Insta 418 User manual

MNL90418 Rev. H 02.27.19

OPERATION AND MAINTENANCE MANUAL

MODEL 418

FOR USE BY QUALIFIED PERSONNEL ONLY

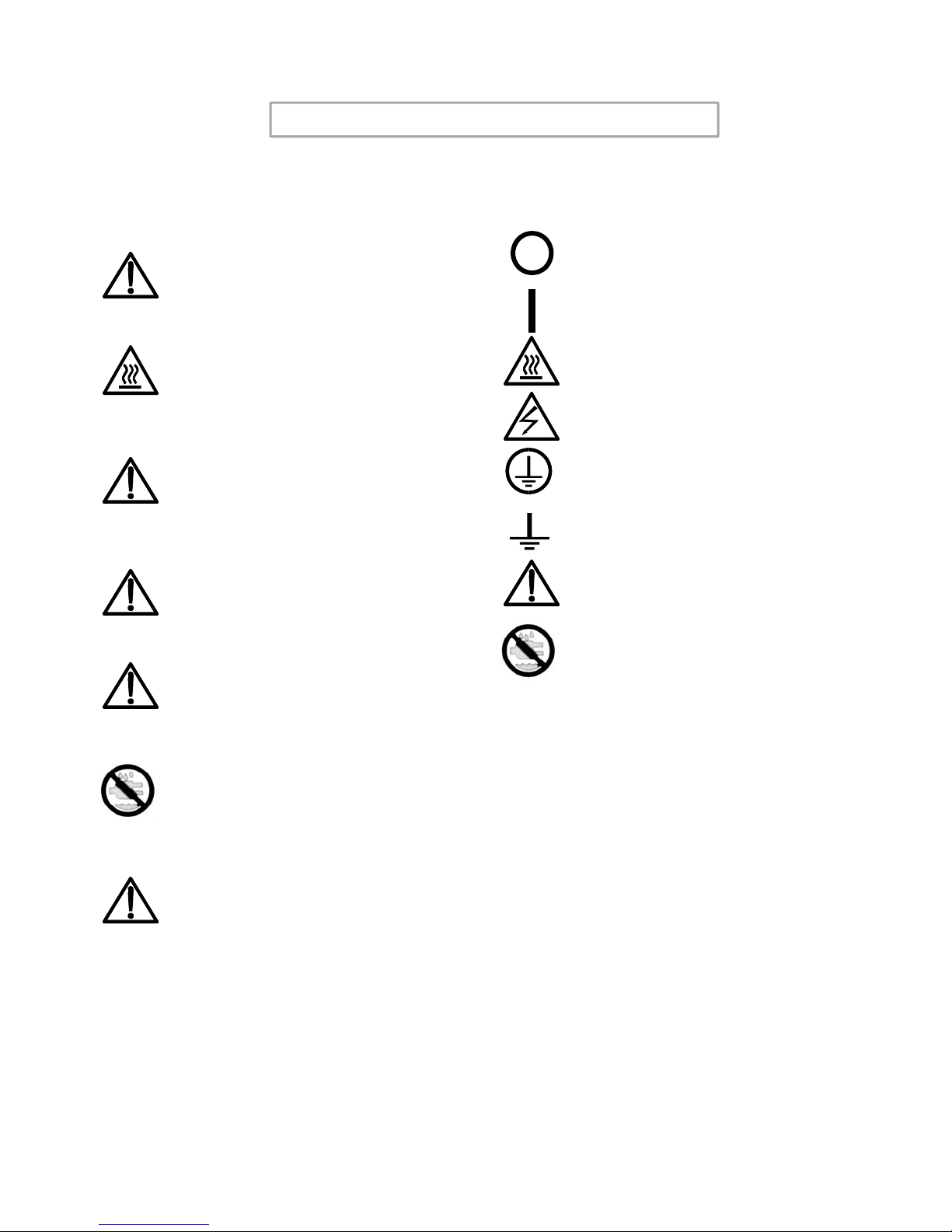

Safety Summary

International Symbols

Safety

Summary

WARNING

In case of power cord damage,

do not attempt to repair or

replace the power cord. Contact

the manufacturer or the local

distributor.

International

Symbols

Power Off

Power On

WARNING

Hot Surface. Avoid contact.

CAUTION

During normal operation, the

bfth hi dtb

Hot Surface

Risk of Electrical Shock

Protective Earth

Terminal

b

ase o

f

th

e mac

hi

ne nee

d

s

t

o

b

e

installed or placed above the wall

socket.

CAUTION

The machine is to be operated by

one person only.

Protective

Earth

Terminal

Ground

Caution – Warning

CAUTION

To reduce the risk of electric

shock and injury to persons,

disconnect from power supply

before servicing and /or cleaning.

CAUTION

Wet conditions

CAUTION

Do not handle the plug with wet

hands, or machinery under wet

conditions.

NOTE

This machine uses a fuse to

protect against risk of fire and

protect

against

risk

of

fire

and

electrical shock. When replacing

the fuse, use a fuse of the same

type and rating.

1

FOR USE BY QUALIFIED PERSONNEL ONLY

2

Congratulations!

Your selection of the Insta Graphic Systems heat

seal machine is a sound business decision. Insta

equipment is the result of the highest quality

engineering and time-tested design. Your new

machine combined with Insta's reputation of

innovation in the heat-sealing field, insures the

continuing capability of delivering the best-decorated

substrates possible.

This manual describes installation, operation, and

maintenance procedures for your new 418 series

machine, as well as easy to use instructions for on-

the- spot maintenance.

Your 418 series machine will have a long, trouble

free life. Read this manual. Keep it with your

machine; it's your key to proper operation and lasting

service.

Limited Machine Warranty

Insta Graphic Systems warrants this heat seal

machine, when operated under normal conditions,

to be free from manufacturing defects in material

and workmanship for a period of one year on parts

(lifetime on the heating element) and 90 days on

labor from the invoice date.

This warranty will be effective only when Insta

authorizes the original purchaser to return the

product to the factory in Cerritos, California, freight

prepaid, and only when the product upon

examination has proven to be defective.

This warranty does not apply to any machine that

has been subjected to misuse, negligence or

accident.

