1

23 4

I. Overview

Thank you for purchasing the GR10-2PHE high speed dierential pulse positioning

module developed and manufactured independently by Inovance. This product

delivers 2*4 MHz high-speed dierential outputs. It supports multiple pulse output

modes, including direction+pulse or CW + CCW. It also supports homing positioning

and left and right limiting. It is ideal choice for applications require a large number

of axes.

This guide describes the specications, characteristics and using methods of the

product. Please read this guide carefully before using to ensure safe usage. Visit our

website (www.inovance.com) for the latest version of the guide.

II. Safety Instructions

Safety Precautions

1. Before installing, using, and maintaining this equipment, read the safety

information and precautions thoroughly, and comply with them during operations.

2. To ensure the safety of humans and equipment, follow the signs on the

equipment and all the safety instructions in this user guide.

3. The "CAUTION", "WARNING" and "DANGER" signs are only supplements to the

safety instructions.

4. Use this equipment according to the designated environment requirements.

Damage caused by improper usage is not covered by warranty.

5. Inovance shall take no responsibility for any personal injuries or property damage

caused by improper usage.

Safety Levels and Denitions

: Indicates that failure to comply with the notice may result in severe

personal injuries or even death.

: The "CAUTION" sign indicates that failure to comply with the notice may

result in minor or moderate personal injury or damage to the equipment.

Please keep this guide well so that it can be read when necessary and forward this

guide to the end user.

During control system design

◆ Provide a safety circuit outside the PLC so that the control system can still work safely

once external power failure or PLC fault occurs.

◆ Add a fuse or circuit breaker because the module may smoke or catch re due to long-

time overcurrent caused by operation above rated current or load short-circuit.

◆ An emergency stop circuit, a protection circuit, a forward/reverse operation inter-

locked circuit, and a upper position limit and lower position limit interlocked circuit

must be set in the external circuits of PLC to prevent damage to the machine.

◆ To ensure safe operation, for the output signals that may cause critical accidents,

please design external protection circuit and safety mechanism;

◆ Once PLC CPU detects abnormality in the system , all outputs may be closed; howev-

er, when a fault occurs in the controller circuit, the output may not be under control.

Therefore, it is necessary to design an appropriate external control circuit to ensure

normal operation;

◆ If the PLC output units such as relays or transistors are damaged, the output may fail

to switch between ON and OFF states according to the commands;

◆ The PLC is designed to be used in indoor electrical environment (overvoltage category

II). The power supply must have a system-level lightning protection device, assuring

that overvoltage due to lightning shock cannot be applied to the PLC power supply in-

put terminals, signal input terminals and output terminals and so forth, so as to avoid

damage to the equipment.

Installation

◆ Installation must be carried out by the specialists who have received the necessary

electrical training and understood enough electrical knowledge.

◆ Disconnect all external power supplies of the system before removing/installing the

module. Failure to do so may result in electric shock, module fault or malfunction.

◆ Do not use the PLC where there are dust, oil smoke, conductive dust, corrosive or

combustible gases, or exposed to high temperature, condensation, wind & rain, or

subject to vibration and impact. Electric shock, re and malfunction may also result

in damage or deterioration to the product.

◆ The PLC is open-type equipment that must be installed in a control cabinet with

lock (cabinet housing protection >IP20). Only the personnel who have received the

necessary electrical training and understood enough electrical knowledge can open

the cabinet.

◆ Prevent metal lings and wire ends from dropping into ventilation holes of the PLC

during installation. Failure to comply may result in re, fault and malfunction.

◆ Ensure there are no foreign matters on ventilation surface. Failure to comply may

result in poor ventilation, which may cause re, fault and malfunction.

◆ Ensure the module is connected to the respective connector securely and hook the

module rmly. Improper installation may result in malfunction, fault or fall-o.

Wiring

◆ Wiring must be carried out by personnel who have received the necessary electrical

training and understood enough electrical knowledge.

◆ Disconnect all external power supplies of the system before wiring. Failure to comply

may result in electric shock, module fault or malfunction.

◆ Install the terminal cover attached to the product before power-on or operation after

wiring is completed. Failure to comply may result in electric shock

◆ Perform good insulation on terminals so that insulation distance between cables will

not reduce after cables are connected to terminals. Failure to comply may result in

electric shock or damage to the equipment.

◆ Prevent dropping metal lings and wire ends drop into ventilation holes of the PLC at

wiring. Failure to comply may result in re, fault and malfunction.

