Insta 256 Series User manual

MODEL

256

OPERATION AND MAINTENANCE MANUAL

MNL90

256 Rev.

E

12.08

.17

1

FOR USE BY QUALIFIED PERSONNEL ONLY

Safety Summary

WARNIN

In case of power cord damage, do no

a emp o repair or replace he power

cord. Con ac he manufac urer or he

local dis ribu or.

WARNIN

Ho surface. Avoid con ac .

CAUTION

The machine is o be opera ed by one

person only.

CAUTION

To reduce he risk of elec ric shock and

injury o persons, urn he machine off

and disconnec he machine from he

power supply before servicing and/or

cleaning.

CAUTION

During normal opera ion, he base of

he machine mus be ins alled or placed

above he wall socke on a level, s able

surface.

NOTE

This machine uses a circui breaker o

pro ec agains fire and elec ric shock.

CAUTION

Do no lean on he machine when he

lower pla en is removed. Care mus be

aken o preven machine from ipping

over. Keep upper pla en close o he

cen er posi ion.

International Symbols

Power Off

Power On

Hot Surface

Risk of Electrical Shock

Protective Earth Terminal

round

Wet Conditions

Start Action

Caution – Warning

2

FOR USE BY QUALIFIED PERSONNEL ONLY

Congratulations!

Your selec ion of he Ins a Graphic Sys ems hea

seal machine is a sound business decision. Ins a

equipmen is he resul of he highes quali y

engineering and ime- es ed design. Your new

machine, combined wi h Ins a’s repu a ion for

innova ion in he hea -sealing field, ensures ha

you will be able o deliver he bes -decora ed

subs ra es possible for years o come.

This manual provides he ins alla ion, opera ion,

and main enance procedures for your 256 series

machine, as well as easy o follow ins ruc ions for

on- he-spo main enance.

Your model 256 machine will have a long, rouble-

free life. Read his manual. Keep i wi h your

machine; i ’s your key o proper opera ion and

las ing service.

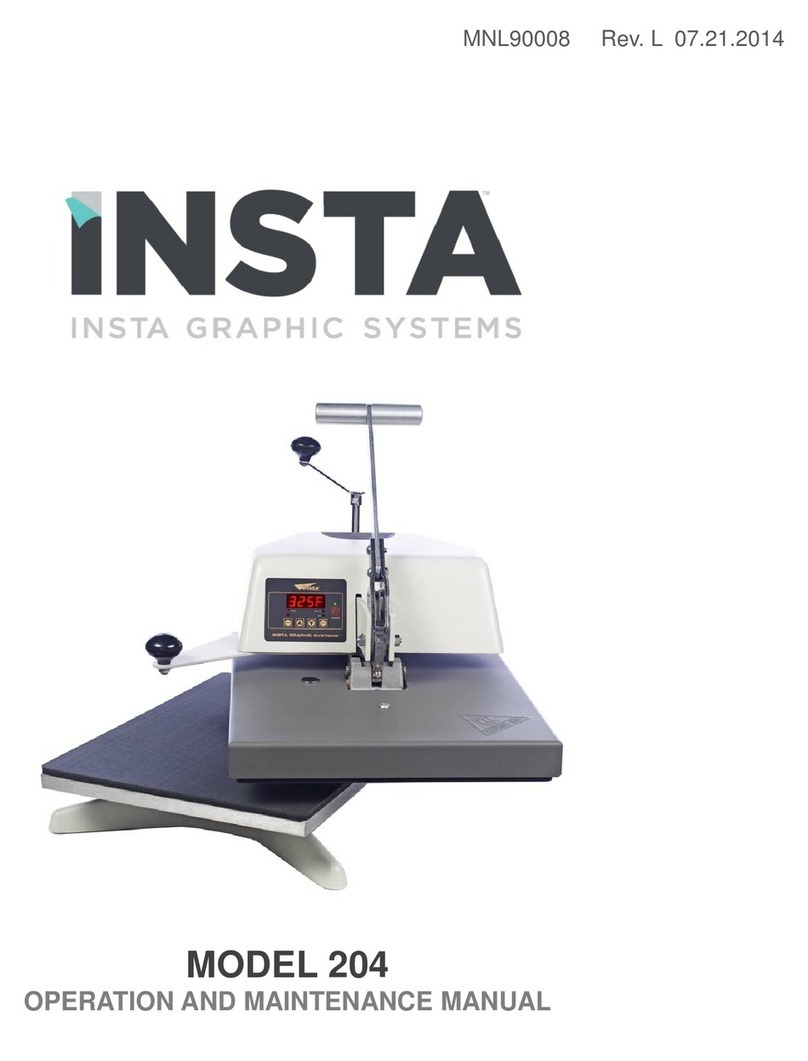

eneral Description

The 256 is a manual swing-away machine capable of

genera ing remendous pressure ha is evenly

dis ribu ed across he area of he 16’’ x 20’’ pla en.

The 256 machine also fea ures a quick-change

mechanism in he lower pla en allowing he lower

pla en o be swi ched or ro a ed in a ma er of

seconds. The hea ing pla en fea ures a cas -in

ubular hea ing elemen ha is densely coiled o

deliver rapid hea ing and cons an , long-las ing and

uniform empera ures.