Insta shall not be liable for the injury, loss or

damage, direct or consequential, arising out of the

use or the inability to use the product.

No claim of any kind shall be greater in amount

than the sale price of the product or part to which

claim is made.

This is the sole warranty given by the company, it is

in lieu of any other warranties, expressed or

implied, in law or in fact, including the warranties of

merchant-ability and fitness for a particular use,

and is ac-cepted as such by the purchaser in taking

delivery of this product.

FOR USE BY QUALIFIED PERSONNEL ONLY

3

IP54=IP

1st Digit5

2nd Digit4

1st

Digit Protection from

solid objects 2nd

Digit Protection from

moisture

0 Non protected 0 Non protected

1Objects greater

than 50mm 1 Dripping water

2Objects greater

than 12mm 2Dripping water

when tilted up to 15

deg.

3Objects greater

than 2.5mm 3 Spraying water

4Objects greater

than 1mm 4 Splashing water

5 Dust protected 5 Water jets

6 Dust tight 6 Heavy seas

-- --- 7 .15m – 1m

immersion

-- --- 8 1m + submersion

Degree of Protection

IP (Ingress Protection) rating according to IEC

60529.

NOTE

IEC 60529 does not specify sealing

effectiveness against the following:

mechanical damage of the equipment;

the risk of explosion; certain types of

liquid conditions, e.g. those that are

produced by condensation; corrosive

vapours; funus; vermin

Installation

DOMESTIC – 418 SERIES

Use a separate 15 amp AC circuit.

Only industrial extension cords with

proper wire size should be used: size

16/3 wire for distances up to 25 feet,

and size 14/3 for distances up to 50

feet.

INTERNATIONAL – 418 SERIES

Use a designated 16 amp AC circuit.

Only industrial extension cords with

proper wire size (2.5 sq. mm) shall be

used.

IMPORTANT

The appliance must be plugged into a

proper receptacle of the proper size

and rating. Equally important the line

voltage must be able to

accommodate this appliance as well

as other appliances operating on this

circuit.

Specifications

MODEL 418

120 V AC, 50/60 Hz, 1000 Watts, 8.3 Amps

230 V AC, 50/60 Hz, 1000 Watts, 4.4 Amps

Weight Model 418 29 Pounds (13.2 KG)

FOR USE BY QUALIFIED PERSONNEL ONLY

4

Operation

1. Turn the power on by pressing the POWER

button on the controller.

2. Set desired temperature and time. Open the

upper platen arm to its fully open position, away

from the lower platen. (See Solid State

Controller Section)

3. Allow the machine to warm up until the selected

temperature is reached.

4. Set the desired pressure by adjusting the

pressure knob on top of the machine

counterclockwise to increase pressure.

5. Place the substrate on lower platen, smoothing

out all wrinkles. Push and hold the cap retainer

in the down position. For a cap, pull the

sweatband out, place the crown on the lower

platen.

6. Position transfer or lettering on substrate.

7. Close the machine by pulling handle down into

locked position.

8. The timer will start automatically and a buzzer

will beep at the end of the time cycle.

9. At the end of the time cycle, open the machine

by lifting handle to the full open position.

10. Unlock cap retainer and remove substrate.

NOTE

Thelowerplatenmaybeadjustedto

accommodatevariouscaps,sleeves,

pantlegs.Slidethelowerplatenz

bracketassemblybylooseningthelock

downknoblocatedinthebaseoftheof

thezbracket.Movethecomplete

lowerplatenassemblyforwardor

backwardtothedesiredlocation.Once

inposition,lockdownthecomplete

assemblybytighteningdownthelock

downknob.

Environmental Conditions

Only operate Insta heat seal machines under

suitable environmental conditions.

1. Placed on a even, non flammable surface.

2. Can support a minimum of 150 lbs. if placed

above a platform.

3. Do not restrict access to the main power

switch.

4. Maintain a clearance around any forms of

liquid.

5. Do not over extend the power cord.

6. The operational voltage should not be 10%

max/min of the rated value.

