3

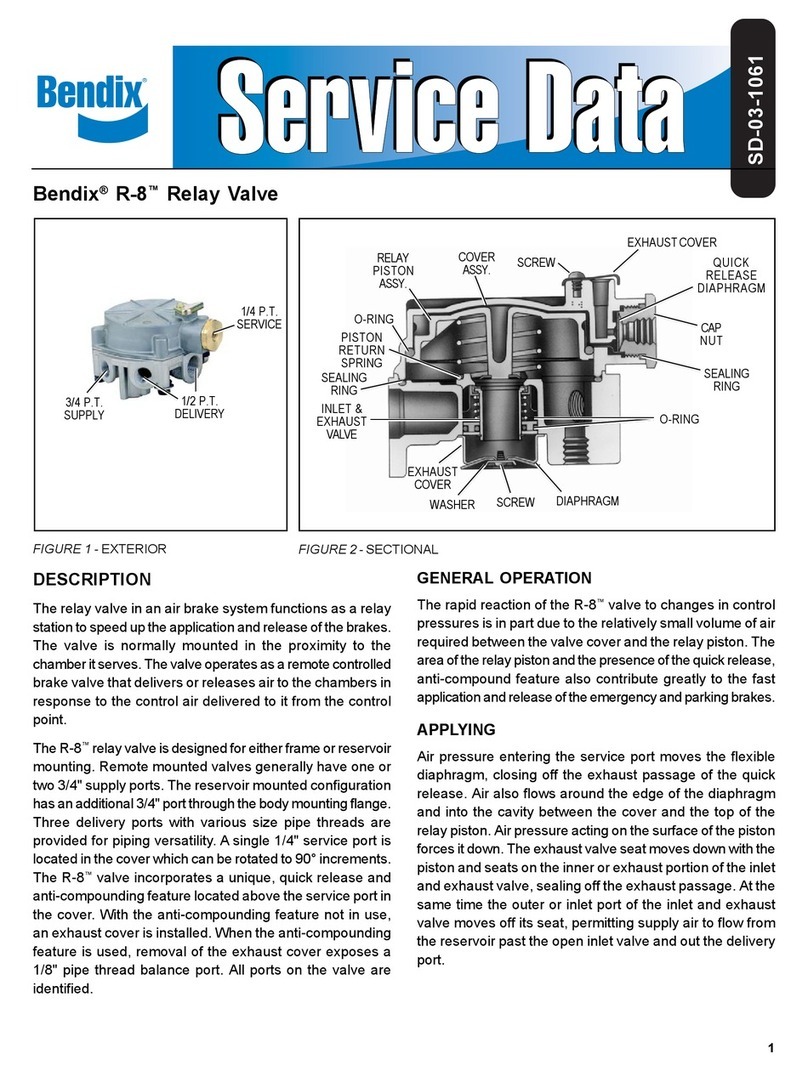

DESCRIPTION

The TC-4™modulating control valve is a cam operated,

graduating type control valve. The valve is used to control

theapplication andrelease ofspring brakeactuators, andis

generallymountedinthecab withineasy reachof thedriver.

Modulatedcontrol ofthe emergencybrakes (springbrakes)

iseffectedbymovingthevalve’sspringloadedlever.Moving

the lever against the resistance of the spring applies the

brakesand,allowing thevalvehandletoreturn, releasesthe

brakes.

When the valve is used for parking, the locking button is

moved into the locked position after the handle has been

moved to the “Brakes Applied” position. The lever is now

mechanically locked in position. To release the lever, the

leveris slightly depressed,the lockbuttonmoved outofthe

locked position and the lever returned to the “Brakes

Released”position.

Portingconsists of one (1)supply port, two (2)delivery and

two (2) exhaust ports.

OPERATION

Reference Figure 2, the TC-4™valve is generally used in

conjunctionwith a relayvalveto control theapplication and

releaseof the springbrakes.In atypicalsystem, the TC-4™

valve and the relay valve receive supply air from the

emergency/parkingreservoir.

RELEASED POSITION (Spring Brakes Released)

In the normal run position, air enters the supply port of the

TC-4™valve,flowsbytheopeninletvalveandoutthedelivery

port.Air flows to the service(control) port of therelayvalve

causing the relay valve to deliver air to the spring brakes,

holdingthemin the released position.

APPLYPOSITION (Spring BrakesApplied)

Movingthe lever to the applypositionallows the inlet valve

to close and the exhaust passage to open. This allows the

air being delivered to the service (control) port of the relay

valveto exhaust toatmosphere (through theexhaust of the

foot brake valve). With air exhausted from the service

(control) port of the relay valve, the relay valve responds,

exhaustingtheairfromthespringbrakes(allowingthebrakes

to apply).

With sufficient air pressure in the emergency/parking

reservoir, modulation of the spring brake application is

possible; the amount of braking force governed by the

positionoftheTC-4™valvelever.

With reference to Figure 2, note that the exhaust of the

TC-4™valveis connectedto a deliveryline of thefoot brake

valve. This prevents the compounding of spring brake and

service brake application forces on the slack adjusters.

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performinganyintrusivemaintenanceprocedures.Awarranty

maybe voidedif intrusive maintenanceis performedduring

thewarranty period.

No two vehicles operate under identical conditions, as a

result, maintenance intervals may vary. Experience is a

valuableguideindeterminingthebestmaintenanceinterval

forair brake systemcomponents.At aminimum, theTC-4™

valveshouldbeinspectedevery6monthsor1500operating

hours,whichevercomes first, for proper operation. Should

the TC-4™valve not meet the elements of the operational

testsnotedinthisdocument,furtherinvestigationandservice

ofthe valvemay berequired.

Checkforproperoperationbeforeplacingvehicleinoperation.

OPERATING AND LEAKAGE TESTS

Ifvalve is to betestedon vehicle, block thevehiclewheels.

Build system pressure to approximately 100 psi and place

lever to “apply” position and observe that spring brakes

apply.

With lever in apply position, lock lever in place with locking

button.Coatexhaustportwithsoapsolution; leakageshould

not exceed a 1" bubble in less than 5 seconds.

(NOTE: If lineis connected toexhaustport, disconnect line

or remove pipe plug from other exhaust port.)

Excessiveleakagewouldindicateafaultyinletvalve.

Releaselockingbutton and place leverinrelease position;

observe that brakes fully release. Coat exhaust port with

soapsolution; leakageshould notexceeda 1"bubble innot

less than 5 seconds. Excessive leakage would indicate

exhaustvalveor lowero-ring leakage.(Iflineatexhaust port

wasdisconnected, connectline and/ortightenfitting orpipe

plug.)

Removedial; whilemaking afull footvalveapplication, coat

top of valve with soap solution. Leakage permitted is a 1"

bubble in not less than 5 seconds.

Excessiveleakage would indicate uppero-ringleakage. (If

lineis not connected toexhaustport, it will benecessaryto

apply 100 psi to the exhaust port to check for upper o-ring

leakage.)

Soap area around supply port cap nut to check for cap nut

o-ringleakage. No leakagepermitted.

Blow out or dry all soap solution and replace dial.

To check modulation of valve, it will be necessary to test

while vehicle is in motion. Select a suitable location to

performbrakingtest.Withvehicleinmotion,applytheTC-4™

valveseveraltimes.