Limited Machine Warranty

Ins a Graphic Sys ems warran s his hea seal

machine, when opera ed under normal condi ions,

o be free from manufac uring defec s in ma erial

and workmanship for a period of one (1) year on

par s (life ime on he hea ing elemen ) and 90 days

on labor from he invoice da e.

This warran y will be effec ive only when Ins a

au horizes he original purchaser o re urn he

produc o he fac ory in Cerri os, California, freigh

prepaid, and only when he produc upon

examina ion has proven o be defec ive.

This warran y does no apply o any machine ha

has been subjec ed o misuse, negligence, or has

been damaged acciden ally or in en ionally.

Ins a shall no be liable for he injury, loss, or

damage, direc ly or indirec ly, arising from he use

or he inabili y o use he produc .

No claim of any kind shall be grea er in amoun

han he sale price of he produc or par o which

claim is made.

See ex ended warran y informa ion on pg. 21.

Please fill out the following for future use:

MODEL NO:

SERIAL NO:

MANUFACTURE DATE:

PURCHASE DATE:

PURCHASE VENDOR:

3

FOR USE BY QUALIFIED PERSONNEL ONLY

Installation

256-S MODEL, 120 VOLT

Use a separate 15 Amp AC circui .

Only indus rial ex ension cords wi h

proper wire size should be used: size

16/3 wire for dis ances up o 25

fee , and size 14/3 for dis ances up

o 50 fee .

256-N MODEL, 230 VOLT

Use a designated 12 Amp AC circui .

Only indus rial ex ension cords wi h

proper wire size (2.5 mm

2

) shall be

used.

IMPORTANT

The appliance mus be plugged in o

a proper recep acle of he proper

size and ra ing. Equally impor an ,

he line vol age mus be able o

accommoda e his appliance as well

as other appliances operating on this

circuit.

Specifications

Vol age

120 Volts AC

50/60 Her z

Model

256

-

S

120 V

1750 Wa s

14.6 Amps

Vol age

230 Volts AC

50/60 Her z

Model

256

-

N

230 V

2200 Wa s

9.6 Amps

Machine Weigh

(Dry) 107 lbs 48.5 kg

Shipping Weigh

(Dry) 122 lbs 55.3 kg

Degree of Protection

The IP (Ingress Pro ec ion) ra ing of his machine

according o IEC 60529 is:

IP54 = IP

1

s

Digi = 5 (Dus Pro ec ed)

2

nd

Digi = 4 (Splashing Wa er)

1

s

Digi Pro ec ion from

solid objec s 2

nd

Digi Pro ec ion from

mois ure

0 No pro ec ed 0 No pro ec ed

1 Objec s grea er

han 50 mm 1 Dripping wa er

2 Objec s grea er

han 12 mm 2

Dripping wa er

when il ed up

o 15°

3 Objec s grea er

han 2.5 mm 3 Spraying wa er

4 Objec s grea er

han 1 mm 4 Splashing wa er

5 Dus pro ec ed 5 Wa er je s

6 Dus igh 6 Heavy seas

-- --- 7 0.15 m – 1 m

immersion

-- --- 8 +1 m

submersion

NOTE:

IEC 60529 does not specify sealing effectiveness against

the following: mechanical damage of the e uipment; the

risk of explosion; certain types of li uid conditions, e.g.

those that are produced by condensation; corrosive

vapor; fungus; vermin.