7. Avoid voltage spikes.

FOR USE BY QUALIFIED PERSONNEL ONLY

5

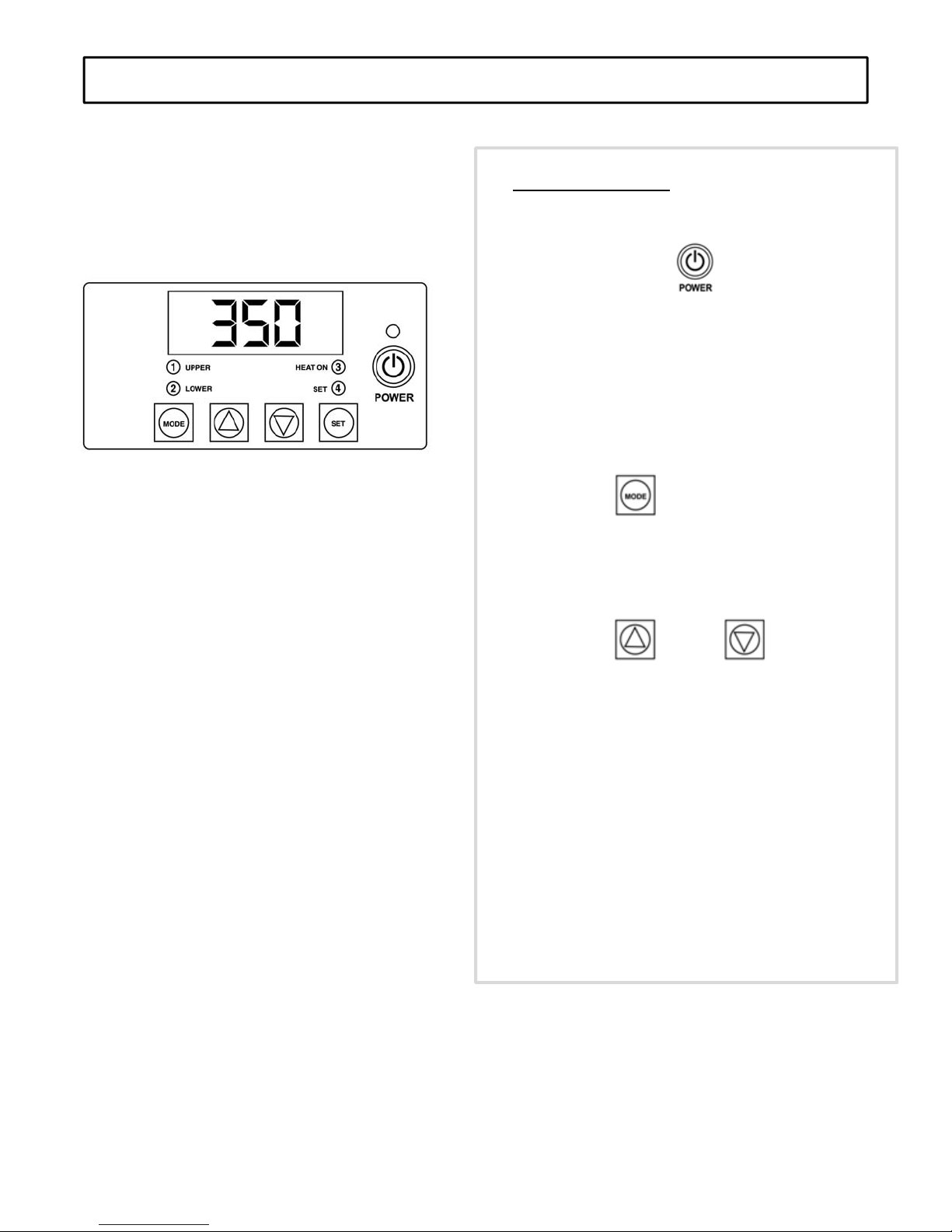

Operation Timer/Temperature

Control

Solid State Controller

This controller has two (2) control features:

1. Temperature - Temperature may be set from

221-446°F (105-230°C).

2. Time - Time may be set from 1 second to 99.59

minutes.

Controller Operation

1. If the temperature is not being displayed, press

the MODE button until temperature is

displayed.

2. Push and hold SET button and simultaneously

push UP (↑) or DOWN (↓) arrow buttons to the

desired temperature setting.

3. Press the MODE button until time is displayed.

4. Push and hold SET button and simultaneously

push UP (↑) or DOWN (↓) arrow buttons to the

desired timer setting.

Timer

•The controller has a count down timer that

automatically activates a buzzer at the

completion of the application.

•Timer display is minutes:seconds. Range is

00:00 to 99:59, Colons (:) flash while timer is

running.

Temperature

Fahrenheit/Centigrade (Celsius)

Conversion

The temperature controller can be programmed to

display either °F or °C

1. Press the MODE button until the temperature is

displayed.

2. Push and hold the UP and DOWN buttons for 5

seconds.

FOR USE BY QUALIFIED PERSONNEL ONLY

6

Preventive Maintenance

Suggestions

The Insta heat seal machines are relatively

maintenance free. For long trouble-free life, the

following preventive maintenance should be

followed:

1. Do not heat seal items such as buttons, pins,

snaps, or zippers that tend to cut the silicone

rubber pad or scratch the Teflon heat platen.

2. Periodically clean the Teflon-coated heat platen

with a non-abrasive piece of cloth. Stubborn

stains may be cleaned, when platen is cool,

with mineral spirits.

3. When the heat platen is hot and not in use,

keep in open position (away from the silicone

rubber pad).

4. To prevent soiling of substrate, periodic wiping

of the entire exterior machine, including

platens, with a clean rag is recommended. If

necessary, use mineral spirits for cleaning a

cold machine. Since mineral spirits are

flammable, use precautions and keep away

from sparks, flame, or hot heat platen.

5. The Model 418 machines require periodic

lubrication with a high-temperature, non-

melting grease (MPPL023).

A. Lubricate the post, handle and cam

assembly depending upon usage. (Once

every month if used continuously.)

WARNING

Power cord replacement

should be from the

manufacturer only (because it

requires a specially prepared

cord).

General Maintenance

It is recommended that you have the following

items available:

A. Regular screw driver

B. Phillips head screw driver

C. Small adjustable wrench

D. Needle nose pliers with insulated handle

E. Set of Allen wrenches

F. Grease gun

G. Special high temperature grease MPPL023

With the above items you should be able to

accomplish most repairs.

Replacement of Silicone

Rubber Pads

1. Make sure heat platen is cool.

2. Use tube of MPPC006 adhesive to bond

silicone rubber pad to metal platen.

NOTE: Read instructions on the tube package

.

3. Be sure that the surface of the silicone platen is

clean. Use a mild solvent such as mineral

spirits.

4. The pad and metal must be thoroughly dry and

clean, before starting the bonding operation.

5. Apply adhesive sealant to the metal platen.

Spread a thin even coat and apply pad

immediately. Apply pressure and position pad

making sure that there is no air entrapment.

NOTE: A serrated blade such as used for

laying down rubber floor tiles would be helpful.

6. Allow to cure overnight under low pressure at

normal room temperature.

FOR USE BY QUALIFIED PERSONNEL ONLY

Automatic Shut Off

Model 418

(418 - Controller P/N MPC90214; Rev. 4.73)

The Automatic Shut Off is designed to save electrical

consumption when the user is not engaged in the usage

of the Insta heat seal machines.

By default, the timer for Automatic Shut Off is set to 2

hours during activation and cannot be changed. Any

disturbance such as a key press or heat press cycle will

reset the timer.

The timer for Automatic Shut Off will begin after every

key press or heat press cycle.

-7 -

Automatic Shut Off

1. Turn on the machine by pressing POWER.

a) ONE beep indicates the Automatic Shut

Off is OFF.

b) TWO beeps indicates the Automatic Shut

Off is ON.

2. Press on the MODE once in order to display the

TIME SETTING.

3. With the TIME SETTING displayed, press and hold

the UP + DOWN ARROWS for 3 to 5 seconds.

a) ONE beep indicates the Automatic Shut

Off is OFF.

b) TWO beeps indicates the Automatic Shut

Off is ON.

4. Repeat step 3 in order to turn ON or OFF the

Automatic Shut Off.

X1

+

FOR USE BY QUALIFIED PERSONNEL ONLY

Safety and Danger Zone Diagram

8

Hot Surface.

