During maintenance & inspection

◆Maintenance & inspection must be carried out by personnel who have the necessary electrical

training and experience.

◆Do not touch the terminals while the power is on. Failure to comply may result in electric shock or

malfunction.

◆Disconnect all external power supplies of the system before cleaning the module or re-tightening

screws on the terminal block or screws of the connector. Failure to comply may result in electric

shock.

◆Disconnect all external power supplies of the system before removing the module or connecting/

removing the communication wirings. Failure to comply may result in electric shock or malfunction.

◆Get acquainted with the guide and ensure safety before online modication, forcible output, and RUN/

STOP operation.

◆Disconnect the power supply before installing/removing the extension card.

At disposal

◆Treat scrapped module as industrial waste. Dispose the battery according to local laws and

regulations.

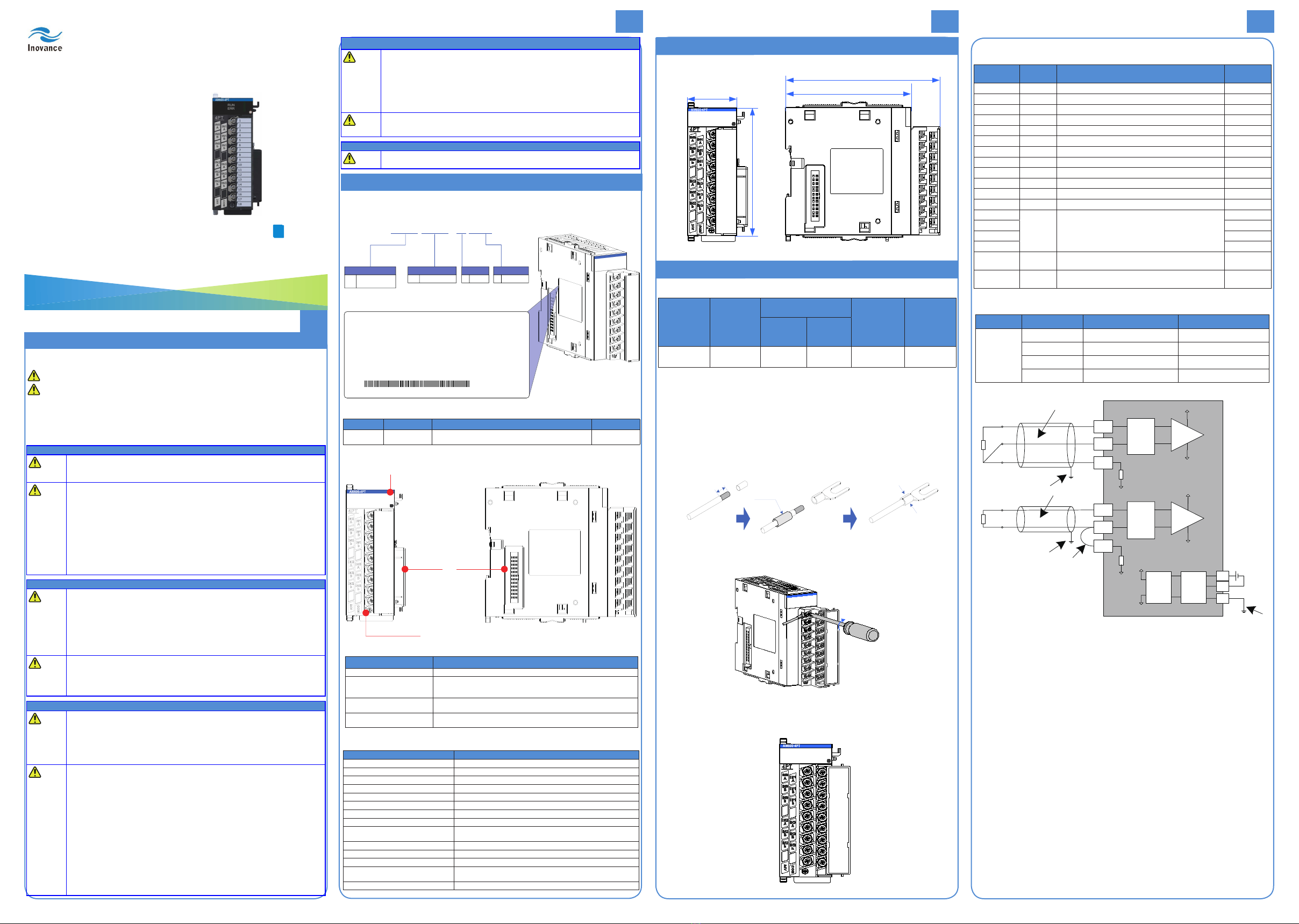

■Mounting Dimensions

Figure 3 Mounting dimensions (in mm)

■Cable Selection

Cable Name Model

Applicable Cable

Diameter

Manufacturer Crimping Tool

Chinese

standard/

MM2

American

standard/

AWG

Y-shaped

cable lug TNS 1.25-3 0.5–0.75 22–18 Suzhou

Yuanli

RYO-8

YYT-8

Those cable lugs are applicable to digital and analog temperature modules, and the cable

rated temperature needs to be higher than 75 °C.

■Cable Preparing Procedures

1) Strip the insulation layer of the cable by 6 mm.

2) Pass the cable through the tube of proper wire size.

3) Insert the exposed end into the hole of the cable lug, and then crimp it with the

recommended crimping tool.

4) Use a 20 mm heat-shrinkable tube (Φ3) to wrap the copper tube of the cable

lug and then perform thermal shrinkage.

6

Pass through the tube of

proper wire size

Crimp it with a

crimping tool

Figure 4 Diagram of cable preparation

5) Put the cable lug onto the terminal and tighten the screw with a screwdriver.

The tightening torque cannot be greater than 0.8 N.m.

