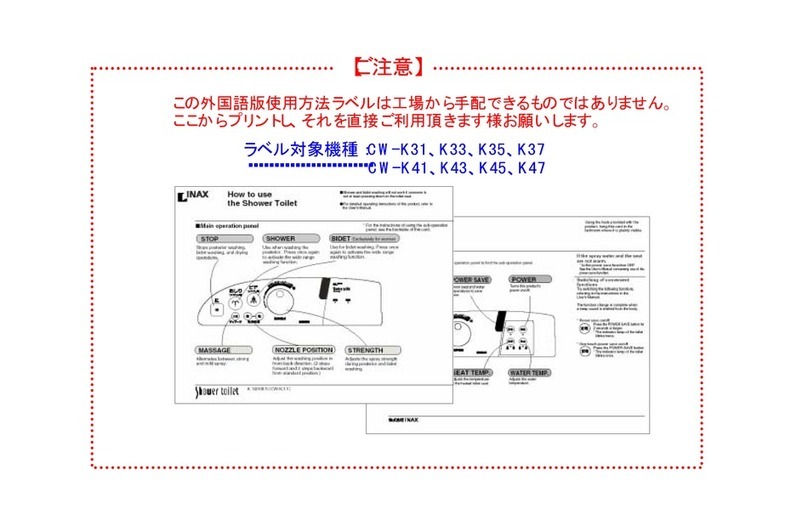

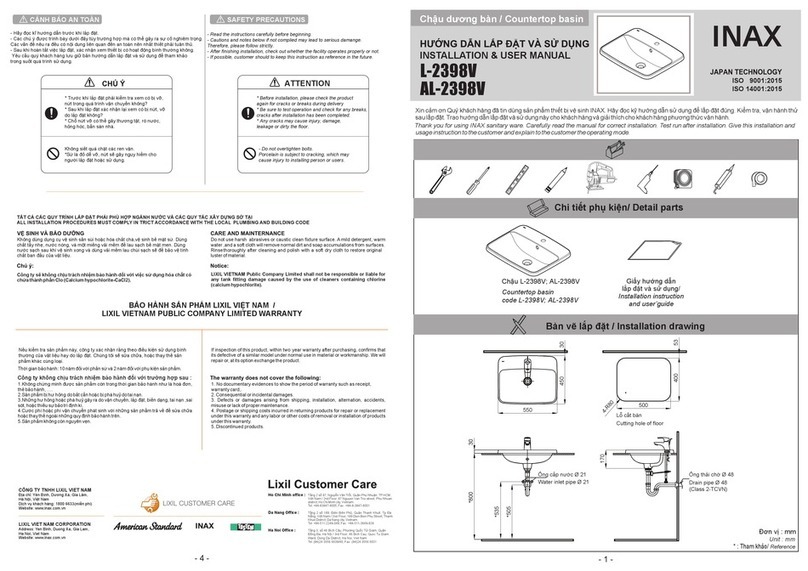

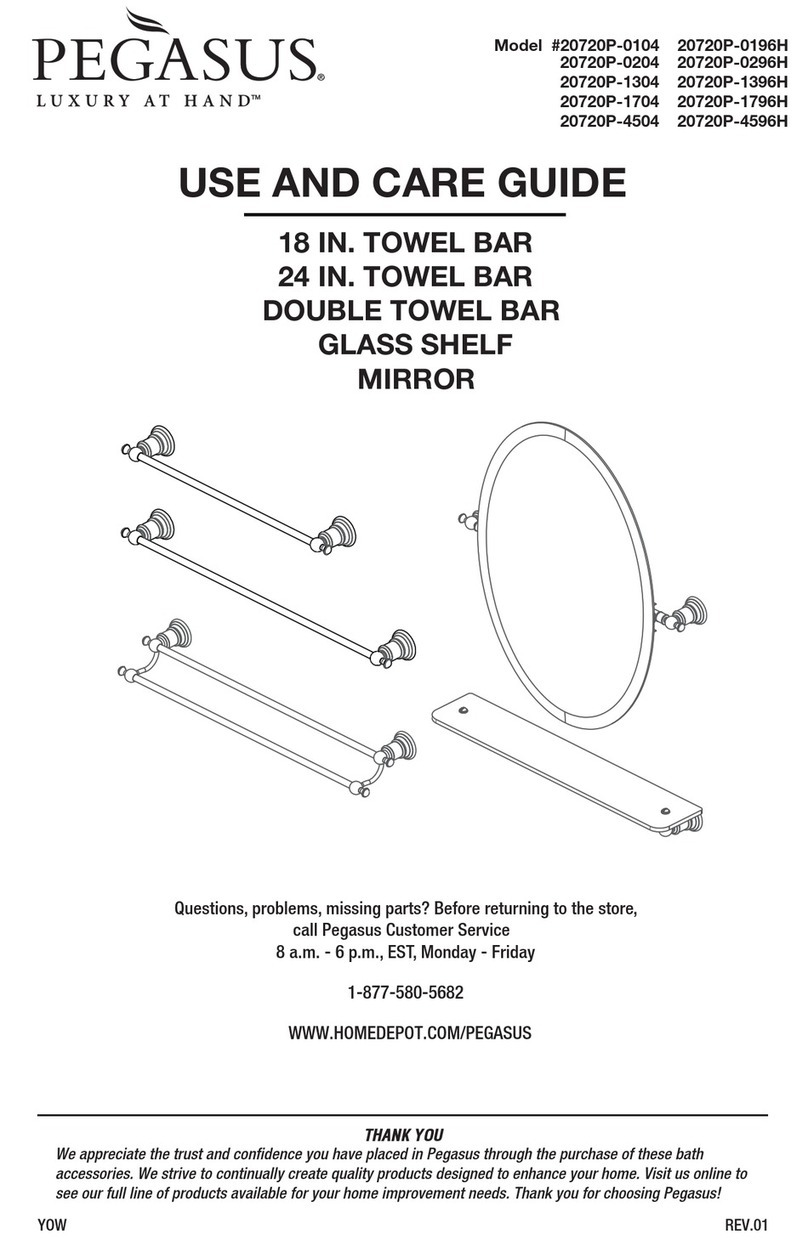

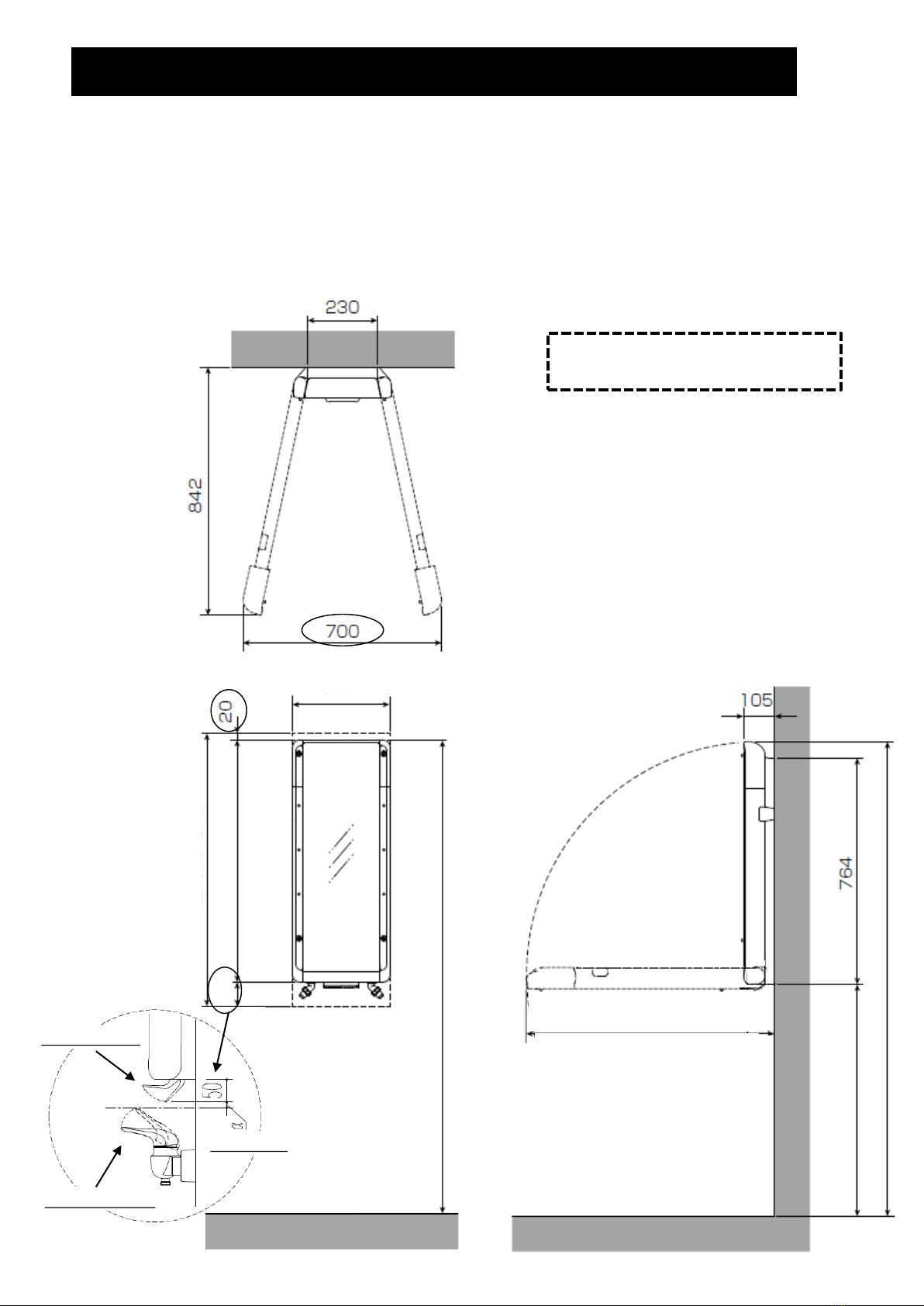

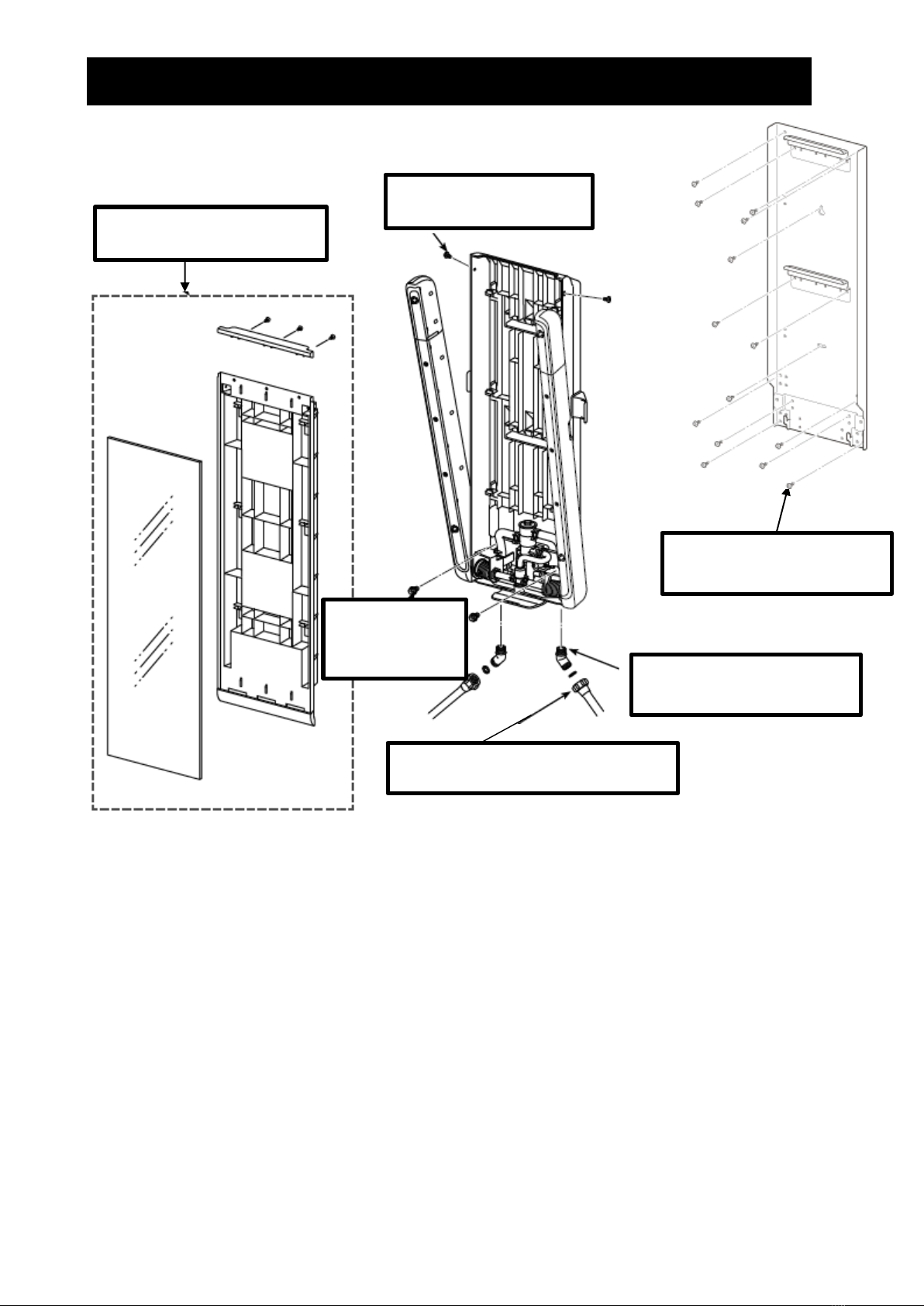

