Industrial Controls IP500AC Manual

Table of contents

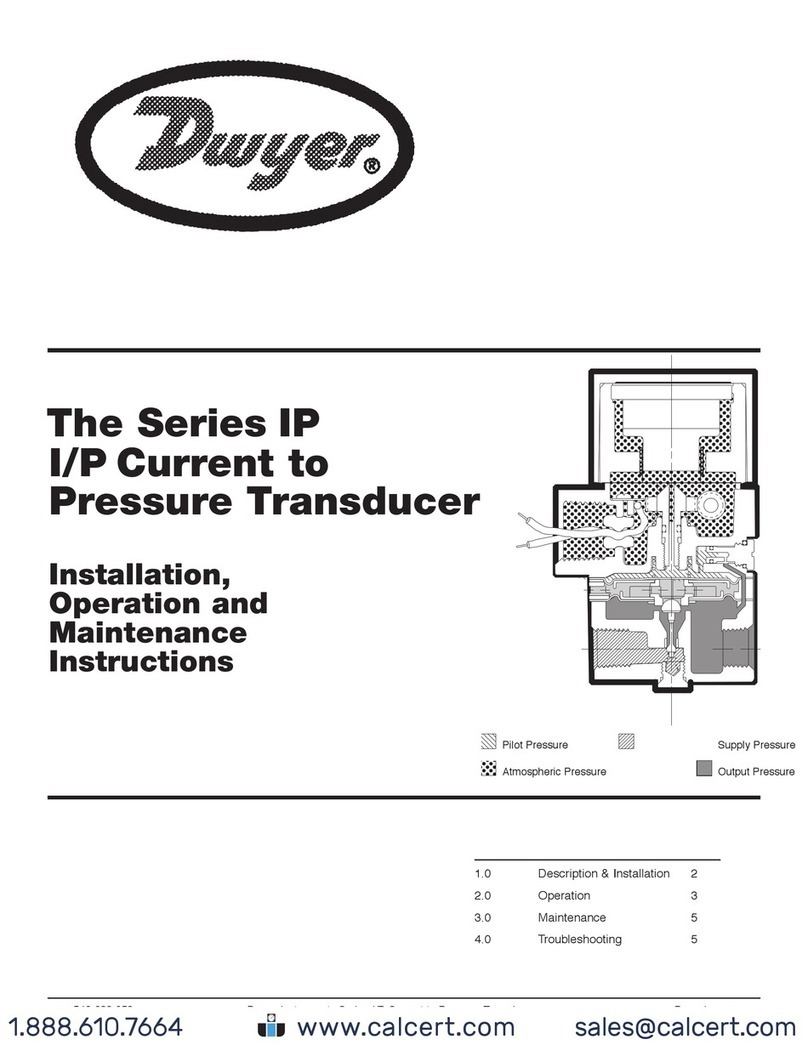

Other Industrial Controls Transducer manuals

Popular Transducer manuals by other brands

Mianyang Weibo Electronic

Mianyang Weibo Electronic WBV412U01 user manual

Mianyang Weibo Electronic

Mianyang Weibo Electronic WBV334U01 user manual

Ideal Vacuum

Ideal Vacuum MKS Baratron 622B manual

Endress+Hauser

Endress+Hauser Nivotester FTL375P Safety instructions

Electro-Voice

Electro-Voice DH2T-16 Technical specifications

S+S Regeltechnik

S+S Regeltechnik PREMASGARD 121 Modbus Series Operating Instructions, Mounting & Installation

S+S Regeltechnik

S+S Regeltechnik PREMASREG 711x-VA Series Operating Instructions, Mounting & Installation

Endress+Hauser

Endress+Hauser Cerabar T PMP131 manual

Balluff

Balluff BTL5-S1 Series user guide

gtm

gtm KTN-LF Series operating manual

B-K Medical

B-K Medical 8808e user guide

B-K Medical

B-K Medical 8551 user guide

B-K Medical

B-K Medical 8870 user guide

Humminbird

Humminbird SIDE IMAGING quick start guide

MKS

MKS HPS Products 999 Quattro Series Operation and maintenance manual

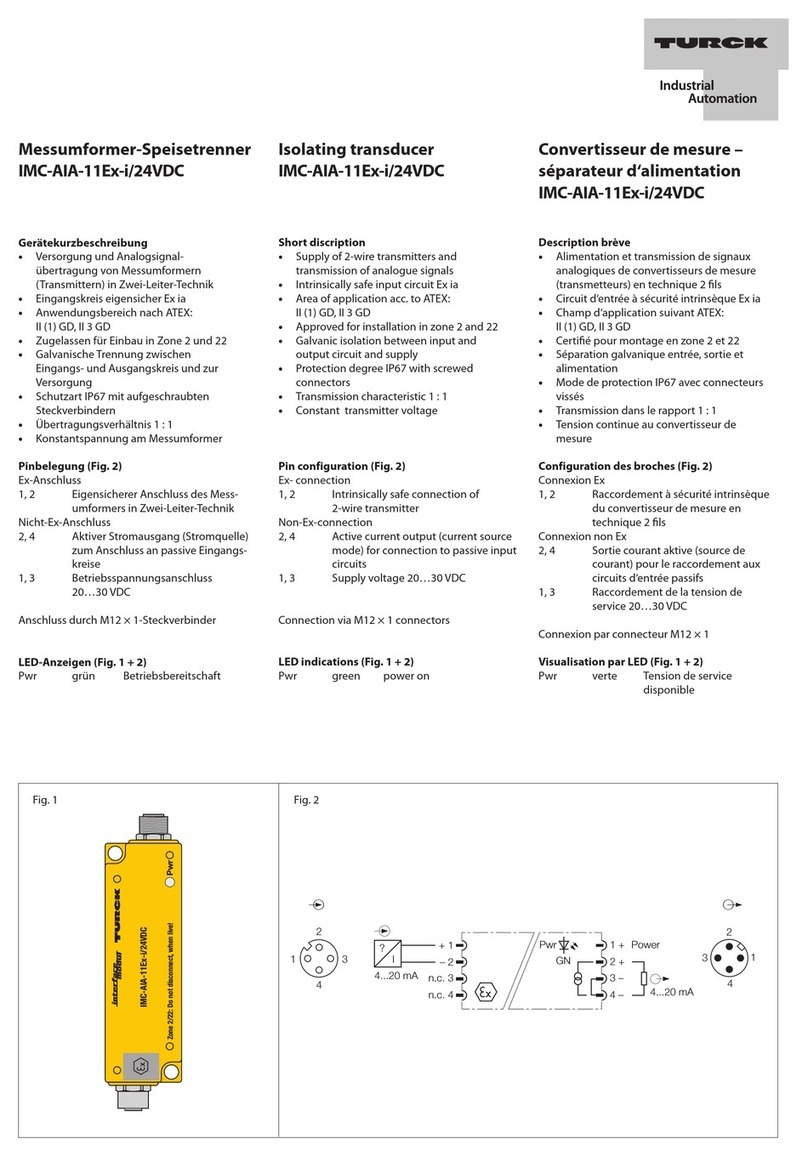

turck

turck interface modul IMC-AIA-11Ex-i/24VDC quick start guide

SOLIDDRIVE

SOLIDDRIVE SD1 Installation & use guide

Teledyne RD Instruments

Teledyne RD Instruments WorkHorse Rio Grande ADCP Operation & User’s Guide