●For mounting work, always contact a professional contractor.

●Keep this instruction manual in a safe place.

●For inquiries, contact one of the offices listed at the end of the

document.

Read this first (for proper and safe use)

This product is only for air conditioning piping. Do not use this for refrigerating or freezing equipment piping.

■The following describes categories of possible risks and damages that may occur when the product is used improperly without

complying with the instruction.

To prevent risks to the user or other people and property damages, the following instructions must be followed.

■

■

Note

※The product may not achieve its expected functions or performance if the following instructions

are not observed.

Caution

Warning

Caution

Warning

Improper handling of the product may cause injury to the user.

Improper handling of the product may cause property damages.

●Always wear work gloves, helmets, etc. while at work.

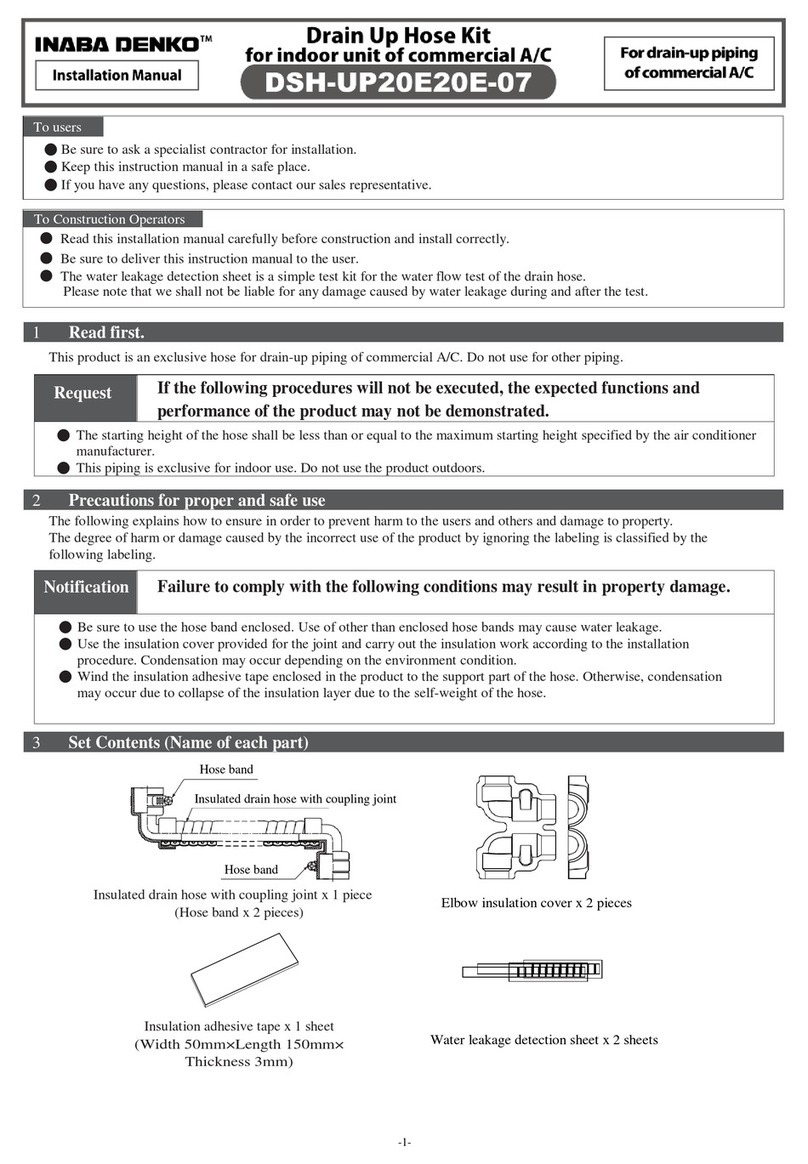

Details of the unit, part names, specifications

Dimensions

A pipe support is required at each floor/level. Use a flexible piping band (model: HBR) for supporting the piping.

Apply ultraviolet shielding measures for outdoor use. Or, the insulation material may deteriorate.

■

Detailsoftheunit

Symbols Names Quantity

SUS304

PC

PP

SUS

SUS

―

Material

A

B

ー

Mainbody(PipeSupportTKL)

HexboltM8x23L

InstructionManual

1

3

1

A-1:Fixationbandx1

A-2:Spacersx2

A-3:

