Insta 234 Plus User manual

MNL90234P Rev. F 09.02.16

OPERATION AND MAINTENANCE MANUAL

MODEL 234 Plus

FOR USE BY QUALIFIED PERSONNEL ONLY

Safety Summary

WARNING

In case of power cord damage, do not

attempt to repair or replace the power

cord. Contact the manufacturer or the

local distributor.

WARNING

Hot Surface. Avoid contact.

WARNING

If this equipment is used in a manner

not specified by the manufacturer,

protection may be impaired.

CAUTION

During normal operation, the base of

the machine needs to be installed or

placed above the wall socket.

CAUTION

The machine is to be operated by one

person only.

CAUTION

To reduce the risk of electric shock

and injury to persons, disconnect from

power supply before servicing and /or

cleaning.

CAUTION

Do not handle the plug with wet

hands, or machinery under wet

conditions.

1

International Symbols

Power Off

Power On

Hot Surface

Risk of Electrical Shock

Protective Earth Terminal

Ground

Wet Conditions

Caution

Warning

M

FOR USE BY QUALIFIED PERSONNEL ONLY

Congratulations!

Your selection of the Insta Graphic Systems

heat seal machine is a sound business

decision. Insta equipment is the result of the

highest quality engineering and time-tested

design. Your new machine combined with

Insta’s reputation of innovation in the heat-

sealing field, insures the continuing capability of

delivering the best decorated substrates

possible.

This manual describes installation, operation,

and maintenance procedures for your new 234

Plus series machine, as well as easy to use

instructions for on-the-spot maintenance.

Your 234 Plus series machine will have a long

trouble-free life. Read this manual. Keep it with

your machine; it's your key to proper operation

and lasting service.

Limited Machine Warranty

Insta Graphic Systems warrants this heat seal

machine, when operated under normal

conditions, to be free from manufacturing

defects in material and workmanship for a

period of one year on parts (lifetime on the

heating element) and 90 days on labor from

the invoice date.

This warranty will be effective only when Insta

authorizes the original purchaser to return the

product to the factory in Cerritos, California,

freight prepaid, and only when the product

upon examination has proven to be defective.

This warranty does not apply to any machine

that has been subjected to misuse, negligence

or accident.

Insta shall not be liable for the injury, loss or

damage, direct or consequential, arising out of

the use or the inability to use the product.

No claim of any kind shall be greater in

amount than the sale price of the product or

part to which claim is made.

This is the sole warranty given by the

company, it is in lieu of any other warranties,

expressed or implied, in law or in fact,

including the warranties of merchant-ability

and fitness for a particular use, and is

accepted as such by the purchaser in taking

delivery of this product.

General Description

The Model 234 Plus has been strategically

designed to generate and evenly distribute

tremendous pressure throughout the entire

platen. And, its cast-in tubular heating element

heats the metal from within, which produces

constant and long lasting heat. A successful

heat transfer application requires 3 key

elements to work in tandem-time, temperature

and pressure. The Model 234 Plus has

mastered those elements and gets the job done

every time.

The manual swing-away machine has proven to

be a true customer favorite. The upper platen

swings almost a full 180 degrees to the right –

leaving the lower platen completely free from

constraints. The exposed lower platen provides

you with unobstructed access while you load

your garments and place your transfers.

2

FOR USE BY QUALIFIED PERSONNEL ONLY

IP54=IP

1st Digit5

2nd Digit4

1st

Digit Protection from

solid objects 2nd

Digit Protection from

moisture

0 Non protected 0 Non protected

1Objects greater

than 50mm 1 Dripping water

2Objects greater

than 12mm 2Dripping water

when tilted up to 15

deg.

3Objects greater

than 2.5mm 3 Spraying water

4Objects greater

than 1mm 4 Splashing water

5 Dust protected 5 Water jets

6 Dust tight 6 Heavy seas

-- --- 7 .15m – 1m

immersion

-- --- 8 1m + submersion

Degree of Protection

IP (Ingress Protection) rating according to IEC

60529.

