1

Intended Use Statement:

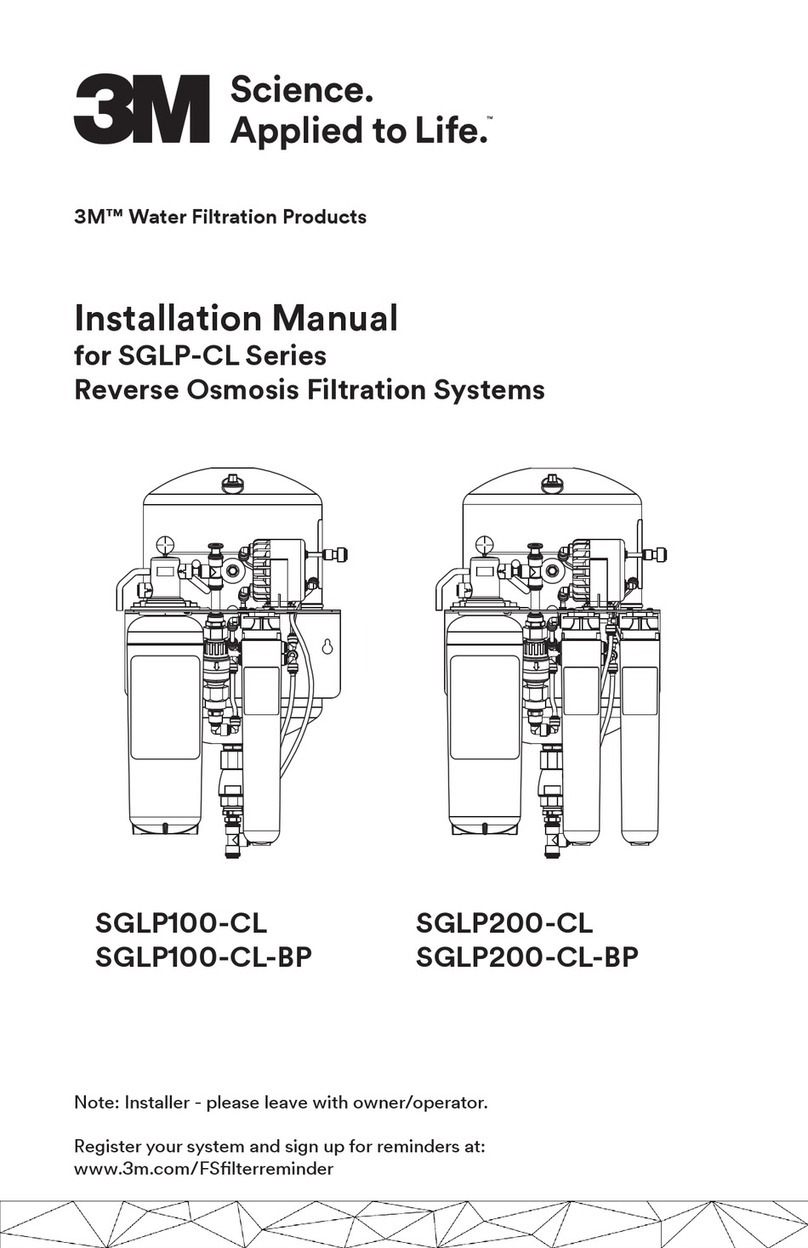

SGLP100-CL, SGLP200-CL and SGLP200-CL-BP are intended for use in ltering potable water and

have not been evaluated for other uses. The products are installed at the point of use and must be

installed as specied in the installation instruction by a qualied professional.

WARNING

Read entire manual. Failure to follow all guides and rules could cause personal injury or

property damage.

• Check with your local public works department for plumbing codes. You must follow their

guidelines as you install the Water Filtration system.

• Your Water Filtration system will withstand up to 125 pounds per square inch (psi) water

pressure. If your water supply pressure is higher than 80 psi, install a pressure reducing valve

before installing the Water Filtration system.

To reduce the risk associated with choking:

• DO NOT allow children under 3 years of age to have access to small parts during the installation

of this product.

To reduce the risk associated with the ingestion of contaminants:

• DO NOT use with water that is microbiologically unsafe or of unknown quality without adequate

disinfection before or after the system.

To reduce the risk associated with hazardous voltage due to an installer drilling through

existing electric wiring or water pipes in the area of installation:

• DO NOT install near electric wiring or piping which may be in path of a drilling tool when

selecting the position to mount the lter bracket.

NOTICE

To reduce the risk associated with property damage due to water leakage or ooding:

• Read and follow Use Instructions before installation and use of this system.

• Change the disposable pre-lter at the recommended interval; the disposable pre-lter MUST be

replaced every 12 months or sooner.

• Change the disposable lter RO membrane at the recommended interval; the disposable lter

RO membrane MUST be replaced every 24 months or sooner.

• Failure to replace the disposable pre-lter and disposable RO membrane at recommended

intervals may lead to reduced lter performance and failure of the lter, causing property

damage from water leakage or ooding.

• Installation and use MUST comply with all state and local plumbing codes.

• Protect from freezing, remove lter cartridge when temperatures are expected to drop below

33°F (4.4°C).

• DO NOT install systems in areas where ambient temperatures may go above 110°F (43.3°C).

• DO NOT install on hot water supply lines. The maximum operating water temperature of this

lter system is 100°F (37.8°C).

• DO NOT install if water pressure exceeds 125 psi (862 kPa). If your water pressure exceeds 80

psi (552 kPa), you must install a pressure limiting valve. Contact a plumbing professional if you

are uncertain how to check your water pressure.

• DO NOT install where water hammer conditions may occur. If water hammer conditions exist

you must install a water hammer arrester. Contact a plumbing professional if you are uncertain

how to check for this condition.

• Where a backow prevention device is installed on a water system, a device for controlling

pressure due to thermal expansion MUST be installed. Contact a plumbing professional if

you are uncertain how to select/install/maintain a thermal expansion device.