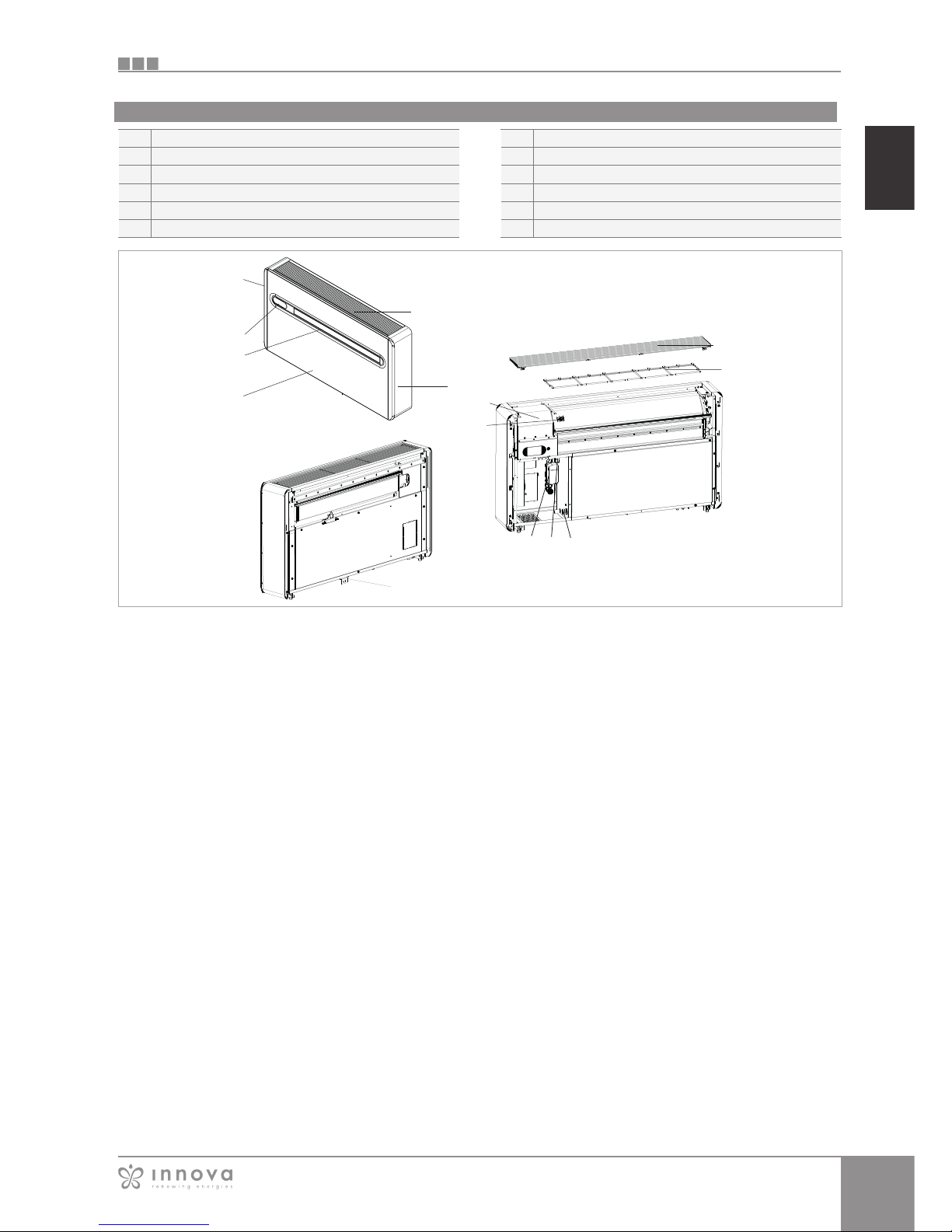

Description

The air conditioning unit "2.0" is the new solution that

represents a significant step towards reducing the

aesthetic impact of air conditioners. With a depth of just

16 centimetres, "2.0" is the most compact and least bulky

of the category. Its aesthetic impact is therefore minimal,

both inside and out.

Optimised Capacities

The conditioning capacities of "2.0" have been optimised

so as to obtain the right temperature for the best level of

comfort and, therefore, less consumption and less noise.

Thanks to the careful choice of sound insulation materials,

the noise is similar to that of a standard wall split unit and

consumption is drastically contained thanks to the new

direct current fan.

BLDC inverter technology

We have perfected the inverter technology to offer the

best in terms of acoustic comfort (noise) and performance:

reduction of consumptions, maintenance of the best

temperature level and humidity level in the room.

