Insta 158P User manual

MODEL 158P

OPERATION AND MAINTENANCE MANUAL

MNL90158P Rev. E 03.11.15

1

FOR USE BY QUALIFIED PERSONNEL ONLY

Safety Summary

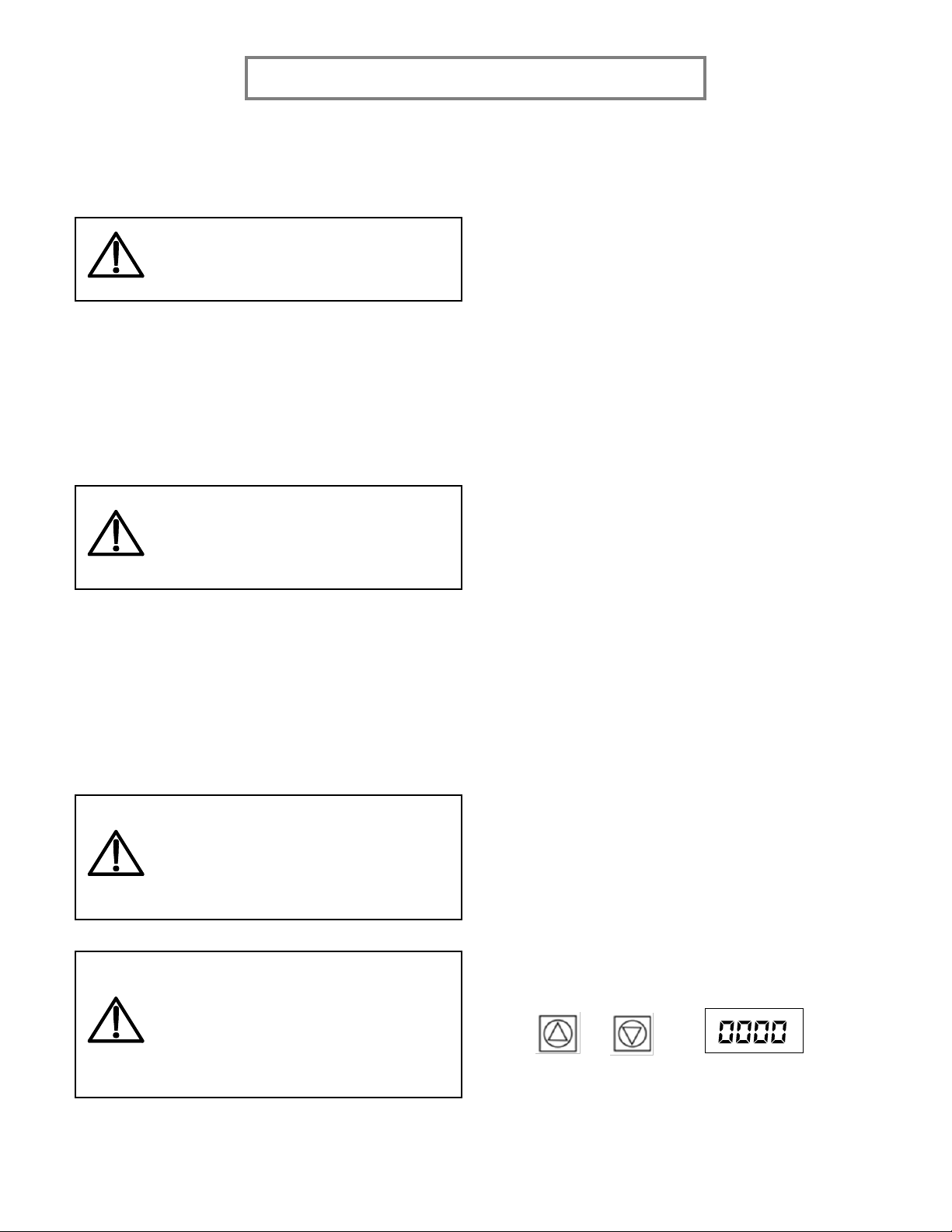

WARNING

In case of power cord damage, do not

attempt to repair or replace the power

cord. Contact the manufacturer or the

local distributor.

WARNING

This machine uses a fuse to protect

against fire and electric shock. When

replacing the fuse, use a fuse of the

same type that is rated for a maximum

1.5A, 250V.

WARNING

Hot surface. Avoid contact.

CAUTION

The machine is to be operated by one

person only.

CAUTION

To reduce the risk of electric shock and

injury to persons, turn the machine off

and disconnect the machine from the

power supply before servicing and/or

cleaning.

CAUTION

During normal operation, the base of

the machine must be installed or placed

above the wall socket on a level, stable

surface.

International Symbols

Power Off

Power On

Hot Surface

Risk of Electrical Shock

Protective Earth Terminal

Ground

Wet Conditions

Start Action

Caution –Warning

2

FOR USE BY QUALIFIED PERSONNEL ONLY

Congratulations!

Your selection of the Insta Graphic Systems heat

seal machine is a sound business decision. Insta

equipment is the result of the highest quality

engineering and time-tested design. Your new

machine, combined with Insta’s reputation for

innovation in the heat-sealing field, ensures that

you will be able to deliver the best-decorated

substrates possible for years to come.

This manual provides the installation, operation,

and maintenance procedures for your 158P series

machine, as well as easy to follow instructions for

on-the-spot maintenance.

Your model 158P machine will have a long, trouble-

free life. Read this manual. Keep it with your

machine; it’s your key to proper operation and

lasting service.