◆ The external wiring specication and installation method must comply with local

regulations. For details, see the wiring section in this guide.

◆ To ensure safety of equipment and operator, use cables with sucient diameter and

connect the cables to ground reliably.

◆ Ensure that all cables are connected to the correct interface. Failure to comply may

result in module and external equipment fault.

◆ Tighten bolts on the terminal block in the specied torque range. If the terminal is not

tight, short-circuit, re or malfunction may be caused. If the terminal is too tight, fall-

o, short-circuit, re or malfunction may be caused.

◆ If the connector is used to connect with external equipment, perform correct crimping

or welding with the tool specied by manufacturer. If connection is in poor contact,

short-circuit, re or malfunction may be caused.

◆ A label on the top of the module is to prevent foreign matters entering the module. Do

not remove the label during wiring. Remember to remove it before system operation,

facilitating ventilation.

◆ Do not bundle control wires, communication wires and power cables together. They

must be run with distance of more than 100 mm. Otherwise, noise may result in mal-

function.

◆ Select shielded cable for high-frequency signal input/output in applications with

serious interference so as to enhance system anti-interference ability.

Operation and Maintenance

◆ Maintenance & inspection must be carried out by personnel who have the necessary

electrical training and experience.

◆ Do not touch the terminals while the power is on. Failure to comply may result in elec-

tric shock or malfunction.

◆ Disconnect all external power supplies of the system before cleaning the module or

re-tightening screws on the terminal block or screws of the connector. Failure to com-

ply may result in electric shock.

◆ Disconnect all external power supplies of the system before removing the module or

connecting/removing the communication wirings. Failure to comply may result in

electric shock or malfunction.

◆ Get with the guide and ensure safety before online modication, forcible output, and

RUN/STOP operation.

◆ Disconnect the power supply before installing/removing the extension card.

Disposal

◆ Treat scrapped module as industrial waste. Dispose the battery according to local laws

and regulations.

III. Product Information

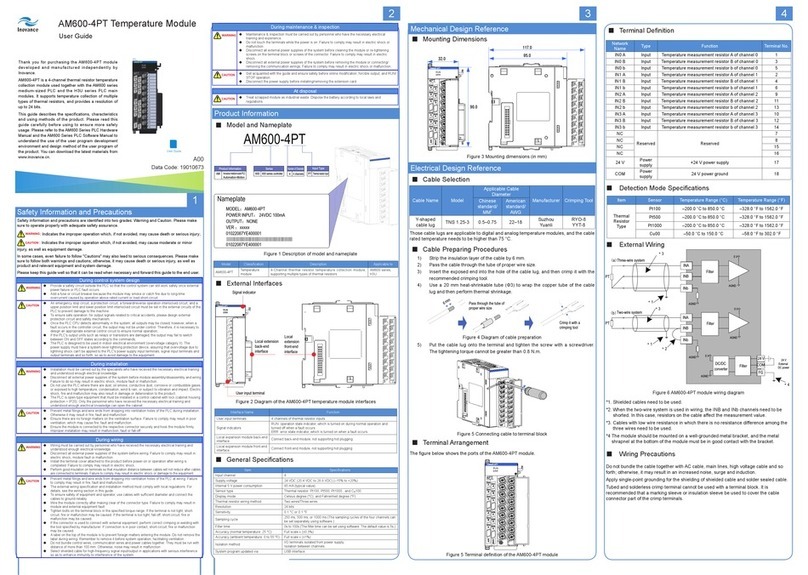

■Model Number and Nameplate

(31)&

.BSL 4FSJFT

.BSL %FTDSJQUJPO

(

.BSL 0VUQVUT

.BSL .PEVMF5ZQF

.OMNYVKKJ*/,,U[ZV[Z

V[RYKVUYOZOUTOTM

1)