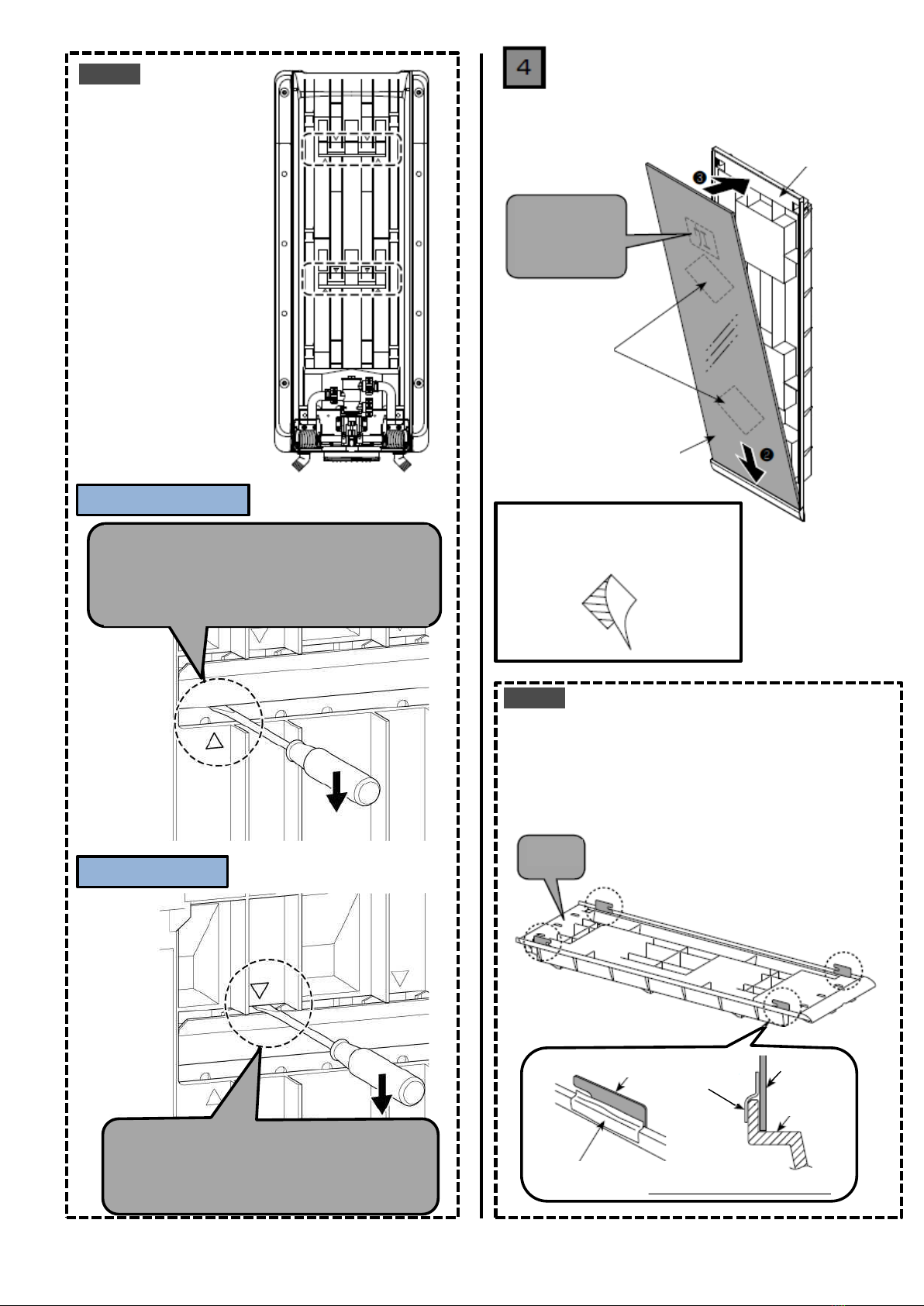

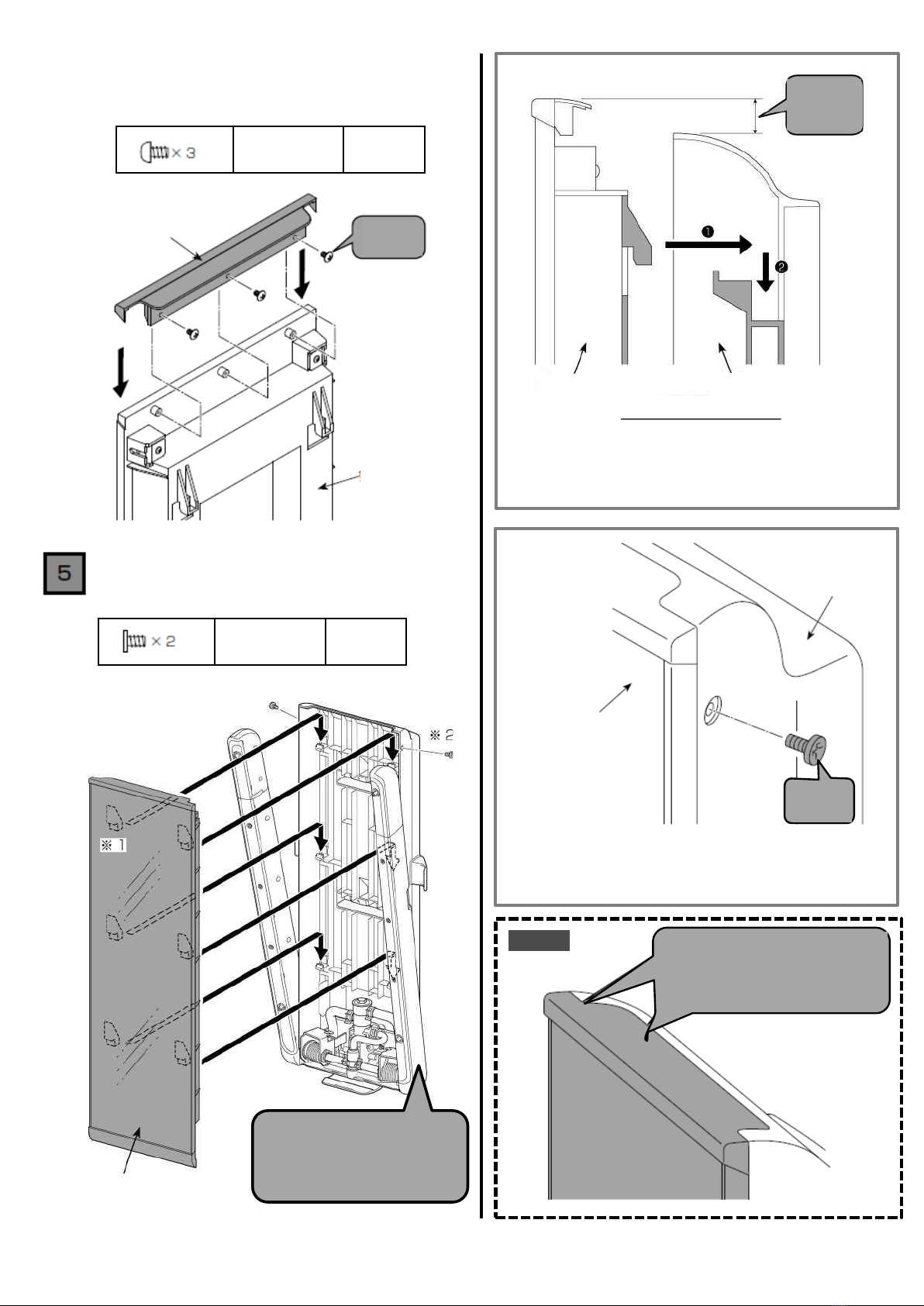

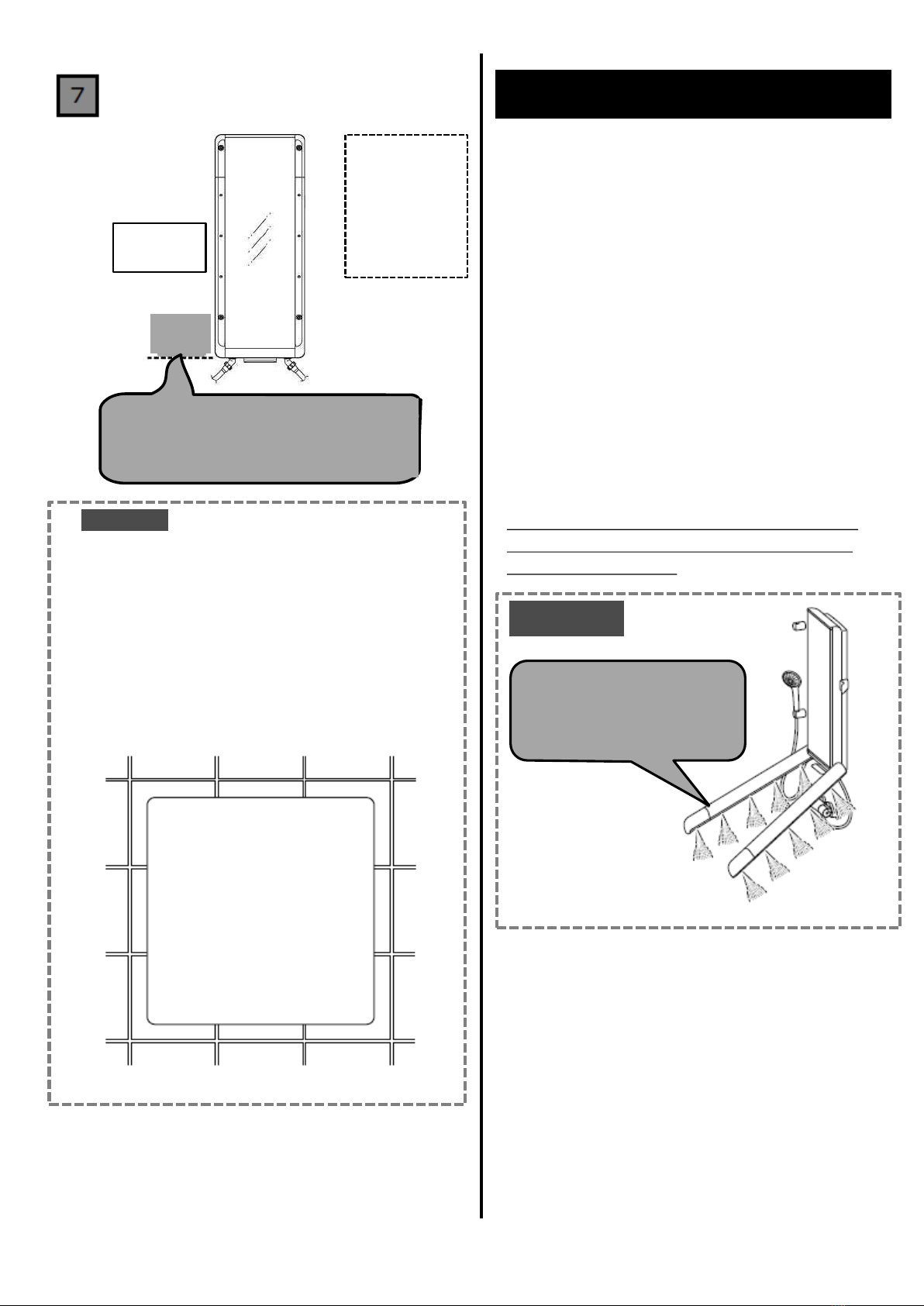

Inax NYSA-1-R-SET(WR)/FW1 User manual