NOTE

IEC 60529 does not specify sealing

effectiveness against the following:

mechanical damage of the equipment;

the risk of explosion; certain types of

liquid conditions, e.g. those that are

produced by condensation; corrosive

vapours; funus; vermin

Installation

DOMESTIC – 234 Plus

Use a separate 15 amp AC

circuit. Only industrial extension

cords with proper wire size should

be used: size 16/3 wire for

distances up to 25 feet, and size

14/3 for distances up to 50 feet.

INTERNATIONAL – 234 Plus

Use a designated 16-amp AC

circuit. Only industrial extension

cords with proper wire size (2.5

sq. mm) shall be used.

IMPORTANT

The appliance must be plugged

into a proper receptacle of the

proper size and rating. Equally

important the line voltage must

be able to accommodate this

appliance as well as other

appliances operating on this

circuit.

Specifications

Voltage 120 Volts AC 50/60 Hertz

Model 234 Plus 1750 Watts 14.6 Amps

Voltage 230 Volts AC 50/60 Hertz

Model 234 Plus 2200 Watts 9.6 Amps

Model 234 Plus

Machine Weight 97 Pounds (44.0 KG)

3

FOR USE BY QUALIFIED PERSONNEL ONLY

4

Operation

1. Turn the power on by pressing the POWER

button on the controller.

2. Set desired temperature and time. Swing the

upper platen arm to its fully open position, away

from lower platen. (See Solid State Controller

section)

3. Allow the machine to warm up until the selected

temperature is reached.

4. Set the desired pressure by adjusting the

pressure knob on the top of the machine. To

reduce pressure, turn knob counter-clockwise.

5. Place the substrate on lower platen, smoothing

out all wrinkles.

6. Position transfer or lettering on substrate.

7. Swing the upper arm into position directly over

the lower platen.

8. Close machine by pulling handle down into

locked position.

9. The timer will start automatically and a buzzer

will beep at the end of the time cycle.

10. Lift safety lock and pull handle up slowly and

move upper platen handle to its full open

position. This technique will avoid transfer

paper (cover) from being pulled off prematurely

due to suction from the separating platens.

11. Swing away arm to the extreme right hand

position and remove substrate.

CAUTION

For safety purposes, it is necessary

to push the handle into the locked

position after it is lifted. This will

eliminate the accidental lowering of

the heat platen handle.

WARNING

If this equipment is

used in a manner not

specified by the

manufacturer,

protection may be

impaired.

Environmental Conditions

Only operate Insta heat seal machines under

suitable environmental conditions.

1. Placed on a even, non flammable surface.

2. Can support a minimum of 300 lbs. if placed

above a platform.

3. Do not restrict access to the main power

switch.

4. Maintain a clearance around any forms of

liquid.

5. Do not over extend the power cord.

6. The operational voltage should not be 10%

max/min of the rated value.