Thanks to the use of the cutting edge BLDC (brushless

direct current) inverter regulation, vibrations have been

completely eliminated and acoustic emissions have been

lowered to exceptional levels.

Both ventilation motors are BLDC to reduce consumption

still further and make flow adjustment more precise.

The energy consumption is extremely low thanks to the

absorption values which, in the case of partial load, fall to

less than 300 W. At the nominal cooling power "2.0", in

the DC Inverter versions, it has a 3.9 EER, in the vanguard

in the sector of fixed-unit monobloc air conditioners.

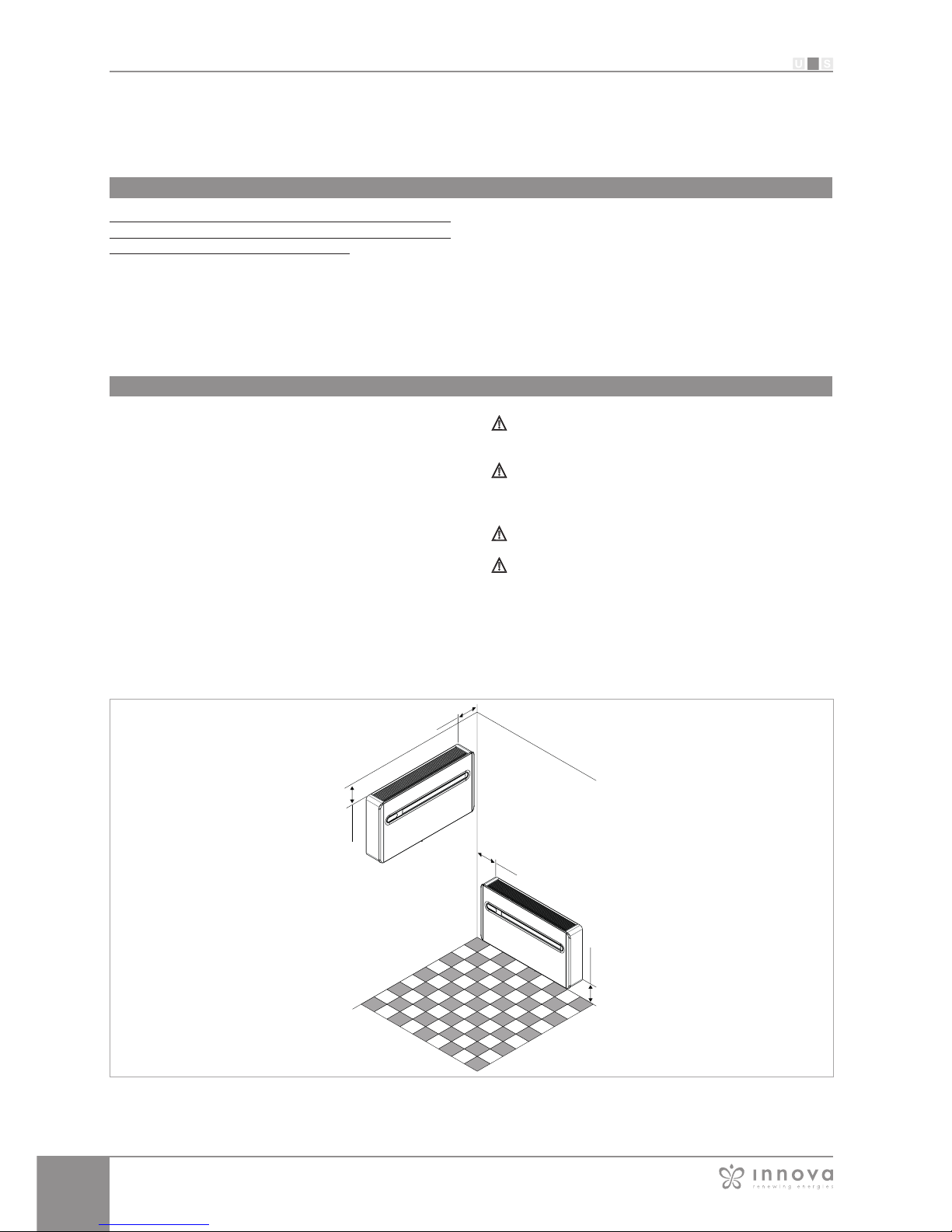

Easy to install

“2.0" can be installed on any perimeter wall either low or

high. Everything needed for installation (template, support

bracket, hole pipes and external grids), excluding the drill

and drill bit, is included in the box.