This manual suits for next models

1

Table of contents

Other Inax Bathroom Fixture manuals

Popular Bathroom Fixture manuals by other brands

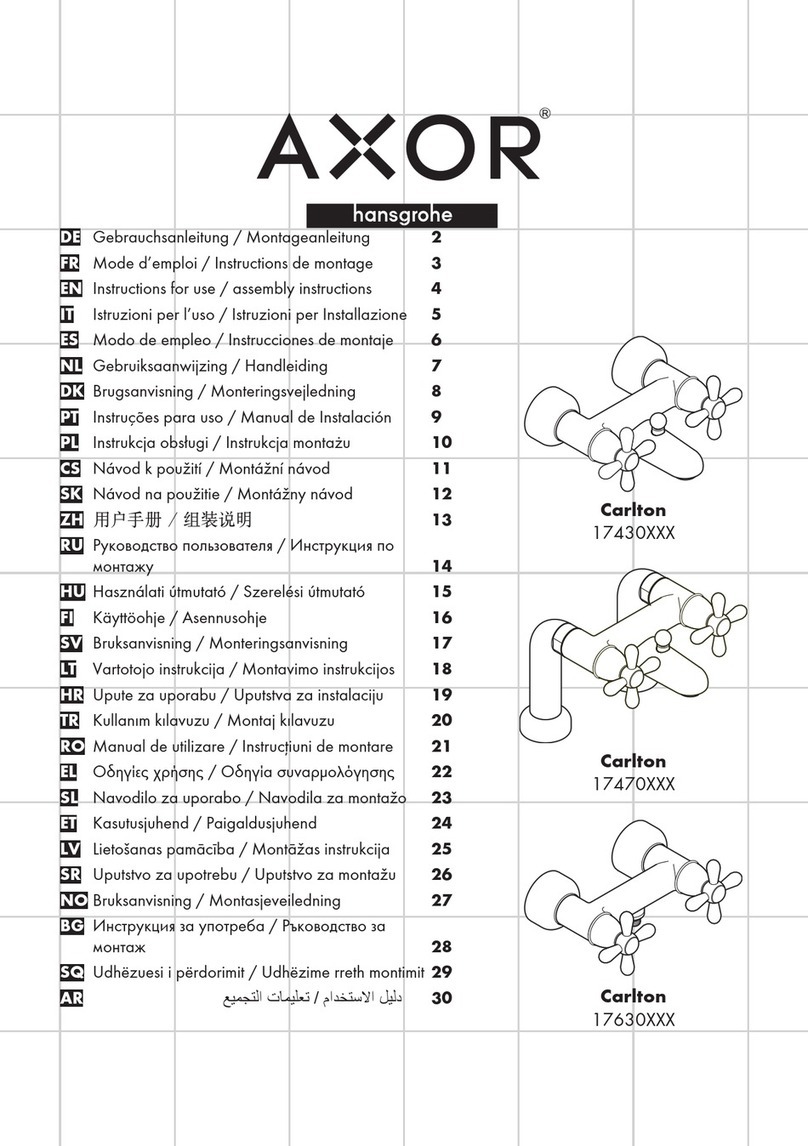