Figure 5 Connecting cable to terminal block

■Terminal Arrangement

The gure below shows the ports of the AM600-4PT module.

Figure 5 Terminal denition of the AM600-4PT module

■Model and Nameplate

Product Information

AM

Inovance medium-sized PLC

Automation-Motion

Series

600

600 series controller

Number of Channels

4

4 channels

Input Type

Thermal resistor input

PT

Nameplate

MODEL˖AM600-4PT

POWER INPUT˖24VDC 100mA

OUTPUT˖NONE

VER ˖xxxxx

01022087YE400001

01022087YE400001

Figure 1 Description of model and nameplate

Model Classication Description Applicable to

AM600-4PT Temperature

module

4-Channel thermal resistor temperature collection module,

supporting multiple types of thermal resistors

AM600 series,

H3U

■External Interfaces

RUN

ERR

User input terminal

Local extension

back-end

interface

Local

extension

front-end

interface

Figure 2 Diagram of the AM600-4PT temperature module interfaces

Interface Name Function

User input terminals 4 channels of thermal resistor inputs

Signal indicators

RUN: operation state indicator, which is turned on during normal operation and

turned off when a fault occurs

ERR: error state indicator, which is turned on when a fault occurs

Local expansion module back-end

interface Connect back-end module, not supporting hot plugging

Local expansion module front-end

interface Connect front-end module, not supporting hot plugging

■General Specications

Item Specications

Input channel 4

Supply voltage 24 VDC (20.4 VDC to 28.8 VDC) (–15% to +20%)

Internal 5 V power consumption 85 mA (typical value)

Sensor type Thermal resistor: Pt100, Pt500, Pt1000 , and Cu100

Display mode: Celsius degree (°C), and Fahrenheit degree (°F)

Thermal resistor wiring method Two wires/Three wires

Resolution 24 bits

Sensitivity 0.1 °C or 0.1 °F

Sampling cycle 250 ms, 500 ms, or 1000 ms (The sampling cycles of the four channels can

be set separately using software.)

Filter time 0s to 100s (The lter time can be set using software. The default value is 5s.)