Remote control and on-board touch-screen display

In addition to the remote control, the touch-screen

display on the unit enables the setting of any function.

There's even a "lock" mode to avoid any improper use.

With a simple action on the touch screen display, the

"heating" function can be deactivated: the appliance will

then operate in "cooling" only, without the need for the

condensate discharge pipe. The orientation of the air

flaps, upwards or downwards, can also be set by simply

pressing a key.

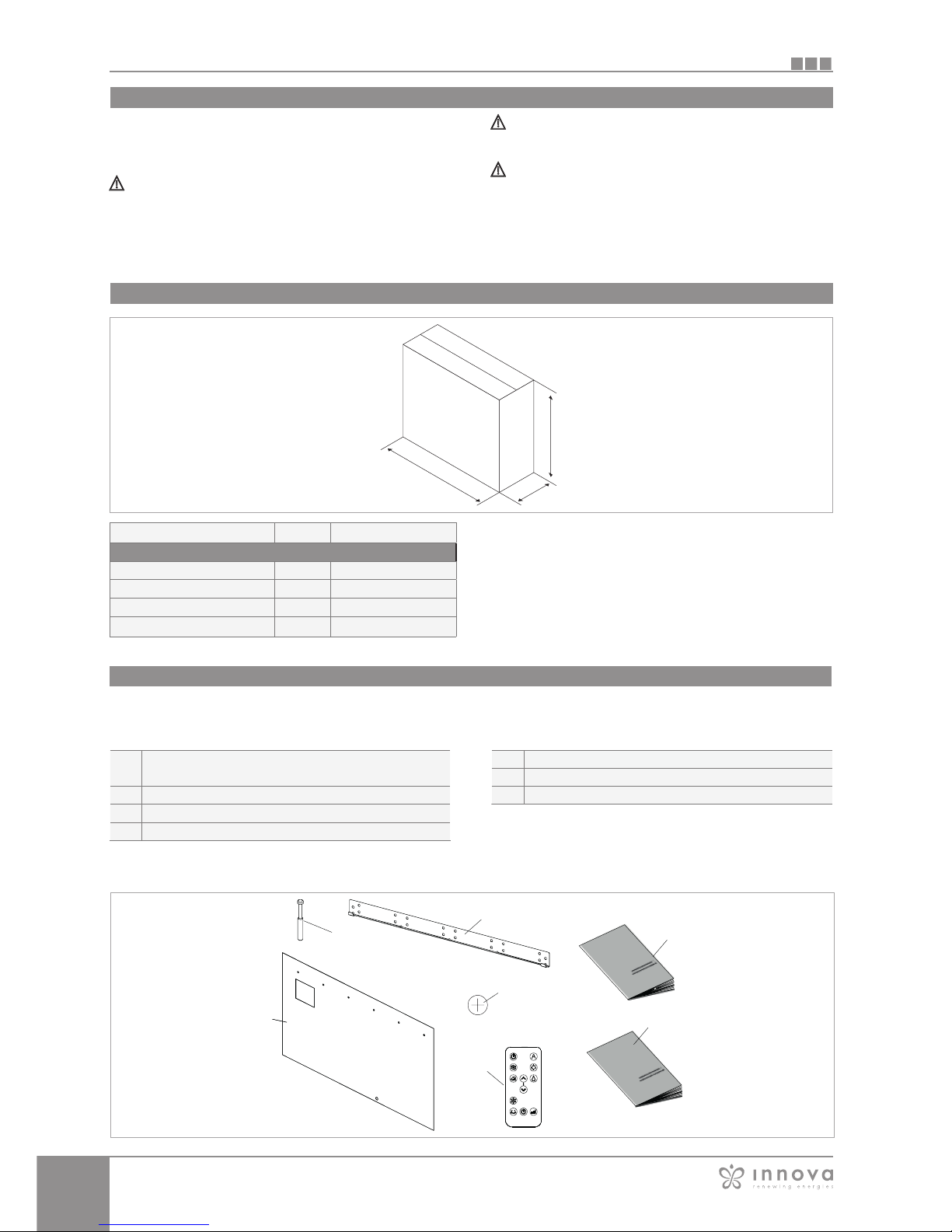

The packing is made of suitable material and carried out

by expert personnel. All units are checked and tested and

are delivered complete and in perfect conditions, however

please perform the following instructions to check the

quality of shipping services:

- upon receipt, check if the box is damaged. If that is

the case, accept the goods with reservations and

keep photographic evidence of any damage found

- unpack and check the contents against the packing

list.