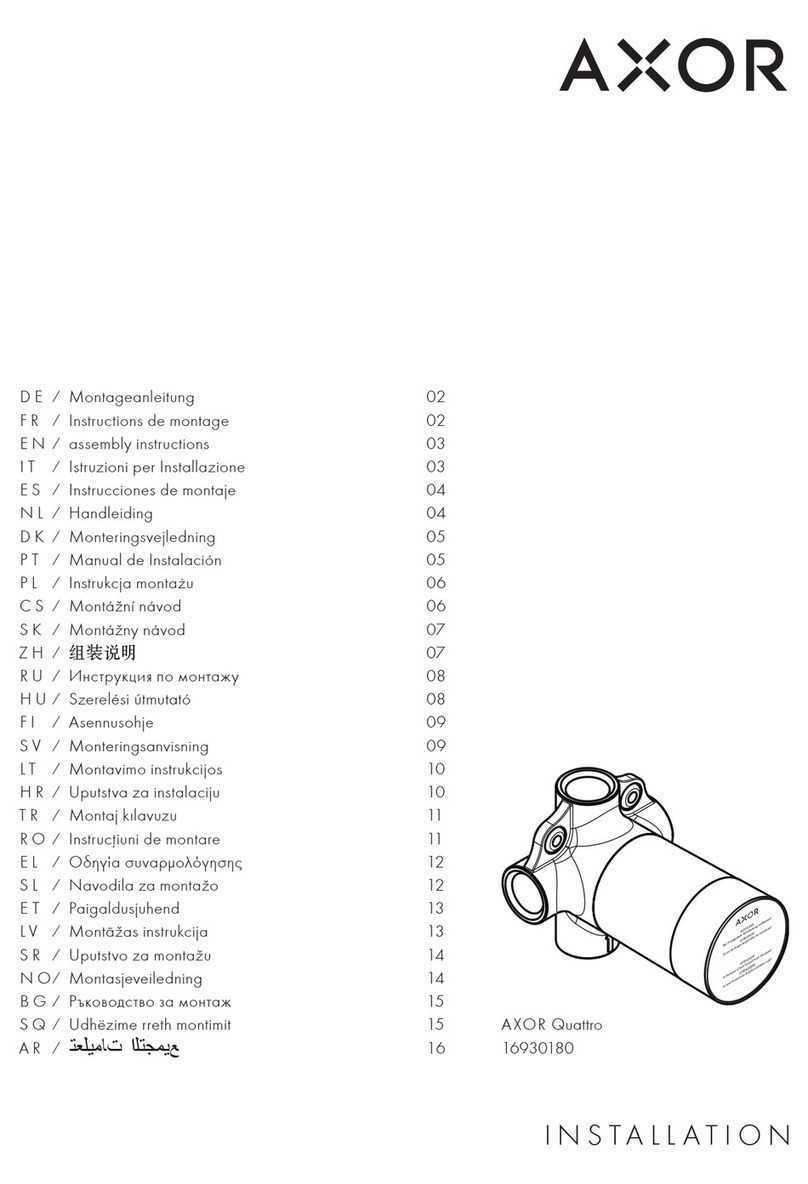

Axor

Axor Quattro 16930180 Installation & assembly instructions

Orbital Systems

Orbital Systems OAS Standart R3 Technology Installation

Clou

