Always wear eye protection when operating or performing maintenance on this tool.

Always turn o the air supply and disconnect the air supply hose before installing, removing or adjusting any accessory on this tool or

before performing any maintenance on this tool.

Note: When reading the instructions, refer to exploded diagrams in parts Information Manuals when applicable (see under Related Documentation

for form numbers).

Disassembly

Do not disassemble the tool any further than necessary to replace

or repair damaged parts.

When grasping a tool or part in a vise, always use leather-covered

or copper-covered vise jaws to protect the surface of the part

and help prevent distortion. This is particularly true of threaded

members and housings.

1.

2.

Do not remove any part which is a press t in or on an assembly

unless the removal of that part is necessary for repairs or

replacement.

Do not disassemble the tool unless you have a complete set of

new gaskets and O-rings for replacements.

Use impulse Tool Rebuild Tools listed in Table 2 .

3.

4.

5.

Changing The Mechanism Fluid

To change the Mechanism Fluid in the Impulse Mechanism, proceed

as follows:

Using a hex wrench, remove the four mechanism Cover Bolts (71)

and Spring Washers (70). Lift the Mechanism Cover (68) o of the

Motor Housing (1). Remove the mechanism Cover Gasket (43).

Lift the assembled mechanism o the Rotor (39).

Using a 2 mm hex wrench, rotate the Torque Adjustment

Screw clockwise until the Screw stops. Rotate the Screw

counterclockwise until it stops or makes six complete revolutions.

Remove the Oil Plug (61) and Oil Plug Seal (60).

With the oil plug opening downward over a container, rotate

the Drive Shaft to purge the uid from the mechanism. As an

alternate method, using the Syringe from the Fluid Replacement

Kit (Part No. EQ106S-K400), purge the uid from the rst cavity.

Then rotate the Drive Shaft to expose the second cavity and

purge the uid using the syringe.

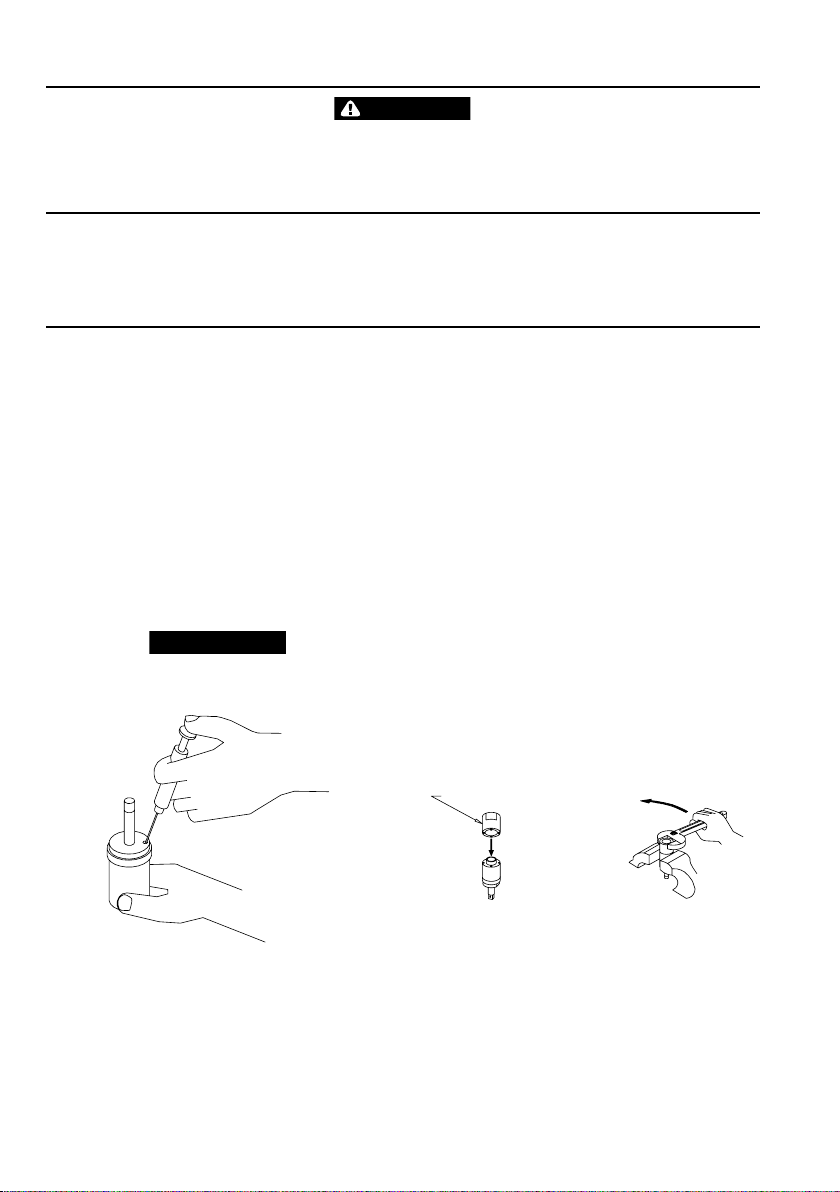

Using the syringe and uid from the Fluid Replacement Kit (Part

No. EQ106S-K400), ll the mechanism with the uid furnished in

the Kit. (Refer to Dwg. TPD1265)

DO NOT SUBSTITUTE ANY OTHER FLUID. Failure to use the uid

provided could damage the tool, increase maintenance and

decrease performance. Use only clean uid in these tools.