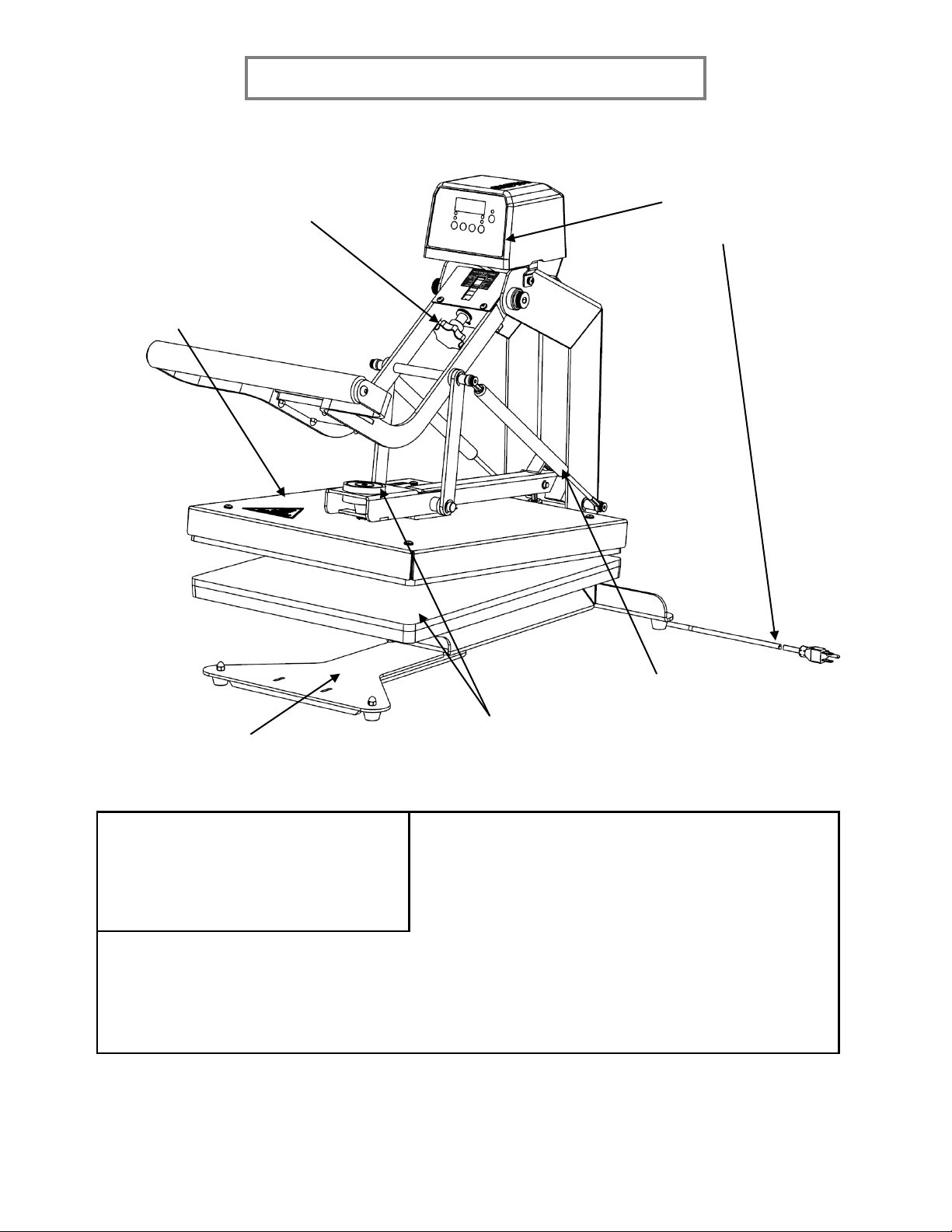

General Description

The 158P is a manual clamp-shell machine capable

of generating tremendous pressures that is evenly

distributed across the area of the 16’’ x 20’’ platen.

The 158P machine also features a smooth,

automatic opening to prevent ghosting, and a

redesigned base to provide improved garment

dressability. The heating platen features a cast-in

tubular heating element that is coiled as densely as

possible to deliver rapid heating and constant, long-

lasting and uniform temperatures.

Limited Machine Warranty

Insta Graphic Systems warrants this heat seal

machine, when operated under normal conditions,

to be free from manufacturing defects in material

and workmanship for a period of one (1) year on

parts (lifetime on the heating element) and 90 days

on labor from the invoice date.

This warranty will be effective only when Insta

authorizes the original purchaser to return the

product to the factory in Cerritos, California, freight

prepaid, and only when the product upon

examination has proven to be defective.

This warranty does not apply to any machine that

has been subjected to misuse, negligence, or has

been damaged accidentally or intentionally.

Insta shall not be liable for the injury, loss, or

damage, directly or indirectly, arising from the use

or the inability to use the product.

No claim of any kind shall be greater in amount

than the sale price of the product or part to which

claim is made.

This is the sole warranty given by the company, IGS,

and is in lieu of any other warranties, expressed or

implied, in law or in fact, including the warranties of

merchantability and fitness for a particular use, and

is accepted as such by the purchaser in taking

delivery of this product.

Please fill out the following for future use:

MODEL NO:

SERIAL NO:

MANUFACTURE DATE:

PURCHASE DATE:

PURCHASE VENDOR:

3

FOR USE BY QUALIFIED PERSONNEL ONLY

Installation

158P, S MODEL, 120 VAC

Use a separate 15 Amp AC circuit.

Only industrial extension cords with

proper wire size should be used: size

16/3 wire for distances up to 25

feet, and size 14/3 for distances up

to 50 feet.

158P, T, D, G MODEL, 230 VAC

Use a designated 16 Amp AC circuit.

Only industrial extension cords with

proper wire size (2.5 mm2) shall be

used.

IMPORTANT

The appliance must be plugged into

a proper receptacle of the proper

size and rating. Equally important,

the line voltage must be able to

accommodate this appliance as well

as other appliances operating on this

circuit.

