MDrive34 Microstepping Datasheet REV121704 1

FEATURES

•Integrated Microstepping Driver

and NEMA 34 High Torque 1.8°

Stepping Motor

•+24 to +75 VDC Input Voltage

•Low Cost

•Extremely Compact

•Optically Isolated Logic Inputs

will Accept +5 to +24 VDC

Signals, Sourcing or Sinking

•Automatic Current Reduction

•Configurable:

- Motor Run/Hold Current

- Motor Direction vs. Directio

Input

- Microstep Resolution to 256

Microsteps/Full Step

•Available Configurations:

- Single Shaft*

- Long Life Linear Actuator

- Internal Optical Encoder*

- Control Knob for Manual

Positioning*

- Integrated Planetary Gearbox*

•Three Stack Sizes Available*

•Current and Resolution May Be

Switched On-The-Fly

•Single Supply

•Interface Uses 12.0" (30.5cm)

Flying Leads

•Graphical User Interface (GUI)

for Quick and Easy Parameter

Setup

* Rotary Motor Only

DESCRIPTION

The MDrive NEMA 34 high torque

Integrated Motor and Driver is ideal

for designers who want the simplicity

of a motor with on-board electronics,

but without the expense of an in-

dexer on each axis. The low cost

MDrive34 puts the system designer

in the driver’s seat to decide the best

method of control. The MDrive34’s

integrated electronics eliminate

the need to run the motor cabling

through the machine, reducing the

potential for problems due to elec-

trical noise.

The MDrive34 uses a NEMA 34

frame size 1.8° high torque mo-

tor combined with a microstep-

ping driver, and accepts up to 14

resolution settings from ½ to 256

microsteps per full step. Setup pa-

rameters include Microstep Resolu-

tion, Motor Run/Hold Current, and

Motor Direction with respect to the

direction input. These settings may

be changed on-the-fly or downloaded

and stored in nonvolatile memory

with the use of a simple GUI which

is provided. This eliminates the need

for external switches or resistors.

Parameters are changed via an SPI

port. MDrive34 operating voltage

ranges from +24 to +75 VDC.