7. Avoid voltage spikes.

FOR USE BY QUALIFIED PERSONNEL ONLY

5

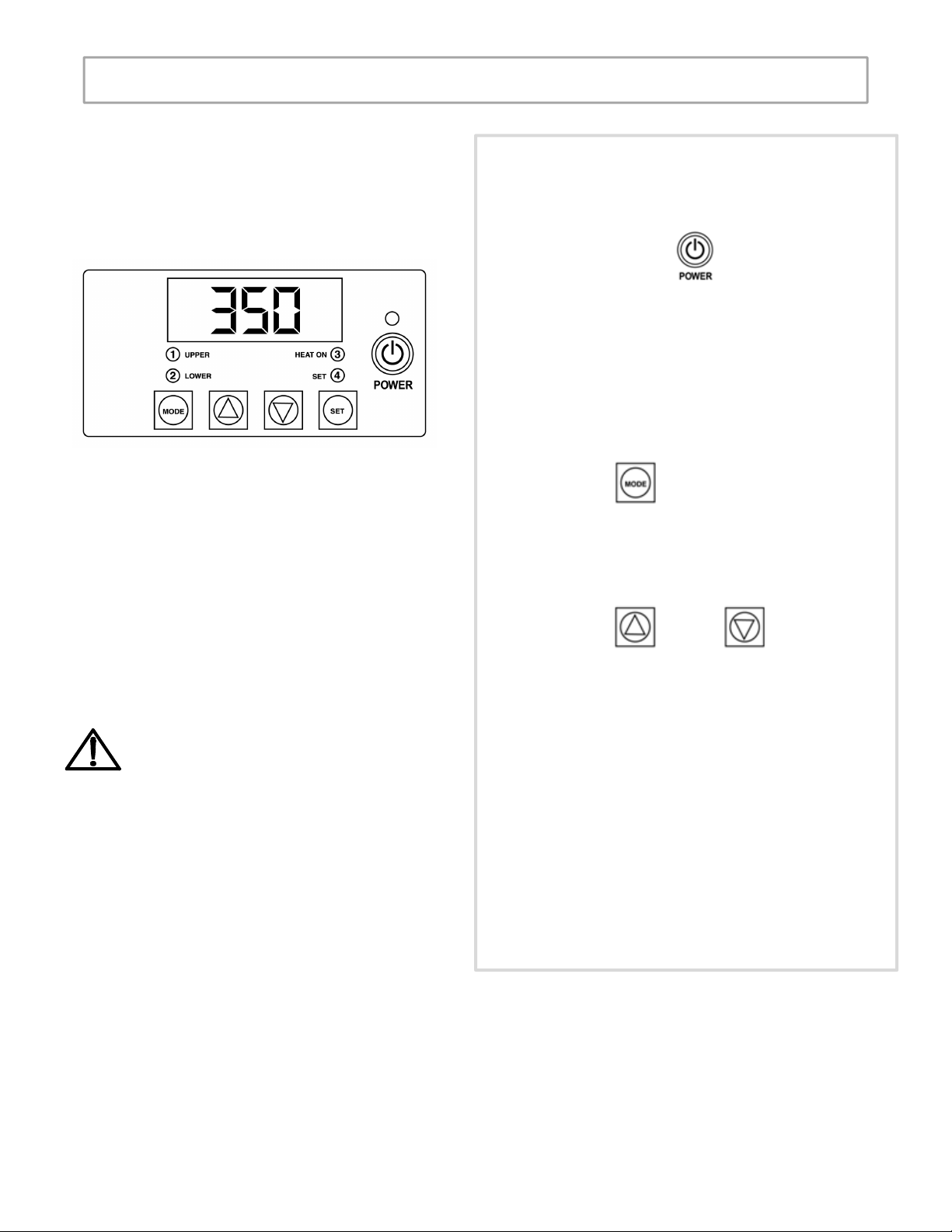

Operation Timer/Temperature

Control

Solid State Controller

This controller has two (2) control features:

1. Temperature - Temperature may be set from

221-446°F (105-230°C).

2. Time - Time may be set from 1 second to 99.59

minutes.

Controller Operation

1. If the temperature is not being displayed, press

the MODE button until temperature is

displayed.

2. Push and hold SET button and simultaneously

push UP (↑) or DOWN (↓) arrow buttons to the

desired temperature setting.

3. Press the MODE button until time is displayed.

4. Push and hold SET button and simultaneously

push UP (↑) or DOWN (↓) arrow buttons to the

desired timer setting.

Timer

•The controller has a count down timer that

automatically activates a buzzer at the

completion of the application.

•Timer display is minutes:seconds. Range is

00:00 to 99:59, Colons (:) flash while timer is

running.

Temperature

Fahrenheit/Centigrade (Celsius)

Conversion

The temperature controller can be programmed to

display either °F or °C

1. Press the MODE button until the temperature is

displayed.

2. Push and hold the UP and DOWN buttons for 5

seconds.

FOR USE BY QUALIFIED PERSONNEL ONLY

6

Preventive Maintenance

Suggestions

The Insta heat seal machines are relatively

maintenance free. For long trouble-free life, the

following preventive maintenance should be

followed:

1. Do not heat seal items such as buttons, pins,

snaps, or zippers that tend to cut the silicone

rubber pad or scratch the Teflon heat platen.

2. Periodically clean the Teflon-coated heat platen

with a non-abrasive piece of cloth. Stubborn

stains may be cleaned, when platen is cool,

with mineral spirits.

3. When the heat platen is hot and not in use,

keep in open position (away from the silicone

rubber pad).

4. To prevent soiling of substrate, periodic wiping

of the entire exterior machine, including

platens, with a clean rag is recommended. If

necessary, use mineral spirits for cleaning a

cold machine. Since mineral spirits are

flammable, use precautions and keep away

from sparks, flame, or hot heat platen.

