17 TM

SPEED CONTROL

TM

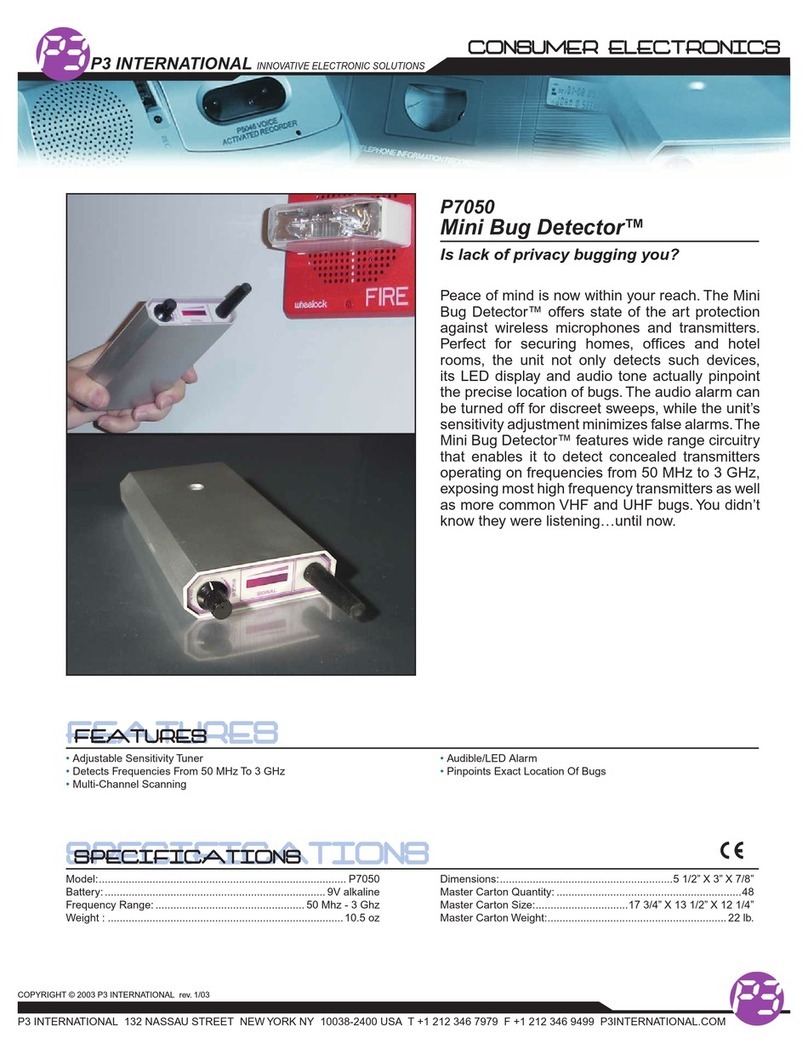

DESCRIPTION

The MDrive17Plus Speed Control offers

system designers cost effective, program-

mable velocity control integrated with a

NEMA 17 high torque 1.8° brushless step

motor and a +12 to +48 volt microstepping

driver.

The MDrive17Plus Speed Control features

a digital oscillator for accurate velocity

control with an output frequency of up

to 5 Megahertz. Output frequency will

vary with the signal applied to the speed

control input and can be limited by the

amount specified by the Maximum Veloc-

ity parameter.

Speed can be adjusted using three modes

of operation: voltage, current and PWM.

The ranges are 0 to +5 volts and 0 to

+10 volts in voltage mode, 0 to 20 mA

and 4 to 20 mA in current mode, and 15

to 25 kHz in PWM mode. This allows the

MDrive17Plus Speed Control to be driven

by a wide variety of sensors and control

devices.

There are two basic methods for control-

ling the velocity: bidirectional and unidi-

rectional. By moving the center point, both

speed and direction are controlled by a

potentiometer or joystick. By setting the

center point to zero or the lower end of the

potentiometer, only velocity is controlled

by the speed control input; direction is

controlled by a separate digital input.

The MDrive17Plus Speed Control has 18

setup parameters, which may be con-

figured using the supplied IMS Analog

Speed Control GUI, or a user-developed

front-end communicating over SPI. The

setup parameters enable the user to con-

figure all MDrive operational parameters

which are stored in nonvolatile memory.