(Dwg. TPD1265)

7. Submerge the ll opening in the remainder of the uid, and using

a wrench, rotate the Drive Shaft to purge any remaining air from

the system.

8. Thread the Oil Plug (61) with the Oil Plug Seal (60) into the

mechanism until it is snug.

9. Using a 2 mm hex wrench, turn the Torque Adjustment Screw

clockwise until it stops. This is the maximum torque position.

1.

2.

3.

4.

5.

6.

10. Wipe the outside of the mechanism dry and clean and remove

the Oil Chamber Plug. Using the syringe, withdraw 1.2 cc of uid

for models 100P4 and 130P4 and 1.3 cc for model 140P6.

11. Install the Oil Plug and tighten it between 20 and 25 in-lb (2.3 and

2.8 Nm) torque.

12. Position a new Mechanism Cover Gasket (43) on the Motor

Housing and install the assembled mechanism on the rotor

shaft (39).

13. Place the mechanism Cover (68) Bushing (67) and Washer (66)

over the Drive Shaft against the Housing and Gasket. Install the

four Mechanism Cover Cap Screws and Lock Washers. Tighten

each Screw between 45 and 50 in-lb (5.1 and 5.6 Nm) torque.

Disassembly of the Impulse Mechanism

Remove the Mechanism Cover Bolts (71) and Spring Washers (70)

and lift the Mechanism Cover (68) o the Motor Housing (1).

Pull the mechanism assembly out of the Cover.

With the oil plug opening downward over a container, rotate the

drive shaft to purge the oil from the mechanism. As an alternate

method, using the syringe from the Fluid Replacement Kit (Part

No. EQ106S-K400), purge the uid from the rst cavity. Then

rotate the Drive Shaft to expose the second cavity and purge the

uid using the syringe.

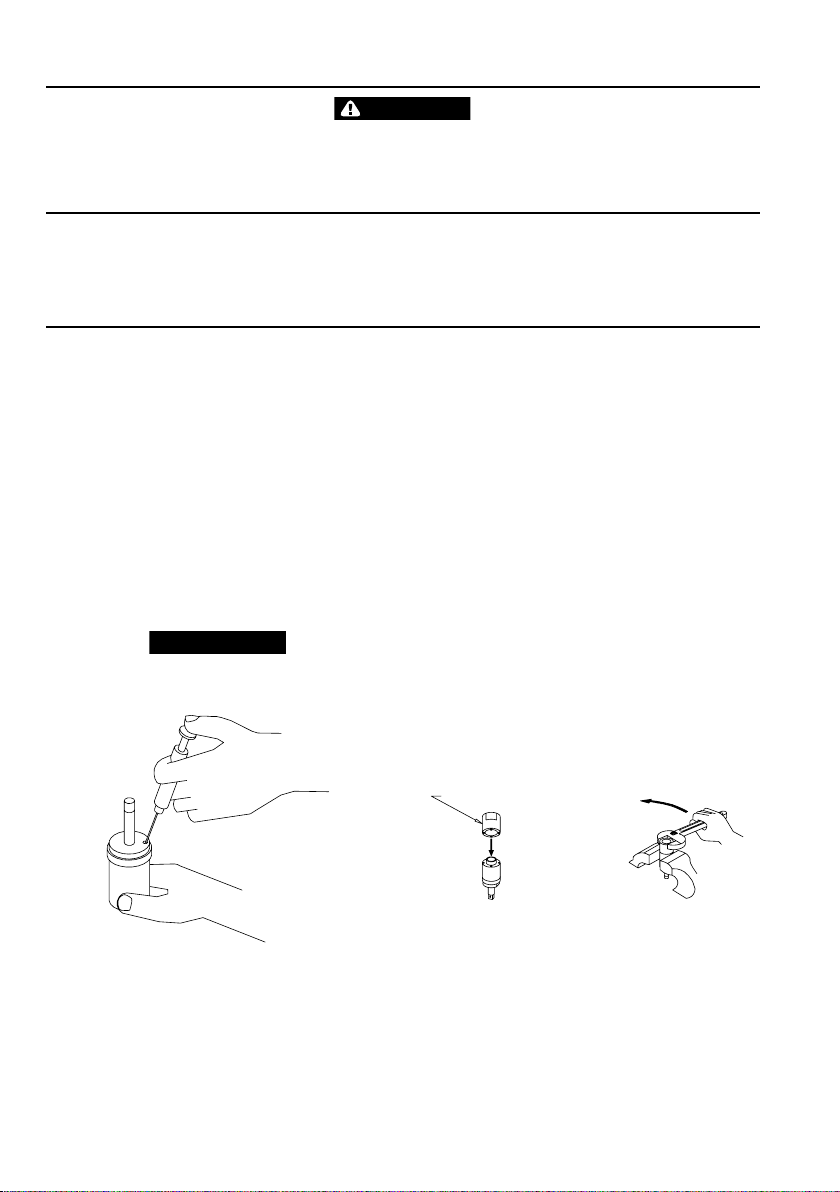

Grasp the ats of the Liner Case (64) in vise jaws with the output

end of the Drive Shaft downward.

Insert the pins of the Housing Cap Spanner Plug from the Tool

Kit into the holes in the Housing Cap (44). Using a wrench on

the plug, unscrew and remove the Liner Cap from the Housing

Assembly. (Refer to Dwg. TPD1267)

SPANNER PLUG

HOUSING CAP COUNTERCLOCKWISE TO LOOSEN

(Dwg. TPD1267)

1.

2.

3.

4.

5.