5. The Model 234 machines require periodic

lubrication with a high-temperature, non-

melting grease (MPPL023).

A. Lubricate the post, handle and cam

assembly depending upon usage. (Once

every month if used continuously.)

B. There are four (4) points of lubrication:

a) Post

b) Lower Cam

c) Guide Post

d) Upper Pin Area

In addition, occasionally apply a few drops of heavy

machine oil to the upper portion of the cam

assembly.

WARNING

Power cord replacement

should be from the

manufacturer only (because it

requires a specially prepared

cord).

General Maintenance

It is recommended that you have the following

items available:

A. Regular screw driver

B. Phillips head screw driver

C. Small adjustable wrench

D. Needle nose pliers with insulated handle

E. Set of Allen wrenches

F. Grease gun

G. Special high temperature grease MPPL023

With the above items you should be able to

accomplish most repairs.

Replacement of Silicone

Rubber Pads

1. Make sure heat platen is cool.

2. Use tube of MPPC006 adhesive to bond

silicone rubber pad to metal platen.

NOTE: Read instructions on the tube package

.

3. Be sure that the surface of the silicone platen is

clean. Use a mild solvent such as mineral

spirits.

4. The pad and metal must be thoroughly dry and

clean, before starting the bonding operation.

5. Apply adhesive sealant to the metal platen.

Spread a thin even coat and apply pad

immediately. Apply pressure and position pad

making sure that there is no air entrapment.

NOTE: A serrated blade such as used for

laying down rubber floor tiles would be helpful.

6. Allow to cure overnight under low pressure at

normal room temperature.

FOR USE BY QUALIFIED PERSONNEL ONLY

Automatic Shut Off

Model 234 Plus

(234 Plus Controller P/N MPC90270 ; Rev. 6.27)

The Automatic Shut Off is designed to save

electrical consumption when the user is not

engaged in the usage of the Insta heat seal

machines.

By default, the timer for Automatic Shut Off is set

to 2 hours during activation and cannot be

changed. Any disturbances such as the key press,

or heat press cycle will reset the timer.

The timer for Automatic Shut Off will begin after

every key press or heat press cycle.

Automatic Shut Off

1. Turn on the machine by pressing POWER.

a) ONE beep indicates the Automatic

Shut Off is OFF.

b) TWO beeps indicates the Automatic

Shut Off is ON.

2. Press on the MODE once in order to display

the TIME SETTING.

3. With the TIME SETTING displayed, press and

hold the UP + DOWN ARROWS for 3 to 5

seconds.

a) ONE beep indicates the Automatic

Shut Off is OFF.

b) TWO beeps indicates the Automatic

Shut Off is ON.

4. Repeat step 3 in order to turn ON or OFF the

Automatic Shut Off.

X1

+

NOTE

The Automatic Shut Off feature

is activated.

7

FOR USE BY QUALIFIED PERSONNEL ONLY

Safety and Danger Zone Diagram

Hot Surface.