4

FOR USE BY QUALIFIED PERSONNEL ONLY

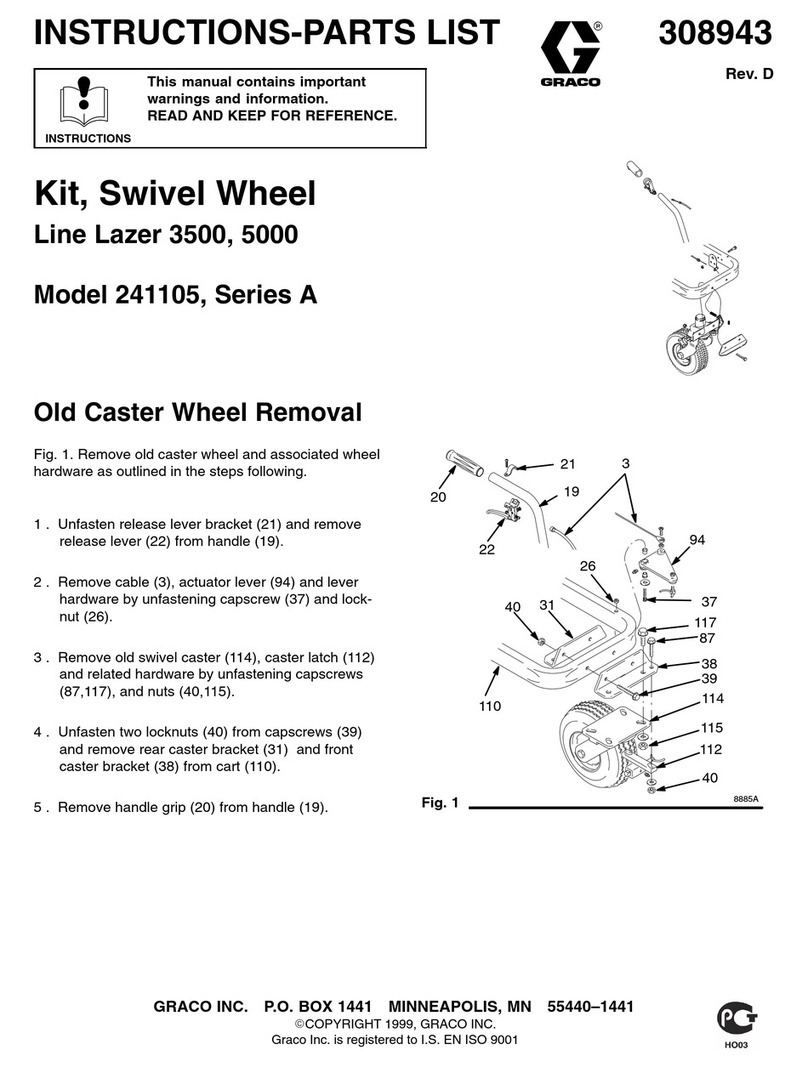

Safety and Danger Zone Diagram

Operating Environment

To maximize user safe y, ensure ha he

following opera ing condi ions are me :

3. The surface can suppor a minimum of 300 lbs (136

kg).

4. The workspace does no res ric access o he main

power swi ch or power cord.

5. The workspace is free of any forms of liquid.

6. The power cord is no overex ended.

7. The machine is connec ed o a surge pro ec or.

Taking hese s eps is crucial in maximizing user

safe y and ensuring a long, rouble-free life for your

machine!

1.

Af er unpacking he machine, ro a e he

pressure crank handle (loca ed behind

he op housing) clockwise o release he

pla en pressure.

2. The machine is placed on an even, non-

flammable surface.

Do no handle he

machinery wi h

we hands

This is a ho surface.

Avoid con ac wi h

upper pla en shroud

Keep hands clear

be ween he upper

and lower pla ens

Machinery should be

opera ed on a secure

fla surface

Do no disable safe y

lock during normal

opera ion

Always place

handle in he

full back posi ion when

machine is no in opera ion

5

FOR USE BY QUALIFIED PERSONNEL ONLY

Configuring Your Machine

Once you have correc ly ins alled

your machine

will wan o configure he se ings of your machine

o ma ch your needs.

1.

Turn the machine on

Plug

your machine

in

,

urn

power swi ch on,

and press he

bu on on he con rol panel

.

The display will briefly show he

c

on roller program revision number.

2.

Set the operating

T

emperature

a.

If he empera ure is no shown, press

MODE

o cycle o he empera ure

display.

NOTE

:

If the platen temperature is BELOW 2

25

°C, the controller will display “Lo F

” or

depending on the units the controller is set to.

b.

Press

SET

o display he curren se

empera ure.

To raise he empera ure, hold

UP.

+

To decrease he empera ure, hold

and DOWN.

+

3.

ive the machine time to heat

FOR USE BY QUALIFIED PERSONNEL ONLY

your machine

, you

will wan o configure he se ings of your machine

urn

he

main

and press he

POWER

.

The display will briefly show he

on roller program revision number.

emperature

If he empera ure is no shown, press

o cycle o he empera ure

25

°F OR 107

” or

“Lo C”

depending on the units the controller is set to.

o display he curren se

To raise he empera ure, hold

SET and

To decrease he empera ure, hold

SET

ive the machine time to heat

NOTE:

Heating may take between 20

minutes depending on the set

temperature. Do not leave the

machine unattended during this time!

2

1

2

+

2

2

+

Heating may take between 20

to 45

minutes depending on the set

temperature. Do not leave the

machine unattended during this time!

1

1

1

6

FOR USE BY QUALIFIED PERSONNEL ONLY

4.

Set the desired

P

ressure

Adjus he pressure

crank handle

behind he op housing.

a.

Turn he

crank

CLOCKWISE

o

he pressure.

b.

Turn he

crank

COUNTER

-

CLOCKWISE

INCREASE he pressure.

NOTE:

In

creasing the pressure increases the

force re uired to close the platens. To

avoid user injury or damage to the

machine, do not attempt to force the

platens closed at very high pressure

levels.

5.

Set the

A

pplication time

a.

Press

MODE

o cycle o he

ime display.

b.

Press

SET

o display he

applica ion ime.

To increase he applica ion ime, hold

SET and UP.

+

To decrease he applica ion ime, hold

SET and DOWN.

+

NOTE:

When lifting the handle, there might

be a popping noise. This is normal and

is caused by suction created between

the platen surfaces. During r

transfers, the noise will diminish.

FOR USE BY QUALIFIED PERSONNEL ONLY

crank handle

loca ed

o

DECREASE

CLOCKWISE

o

creasing the pressure increases the

force re uired to close the platens. To

avoid user injury or damage to the

machine, do not attempt to force the

platens closed at very high pressure

ime display.

applica ion ime.

To increase he applica ion ime, hold

To decrease he applica ion ime, hold

Increase pressure

When lifting the handle, there might

be a popping noise. This is normal and

is caused by suction created between

the platen surfaces. During r

egular

transfers, the noise will diminish.

