parameters (Optional). ............................80

3.7 Photovoltaic function...............................81

3.8 Deaeration Function. ...............................81

3.9 Victrix kW TT Special functions............81

3.10Victrix Tera Special functions.................81

3.11Magis Pro Special functions....................81

3.12Radiant panel systems..............................81

3.13Flow set calculation..................................81

3.14Annual maintenance:...............................82

3.15Decommissioning.....................................82

3.16Technical data. ..........................................83

3.17Product sheet.............................................83

3.18Product che (in compliance with

Regulation 812/2013)...............................84