Avoid contact

with Upper Platen

Shroud and

Aluminum

Casting

Keep hands clear

Do not handle the

machinery with

wet hands

Machinery should

be operated

under a secure

flat surface

8

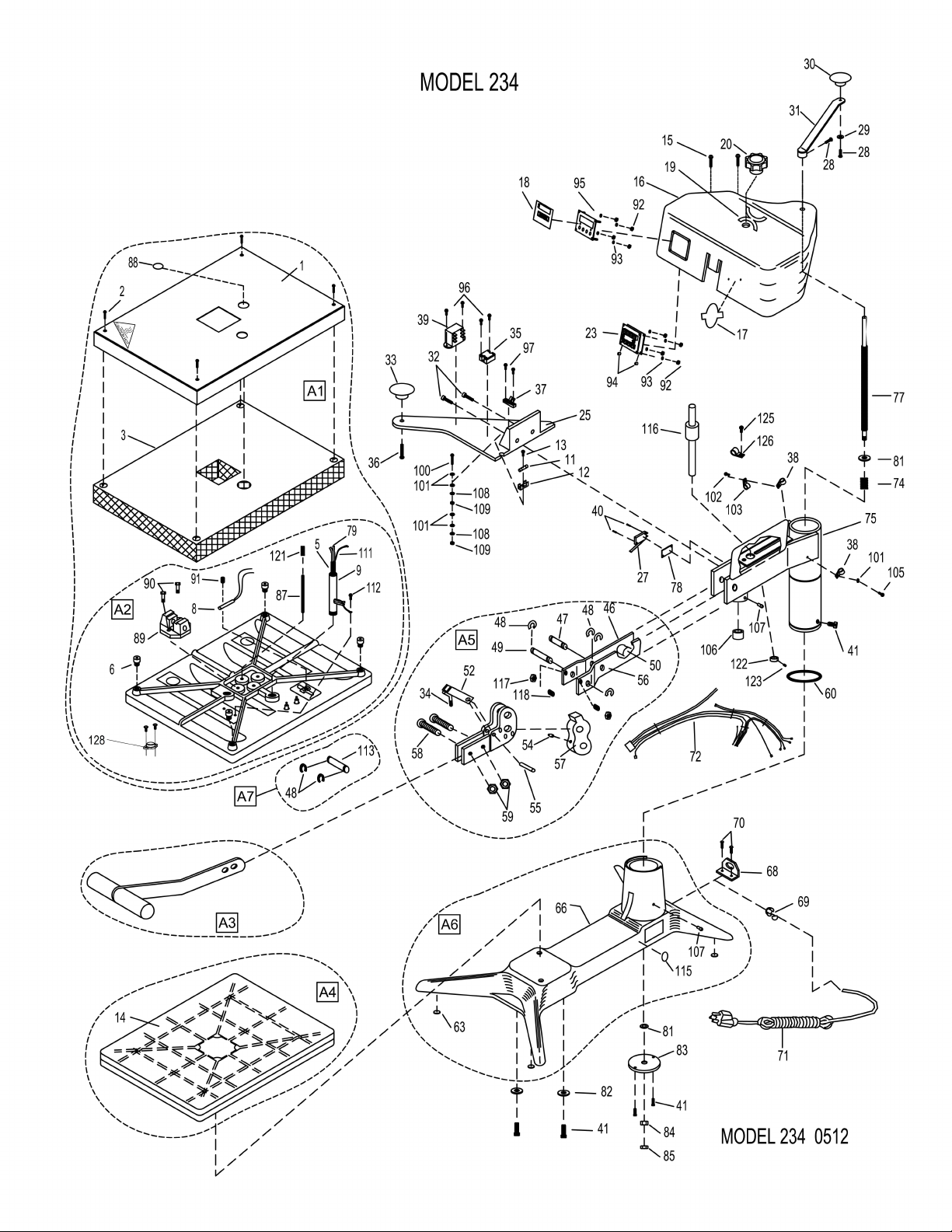

120V AC 230V AC

1SHROUD, HEAT MPSS228 MPSS228

2SCREW, PAN HD #10 x 1" LG PHIL SH METAL MPSS143 MPSS143

3INSULATION, FIBERGLASS MPI90158 MPI90158

5TUBING, SHRINK TFE AWG7 MPPS131 MPPS131

6INSULATORS, SPACER (4/SET) MPSI089 MPSI089

8SENSOR, TEMPERATURE MPPS210 MPPS210

9GUIDE POST MPSP084 MPSP084

11 FUSE (1 AMP, 250V) MPPF701R MPPF701R

12 FUSE HOLDER MPPF708 MPPF708

13 SCREW, PHILLIP PAN HEAD 2-56 x .25 LONG MHSP25614 MHSP25614

14 PAD, SILICONE RUBBER MPP031 MPP031

15 SCREW, PHILLIP PAN HEAD 10-24 x 0.5 LONG MHSP102412 MHSP102412

16 HOUSING, INSTRUMENT MPSH234P MPSH234P

17 TMT LOGO PLATE MPTMT234 MPTMT234

18 LABEL, OVERLA

Y

MPL90177 MPL90177

19 LABEL PRESSURE OVERLAY 234P MPL90442 MPL90442

20 KNOB, PRESSURE ADJUST MPPK018 MPPK018

23 CONTROLLER, DIGITAL MPC90270 MPC90270

25 HANDLE, SWING AWA

Y

MPH90002 MPH90002

27 SWITCH, MICRO MPPS043 MPPS043

28 SCREW, BUT HD 1/4-20 X .75" LG MHSB142034 MHSB142034

29 WASHER, SAE 1/4" MHWSAE14 MHWSAE14

30 KNOB, HANDLE (MUSHROOM) MPPK017 MPPK017

31 PRESSURE ADJUSTMENT CRANK ASSEMBL

Y

MPSP90322 MPSP90322

32 SCREW, SOCKET HD 1/4-20 x 0.50 LONG MHSSH142012 MHSSH142012

33 KNOB, MUSHROOM MPPK017 MPPK017

34 CAP, VINYL BLACK 5/16" x .281 LONG MPC90006 MPC90006

35 RELAY MPR90217 MPR90217

36 SCREW, BUTTON HD 1/4-20 x 0.875 LONG MHSB142078 MHSB142078

37 TERMINAL BLOCK MPB90006 MPB90006

38 CLAMP, CABLE 1/4 IN MHCC14 MHCC14

39

A

TRANSFORMER (USA MODEL) MPT90001 MPT90001

39B TRANSFORMER (EUROPEAN MODEL) MPT90319 MPT90319

40 SCREW, ROUND HEAD 4-40 x 0.625 LONG MHSR44058 MHSR44058

41 SCREW, SOCKET HD 5/16-18 x 1/2 LONG MHSSH5161812 MHSSH5161812

46 PRESSURE ADJUST LEVER (LH) MPSP2221 MPSP2221

47 PIN, PIVOT (LOWER) MPSP2211 MPSP2211

48 E-CLIPS MPSC240 MPSC240