2

1

2

+

2

+

Decrease pressure

1

1

7

FOR USE BY QUALIFIED PERSONNEL ONLY

Basic Operation

1.

Swing he

upper pla en

o he ri

gh using

he s ainless s eel handle.

2.

Place he subs ra e on he lower pla en.

3.

Posi ion he ransfer or le ering on he

subs ra e.

4

.

Swing he

upper pla en

bac

k using he

s ainless s eel handle.

5

.

Close he pla ens by pulling he handle

down wi h bo h hands un il he machine

self-locks.

NOTE:

Do not attempt to force the platens

closed. Doing so may result in user

injury or damage to the machine.

6

.

The imer will s ar au oma ically when

he pla ens are closed. A buzzer will

sound when he imer reaches zero.

7

.

Release he handle lock and

bring

he

handle up comple ely o he back o keep

he pla en raised. Swing away he upper

assembly and remove he subs ra e.

WARNIN

:

Use only the stainless steel handle to

swing the upper platen open and

closed. Do not push or pull the upper

platen to swing the top assembly.

WARNIN :

When replacing the lower platen, raise

up and keep the upper platen close to

the center position. Do not lean on

machine to prevent tipping over.

Controller Features

Basic Controller Functions

This con roller has wo (2) main con rol fea ures:

1. Temperature – he empera ure may be se

from 225 – 425 °F (107 – 218 °C).

2. Timer – he cycle imer may be se from 1

second o 99:00 minu es.

Temperature Control

The empera ure con rol has a range from 225 –

425 °F (107 – 218 °C). The empera ure uni can be

swi ched be ween °F and °C, and a empera ure

offse can be applied o adjus he empera ure

reading (see advanced controller functions on pg.8).

For se ing he se empera ure, see Configuring

your Machine on pg. 5.

Timer

The con roller fea ures an applica ion imer ha will

coun down and will s ar beeping when he imer

has reached 0. The ime display is in he

minu es:seconds forma , and ranges from 00:00 o

99:00. When he imer is running, he colons (:) will

flash. For se ing he applica ion imer, see he basic

opera ions sec ion.

8

FOR USE BY QUALIFIED PERSONNEL ONLY

Advanced Con roller Func ions

Automatic Shut Off

The au oma ic shu off func ion is designed o

reduce elec rical usage

when he Ins a hea seal

machine is idle. When ac ive, any user inpu such as

key presses or s ar ing a hea press cycle will rese

he imer for he au oma ic shu off.

The au oma ic shu off has a non-

adjustable timer

of 2 hours. By defaul , he au oma i

c shu off is

Setting the Automatic Shut Off

The au oma ic shu off can be se o

ON

1. Press MODE o cycle o he

TIMER.

→

2. Press and hold UP and DOWN

for 3 o 5

seconds o urn he au oma ic shu off

or OFF.

a. ONE

beep indica es ha he

au oma ic shu off is

OFF

b. TWO beeps indica e

ha he

au oma ic shu off is

ON

Changing the Temperature Scale

1. Press MODE o cycle o he

TEMPERATURE

→

2. Press and hold UP and

DOWN

seconds o swi ch he empera ure scale.

+ →

Setting the Temperature Offset

1.

Swi ch he empera ure scale o Fahrenhei .

2.

Le he pla en empera ure s abilize. Use a

hea -reading ool such as a

pyrome er

empera ure s rips o find he empera ure

FOR USE BY QUALIFIED PERSONNEL ONLY

The au oma ic shu off func ion is designed o

when he Ins a hea seal

machine is idle. When ac ive, any user inpu such as

key presses or s ar ing a hea press cycle will rese

adjustable timer

c shu off is

on.

ON

or OFF.

TIMER.

for 3 o 5

seconds o urn he au oma ic shu off

ON

beep indica es ha he

OFF

.

ha he

ON

.

Changing the Temperature Scale

TEMPERATURE

.

DOWN

for 3 o 5

seconds o swi ch he empera ure scale.

Swi ch he empera ure scale o Fahrenhei .

Le he pla en empera ure s abilize. Use a

pyrome er

or

empera ure s rips o find he empera ure

a he cen er of he pla en.

3. En er he

empera ure offse adjus

pressing and holding

MODE

5 seconds.

+

→

4.

XX is he curren empera ure offse . Press

SET and UP

o increase he offse .

Increasing he offse will increase he

display empera ure by he corresponding

amoun .

+

→

→

Press SET and DOWN

of

fse . Decreasing he offse will decrease

he display empera ure by he

corresponding amoun .

+

→

→

5.

Change he offse so ha he display

empera ure ma ches he empera ure

measured in s ep 1.

6.

When he desired empera

been reached, press and hold

SET

for 3 o 5 seconds o exi

+

NOTE:

For the best accuracy, it is suggested

that the temperature offset adjustment

be done in the Fahrenheit scale.

a he cen er of he pla en.

empera ure offse adjus

by

MODE

and SET for 3 o

→

XX is he curren empera ure offse . Press

o increase he offse .

Increasing he offse will increase he

display empera ure by he corresponding

→

o decrease he

fse . Decreasing he offse will decrease

he display empera ure by he

corresponding amoun .