Avoid contact

with Upper Platen

Shroud and

Aluminum

Casting

Keep hands clear

Do not handle the

machinery with

wet hands

Machinery should

be operated

under a secure

flat surface

TAN

GREEN

BROWN

GREEN/YELLOW

BROWN

BLUE

12 Vac

7

8

11

12

BLUE

1

2

5

6

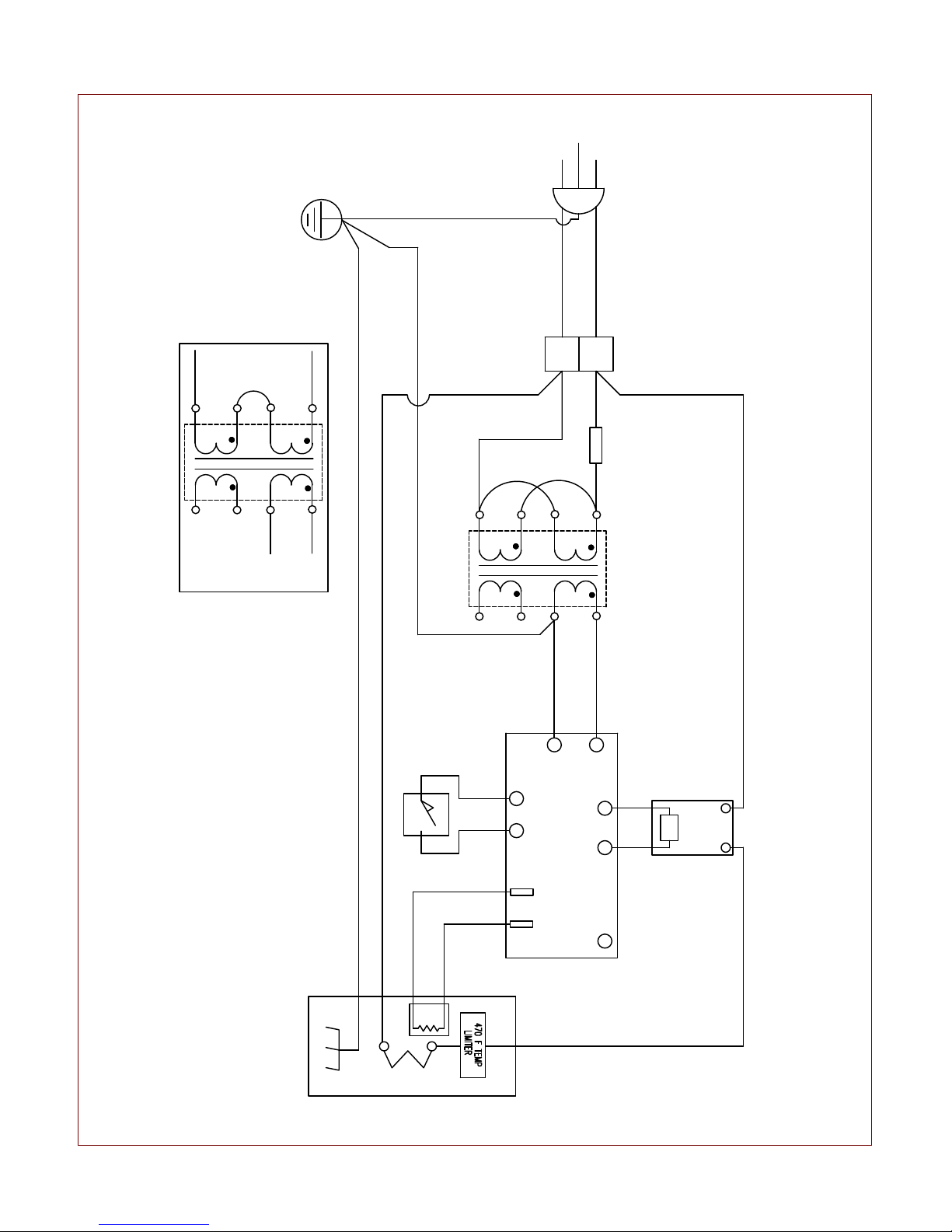

230V TRANSFORMER MODEL 418 WIRING DIAGRAM 0811

GROUND

GREEN/YELLOW

GREEN

(GREEN/YELLOW-EUROPE)

BLACK

(BROWN-EUROPE)

WHITE

(BLUE-EUROPE)