The versatile, compact MDrive17Plus

Speed Control is available in multiple

FEATURES

• Highly Integrated Microstepping Driver,

Intelligent Variable Speed Controller and

NEMA 17 High Torque 1.8° Brushless

Step Motor

• Advanced 2nd Generation Current

Control for Exceptional Performance and

Smoothness

• Single Supply: +12 to +48 VDC

• Cost Effective

• Extremely Compact

• 20 Microstep Resolutions up to

51,200 Steps Per Rev Including:

Degrees, Metric, Arc Minutes

• 10-bit Analog Speed Control Input

Accepts:

- 0 to +5 VDC

- 0 to +10 VDC

- 4 to 20 mA

- 0 to 20 mA

- 15 to 25 kHz PWM

• Automatic Current Reduction

• Electronically Configurable:

- Motor Run/Hold Current

- Microstep Resolution

- Acceleration/Deceleration

- Initial and Max Velocity

- Hold Current Delay Time/Motor

Settling Delay Time

- Programmable Filtering for the

Start/Stop Input

• Available Options:

- Long Life Linear Actuators**

- External Optical Encoder

- Integrated Planetary Gearbox

- Control Knob for Manual Positioning

- Linear Slide

• 3 Rotary Motor Lengths Available

• Setup Parameters May Be Switched

On-The-Fly

• Interface Options:

- Pluggable Terminal Strip

- 12.0” (30.5cm) Flying Leads

• Graphical User Interface (GUI) for Quick

and Easy Parameter Setup

** Consult Factory for Availability.

www.imshome.com

configurations to fit various system needs.

Rotary motor versions come in three

lengths and may include an optical en-

coder, control knob, planetary gearbox or

linear slide. Long life Acme screw linear

actuators** are also available.

Connector style options give you choices

for the best fit and features. Select from

12.0" (30.5cm) flying leads or pluggable

terminal strip.

MDrivePlus connectivity has never been

easier with options ranging from all-inclu-

sive QuickStart Kits to individual inter-

facing cables and mating connector kits

to build your own cables. See pg 4.

The MDrive17Plus is a compact, powerful

and cost effective motion control solution

that will reduce system cost, design and

assembly time for a large range

of brushless step motor applications.