Temporarynutfixationplatex1

A-4:HexnutM8x3

TKL-3K

TKL-4K

TKL-5K

TKL-6K

TKL-7K

TKL-8K

TKL-9K

TKL-10K

TKL-11K

TKL-12K

TKL-13K

TKL-14K

Models

φ9.52

φ12.70

φ15.88

φ19.05

φ22.22

φ25.40

φ28.58

φ31.75

φ34.92

φ38.10

φ41.28

φ44.45

Compatible pipe sizes

30

32

34

36

37

39

41

43

44

46

48

49

A B

59

61

63

65

66

68

70

72

73

75

77

78

Unit: mm

A

B

45

86

20230714

【4】 【1】

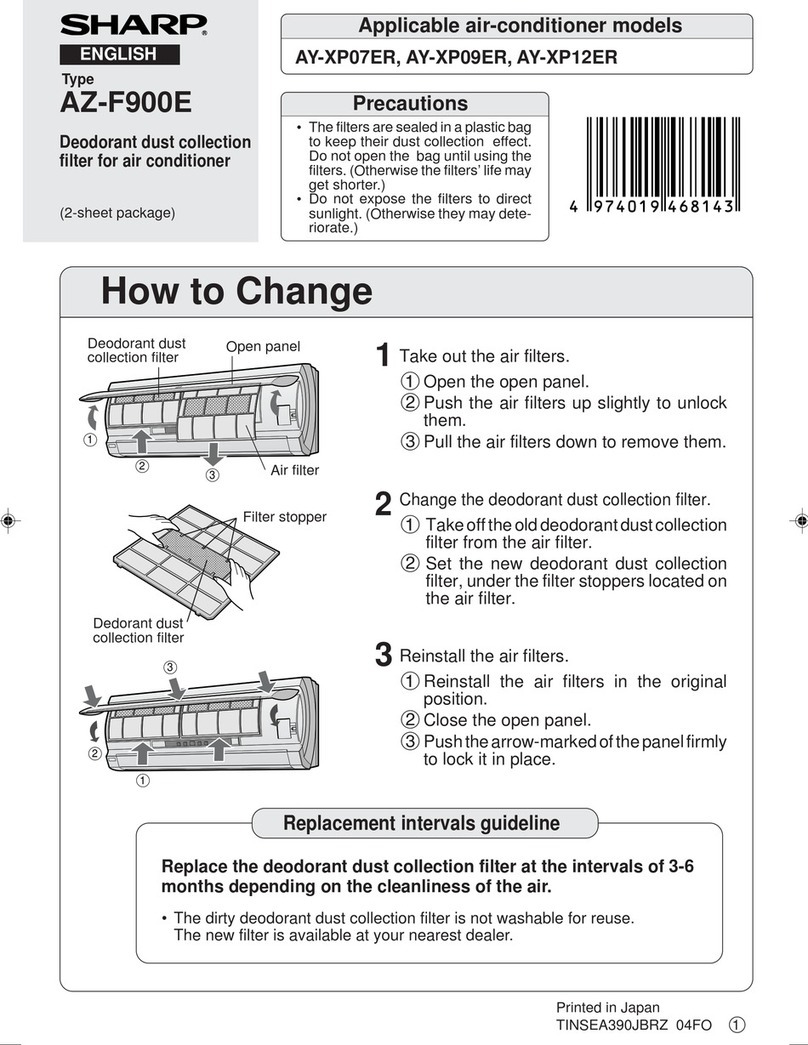

Mounting procedure

For dew proofing, mount a TKL insulation cover (our company’s model: TKL-SH, TKL-DH)

on the Pipe Support.

■Mounting an insulation cover (for dew proofing)

[Fig. 7] For TKL-B/TKL-K

[Fig. 8]

4

.1

※ A gap plug is included in the package of TKL insulation cover (TKL-6SH/6DH〜14SH/14DH).

(This is not required for TKL-3K〜5K, and it is not included in the package of TKL-3SH/3DH〜5SH/5DH)

For TKL-U

②0〜10mm

①0〜10mm

①②5〜15mm

Insulation cover Insulation cover

Gap plug Gap plug

For TKL-U

Wrap the adhesive tape in

a vertical direction.

➡

●②●②

Insulation

cover joint

Adhesive tape

Instruction

Manual

For air conditioning

piping only

TKL-3K

φ

9.52

With reference to [Fig. 7], cut the end of the insulation cover (dimension (1)).

Insulation cover

Insulation material

Insulation joint

adhesive tape

(JTA)

Insulation

cover joint

Insulation cover Gap plug Insulation cover

Gap plug

.2 Place an insulation joint adhesive tape (our company’ s

model: JTA) around the joint between the insulation cover

and the insulation material of the piping, overlapping it at

least 10 mm on the circumference. [Fig. 8]

.3Place an adhesive tape (our company’ s model: HF, HV, HR) around the joint of the insulation cover

on the base bracket to prevent the joint from opening. [Fig. 9]

Clean and remove all dusts and stains from the surface where the insulation

joint adhesive tape is placed.

(Note)

When placing the insulation joint adhesive tape at the edge of the T-portion of

the insulation cover, use your hand to press the tape wrinkles and push the

tape into the embossed shape (concave and convex shapes) so that the tape

adheres tightly to the material.

(Note)

[Fig. 9]

For TKL-B/TKL-K

See the following website for more information;

(up-to-date & technical information, etc.)

https://www.inaba-denko.com/en/

INABA DENKO COMPANY

Place the adhesive tape at the top of

the joint, covering more than half of

its circumference.

Place the adhesive tape around

in a horizontal direction.

Pipe Support TKL (without brazing)

Compatible copper tube size

For customers

●Be sure to read this instruction manual carefully and then install

the product properly.

●Be sure to hand this instruction manual to the customer.

●This instruction manual is valid only in Japan.

For installation contractors

●If there is a possibility of damage to the elbow at the uptake or downtake part of vertical piping, use an

expansion elbow (expansion loop, expansion offset, etc.) to absorb thermal expansion and contraction of

the copper tube.

●Make sure that the fixation band size matches the copper tube size before use.

●Fixation bands cannot be reused as they are deformed when opened after they are closed once.

●Do not use strap bolts as these are not strong enough.

●Always use a dedicated TKL base bracket for installation.

A-1

A-3

A-4

A-2