1

2

BLACK

BLUE

GREEN/YELLOW

HEAT PLATEN

RTD

WHITE

WHITE

PURPLE

YELLOW

MICRO SWITCH

C NO

67

TIMER

START SENSOR

TEMPERATURE

CONTROL

3

5OP-2

N/C

+12V

4

OP-1

2

12 Vac

INPUT

1

12 Vac

7

8

11

12

1

2

5

6

WHITE

WHITE

BROWN

GREEN/YELLOW

120V TRANSFORMER

TAN

RED

GRAY

BLACK

COIL

NO

RELAY

C

TERMINAL

BLOCK

MODEL 418

FUSE 1 AMP

250V

MODEL 418

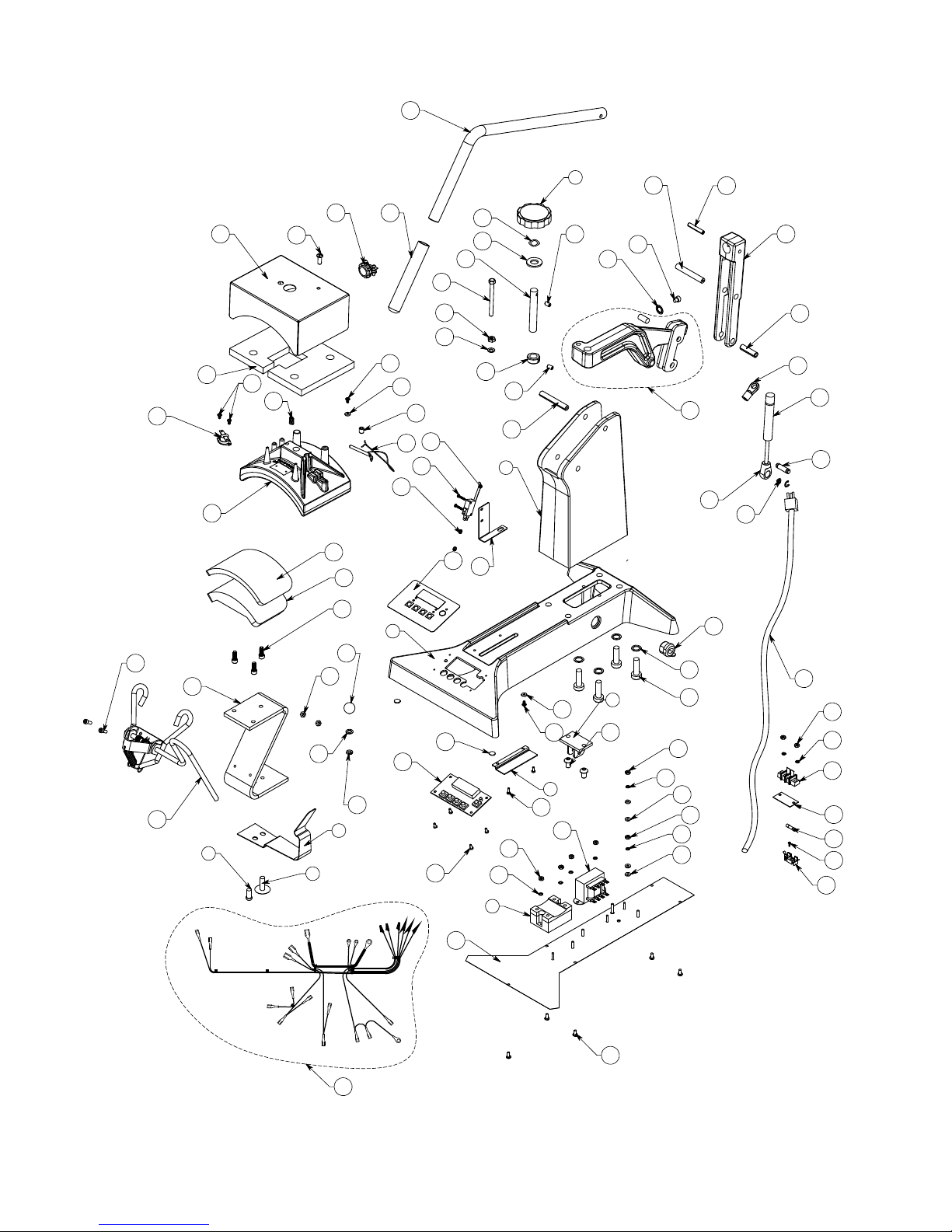

79

81

12

33

19

29

30

32

18

56

16

53

18

27

25 52

3

38

20

15

11

8

17

1

70

63

9

47

46

21

24

34

2

35

48 54

55

37

36

4

14 49

41

75

28

39

10

33

42

5

507

31

50

77

57

60 61

62

63

69

67

68

66

64

65

63

64

65

6

63

70

13

26

80

74

71

15

76

70

64

65

64

65

51

22

78

70

45

82

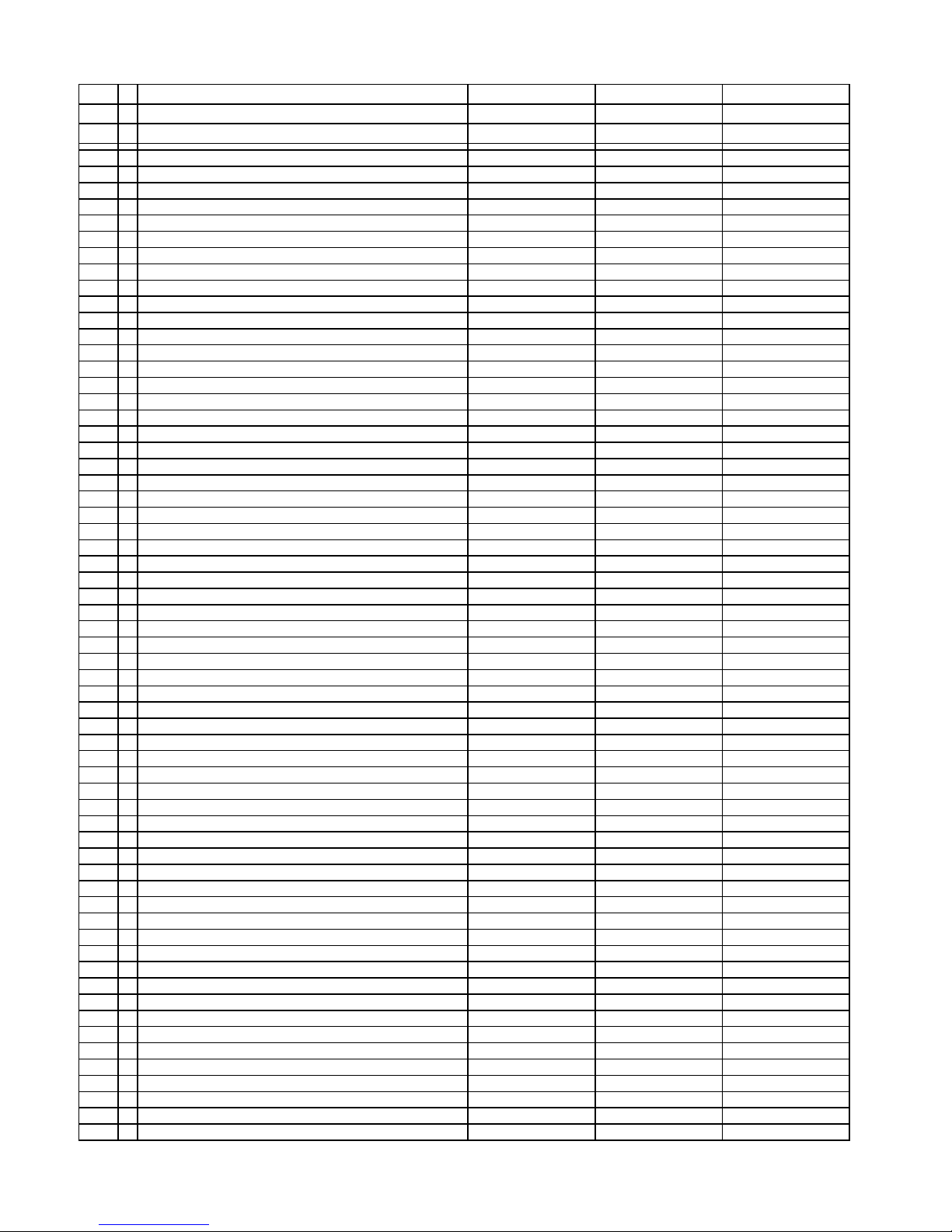

MODEL

MODEL

MODEL

418

418

418 EUR

NO

PART NAME

120V AC

230V AC

230V AC

1

418 BASE

MPB90184

MPB90184

MPB90184

2

BASE UPRIGHT

MPB90183

MPB90183

MPB90183

3

CLEVIS ASSY, GAS SPRING

MPC90190

MPC90190

MPC90190

4

SCREW, BUTTON HEAD 1/4-20 x 5/8

MHSB142058

MHSB142058

MHSB142058

5

CARRIAGE BOLT 1/4-20 x 1.0

MHBC14201

MHBC14201

MHBC14201

6

KNOB, PRESSURE ADJUST

MPPK018

MPPK018

MPPK018

7

RETAINER, CARRIAGE BOLT

MPR90200

MPR90200

MPR90200

8

LOCKING PLATE CAP DEVICE

MPSC413

MPSC413

MPSC413

9

RELAY, SOLID STATE

MPR90217

MPR90217

MPR90217

10

SILICONE RUBBER PAD

MPP90194

MPP90194

MPP90194

11

INTER LOCK WASHER ¼

MHWL14

MHWL14

MHWL14

12

HANDLE

MPH90197

MPH90197

MPH90197

13

BREAK OVER ARM MACHINING

MPA90213

MPA90213

MPA90213

14

SHROUD, UPPER PLATEN

MPS90198

MPS90198

MPS90198

15

WASHER ¼

MHWSAE14

MHWSAE14

MHWSAE14

16

PIN, LOWER CLEVIS

MPP90201

MPP90201

MPP90201

17

CAP HOLD DOWN DEVICE ASSEMBLY

MPSR021

MPSR021

MPSR021

18

PIN, ROLL 3/8” x 2-1/2”

MHPR38212

MHPR38212

MHPR38212

19

GRIP, RUBBER

MPSH168

MPSH168

MPSH168

20

DIGITAL CONTROL

MPC90214

MPC90214

MPC90214

21

BOTTOM COVER ASSEMBLY

MPC90202

MPC90202

MPC90202

22

HEX NUT 1/4-20

MHNH1420

MHNH1420

MHNH1420

24

PAN HEAD SLOTTED SCREW 8-32 X 3/8

MHSP83238

MHSP83238