Clou Flush 6 CL/03.14060 installation instructions

Clou

Clou First CL/04.06030 installation instructions

Duscholux

Duscholux Air X installation instructions

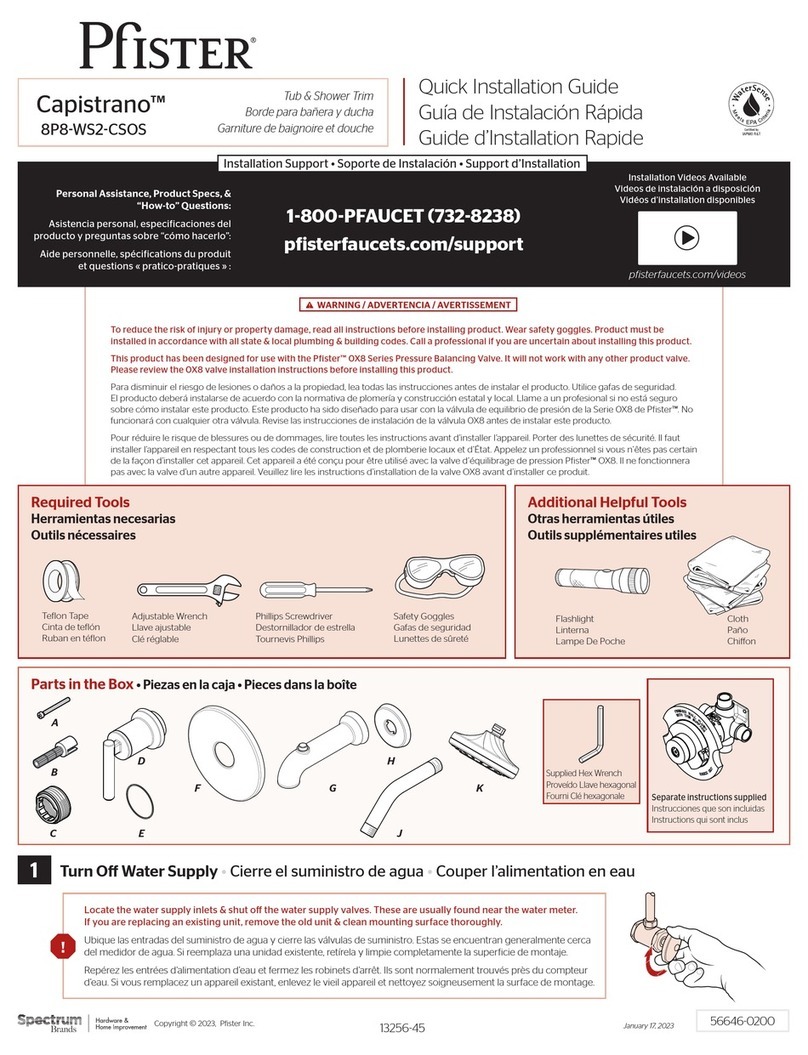