→

Change he offse so ha he display

empera ure ma ches he empera ure

When he desired empera

ure offse has

been reached, press and hold

MODE and

for 3 o 5 seconds o exi

.

For the best accuracy, it is suggested

that the temperature offset adjustment

be done in the Fahrenheit scale.

9

FOR USE BY QUALIFIED PERSONNEL ONLY

Preventive Maintenance Suggestions

Ins a hea seal machines are rela ively main enance

free. For a long, rouble-free life, he following

preven ive main enance should be followed:

1. Clean he Teflon-coa ed upper pla en

periodically wi h a piece of non-abrasive

clo h. S ubborn s ains may be removed wi h

mineral spiri s when he pla en is cool. Take

care no o rub he Teflon coa ing off.

2. To preven he subs ra es from becoming

soiled, periodically wipe he en ire ex erior

of he machine, including he pla ens, wi h

a clean rag. If necessary, use mineral spiri s

for cleaning a cold machine. Since mineral

spiri s are flammable, do no clean wi h

mineral spiri s while he machine is ho .

3. Periodically lubrica e he join s and pins of

he machine wi h a high- empera ure, non-

mel ing grease (MPPL023). Poin s of

lubrica ion are illus ra ed in he nex page.

4. Avoid direc ly pressing i ems such as

bu ons, pins, snaps, or zippers ha end o

cu he silicone rubber pad or scra ch he

Teflon-coa ed hea pla en.

eneral Maintenance

I is recommended ha you have he following

i ems available:

1. Phillips head screw driver

2. Needle nose pliers wi h insula ed handle

3. Se of me ric Allen wrenches

4. Special mul i-purpose grease MPPL023

Wi h he above i ems you should be able o

perform mos general main enance and repairs.

WARNIN :

Do not attempt to remove the upper

platen alone.

Replacing the Silicone Pad

1. Make sure ha he lower pla en is cool.

Remove he lower pla en from he machine

base.

2. Use a mild solvent such as mineral spirits

o clean he surface of he lower pla en.

3. Bo h he silicone pad and lower pla en mus

be horoughly dry and clean (wai a leas

45 minu es af er using he solven ) before

s ar ing he bonding opera ion.

4. Use a ube of MPPC006 adhesive o bond

he silicone rubber pad o he lower pla en.

Spread a hin and even coa over he lower

pla en. Clear any adhesive from he side

edges of he lower pla en.

5. Quickly apply he silicone pad. Make sure

no air bubbles form.

6. Remove excess glue from he edges of he

pla en. Flip he pla en over, pad-down, and

allow i o cure for 24 hours a room

empera ure.

NOTE:

Read and follow all instructions on the

adhesive package.

A putty knife or similar tool is

recommended for spreading the adhesive

evenly on the lower platen.