MHSP83238

25

HEX NUT 10-32

MHNH1032

MHNH1032

MHNH1032

26

CLIP E RETAINING 5/16

MPSC242

MPSC242

MPSC242

27

HEX NUT 4-40

MHNH440

MHNH440

MHNH440

28

SET SCREW 5/16-18 X 3/8

MHSST5161838

MHSST5161838

MHSST5161838

29

PIN, ROLL ¼ X 1-1/2

MHPR14112

MHPR14112

MHPR14112

30

ADJUSTMENT SCREW

MPS90203

MPS90203

MPS90203

31

HEX BOLT, 1/4-20 x 2-3/4

MHBH1420234

MHBH1420234

MHBH1420234

32

COLLAR ADJUSTMENT

MPSP247

MPSP247

MPSP247

33

SET SCREW 10-32 X 3/16

MHSST1032316

MHSST1032316

MHSST1032316

34

STRAIN RELIEF

MPSS168

MPSS168

MPSS168

35

SCREW, SOCKET HEAD 10-32 X ½

MHNH103212

MHNH103212

MHNH103212

36

OVERLAY, DIGITAL CONTROL

MPL90349

MPL90349

MPL90349

37

KNOB, BLACK

11088817

11088817

11088817

38

SCREW, BUTTON HEAD 1/4-20 X ½

MHSB142012

MHSB142012

MHSB142012

39

SENSOR, 2000 OHM

MPPS210

MPPS210

MPPS210

40

SCREW, PHILLIPS 6-32X1/4

MHSP63214

MHSP63214

MHSP632143

41

INSULATION

MPSP249

MPSP249

MPSP249

42

FOOT, RUBBER

MPF90004

MPF90004

MPF90004

45

MICRO SWITCH

MPPS043

MPPS043

MPPS043

46

TERMINAL BLOCK ASSEMBLY

MH11096914

MH11096914

MH11096914

47

TRANSFORMER

MPT90001

MPT90001

MPT90001

48

ZEE, LOWER PLATEN SUPPORT

MPSS471

MPSS471

MPSS471

49

SCREW, PHILLIPS 12-24 X 5/8

MHSP122458

MHSP122458

MHSP122458

50

SCREW, PHILLIPS 6-32 X 5/16

MHSP632516

MHSP632516

MHSP632516

51

SCREW, PHILLIPS 4-40 X 7/8

MHSR44078

MHSR44078

MHSR44078

52

POWER CORD

MPPW141

MPPW142

MPPW202

53

WIRE HARNESS

MPW90325

MPW90325

MPW90325

54

SCREW, SOCKET HEAD 3/8-16 X 1.0

MHSSH38161

MHSSH38161

MHSSH38161

55

WASHER, LOCK 3/8

MHWL38

MHWL38

MHWL38

56

PIN, ROLL 3/8 X 1-3/8

MPP90206

MPP90206

MPP90206

57

LOWER PLATEN

MASP469

MASP469

MASP469

60

WASHER, LOCK INTERNAL TOOTH #10

MHWLIT10

MHWLIT10

MHWLIT10

61

BUMPER

MH100455166

MH100455166

MH100455166

62

HI-TEMPERATURE LIMITER

MPPT045

MPPT045

MPPT045

63

HEX NUT 6-32

MHNH632

MHNH632

MHNH632

64

WASHER #6

MHWSAE6

MHWSAE6

MHWSAE6

65

WASHER #6 INTERNAL TOOTH LOCK

MHWLIT6

MHWLIT6

MHWLIT6

66

FUSE HOLDER

MPPF708

MPPF708

MPPF708

67

FUSE (1 AMP, 250V)