(FOFSBM.PEVMF

.BSL "VY'VODUJPO

&UIFS$"5DPNNVOJDBUJPO&

3

3FNPUFNPEVMF

3UJKR

8GZKJOTV[Z

8GZKJU[ZV[Z

9KXOGR4U

4GSKVRGZK

MODELGR10-2PHE

POWER INPUT24VDC 250mA

OUTPUT5VDC 150mA DIFF LOAD

XXXXXXXXXXXXXXXX

<KXYOUT4U

VER:XXXXX

XXXXXXXXXXXXXXXX

Figure 1 Description of model and nameplate

Model Category Description Applicable

Model

GR10-2PHE

EtherCAT high-speed

dierential pulse

positioning module

Supports 2-channel high-

speed dierential output

pulse and 8 inputs

AM600 series

■External Interface

No. Interface Name Function

①State indicator

PWR Power indicator Green ON when power

supply is switched on

RUN Running status

indicator Green

ON when the

module is in normal

operation

SF Fault indicator Red ON when the module

is faulty

ERR State machine

error indicator Red

ON when an error

occurs in the state

machine

② Signal indicator

CH0/1 Indicator Green On when channel 0/1

is ready to output

A/B Pulse+direction

Indicator Green /

X0-X3 Digital input

indicator Green On when the input

signal is active

③Address DIP

switch

16-bit station address rotary switch. Decimal slave

address = ADDR1*16+ADDR0 (address 0–255)

④

EtherCAT

communication

port

X1 IN: EtherCAT input

X2 OUT: EtherCAT output for connecting back-end

EtherCAT slaves

⑤24 V power input

terminal For module power supply input

⑥User output

terminals See "Electrical Design Reference" for details

19011286 A01

■General Specications

Item Specications

Power supply

specications 24 VDC (20.4 VDC to 28.8 VDC) (–15% to +20%)

Input current Max. 0.25 A

Number of

positioning

channels

2

Ordinary output

signal Sink output: 24 V, response time: 0.5 ms

Dierential pulse

output Pulse+direction, CW/CCW, A/B (output frequency: 4 MHz)

Digital input 8 (sink and source)

System program

upgrade method USB rmware upgrade

Positioning Absolute pulse positioning, relative pulse positioning, speed

control, multiple homing methods

Communication

protocol EtherCAT industrial real-time bus protocol, 100 Mbps

Network port/

network cable

Standard network port with Cat 5e network cables below 100

meters

Station number

range

1–255 if set by DIP switch

0–65535 if automatically allocated through a network bus.

Operating

temperature -5–55℃

Storage

temperature -25–70℃

Humidity 10–95%, no-condensation

IP rating IP20

The specic performance indicators are as follows:

Item Specications

Communication protocol EtherCAT protocol

Service supported CoE (PDO, SDO)

Min. sync period 500 us (TYP)

Synchronization mode Input and output synchronization or DC-distributed

clock

Physical layer 100BASE-TX

Baud rate 100 Mbit/s (100Base-TX)

Duplex mode Full duplex

Topological structure Linear topological structure

Transmission medium Network cables, see "Electrical Design Reference"

Transmission distance Less than 100 m between two nodes

EtherCAT frame length 44–1,498 bytes

Process data Max. 1486 bytes per frame

Synchronization jitter of

two slave stations < 1us

Update time Approx. 500 us

■Output specication

Item SINK output Item Dierential output

Output type Transistor NPN Output type 5 V dierential output

ON response

time Less than 0.5 ms Insulation Optocoupler isolation

Insulation Optocoupler isolation Max. output

frequency 4 MHz

Open-circuit

leakage

current

Less than 0.1 mA/30 VDC Output

mode

Pulse+direction, A/B

phase single frequency,

CW/CCW

Min. load 5 mA (DC5V–24V) Number of

channels 2

Max. load

Resistive load: 0.5 A/point

Inductive load: 7.2 W/24 V

Lamp load: 0.9 W/24 V

-- --

■Input specication

Item Specications

Input type SINK/SOURCE input

Input voltage DC 24 V

Input resistance 3.3KΩ

Input is ON Input current is above 3.5 mA

Input is OFF Input current is below 1.5 mA

GR10-2PHE HS Dierential

Pulse Positioning Module

User Guide

MD500系列

通用变频器综合手册

MD500

系列通用变频器综合手册

由于本公司持续的产品升级造成的内容变更,恕不另行通知

A00

资料编码 19010306

版权所有 深圳市汇川技术股份有限公司

Copyright Shenzhen Inovance Technology Co., Ltd.

服务与技术支持APP官方微信

深圳市汇川技术股份有限公司

Shenzhen Inovance Technology Co., Ltd.

地址:深圳市宝安区宝城70区留仙二路鸿威工业区E栋

总机:(0755)2979 9595

传真:(0755)2961 9897

客服:400-777-1260

http://www.inovance.com

苏州汇川技术有限公司

Suzhou Inovance Technology Co., Ltd.

地址:苏州市吴中区越溪友翔路16号

总机:(0512)6637 6666

传真:(0512)6285 6720

客服:400-777-1260

http://www.inovance.com

Min

Max

综合手册

二维码

销售服务联络地址

条形码位置

放置二维码后删除虚框

*19011286A01*