10

FOR USE BY QUALIFIED PERSONNEL ONLY

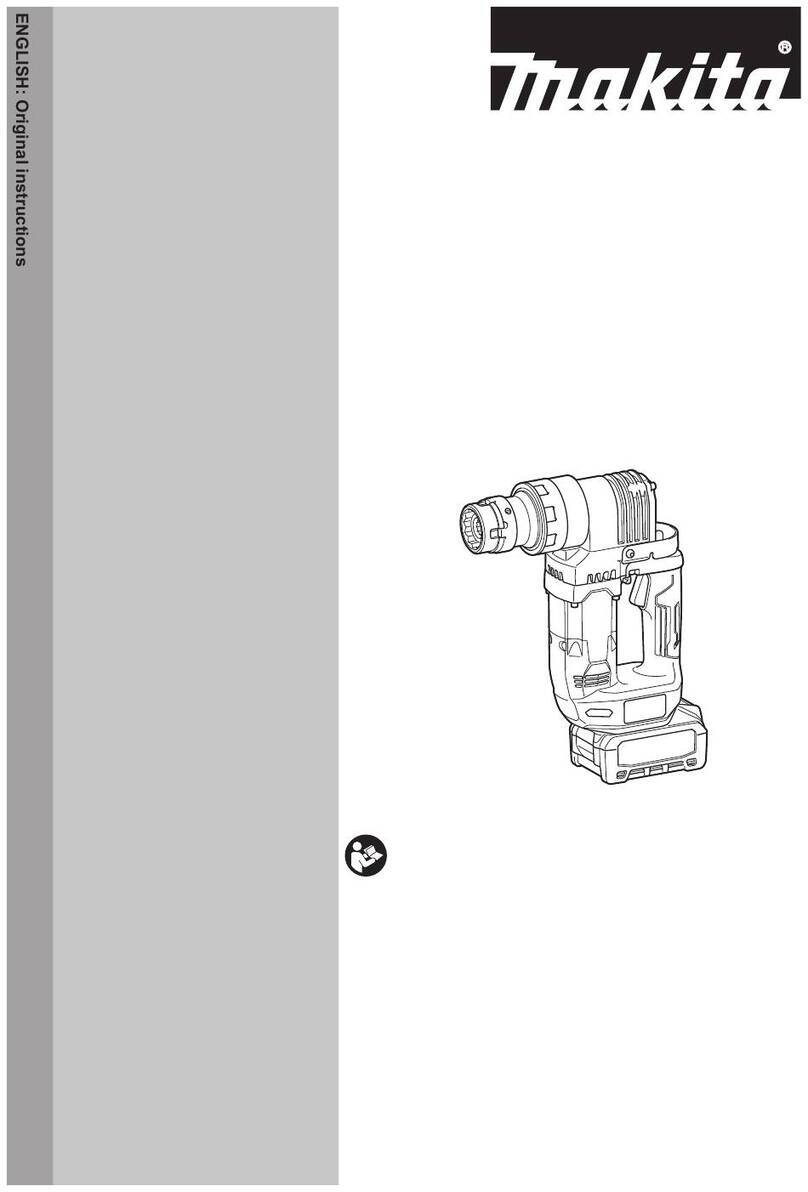

Suggested Points of Lubrication

Caution: Use high temperature grease only!

Lubrica e hese wo gaps wi h grease from he op

and allow grease o reach he cen er pin.

Recommend once a mon h for normal use.

Lubrica e hese four gaps wi h small amoun of

grease. Recommend once a mon h for normal use.

11

FOR USE BY QUALIFIED PERSONNEL ONLY

MODEL

256

-

N

WIRIN DIA RAM

12

FOR USE BY QUALIFIED PERSONNEL ONLY

MODEL

256

-

S

WIRIN DIA RAM

13

FOR USE BY QUALIFIED PERSONNEL ONLY

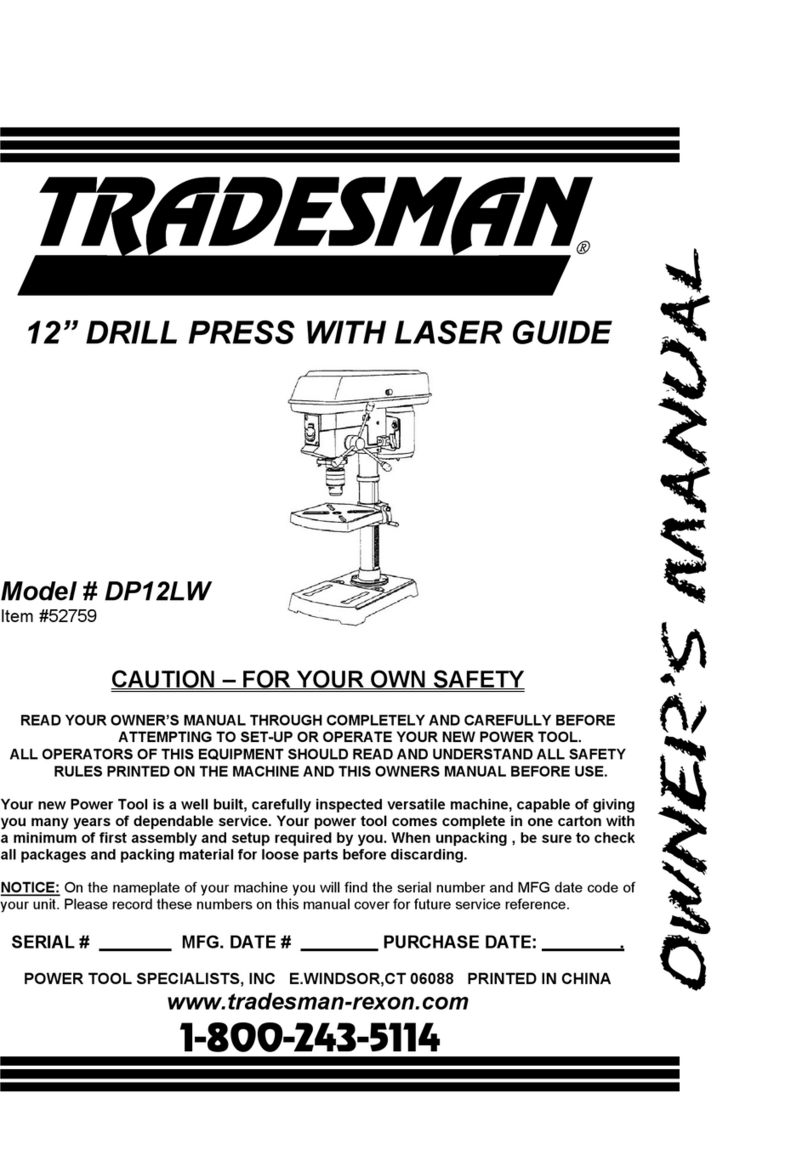

MODEL 256 EXPLODED VIEW

A1

–

Pla en Assembly

FOR USE BY QUALIFIED PERSONNEL ONLY

A2

–

Top Frame Assembly

14

FOR USE BY QUALIFIED PERSONNEL ONLY

MODEL

ITEM NO. ASSEMBLY NO.

