-7-

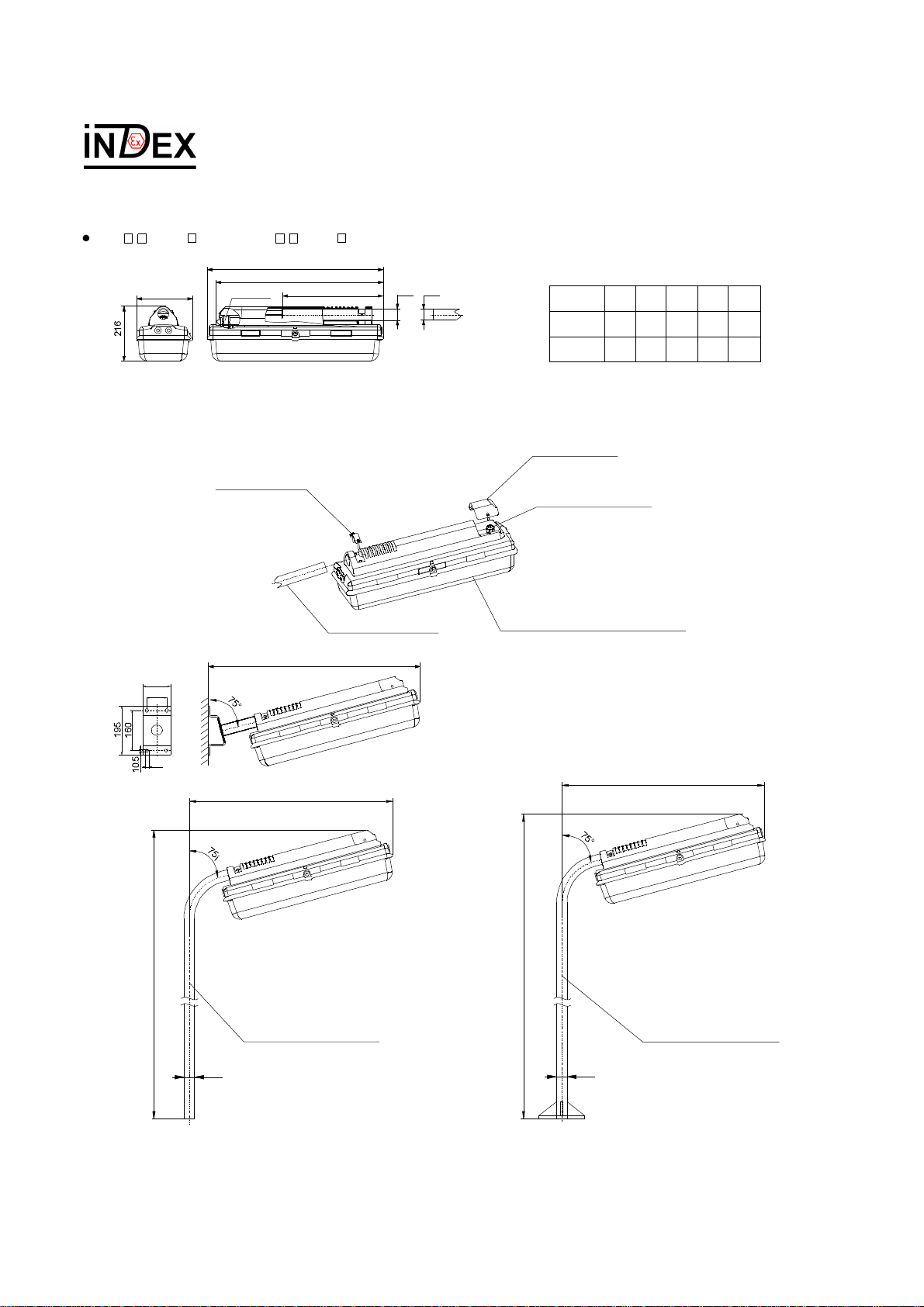

Wiring diagram

WWW.INDEXELEKTRO.NL

Z0865/0866-rev.17.08.17

L

N

PE

L

N

PE

L

N

PE

Wiring diagram for emergency

LED linear light fitting

L2

L1

N

PE

L2

L1

N

PE

L3

L2

L1

N

PE

L

N

PE

External light switch

- Transport and storage in original packaging only

- National safety and installations regulations and the generally accepted rules

of engineering practice must be observed when mounting and operating this equipment.

-

- Explosion-proof(emergency)LED linear light fitting is suitable for use in hazardous areas, zone 1-2 and 21-22.

- Explosion-proof(emergency)LED linear light fitting should be used under the following atmospheric conditions:

* The pressure is 80kPa(0.8bar)~110kPa(1.1bar) ;

* The volume ratio of standard oxygen content is 21% air;

* The Ambient air relative humidity is less than: 95%;

* There is no obvious shake and impact vibration place;

* Under the environment of gas that there is no obvious destruction insulation or vapor;

The users shall follow instructions in order to ensure the normal working and safety of the explosion-proof (emergency)

LED linear light fitting

- Cables must be connected with due care.

- Crimped joint for wires should be done (such as compressing and connecting with wiring lug or bushing) to prevent

multiconductor slipping from stipulated position or not to be compressed.

- Insulation must come up to the terminal.

- Electrical wire must not be damaged;

- All screws on the connection terminals, including unused ones, must be fully tightened. A check must be carried out on correct

installation before the devices go into service.

- The required IP rating for explosion-proof degree of protection must be assured.

- Caution: Clean only with a damp cloth!

- If a clearance hole is used for the mounting of the stopping plug, it shall have a diameter no greater than 0.7mm more

- than the largest normal thread size of the stopping plug being used.

- After power off, the time of light fitting internal capacitor discharge to remaining 0.02mJ is less than 200ms

Operation/installation

Cable gland,stopping plug

- Generally, only certified cable glands and stopping plugs are permitted for use. However, the explosion-proof performance

after the coordinate use should not be lower than the explosion-proof performance of the overall product;

- When using cable entries with lower IP66 protection than that which applies to the device, the IP protection of the whole device

will be reduced.

-The mounting directives applicable to the cable entries used shall be observed.

-Care has to be taken that when fitting the cable entries, sealing inserts appropriate to the cable diameter are used.

-The outside diameter range of cable is detailed in the label on the cable.

-Unused holes shall be closed with a certified blanking plug and the diameter of blanking plug shall be properly adapted to the

cable diameter.

-In order to ensure the required minimum protection category, the bolts of cable glands, blanking plug and relevant sealing bolts

are to be tightened down.

-The clearance holes for plain entries shall have a diameter not more than 0,7 mm greater than the nominal diameter of the

entry thread gland or fitting. The inside of the enclosure shall be provided with sufficient room to attach a locknut to the gland

or fitting.