Spectrum Brands

Spectrum Brands Pfister Capistrano 8P8-WS2-CSOS Quick installation guide

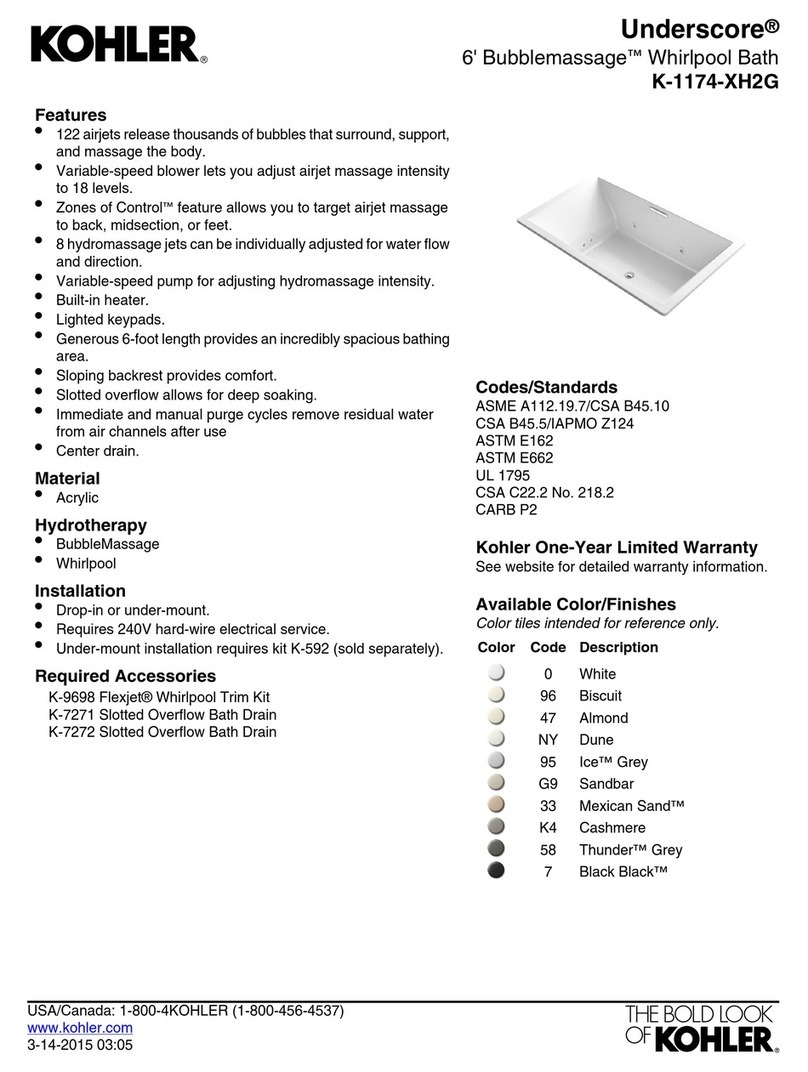

Kohler

Kohler Underscore K-1174-XH2G quick start guide