MPPF701R

MPPF701R

MPPF701R

68

SCREW, PHILLIPS 2-56 X 1/4

MHSP25614

MHSP25614

MHSP25614

69

MARKER STRIP

MS6992

MS6992

MS6992

70

SCREW, PAN HD 6-32 X 1/4

MHSP63214

MHSP63214

MHSP63214

77

SCREW, SOCKET HEAD 1/4-20 X 5/8

MHSSH142058

MHSSH142058

MHSSH142058

78

WASHER #1/2

MHWSAE12

MHWSAE12

MHWSAE12

79

WASHER WAVE #1/2

MH5806282

MH5806282

MH5806282

80

MTG. BRACKET MIRCO SWITCH

MH100455169

MH100455169

MH100455169

81

HELICOIL INSERT, 1/2"-13 X 1/2" LONG

MH11858CN500

MH11858CN500

MH11858CN500

A1

LINK ARM ASSEMBLY

MPL90211

MPL90211

MPL90211

A2

GAS SPRING ASSEMBLY

MPS90192

MPS90192

MPS90192

A3 LOWER PLATEN ASS’Y W/RUBBER MPSP468 MPSP468 MPSP468

A4 UPPER PLATEN, WIRING ONLY MPP4183W MPP4184W MPP4184W

A5 UPPER PLATEN COMPLETE ASSEMBLY MPP4183A MPP4184A MPP4184A

A6 LOWER PLATEN COMPLETE ASSEMBLY MPP90275 MPP90275 MPP90275

13

FOR USE BY QUALIFIED PERSONNEL ONLY

INSTA GRAPHIC SYSTEMS

Heat Press Limited Warranty

This limited warranty (“warranty”) is given only to the original end-user/retail purchaser

(referred to in this warranty as “Original Purchaser”) of the accompanying product and

accessories (collectively referred to in this warranty as “The Product”).

What is covered?

•“The Product” includes Machines, Parts and/or Accessories.

•Except as otherwise provided herein, Insta Graphic Systems (“Insta”) warrants that The

Product will be free from defects in materials and workmanship when used under

normal conditions.

What is the length of the Warranty Periods?

•Machines: Life time on the heating element, one year parts and 90 days labor from the

original purchase date (end-user).

•Additional Parts and Accessory Items: 90 days from the original purchase date.

This warranty does not cover:

•Physical damage to the Product;

•Damage caused by improper installation, improper or abnormal use, misuse, neglect or

accident (including but not limited to transporting The Product without the proper

preparation and/or packaging);

This limited warranty is VOID, if

•the Product has been altered or modified in any way (including but not limited to

attempted warranty repair without authorization from Insta and/or alteration/removal of

the serial number).

•the warranty period is expired,

•the serial number label is missing or unrecognizable,

•the defect was subject to abuse, improper use not conforming to product manual

instructions

•the defect was subject to Force Majeure, such as acts of God, flood, lightning,

earthquake, war, vandalism, theft, brownouts or sags (damage due to low voltage

disturbances)

What to do if you think your Product is eligible for warranty service: Immediately report your

model, serial number and purchase date of the equipment.

What Insta will ask you to do?

After contacting Insta you may be asked to deliver (by hand if you prefer) or send The Product

properly packaged, freight prepaid, to Insta or Insta’s service center together with your bill of

14

FOR USE BY QUALIFIED PERSONNEL ONLY

sale. A Return Authorization is required for all returned goods. Failure to obtain the RA will

result in the refusal of the shipment.

You are responsible for the cost of shipping, packing of The Product and insurance (if

you desire). You are also responsible for loss or damage to The Product in shipping.

If The Product does not operate as warranted above during the applicable warranty period,

Insta shall, at its option and expense (except for shipping cost), repair the defective product or

part, deliver to the customer an equivalent product or part to replace the defective item. All

products that are replaced will become the property of Insta.

If The Product is not covered by this warranty, you will be charged for any service and/or

replacement parts/products at Insta’s then current published rates, as well as, for the freight.

What happens when Insta elects to replace your Machine?

When a replacement Machine is authorized by Insta, Insta will send a replacement Machine

and issue a Return Authorization for the return of the Product. The Purchaser will be charged

for the new machine at the time of the shipment. Once the machine is returned and the

warranty confirmed, The Purchaser will receive a credit/refund. The replacement machine you

receive (will be covered by the balance of the limited warranty period remaining on the original

product, plus an additional thirty (30) days. You will keep the replacement machine that is sent

to you and your original machine shall become the property of Insta.

THIS WARRANTY IS GIVEN IN LIEU OF ALL OTHER WARRANTIES, WRITTEN OR ORAL,

WHETHER EXPRESSED BY AFFIRMATION, PROMISE, DESCRIPTION, DRAWING,

MODEL OR SAMPLE. ANY AND ALL WARRANTIES OTHER THAN THIS ONE, WHETHER

EXPRESSED OR IMPLIED INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, ARE HEREBY DISCLAIMED. INSTA

SHALL HAVE NO LIABILITY FOR DEFECTS OF ANY NATURE WHATSOEVER EXCEPT AS

PROVIDED FOR HEREIN.

This Limited Warranty (and Insta’s obligation to you) may not be changed in any way unless

you and Insta sign the same piece of paper in which we (1) refer to The Product and your bill

of sale date, (2) describe the change to this warranty and (3) agree to make that change.

Important:

We recommend that you keep all original packing materials, in the event that you need to ship

the Product.