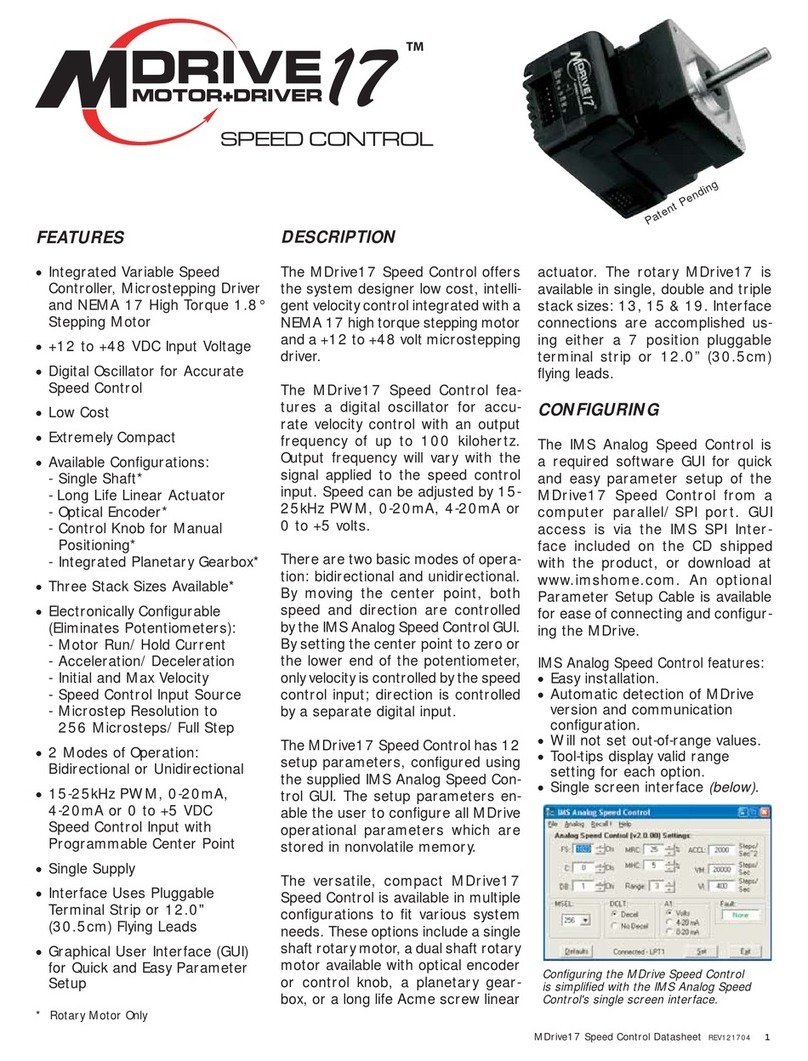

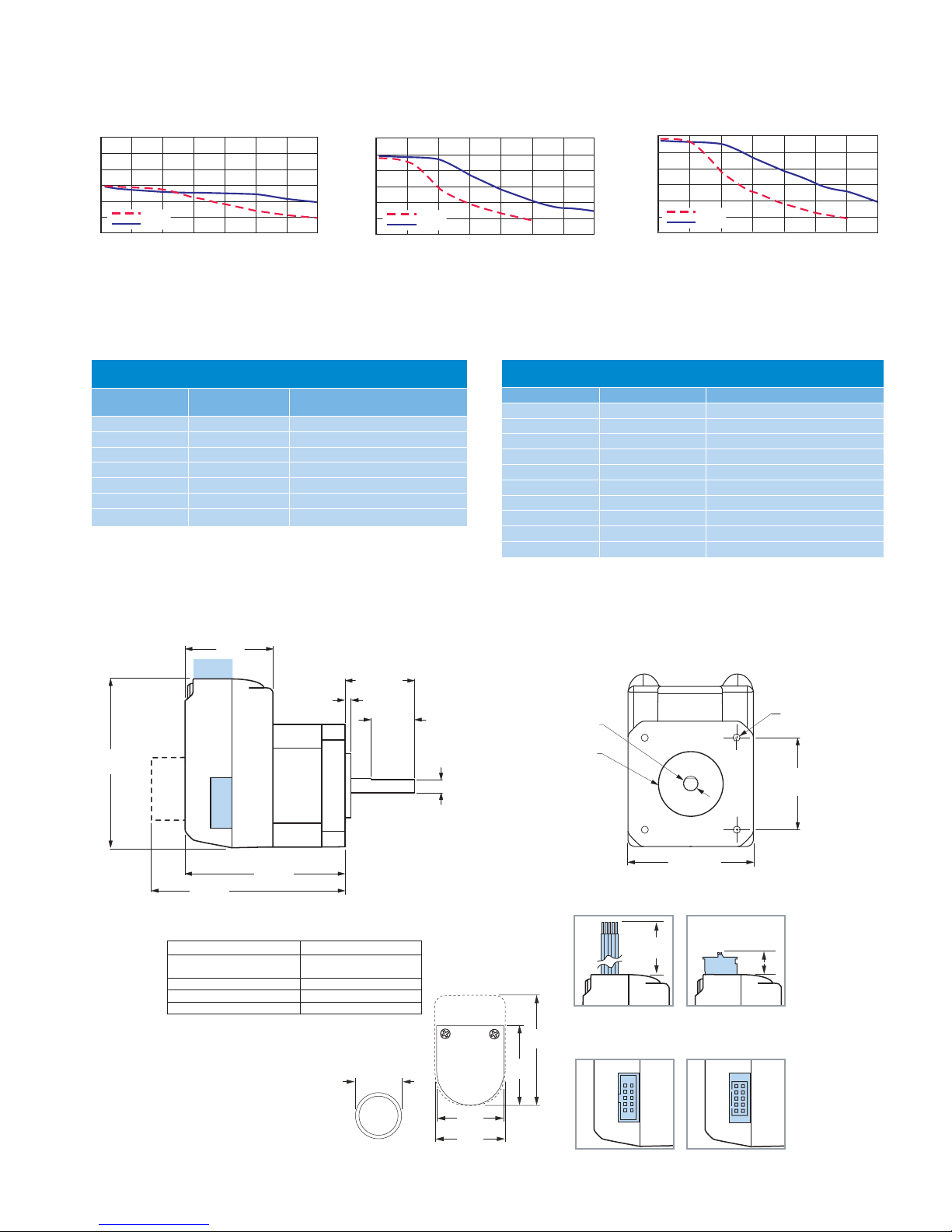

CONFIGURING

The IMS Analog Speed Control is a soft-

ware GUI for quick and easy parameter

setup of the MDrivePlus Speed Control

from a computer's USB port. GUI ac-

cess is via the IMS SPI Motor Interface

available at www.imshome.com. The IMS

interface is also used to upgrade MDrive-

Plus Speed Control firmware.

IMS Analog Speed Control features:

• Easy installation.

• Automatic detection of MDrivePlus ver-

sion and communication configuration.

• Will not set out-of-range values.

• Tool-tips display valid range setting for

each option.

• Simple screen interface.

Excellence in Motion

new