DESCRIPTION

A1 MB256-001

PLATEN ASSEMBLY

A1-01

MT256

-

003

-

120

UPPER PLATEN, 16x20

A1-02

MT256

-

000

-

120

COMPLETE UP

A1-03

MT256

-

003

-

230

UPPER PLATEN, 16x20

A1-04

MT256

-

000

-

230

COMPLETE UPPER PLATEN ASSY

A2 MB256-002

TOP FRAME ASSEMBLY

A3 MB256-003

BASE FRAME ASSEMBLY

A3

–

Base Frame Assembly

FOR USE BY QUALIFIED PERSONNEL ONLY

MODEL

256 SUB ASSEMBLIES

DESCRIPTION

PAGE NO.

PLATEN ASSEMBLY

13

UPPER PLATEN, 16x20

–

120V VERSION

13

COMPLETE UP

PER PLATEN ASSY

1

–

120V VERSION

13

UPPER PLATEN, 16x20

–

230V VERSION

13

COMPLETE UPPER PLATEN ASSY

1

–

230V VERSION

13

TOP FRAME ASSEMBLY

15

BASE FRAME ASSEMBLY

17

Base Frame Assembly

PAGE NO.

13

– 14

13

– 14

13

– 14

13

– 14

13

– 14

15

– 16

17

15

FOR USE BY QUALIFIED PERSONNEL ONLY

A1 –

16 x 20 PLATEN ASSEMBLY

FOR USE BY QUALIFIED PERSONNEL ONLY

16 x 20 PLATEN ASSEMBLY

16

FOR USE BY QUALIFIED PERSONNEL ONLY

ITEM NO.

PART/ASSY NO.

DESCRIPTION

QTY

1

MP256

-

001

HEAT SHROUD

1

2

MH001

-

M04

-

00

9

SCREW, PAN HEAD, M4 x 1

5

4

2a

MH007

-

0

30

SILICON

E

RUBBER FOOT

4

3

MP256

-

002

FIBERGLASS INSULATION

1

4

MT256

-

001

-

120/230

UPPER PLATEN

, 16 x 20 (

120V or 230V

)

wi h wiring

1

4b

MH001

-

M04

-

00

4

SCREW, PAN HEAD, M4 x 6

6

6

MP256

-

003

PLASTIC STANDOFF

4

7

MH256

-

009

-

001

SENSOR, RTD TEMP

1

9

MP256

-

004

GUIDE POST

1

10

MH001

-

M06

-

012

SCRE

W, SOCKET HEAD, M6 x 60

1

11

MP256

-

005

CLEVIS, UPPER PLATEN

1

12

MH001

-

M08

-

010

SCREW, HEX HEAD, M8 x 25

6

13

MP256

-

006

PIN, CLEVIS

1

14

MPPP041

SILICONE PAD 16 x 20

1

14a

MT256

-

002

LOWER PLATEN, 16 x 20

1

14b

MP256

-

009

SHAFT, LOWER PLATEN

1

14c

MH0

01

-

M08

-

009

SCREW, SOCKET HEAD, M8 x 20

1

14d

MH001

-

M08

-

013

SCREW, SET, M8 x 10

1

14e

MH001

-

M03

-

004

SCREW, PAN HEAD, M3 x 6

2

16d

MP256

-

011

SCREW, SET M8X25

2

48

MH007

-

0

19

C

-

RING, CLEVIS PIN

4

84

MH009

-

002

HIGH TEMPERATURE LIMITER (

230

V ONLY)

1

84

MPP

T046

HIGH TEMPERATURE LIMITER (

120

V ONLY)

1

85

MPPW700

HEATER WIRE

AR

A1

-

01

MT256

-

003

-

120

UPPER PLATEN, 16x20

–

120V VERSION

A1

-

02

MT256

-

000

-

120

COMPLETE UPPER PLATEN ASSEMBLY

1

–

120V VERSION

A1

-

03

MT256

-

003

-

230

UPPER PLATEN, 16x20

–

230V VERSION

A1

-

0

4

MT256

-

000

-

230

COMPLETE UPPER PLATEN ASSEMBLY

1

–

230V VERSION

1.

Comple e upper p

la en assembly includes he hea ed pla en plus wiring, fiberglass insula ion and pro ec ive shroud cover.