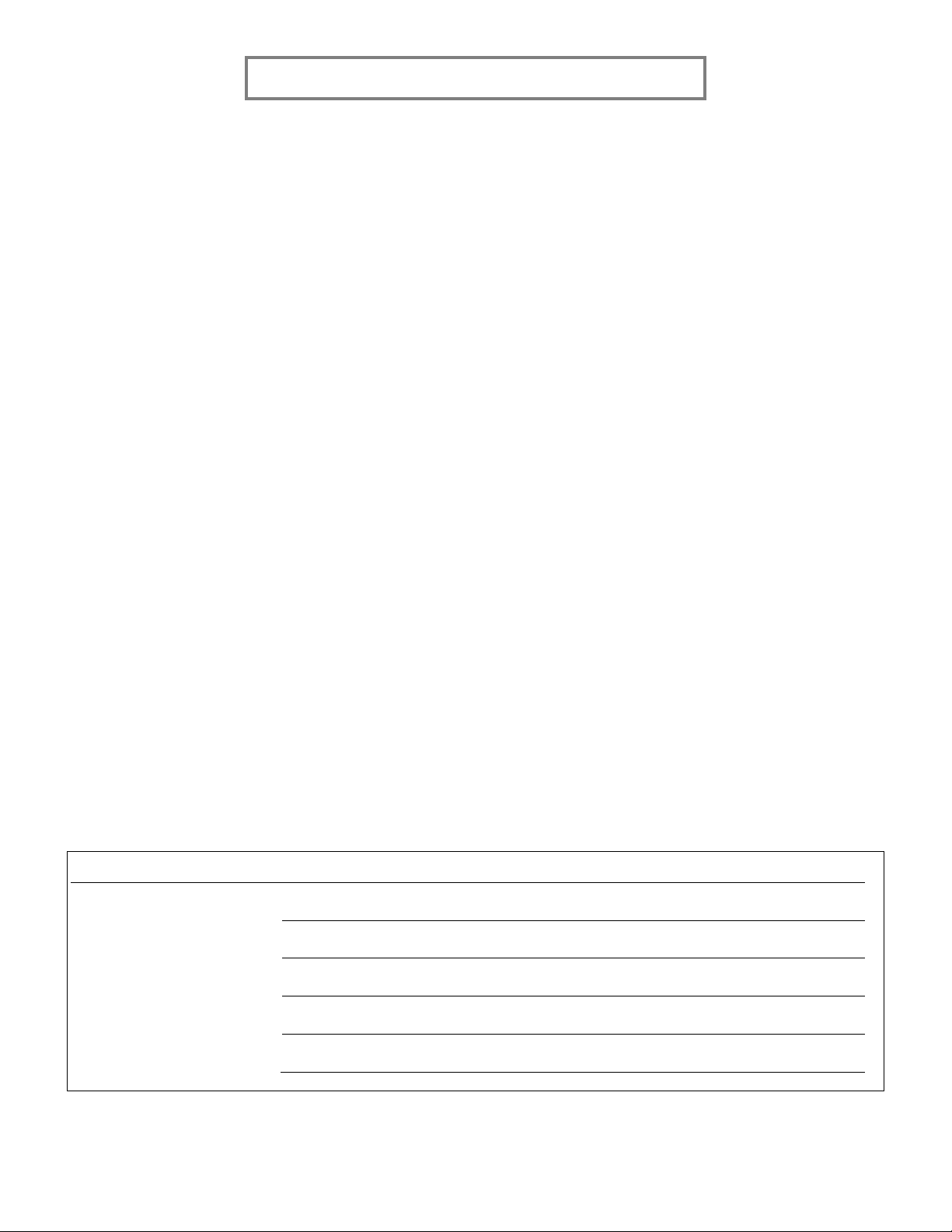

Specifications

Voltage

120 Volts AC

50/60 Hertz

Model 158P

(S)

1,750 Watts

14.6 Amps

Voltage

230 Volts AC

50/60 Hertz

Model 158P

(D, T, G)

2,200 Watts

9.6 Amps

Machine Weight

145 lbs

65.9 kg

Degree of Protection

The IP (Ingress Protection) rating of this machine

according to IEC 60529 is:

1st Digit

Protection from

solid objects

2nd Digit

Protection from

moisture

0

Not protected

0

Not protected

1

Objects greater

than 50 mm

1

Dripping water

2

Objects greater

than 12 mm

2

Dripping water

when tilted up

to 15°

3

Objects greater

than 2.5 mm

3

Spraying water

4

Objects greater

than 1 mm

4

Splashing water

5

Dust protected

5

Water jets

6

Dust tight

6

Heavy seas

--

---

7

0.15 m –1 m

immersion

--

---

8

+1 m

submersion

NOTE:

IEC 60529 does not specify sealing effectiveness against

the following: mechanical damage of the equipment; the

risk of explosion; certain types of liquid conditions, e.g.

those that are produced by condensation; corrosive

vapor; fungus; vermin.

4

FOR USE BY QUALIFIED PERSONNEL ONLY

Safety and Danger Zone Diagram

Do not handle machine

with wet hands or in a

wet environment.

Do not adjust the

pressure while the

upper platen is lowered

Do not grasp during

operation. Do not attempt

to remove while the upper

platen is down or hot.

Keep hands clear

during operation.

Machine should be operated

on a secure flat surface.

Hot surface. Avoid contact

with the platen shroud and

aluminum casting.

Operating Environment

3.

The workspace does not restrict access to the main

power switch or power cord.

To maximize user safety, ensure that the

following operating conditions are met:

4.

The workspace is free of any forms of liquid.

5.

The power cord is not over-extended.

1.

The machine is placed on an even,

non-flammable surface.

6.

The machine is connected to a surge protector.

Taking these steps is crucial in maximizing user

safety and ensuring a long, trouble free-life from

your machine!

2.

The surface can support a minimum

of 300 lbs.