Accuracy (normal temperature: 25 °C) Full scale x (±0.3%)

Accuracy (ambient temperature: 0 to 55 °F) Full scale x (±1%)

Isolation method I/O terminals isolated from power supply;

Isolation between channels

System program updated via USB interface

Safety Information and Precautions

User Guide

AM600-4PT Temperature Module

Safety information and precautions are identied into two grades: Warning and Caution. Please make

sure to operate properly with adequate safety assurance.

: Indicates the improper operation which, if not avoided, may cause death or serious injury;

: Indicates the improper operation which, if not avoided, may cause moderate or minor

injury, as well as equipment damage.

In some cases, even failure to follow "Cautions" may also lead to serious consequences. Please make

sure to follow both warnings and cautions; otherwise, it may cause death or serious injury, as well as

product and relevant equipment and system damage.

Please keep this guide well so that it can be read when necessary and forward this guide to the end user.

During control system design

◆Provide a safety circuit outside the PLC so that the control system can still work safely once external

power failure or PLC fault occurs.

◆Add a fuse or circuit breaker because the module may smoke or catch re due to long-time

overcurrent caused by operation above rated current or load short-circuit.

◆An emergency stop circuit, a protection circuit, a forward/reverse operation interlocked circuit, and a

upper position limit and lower position limit interlocked circuit must be set in the external circuits of the

PLC to prevent damage to the machine.

◆To ensure safe operation, for output signals related to critical accidents, please design external

protection circuit and safety mechanism;

◆Once the PLC CPU detects abnormality in the system, all outputs may be closed; however, when a

fault occurs in the controller circuit, the output may not be under control. Therefore, it is necessary to

design an appropriate external control circuit to ensure normal operation;

◆If the PLC's output units such as relays or transistors are damaged, the output may fail to switch

between ON and OFF states according to the commands;

◆The PLC is designed to be used in indoor electrical environment (overvoltage category II). The

power supply must have a system-level lightning protection device, assuring that overvoltage due to

lightning shock can't be applied to the PLC's power supply input terminals, signal input terminals and

output terminals and so forth, so as to avoid damage to the equipment.

During installation

◆Installation must be carried out by the specialists who have received the necessary electrical training

and understood enough electrical knowledge.

◆Disconnect all external power supplies of the system before module assembly/disassembly and wiring.

Failure to do so may result in electric shock, module fault or malfunction.

◆Do not use the PLC where there are dust, oil smoke, conductive dust, corrosive or combustible gases,

or exposed to high temperature, condensation, wind & rain, or subject to vibration and impact. Electric

shock, re and malfunction may also result in damage or deterioration to the product.

◆The PLC is open-type equipment that must be installed in a control cabinet with lock (cabinet housing

protection > IP20). Only the personnel who have received the necessary electrical training and

understood enough electrical knowledge can open the cabinet.

◆Prevent metal lings and wire ends from dropping into ventilation holes of the PLC during installation.

Otherwise it may result in re, fault and malfunction.

◆Ensure there are no foreign matters on the ventilation surface. Failure to comply may result in poor

ventilation, which may cause re, fault and malfunction.

◆Ensure the module is connected to the respective connector securely and hook the module rmly.

Improper installation may result in malfunction, fault or fall-off.

During wiring

◆Wiring must be carried out by personnel who have received the necessary electrical training and

understood enough electrical knowledge.

◆Disconnect all external power supplies of the system before wiring. Failure to comply may result in

electric shock, module fault or malfunction.

◆Install the terminal cover attached to the product before power-on or operation after wiring is

completed. Failure to comply may result in electric shock.

◆Perform good insulation on terminals so that insulation distance between cables will not reduce after cables

are connected to terminals. Failure to comply may result in electric shock or damage to the equipment.

◆Prevent metal lings and wire ends from dropping into ventilation holes of the PLC at wiring. Failure

to comply may result in re, fault and malfunction.

◆The external wiring specication and installation method must comply with local regulations. For

details, see the wiring section in this guide.

◆To ensure safety of equipment and operator, use cables with sufcient diameter and connect the

cables to ground reliably.

◆Wire the module correctly after making clear of the connector type. Failure to comply may result in

module and external equipment fault.