49 PIN, CAM PIVOT (UPPER) MPSP262 MPSP262

50 NUT, PRESSURE ADJUSTMENT MPSP2209 MPSP2209

52 SAFETY LOC

K

MPSL240 MPSL240

54 FITTING, GREASE (SHORT) MPSF145 MPSF145

55 PIN, ROLL (SAFETY LOCK) MPSR141 MPSR141

56 PRESSURE ADJUST LEVER (RH) MPSP2220 MPSP2220

57 CAM MPSC220 MPSC220

58 SCREW, BUTTON HD 5/16-18 x 1.00 LONG MHSB516181 MHSB516181

59 NUT, HEX JAM 5/16-18 MHNHJ51618 MHNHJ51618

60 O'RING MPSS273 MPSS273

63 FEET, RUBBER (4/SET) MPF90004 MPF90004

66 BASE MPSB204 MPSB204

68 BRACKET, STRAIN RELIEF CORD MPSS163 MPSS163

69 STRAIN, RELIEF MPSS168 MPSS168

70 SCREW, PHILLIP PAN HEAD 10-32 x 0.375 LONG MHSP103238S MHSP103238S

MODEL VOLTAGE

P/N PART NAME

MODEL 234P 090216

120V AC 230V AC

71 POWER CORD (USA MODEL) MPPW141 MPPW142

71

A

POWER CORD (EUROPEAN MODEL) N/

A

MPPW202

71B POWER CORD (UK MODEL) N/

A

MPPW203

72 WIRE HARNESS MPW90361 MPW90361

74 SPRING, CAM MPSS201 MPSS201

75 POST, ARM ASSY 234P MPSP234P MPSP234P

77 SCREW, PRESSURE ADJUSTMENT MPSS070 MPSS070

78 INSULATION, MICRO SWITCH MH700214 MH700214

79 WIRE, HEATER MPPW700 MPPW700

81 WASHER, SAE 1/2" MHWSAE12 MHWSAE12

82 WASHER, CUT 5/16 I.D. MHWC516 MHWC516

83 PLATE, POST STOP MPSP20450 MPSP20450

84 NUT, JAM 1/2-20 MHNHJ1220 MHNHJ1220

85 NUT, JAM SELF-LOCKING 1/2-20 MHNHJSL1220 MHNHJSL1220

87 STUD THREADED 1/4-20 x 3.50 LONG MPS90277 MPS90277

88 PLUG, BUTTON 7/8 IN MPP90006 MPP90006

89 CLEVIS MPSP221 MPSP221

90 BOLT, HEX 5/16-18 X 1.0 IN LONG SS

T

MHBH516181S MHBH516181S

91 SCREW, SOCKET SET 3/8-16 x 0.5 IN MHSST381612 MHSST381612

92 NUT, HEX 6-32 MHNH632 MHNH632

93 WASHER, SHIM #6 (.031) MH311150019 MH311150019

94 SPACER, LONG NYLON 0.166 ID X 1/4 IN MH110969111 MH110969111

95 PLATE, CONTROLLER MPP90011 MPP90011

96 SCREW, PHILLIP PAN HEAD 8-32 x 0.25 IN MHSP83214 MHSP83214

97 SCREW, PHILLIP PAN HEAD 8-32 x 0.5 IN MHSP83212 MHSP83212

100 SCREW, PHILLIP PAN HEAD 8-32 x 1.0 IN MHSP8321 MHSP8321

101 WASHER, #8 SAE MHWSAE8 MHWSAE8