5

FOR USE BY QUALIFIED PERSONNEL ONLY

Basic Machine Operation

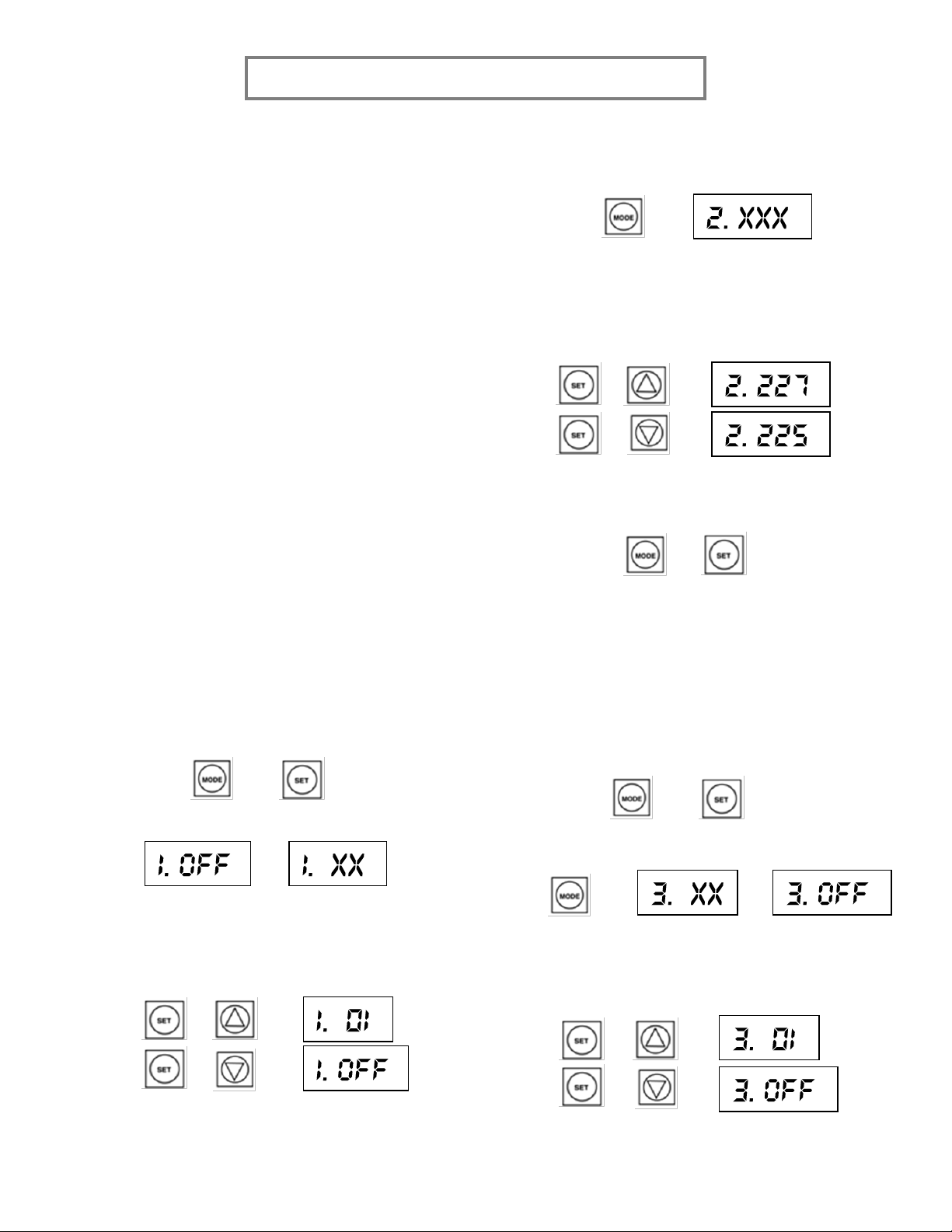

1. Press the POWER button on the controller to turn

the machine on.

2. Set your desired temperature:

a. Press MODE to cycle to the temperature display.

b. Hold SET and UP to increase the temperature.

+

OR

Hold SET and DOWN to decrease the temperature.

+

NOTE:

If the platen temperature is BELOW 225 °F OR 107 °C,

the controller will display “LO F” or “LO C” depending

on the units the controller is set to.

OR

3. Allow the machine to heat to the selected set

temperature.

NOTE:

Heating may take anywhere between 20 –

45 minutes depending on the set

temperature. Do not leave the machine

unattended during this time!

1

2

+

1

2

+

1

2

6

FOR USE BY QUALIFIED PERSONNEL ONLY

4. Set the desired pressure by adjusting the pressure

adjust wheel located on the handle assembly.

a. Turn the knob CLOCKWISE to DECREASE the

pressure.

b. Turn the knob COUNTER-CLOCKWISE to

INCREASE the pressure.

NOTE:

Increasing the pressure increases the force

required to close the platens. To avoid user

injury or damage to the machine, do not

attempt to force the platens closed at very

high pressure levels.

5. Set your desired timer duration.

a. Press MODE to cycle to the timer display.

b. Hold SET and UP to increase the timer duration.

+

OR

Hold SET and DOWN to decrease the timer duration.

+

OR

Less pressure

More pressure

1

1

1

2

2

2

+

+

7

FOR USE BY QUALIFIED PERSONNEL ONLY

Basic Operation (Continued)

6.

Place the substrate on the lower platen.

NOTE:

Attempting to press substrates thicker

than ¼’’ is not recommended.

7.

Position transfer or lettering on

substrate.

8.

Close the platens by pulling down the

handle with both hands until the magnet

activates.

NOTE:

Do not attempt to force the platens

closed. Doing so may result in user injury

or damage to the machine.

9.

The timer will start automatically when

the platens are closed. A buzzer will

sound when the timer reaches zero.

10.

The platens will automatically open when

the timer reaches zero. Remove the

substrate and transfer.

NOTE:

The buzzer will sound during the last

three (3) seconds of the time cycle to alert

the user that the machine will be

opening.

NOTE:

The sealing cycle can be stopped at any

time by pressing the MODE button on the

controller. The machine will automatically

end the sealing cycle and the platens will

disengage and open.

Controller Features

Basic Controller Functions

This controller has three (3) main control features:

1. Temperature –the temperature may be set

from 225 –425 °F (107 –218 °C).

2. Timer –the cycle timer may be set from 1

second to 99:59 minutes.

3. Cycle Counter –the cycle counter counts

the number of applications up to 9,999

cycles.

Temperature Control

The temperature control has a range from 225 –

425 °F, or 107 –218 °C. The temperature unit can

be switched between °F and °C, and a temperature

offset can be applied to adjust the temperature

reading (see advanced controller functions). For

setting the set temperature, see the basic

operations section.

Timer

The controller features an application timer that

controls when the machine automatically opens.

The timer display is in the minutes:seconds format,

and ranges from 00:00 to 99:59. When the timer is

running, the colons (:) will flash. For setting the

application timer, see the basic operations section.

Cycle Counter

The controller has a built-in cycle counter. To access

the counter, press the MODE button until the

counter is displayed. The counter display range is

from 0000 to 9999.

To reset the cycle counter, press and hold the UP

and DOWN buttons for three (3) seconds until the

counter resets to zero (0000).

