4.0 GENERAL NOTICES

4.1.1

SAFETY MEASURES

This instruction manual is an integral part of the appliance and therefore must be kept with care and must

ALWAYS accompany the appliance even in case of its sale to another owner or user or to a transfer to

another plant. In case it is damaged or lost, request another copy from the Technical Service of the area.

During all operations on the device it is necessary to observe the precautions specified in this manual and

on the labels attached to the appliance, as well as all the precautions suggested by common sense, and

the safety regulations currents at the place of installation.

Please read this manual carefully before proceeding with any operation (installation, maintenance, use)

and follow scrupulously the instructions contained in the individual chapters. Failing to comply with the

instructions contained in this manual and use the appliance outside the operating limits specified will void

the warranty.

Make known these instructions to all staff interested at the machine.

The manufacturer assumes no responsibility for damage to people or property arising from the failure to

compliance with the rules contained in this booklet.

In case of replacement of parts, use only original spare parts.

You should always use personal protective elements to perform actions on the devices.

The installation and maintenance of air conditioning equipment may be dangerous because within these

devices there are pressurized refrigerant gas and electrical devices. Therefore the installation, initial start -up

and subsequent maintenance must be carried out by authorized and qualified personnel only.

In case of leakage of refrigerant fluid, it is mandatory to ventilate the room, considering also that refrigerant

fluid when exposed to flame produces toxic gas.

When refilling the system, after eventual leakage and repair, be sure that inside the refrigerant circuit does

not enter any substance, such as air, other than the specified refrigerant (R410A). The presence of air or

other foreign substances in the circuit of refrigerant may cause an abnormal increase of pressure or

breakage, resulting in personal injury.

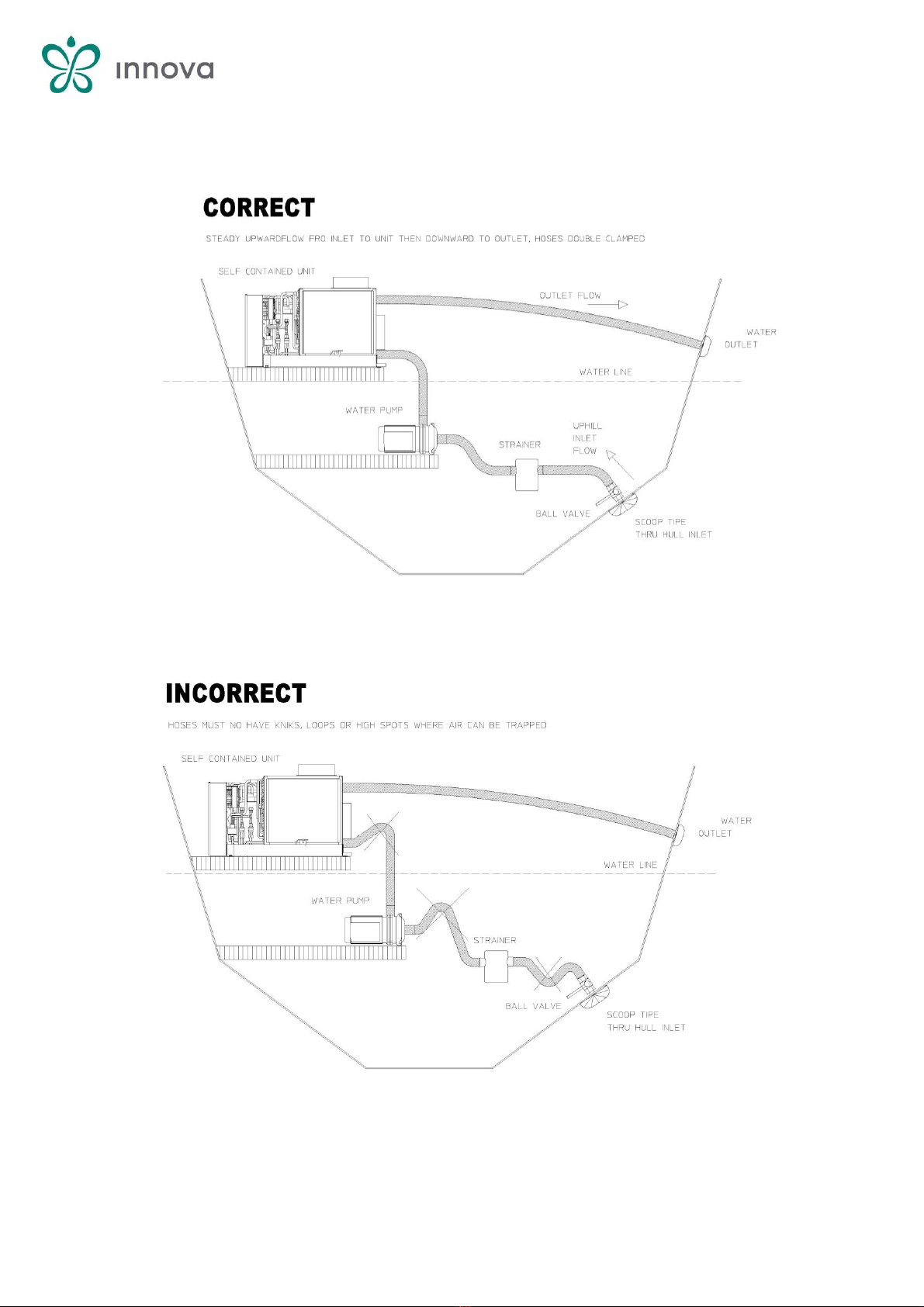

In the case of water spills from seawater circuit, switch off immediately compressor and source-side pump

and shut off Manual Valves in order to stop the flow.

If the unit is not in use during cold weather, drain all hydraulic circuits connected to the unit, as well as the seawater

condenser, to prevent freezing.

Some parts of the appliance produce heat during operation. The room installation must ensure adequate

ventilation and proper heat dissipation.

4.1.2

PROHIBITION S

We remember that the use of products that use electricity and water involves the observance of some

basic safety rules such as:

It is forbidden the use by children and unassisted disabled people.

Do not touch the appliance when barefoot or with wet or damp parts of the body.