102 SCREW, SOCKET HEAD 1/4-20 x .50 IN MHSSH142012 MHSSH142012

103 CLAMP, CABLE METAL 3/8 IN. MHCC38 MHCC38

105 SCREW, PHILLIP PAN HEAD 8-32 x .375 IN MHSP83238 MHSP83238

106 BUSHING, GUIDE POST MPSB070 MPSB070

107 FITTING, GREASE (LONG) MPSF144 MPSF144

108 WASHER LOCK INT #8 MHWLIT8 MHWLIT8

109 NUT, HEX 8-32 MHNH832 MHNH832

111 GROUND WIRE MPW90125 MPW90125

112 SCREW, PHILLIP PAN 8-32 x 0.25 LG MHSP83214 MHSP83214

113 LUG PIN MPP0139 MPP0139

115 LABEL, ROHS/WEE MPL90175 MPL90175

116 PRESSURE ADJ SCREW MPS90295 MPS90295

117 NUT, HEX 3/8-1 MHNH3816 MHNH3816

118 DETENT, PLUNGER SPRING 3/8-16 MPSP134 MPSP134

121 SPRING, COMPRESSION MP290276 MP290276

122 LOCK NUT, PRESSURE ADJ MPSP247 MPSP247

123 SET SCREW 10-32 x 3/16 LONG MHSST1032316 MHSST1032316

125 SCREW, PHILLIP PAN HEAD 8-32 x 0.375 LONG MHSP83238 MHSP83238

126 CLAMP, CABLE METAL 1/2 IN MHCC12 MHCC12

127 SCREW, SOCKET HD 5/16-18 x 0.75 LONG MHSSHS161834 MHSSHS161834

128 HIGH TEMP LIMITER MH009-002 MH009-002

A

1PLATEN, HEAT ASS

Y

MPSP082 MPSP092

A

2PLATEN, UPPER (WIRING ONLY) MPSP090 MPSP091

A

3HANDLE, PRESSURE ASS'

Y

MPSH515 MPSH515

A

4PLATEN, LOWER ASS

Y

MPP90160 MPP90160

A

5CAM/PRESSURE LEVER ASS

Y

MPSC201 MPSC201

A

6BASE ASS

Y

MPSB234

A

MPSB234

A

A

7LUG PIN ASS

Y

MPP90141 MPP90141

A

8STUD, MICROSWITCH ACTIVATOR ASSY 234 MPS90358 MPS90358

P/N PART NAME MODEL VOLTAGE

MODEL 234P 090216

FOR USE BY QUALIFIED PERSONNEL ONLY

13

Notes:

FOR USE BY QUALIFIED PERSONNEL ONLY

14

13925 E. 166th St. • Cerritos, CA USA 90702 • (800) 421-6971 • Fax (562) 404-3010

Other Insta Power Tools manuals

Popular Power Tools manuals by other brands

Bosch

Bosch GRO 10,8 V-LI Original instructions

Stanley

Stanley FATMAX KFFMES340 Original instructions

CPS

CPS Pro-Set TLTWSAE Imperial Instructions for use

ISC

ISC RP280 Instructions for Installation/Set-up, Operation, and Maintenance

Ronix

Ronix RA-8016 Safety instructions

Enerpac

Enerpac W22000X Series instruction sheet