◆Tighten bolts on the terminal block in the specied torque range. If the terminal is not tight, short-

circuit, re or malfunction may be caused. If the terminal is too tight, fall-off, short-circuit, re or

malfunction may be caused.

◆If the connector is used to connect with external equipment, perform correct crimping or welding with

the tool specied by manufacturer. If connection is in poor contact, short-circuit, re or malfunction

may be caused.

◆A label on the top of the module is to prevent foreign matters entering the module. Do not remove the

label during wiring. Remember to remove it before system operation, facilitating ventilation.

◆Do not bundle control wires, communication wires and power cables together. They must be run with

distance of more than 100 mm. Otherwise, noise may result in malfunction.

◆Select shielded cable for high-frequency signal input/output in applications with serious interference

so as to enhance immunity to interference of the system.

Product Information

Mechanical Design Reference

Electrical Design Reference

■Terminal Denition

Network

Name Type Function Terminal No.

IN0 A Input Temperature measurement resistor A of channel 0 1

IN0 B Input Temperature measurement resistor B of channel 0 3

IN0 b Input Temperature measurement resistor b of channel 0 5

IN1 A Input Temperature measurement resistor A of channel 1 2

IN1 B Input Temperature measurement resistor B of channel 1 4

IN1 b Input Temperature measurement resistor b of channel 1 6

IN2 A Input Temperature measurement resistor A of channel 2 9

IN2 B Input Temperature measurement resistor B of channel 2 11

IN2 b Input Temperature measurement resistor b of channel 2 13

IN3 A Input Temperature measurement resistor A of channel 3 10

IN3 B Input Temperature measurement resistor B of channel 3 12

IN3 b Input Temperature measurement resistor b of channel 3 14

NC

Reserved Reserved

7

NC 8

NC 15

NC 16

24 V Power

supply +24 V power supply 17

COM Power

supply 24 V power ground 18

■Detection Mode Specications

Item Sensor Temperature Range (°C) Temperature Range (°F)