17

FOR USE BY QUALIFIED PERSONNEL ONLY

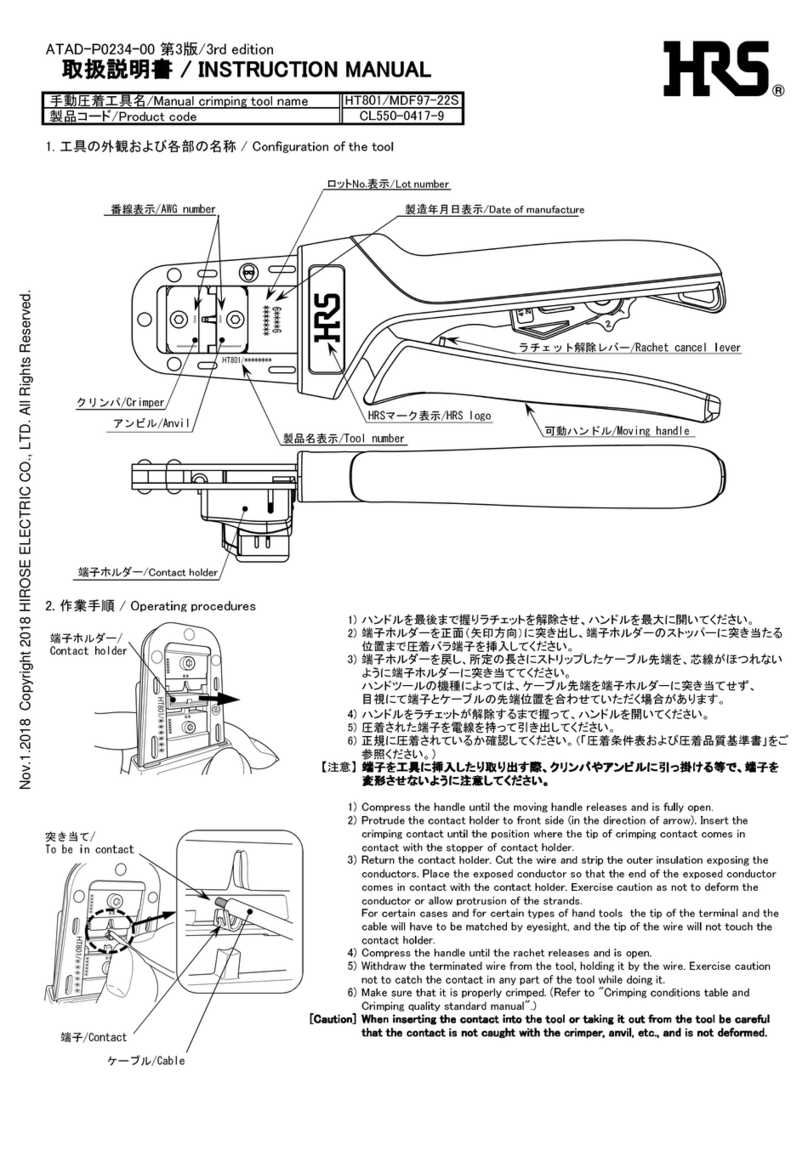

A2 – TOP FRAME ASSEMBLY

FOR USE BY QUALIFIED PERSONNEL ONLY

18

FOR USE BY QUALIFIED PERSONNEL ONLY

ITEM NO. PART/ASSY NO. DESCRIPTION QTY

16 MP256-010 HOUSING 1

16a MH001-M04-005 THUMB SCREW, HOUSING 4

16b MH006-003 256 DIGITAL CONTROLLER 1

16c MH004-004 ELECTRICAL POWER ROCKER 1

18 MP256-012 CONTROLLER OVERLAY 1

19 MP256-013 CONTROLLER BRACKET 1

20 MH001-M03-004 SCREW, PAN HEAD, M3 x 6 4

21a MH002-M03-001 NUT, HEX, M3 4

22 MH001-M08-014 SCREW, SOCKET HEAD, M8 x 10 6

23 MP256-013 BRACKET ASSEMBLY, SWING ARM 1

23b MH002-M06-001 NUT, HEX, M6 6

24 MP256-014 BRACKET ASSEMBLY, ELECTRONICS 1

24d MH005-003 SOLID STATE RELAY 1

24e MH008-001 POWER TRANSFORMER 1

24f MH256-004-001 CIRCUIT BREAKER (20A) 120V ONLY 1

24f MH256-004-002 CIRCUIT BREAKER (15A) 230 V ONLY 1

24g MH004-003 TERMINAL BLOCK 1

24h MB256-007-002 CLAMP, CABLE NYLON 2

25 MP256-015 SWING AWAY ARM ASSEMBLY 1

26 MH001-M06-013 SCREW, SOCKET HEAD, M6 x 14 5

29 MH001-M04-006 SCREW, PAN HEAD, M4 x 10 3

30 MH001-MO4-007 SCREW, PAN HEAD, M4 x 10 WITH WASHER 9

45 MP256-023 LEVER ARM BRACKET, RIGHT 1

46 MP256-024 LEVER ARM BRACKET, LEFT 1

50 MP256-026 CAM 1

52 MP256-027 SAFETY LOCK 1

56 MH002-M08-001 NUT, HEX, M8 2

57 MP256-028 LEVER ARM 1

58 MP256-029 LEVER ARM HANDLE 2

59 MH001-M10-001 LEVER ARM HANDLE THREADED STUD 1

67

MH001

-

M08

-

005

SCREW, SOCKET HEAD, M8 x 28

2

78

MH003

-

M08

-

003

WASHER, 8.3 x 13.6 x 1.6

2

79

MP256

-

033

SPRING PIN

1

80

MB256

-

004

WIRE HARNESS ASSEMBLY

1

19

FOR USE BY QUALIFIED PERSONNEL ONLY

A3 – BASE FRAME ASSEMBLY

FOR USE BY QUALIFIED PERSONNEL ONLY

This manual suits for next models

2

Table of contents

Other Insta Power Tools manuals

Popular Power Tools manuals by other brands

Scheppach

Scheppach IW900 Translation of original operating manual

Powercraft

Powercraft 61000 instruction manual

BGS technic

BGS technic 3237 quick start guide

AEG

AEG STEP 1200 XE Original instructions

Drytac

Drytac HOT PRESS HGP220 user manual

Central Machinery

Central Machinery 33497 Owner's manual & safety instructions