+ →

8

FOR USE BY QUALIFIED PERSONNEL ONLY

Advanced Controller Functions

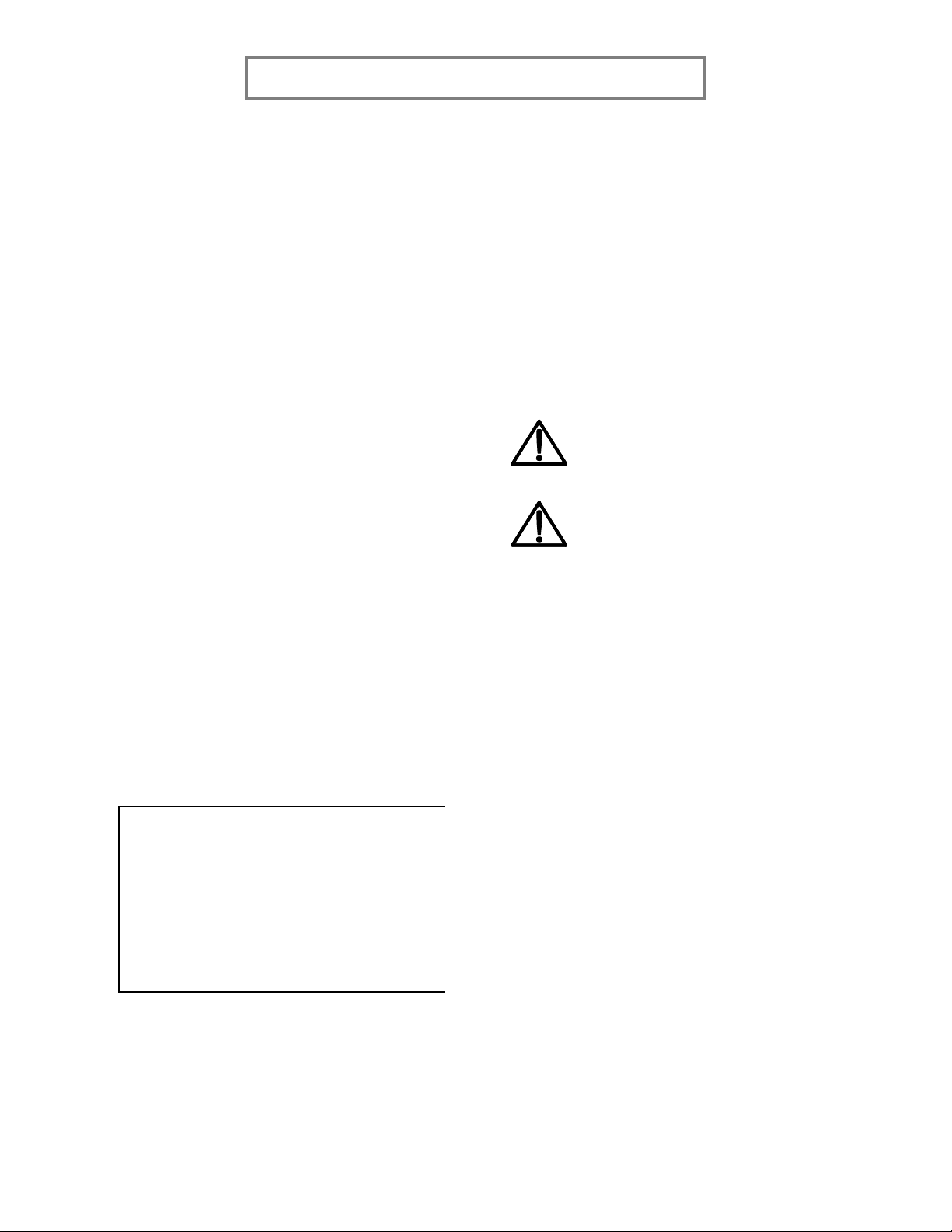

Sleep Mode and Automatic Shut Off

The sleep mode/automatic shut off functions are

designed to reduce electrical usage when the Insta

heat seal machine is idle. When active, any user

input such as key presses or starting a heat press

cycle will reset the timers for both sleep mode and

the automatic shut off.

Both the sleep mode and the automatic shut off can

be disabled. When the automatic shut off is

disabled, the sleep mode will hold until the machine

is interrupted. When only the sleep mode is

disabled, the automatic shut off timer will begin

after every key press or heat press cycle.

Configuring Sleep Mode

To configure sleep mode, the SLEEP TIME and the

SET BACK TEMPERATURE are set. The sleep time is

the time the machine is idle before it goes to sleep,

and the set back temperature is the temperature it

reverts to while asleep.

Setting Sleep Time

1. Cycle to the CYCLE COUNTER. Enter the

FACTORY MODE by pressing and holding

MODE and SET for 3 to 5 seconds.

+

2. The display should look like the following:

OR

Where XX is a number up to 99 minutes.

3. Press SET and UP to increase the sleep time.

Press SET and DOWN to decrease the sleep

time or disable sleep mode.

+ →

+ →

Setting the Set Back Temperature

1. After setting the sleep time, press MODE to

cycle to the set back temperature.

→

The display will show XXX, which is a

temperature from 225 –300 °F.

2. Press SET and UP to increase the set back

temperature, or press SET and DOWN to

decrease the set back temperature.

+ →

+ →

3. When the desired set back temperature has

been set, press and hold MODE and SET for

3 to 5 seconds to exit FACTORY MODE.

+

Setting the Automatic Shut Off

Like the sleep mode, the automatic shut off can be

set to OFF, or a time ranging from 1 minute to 99

minutes.

1. Cycle to the CYCLE COUNTER. Enter the

FACTORY MODE by pressing and holding

MODE and SET for 3 to 5 seconds.

+

2. Press MODE to cycle to the automatic shut

off.

→OR

3. Press SET and UP to increase the automatic

shut off timer. Press SET and DOWN to

decrease the timer or disable the automatic

shut off.

+ →

+ →

9

FOR USE BY QUALIFIED PERSONNEL ONLY

4. When the automatic shut off timer has

been set, exit the FACTORY MODE by

pressing and holding MODE and SET for 3 to

5 seconds.

+

Changing the Temperature Scale

1. Cycle to the CYCLE COUNTER. Enter the

FACTORY MODE by pressing and holding

MODE and SET for 3 to 5 seconds.

+

2. Press MODE to cycle to the temperature

scale selection.

→OR

3. If the display shows F, the controller is

currently set to Fahrenheit. If the display

shows C, then it is set to Celsius. Press SET

and UP or DOWN to switch between

Fahrenheit and Celsius.

+ OR

↔

4. When the desired temperature scale has

been selected, press and hold MODE and

SET for 3 to 5 seconds to exit the FACTORY

MODE.

+

Setting the Temperature Offset

1. Cycle to the CYCLE COUNTER. Enter the

FACTORY MODE by pressing and holding

MODE and SET for 3 to 5 seconds.

+

2. Press MODE to cycle to the temperature

offset.

→

3. XX is the current temperature offset. Press

SET and UP to increase the offset.

Increasing the offset will increase the

display temperature by the corresponding

amount.

+ →

→

Press SET and DOWN to decrease the

offset. Decreasing the offset will decrease

the display temperature by the

corresponding amount.

+ →

→

4. When the desired temperature offset has

been reached, press and hold MODE and

SET for 3 to 5 seconds to exit the FACTORY

MODE.

+

10

FOR USE BY QUALIFIED PERSONNEL ONLY

Preventive Maintenance Suggestions

Insta heat seal machines are relatively maintenance

free. For a long, trouble-free life, the following

preventive maintenance should be followed:

1. Clean the Teflon-coated heat platen

periodically with a piece of non-abrasive

cloth. Stubborn stains may be removed with

mineral spirits when the platen is cool. Take

care not to rub the Teflon coating off.

2. To prevent the substrates from becoming

soiled, periodically wipe the entire exterior

of the machine, including the platens, with

a clean rag. If necessary, use mineral spirits

for cleaning a cold machine. Since mineral

spirits are flammable, do not clean with

mineral spirits while the machine is hot.

3. Periodically lubricate the joints and pins of

the machine with a high-temperature, non-

melting grease (MPPL023).

4. Avoid pressing items such as buttons, pins,

snaps, or zippers that tend to cut the

silicone rubber pad or scratch the Teflon-

coated heat platen.

5. Periodically inspect the three air springs for

leaks, dents, and other forms of damage.

General Maintenance

It is recommended that you have the following

items available:

1. Flat head screw driver

2. Phillips head screw driver

3. Small adjustable wrench

4. Needle nose pliers with insulated handle

5. Set of metric Allen wrenches

6. Special high-temperature grease MPPL023

With the above items you should be able to

accomplish most repairs.

WARNING:

Power cord replacement should be from

the manufacturer only.

WARNING:

Do not attempt to remove the upper

platen alone.

Replacing the Silicone Pad

1. Make sure that the lower platen is cool.

Remove the lower platen from the machine

base.