The MDrive34 is available in multiple

configurations to fit various system

needs including a single shaft rotary

motor with optional internal optical

encoder, a dual shaft rotary motor

with control knob, a planetary gear-

box, or a long life Acme screw linear

actuator. The rotary MDrive34 is

available in single, double and triple

stack sizes: 24, 31 & 47. Interface

MI

R

TEPPING

Patent Pending

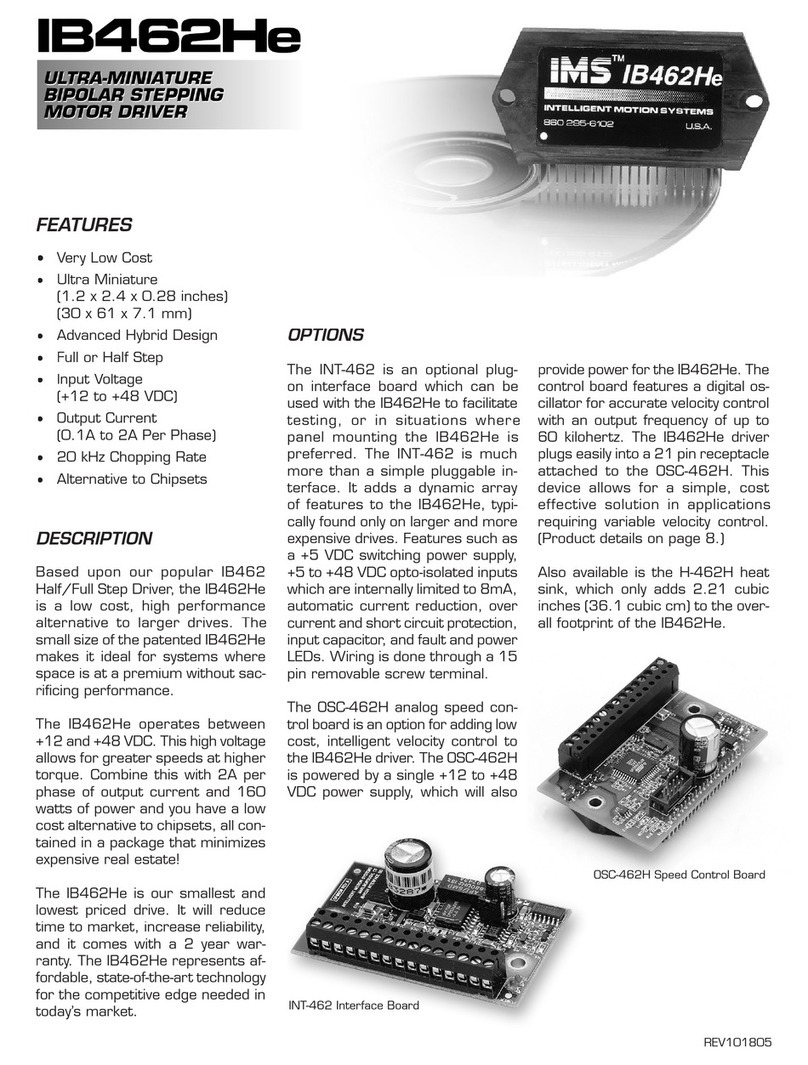

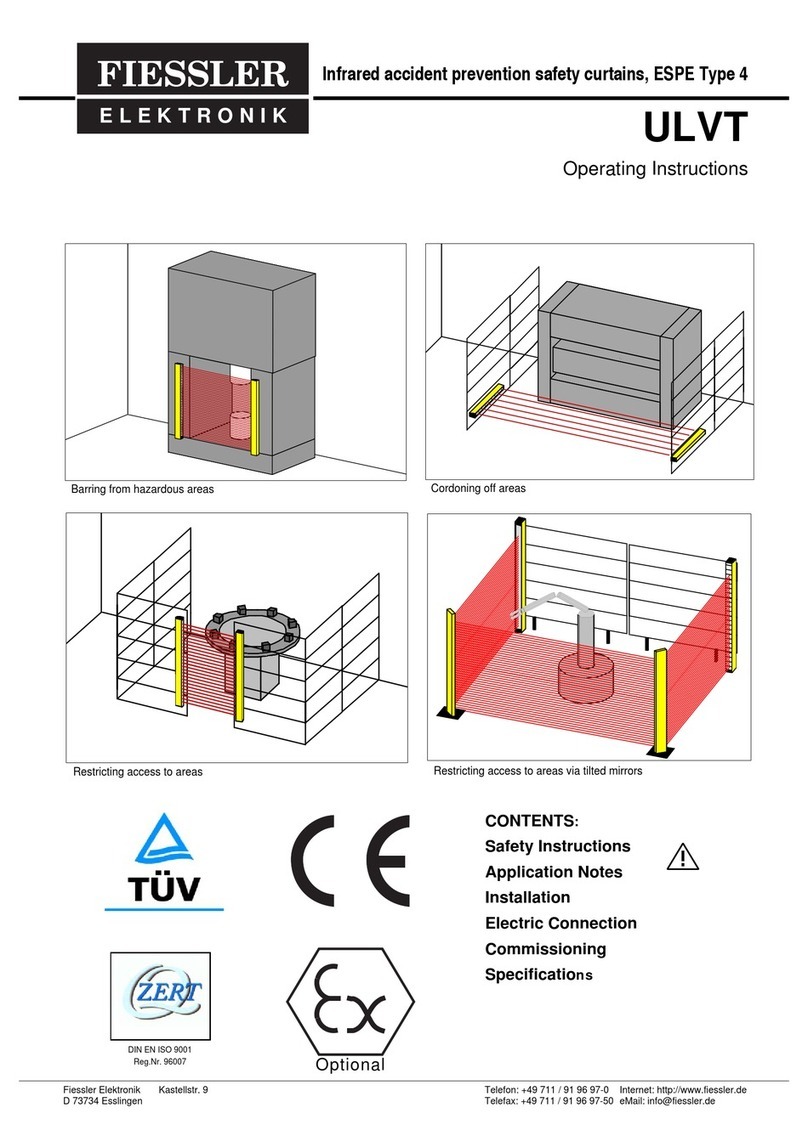

The IMS Motor Interface GUI simplifies MDrive

configuring with a single screen interface.

connections are accomplished using

12.0" (30.5cm) flying leads.

The MDrive34 is a compact, pow-

erful and inexpensive solution that

will reduce system cost, design and

assembly time for a large range of

stepping motor applications.

CONFIGURING

The IMS Motor Interface software

is an easy to install and use GUI

for configuring the MDrive34 from

a computer parallel/SPI port. GUI

access is via the IMS SPI Inter-

face included on the CD shipped

with the product, or download at

www.imshome.com. An optional

cable is available for ease of con-

necting and configuring the MDrive.

.

The IMS Motor Interface features:

•Easy installation.

•Automatic detection of MDrive

version and communication

configuration.

•Will not set out-of-range values.

•Tool-tips display valid range

setting for each option.

•Single screen interface

(below)

.