noken

noken ACRO COMPACT 100080134 N380000003 manual

Bradley

Bradley OmniDeck 4000 Series installation guide

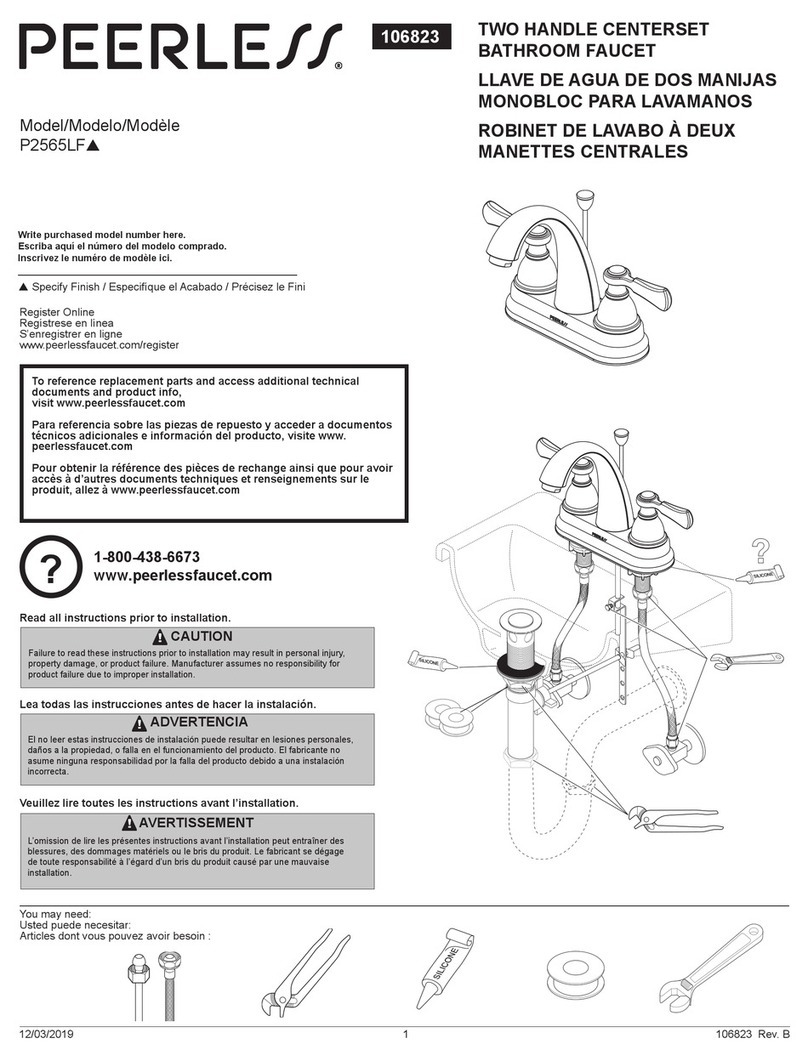

PEERLESS