2. Use a mild solvent such as mineral spirits

to clean the surface of the lower platen.

3. Both the silicone pad and lower platen must

be thoroughly dry and clean (wait at least

45 minutes after using the solvent) before

starting the bonding operation.

4. Use a tube of MPPC006 adhesive to bond

the silicone rubber pad to the lower platen.

Spread a thin and even coat over the lower

platen. Clear any adhesive from the ring of

air holes on the lower platen.

5. Quickly apply the silicone pad. Make sure

no air bubbles form.

6. Remove excess glue from the edges of the

platen. Flip the platen over, pad-down, and

allow it to cure for 24 hours at room

temperature.

NOTE:

Read and follow all instructions on the

adhesive package.

A putty knife or similar tool is

recommended for spreading the adhesive

evenly on the lower platen.

11

FOR USE BY QUALIFIED PERSONNEL ONLY

12

FOR USE BY QUALIFIED PERSONNEL ONLY

MODEL 158P

ITEM NO.

ASSEMBLY NO.

DESCRIPTION

PAGE NO.

A1

MB158P-001

BASE FRAME ASSEMBLY

13 - 14

A2

MB158P-003

HANDLE ASSEMBLY

15 - 16

A3

MB158P-005

PIVOT ARM ASSEMBLY

17

A4

MB158P-007

16 x 20 LOWER PLATEN ASSEMBLY

18

A5

MB158P-008

16 x 20 UPPER PLATEN ASSEMBLY

19 - 20

13

FOR USE BY QUALIFIED PERSONNEL ONLY

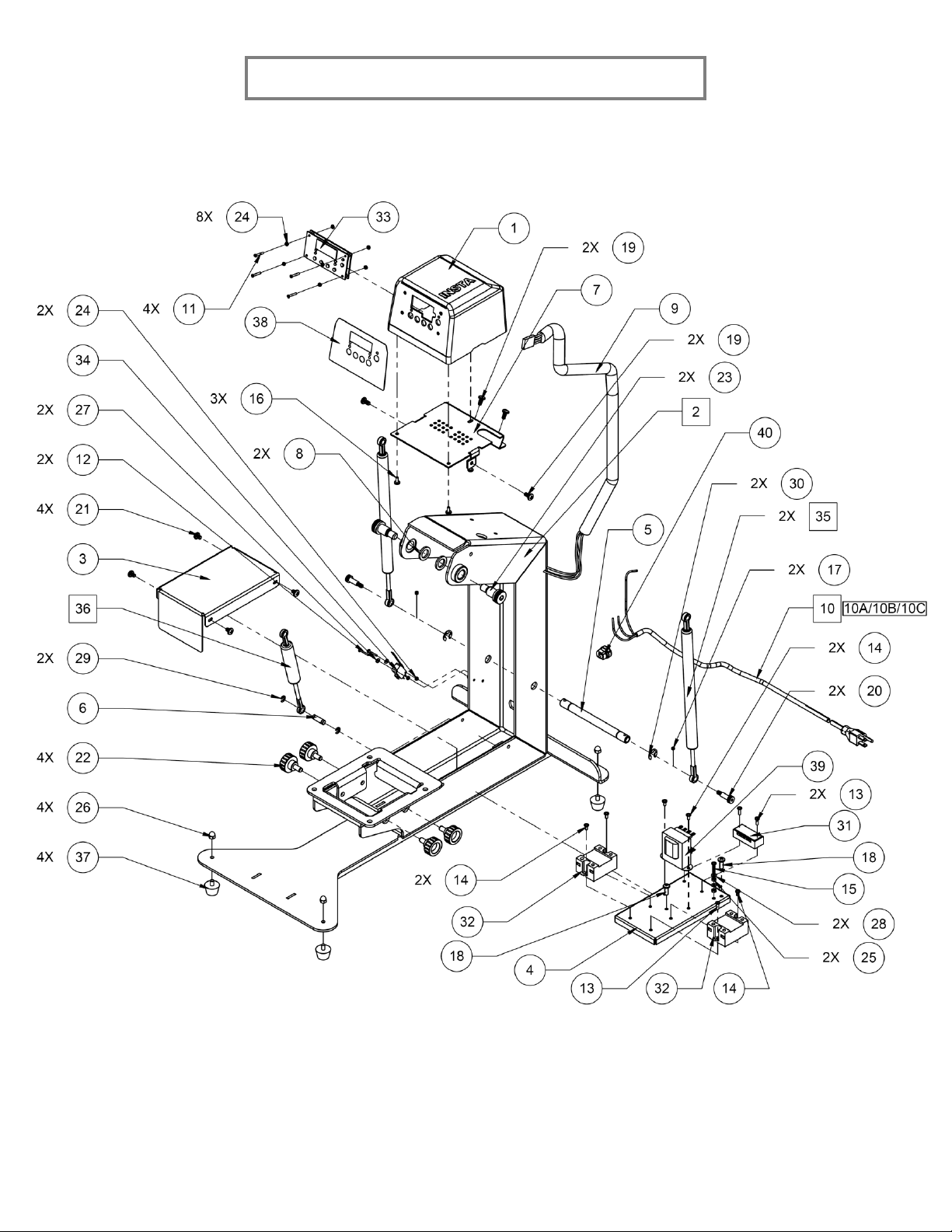

A1 –BASE FRAME ASSEMBLY

14

FOR USE BY QUALIFIED PERSONNEL ONLY

ITEM NO.

PART/ASSY NO.

DESCRIPTION

QTY

1

MP158P-001

PLASTIC HOUSING

1

2

MB158P-002

BASE FRAME, FORM

1

3

MP158P-003

COVER, ELEC. COMPONENTS

1

4

MP158P-004

ELECTRONIC MOUNTING PLATE

1

5

MP158P-005

BASE, PIN

1

6

MP158P-006

BASE, SPRING TAB ROD

1

7

MP158P-007

HOUSING BRACKET

1

8

MP158P-008

STEEL SHIM

2

9

MP158P-009

WIRE HARNESS, MS158P

1

10

MB201-047-S

POWER CABLE ASSY (120 V)

1

10A

MB201-047-T

POWER CABLE ASSY (230 V, EUROPE)

1

10B

MB201-047-D

POWER CABLE ASSY (230 V, US)

1

10C

MB201-047-G

POWER CABLE ASSY (230 V, UK)