- check that none of the parts have been damaged

during shipment. In case of damage, report it to

the shipping company within 3 days of receipt by

registered letter with return receipt and attaching

photographic documentation. A copy should also be

sent by fax to the MANUFACTURER. No notice of

damage incurred will be accepted after 3 days from

delivery.

Keep the packing at least for the duration of the

warranty period, in case you need to ship the air-

conditioner to the service centre for repair. Dispose

of the packing materials in compliance with current

regulations on waste disposal.

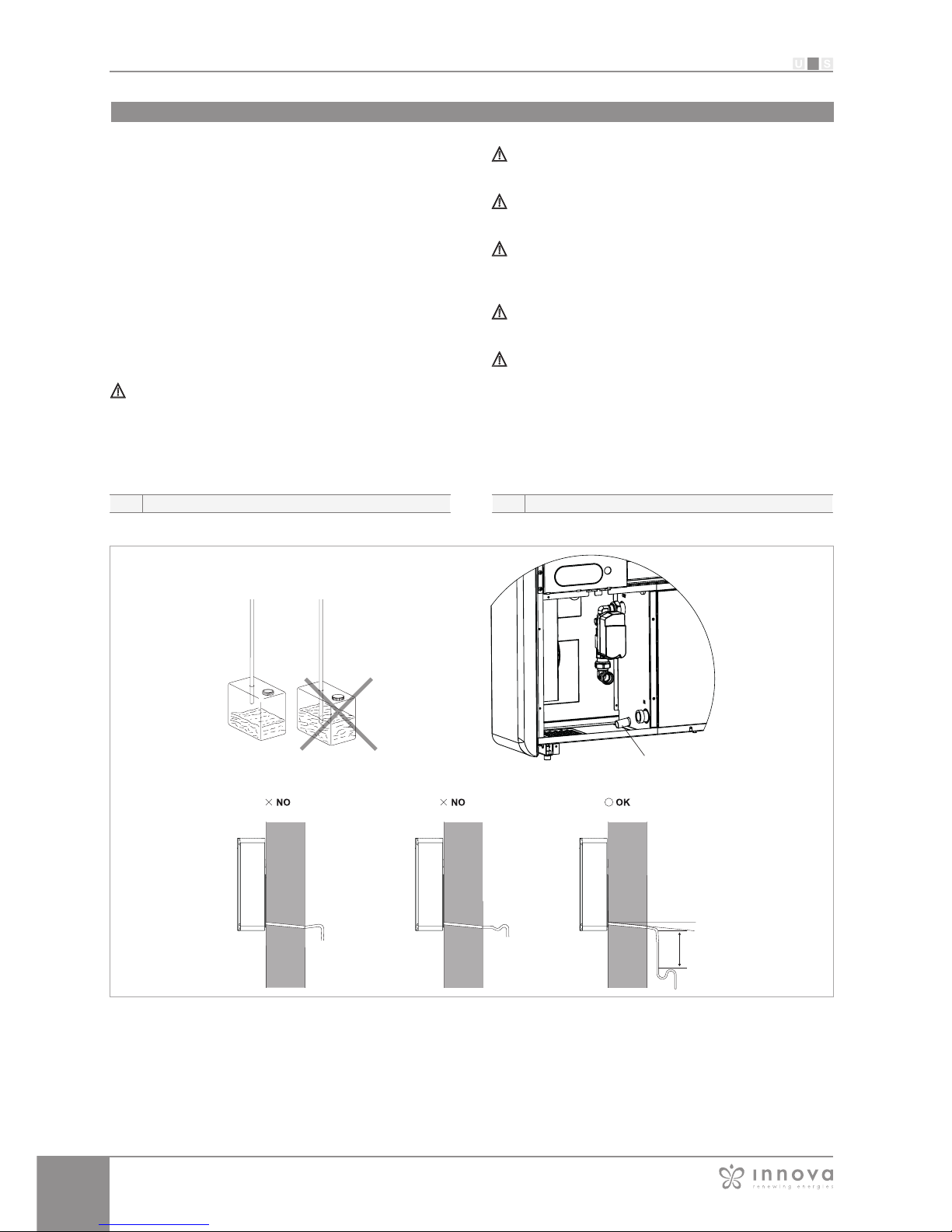

Storage

Store the box in a closed environment protected from

atmospheric agents and isolate it from the floor using

planks or pallets.

Do not turn the carton upside down