13925 E. 166th St. ● Cerritos CA USA 90702 ● (800) 421-6971 ● Fax (562) 404-3010

Parts Orders ● (800) 426-3609 ● (562) 404-3000 Ext. 215

Technical Support ● (800) 426-3609 ● (562) 404-3000 Ext. 351

In-House Repair ● (800) 426-3609

Table of contents

Other Insta Power Tools manuals

Popular Power Tools manuals by other brands

EIBENSTOCK

EIBENSTOCK EPG 400 A Original instructions

XTline

XTline XT106230 Operation manual

Westfalia

Westfalia 81 60 35 instruction manual

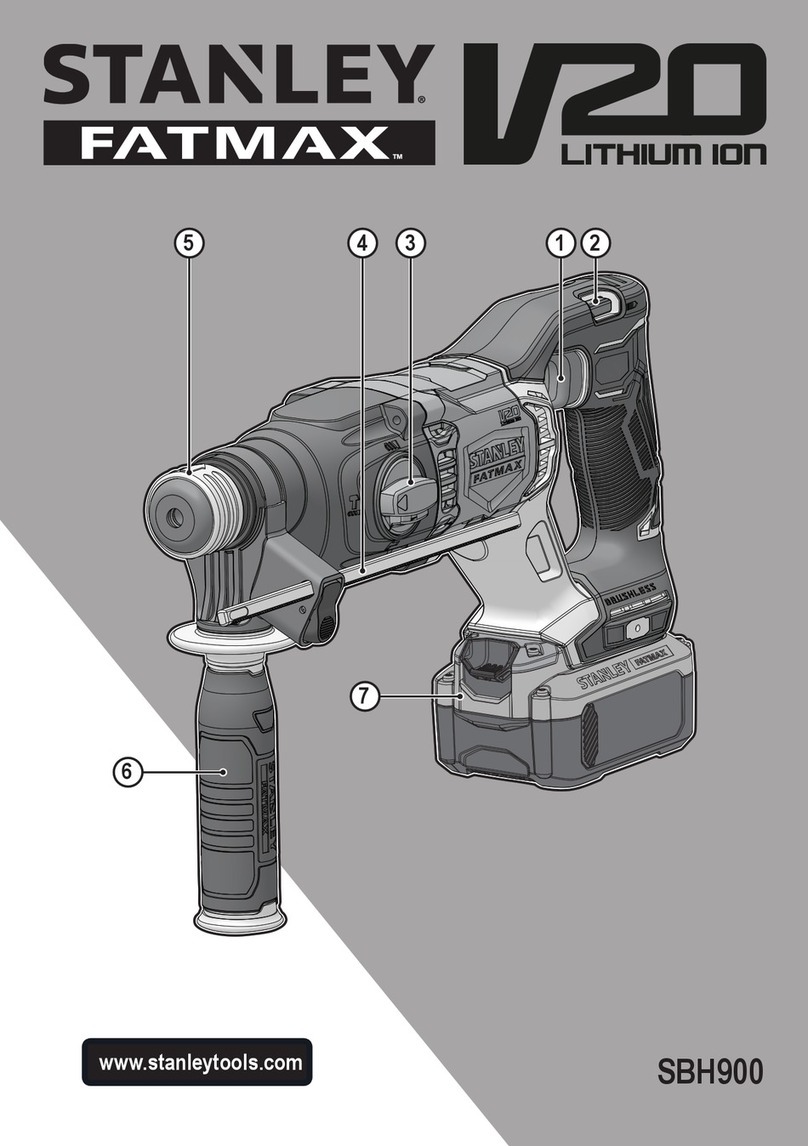

Stanley

Stanley FATMAX V20 LITHIUM ION SBH900 manual

Bosch

Bosch GBH 5-40 DCE Professional Original instructions

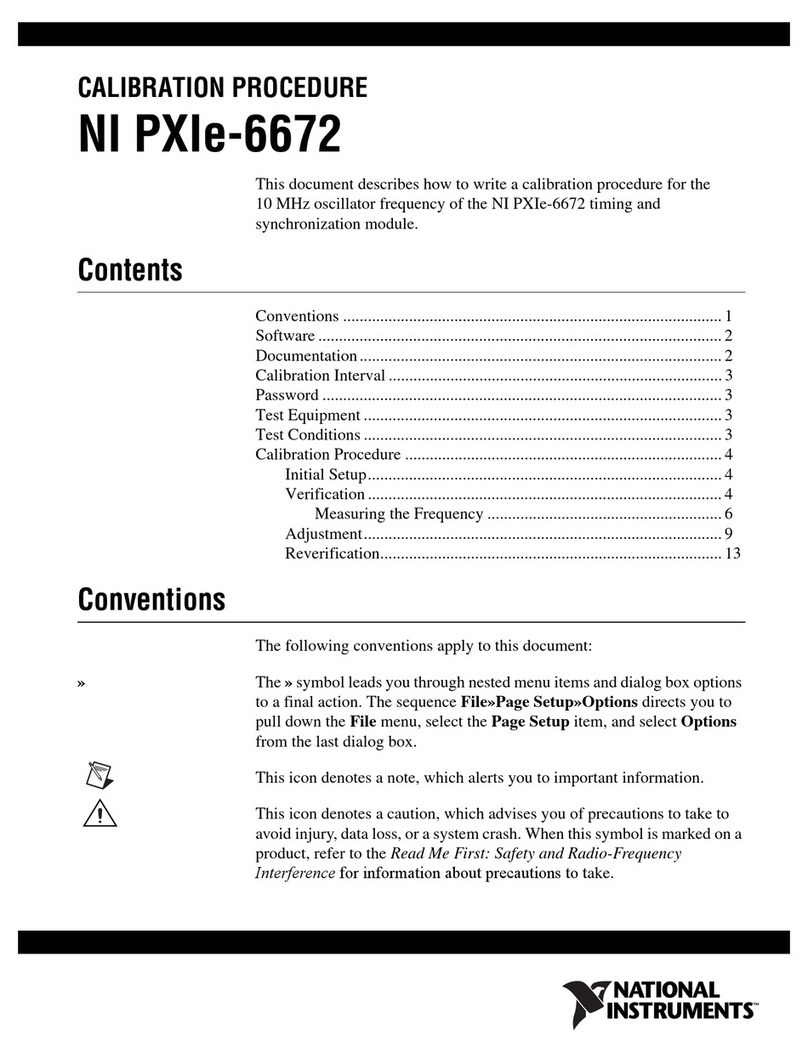

National Instruments

National Instruments Network Adapter NI PXIe-6672 CALIBRATION PROCEDURE