1

11

MH001-M03-002

SCREW, FLAT HEAD, M3 x 0.5 x 20

4

12

MH001-M03-003

SCREW, PAN HEAD, M3 x 0.5 x 20

2

13

MH001-M04-001

SCREW, PAN HEAD, M4 x 0.7 x 12

3

14

MH001-M04-002

SCREW, PAN HEAD, M4 x 0.7 x 8

5

15

MH001-M04-003

SCREW, PAN HEAD, M4 x 0.7 x 20

1

16

MH001-M05-001

SCREW, PAN HEAD, M5 x 0.8 x 10

3

17

MH001-M05-004

SCREW, SET, M5 x 0.8 x 5

2

18

MH001-M06-001

SCREW, PAN HEAD, M6 x 1.0 x 16

2

19

MH001-M06-003

SCREW, PAN HEAD, M6 x 1.0 x 12

4

20

MH001-M06-005

SCREW, SHOULDER, SOCKET, M6 x 1 x 20/11

2

21

MH001-M06-010

SCREW, PAN HEAD, M6 x 1.0 x 8

4

22

MH001-M08-006

KNOB WITH FLUTED RIM

4

23

MH001-M12-001

SCREW, SHOULDER, HEX, M12 x 1.75 x 18

2

24

MH002-M03-001

NUT, HEX, M3 x 0.5

10

25

MH002-M04-001

NUT, HEX, M4 x 0.7

2

26

MH002-M06-002

NUT, ACORN, HEX, M6 x 1

4

27

MH003-M03-002

WASHER, FLAT, M3 x 1 x 8

2

28

MH003-M04-002

WASHER, FLAT, M4 x 0.7 x 9

2

29

MH003-M08-001

E-CLIP, RETAINING RING, M8

2

30

MH003-M14-001

E-CLIP, RETAINING RING, M14

2

31

MH004-001

TERMINAL BLOCK, 4 CONTACT

1

32

MH005-001

SOLID STATE RELAY

2

33

MH006-002

158P DIGITAL CONTROLLER

1

34

MH007-003

MICRO SWITCH

1

35

MH007-008

GAS SPRING, LONG

2

36

MH007-009

GAS SPRING, SHORT

1

37

MH007-010

RUBBER FOOTING

4

38

MH007-020

158P DECAL CONTROLLER

1

39

MPT90001

TRANSFORMER 12AC

1

15

FOR USE BY QUALIFIED PERSONNEL ONLY

A2 –HANDLE ASSEMBLY

16

FOR USE BY QUALIFIED PERSONNEL ONLY

ITEM NO.

PART/ASSY NO.

DESCRIPTION

QTY

40

MB158P-004

HANDLE ASSEMBLY, FORM

1

41

MP158P-024

HANDLE, MAGNET PLATE

1

42

MP158P-025

HANDLE BAR

1

43

MP158P-026

PRESSURE BAR

1

44

MP158P-027

PRESSURE PLATE

1

45

MP158P-028

HANDLE, PIN

1

46

MP158P-029

HANDLE, FOAM

1

47

MP158P-030

LINK

2

48

MP158P-031

PRESSURE BOLT

1

49

MP158P-032

PRESSURE DECAL

1

50

MP158P-033

PRESSURE SPACER

1

51

MP158P-034

STOP RING

1

52

MP158P-035

HANDLE, MAGNET SPACER

1

53

MH001-M05-007

SCREW, PAN HEAD, M5 x 0.8 x 20

4

54

MH001-M06-009

SCREW, SET, CONE POINT, M6 x 1 x 8

5

55

MH001-M08-002

SCREW, ROUND, M8 x 1.25 x 18

2

56

MH002-M05-002

NUT, HEX, ACORN, M5 x 0.8

4

57

MH003-M06-004

WASHER, FLAT, M6 x 1.6 x 18

1

58

MH003-M14-002

WASHER, EXTRA-THICK FLAT, M14

2

59

MH007-014

THRUST BEARING

2

60

MH007-011

PRESSURE ADJ. KNOB

1

16

MH001-M05-001

SCREW, PAN HEAD, M5 x 0.8 x 10

2

17

MH001-M05-004

SCREW, SET, M5 x 0.8 x 5

2

20

MH001-M06-005

SCREW, SHOULDER, SOCKET, M6 x 1 x 20/11

2

30

MH003-M14-001

E-CLIP, RETAINING RING, M14

2

17

FOR USE BY QUALIFIED PERSONNEL ONLY

A3 –PIVOT ARM ASSEMBLY

ITEM NO.

PART/ASSY NO.