Thermal

Resistor

Type

Pt100 –200.0 °C to 850.0 °C –328.0 °F to 1562.0 °F

Pt500 –200.0 °C to 850.0 °C –328.0 °F to 1562.0 °F

Pt1000 –200.0 °C to 850.0 °C –328.0 °F to 1562.0 °F

Cu00 –50.0 °C to 150.0 °C –58.0 °F to 302.0 °F

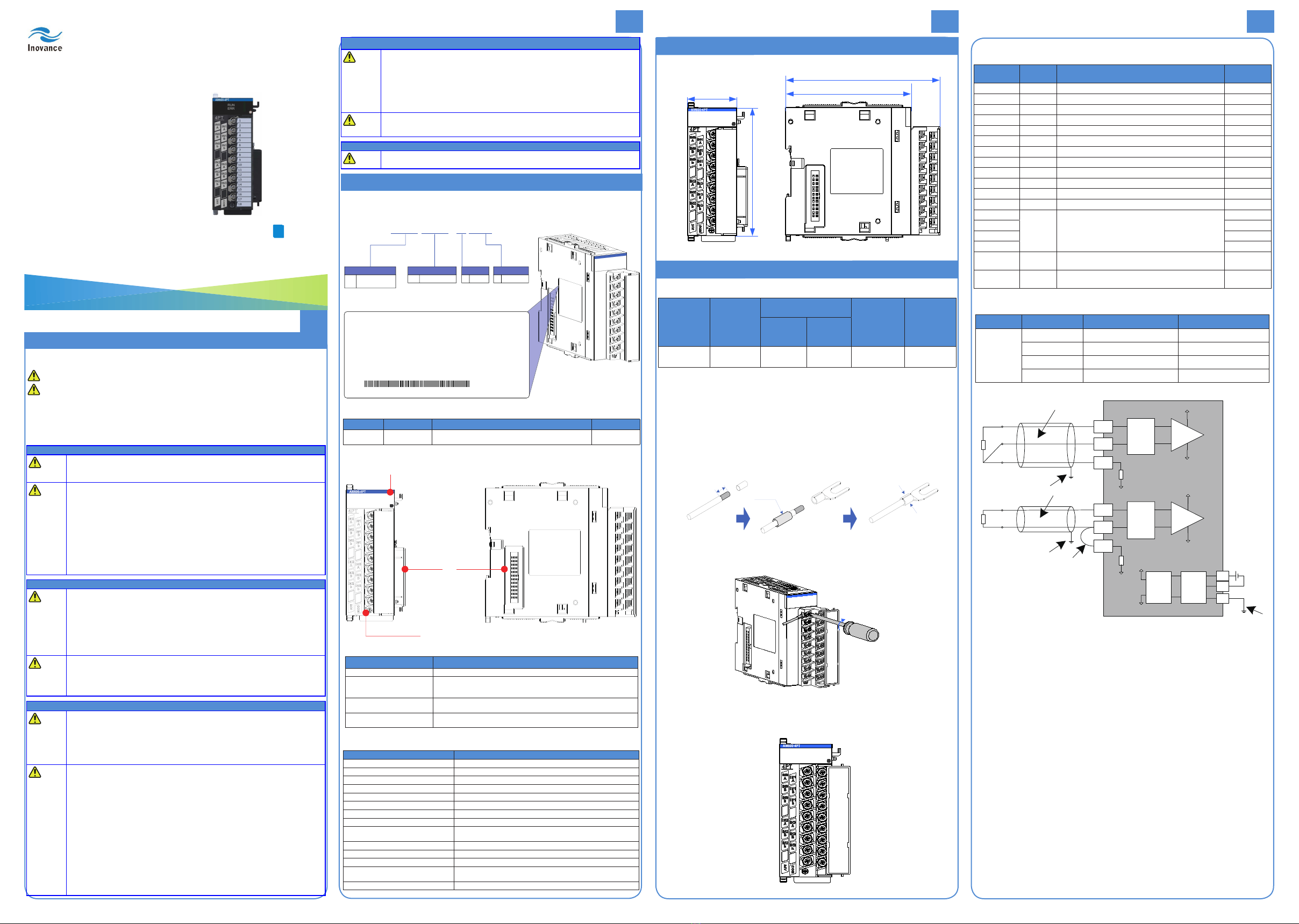

■External Wiring

PT

24

V

COM

FG

Filter

DC/DC

converter

Filter

Filter

INA

INB

INb

INA

INB

INb

AGND

AGND

AGND

AGND

AGND

5V

5V

5V

24 V

External

DC power

γ1

γ3

PT

γ1

γ2

γ3

bTwo-wire system

aThree-wire system

Figure 6 AM600-4PT module wiring diagram

*1. Shielded cables need to be used.

*2. When the two-wire system is used in wiring, the INB and INb channels need to be

shorted. In this case, resistors on the cable affect the measurement value.

*3. Cables with low wire resistance in which there is no resistance difference among the

three wires need to be used.

*4 The module should be mounted on a well-grounded metal bracket, and the metal

shrapnel at the bottom of the module must be in good contact with the bracket.

■Wiring Precautions

Do not bundle the cable together with AC cable, main lines, high voltage cable and so

forth; otherwise, it may result in an increased noise, surge and induction.

Apply single-point grounding for the shielding of shielded cable and solder sealed cable.

Tubed and solderless crimp terminal cannot be used with a terminal block. It is

recommended that a marking sleeve or insulation sleeve be used to cover the cable

connector part of the crimp terminals.

A00

Data Code: 19010673

Thank you for purchasing the AM600-4PT module

developed and manufactured independently by

Inovance.

AM600-4PT is a 4-channel thermal resistor temperature

collection module used together with the AM600 series

medium-sized PLC and the H3U series PLC main

modules. It supports temperature collection of multiple

types of thermal resistors, and provides a resolution of

up to 24 bits.

This guide describes the specications, characteristics

and using methods of the product. Please read this

guide carefully before using to ensure more safely

usage. Please refer to the AM600 Series PLC Hardware

Manual and the AM600 Series PLC Software Manual to

understand the use of the user program development

environment and design method of the user program of

the product. You can download the latest materials from

www.inovance.cn.

1

234

User Guide