PEERLESS Elmhurst P2565LF Series quick start guide

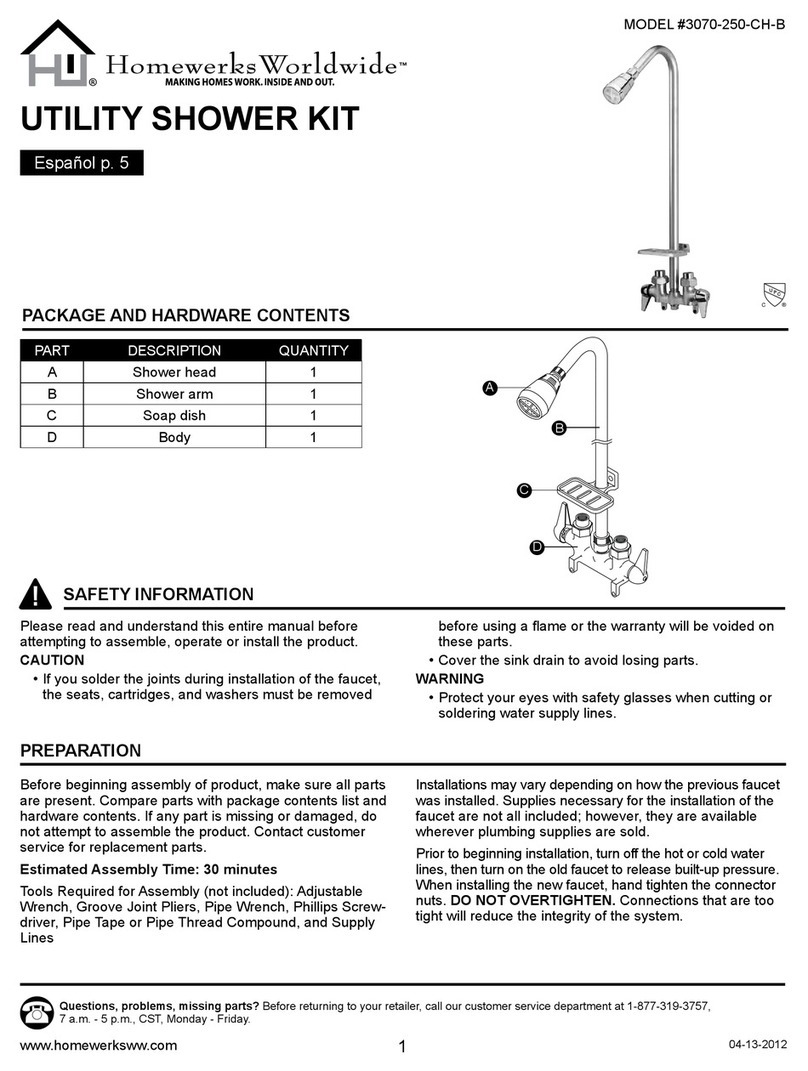

Homewerks Worldwide

Homewerks Worldwide 3070-250-CH-B manual

Reece

Reece Showerama 610 Single Bowl Technical guide