DESCRIPTION

QTY

61

MB158P-006

PIVOT ARM, FORM

1

62

MP158P-044

PIN, PIVOT ARM

1

63

MP158P-045

BUMPER, PIVOT ARM

1

64

MP158P-046

PLASTIC WASHER

4

29

MH003-M08-001

E-CLIP, RETAINING RING, M8

4

18

FOR USE BY QUALIFIED PERSONNEL ONLY

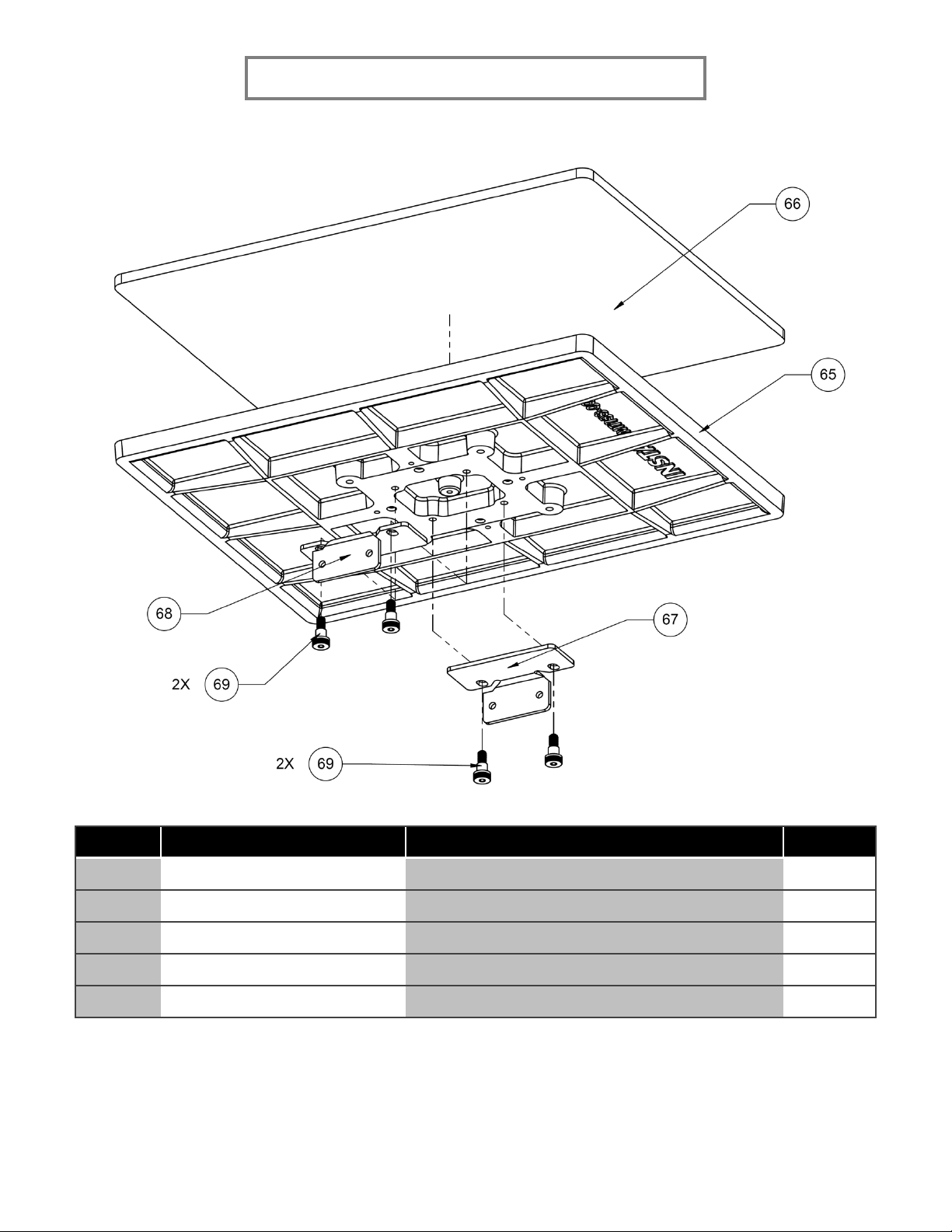

A4 –16 x 20 LOWER PLATEN ASSEMBLY

ITEM NO.

PART/ASSY NO.

DESCRIPTION

QTY

65

MT158-006

PLATEN, LOWER, 16 x 20

1

66

MH007-012

16 x 20 SILICONE PAD

1

67

MP158P-073L

PLATEN MOUNTING BRACKET, LEFT

1

68

MP158P-073R

PLATEN MOUNTING BRACKET, RIGHT

1

69

MH001-M08-003

SCREW, SHOULDER, HEX, M8 x 1.25 x 10/13

4

19

FOR USE BY QUALIFIED PERSONNEL ONLY

A5 –16 x 20 UPPER PLATEN ASSEMBLY

Table of contents

Other Insta Power Tools manuals

Popular Power Tools manuals by other brands

Worcraft PROFESSIONAL

Worcraft PROFESSIONAL CAC-S20LiA instruction manual

KUDOS

KUDOS HYCP-4413 SAFE OPERATION & MAINTENANCE INSTRUCTIONS

Avdel

Avdel 07572 instruction manual

Bosch

Bosch GSA 18 V-LI Professional Original instructions

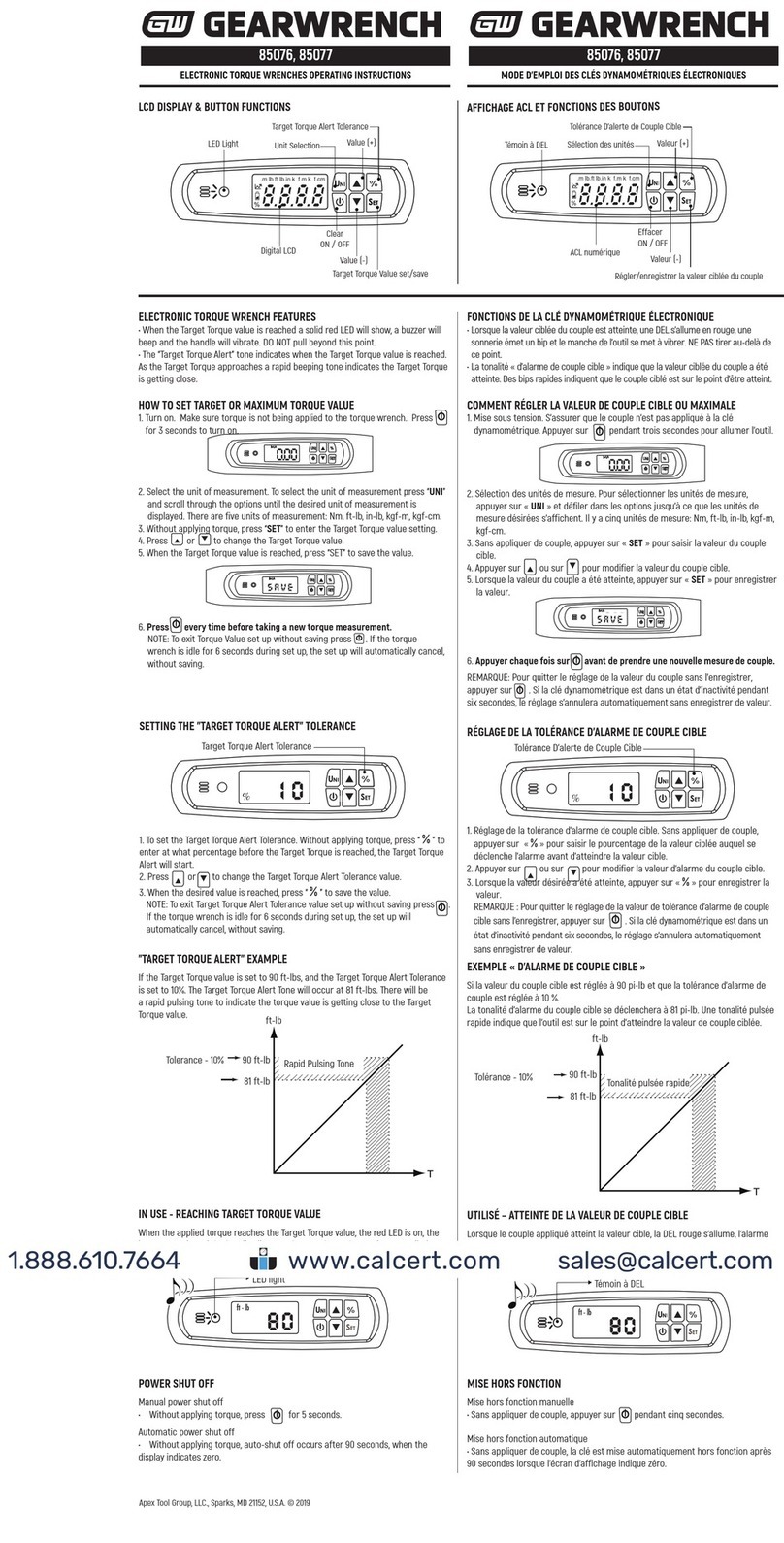

Gearwrench

Gearwrench 85076 operating instructions

Desontter

Desontter CP4444-1 manual