Insta 288 User manual

MODEL

288

OPERATION AND MAINTENANCE MANUAL

MNL90

288 B 12.01.2017

1

FOR USE BY QUALIFIED PERSONNEL ONLY

Safety Summary

WARNING

In case of power cord damage, do not

attempt to repair or replace the power

cord. ontact the manufacturer or the

local distributor.

WARNING

Hot surface. Avoid contact.

CAUTION

The machine is to be operated by one

person only.

CAUTION

To reduce the risk of electric shock and

injury to persons, turn the machine off

and disconnect the machine from the

power supply before servicing and/or

cleaning.

CAUTION

During normal operation, the base of

the machine must be installed or placed

above the wall socket on a level, stable

surface.

CAUTION

Do not lean on the machine when the

lower platen is removed. are must be

taken to prevent machine from tipping

over. Keep upper platen as close as to

the center position.

I ter atio al Symbols

Power Off

Power O

Hot Surface

Risk of Electrical Shock

Protective Earth Termi al

Grou d

Wet Co ditio s

Start Actio

Cautio – War i g

2

FOR USE BY QUALIFIED PERSONNEL ONLY

Co gratulatio s!

Your selection of the Insta Graphic Systems heat

seal machine is a sound business decision. Insta

equipment is the result of the highest quality

engineering and time-tested design. Your new

machine, combined with Insta’s reputation for

innovation in the heat-sealing field, ensures that

you will be able to deliver the best-decorated

substrates possible for years to come.

This manual provides the installation, operation,

and maintenance procedures for your 288 series

machine, as well as easy to follow instructions for

on-the-spot maintenance.

Your model 288 machine will have a long, trouble-

free life. Read this manual. Keep it with your

machine; it’s your key to proper operation and

lasting service.

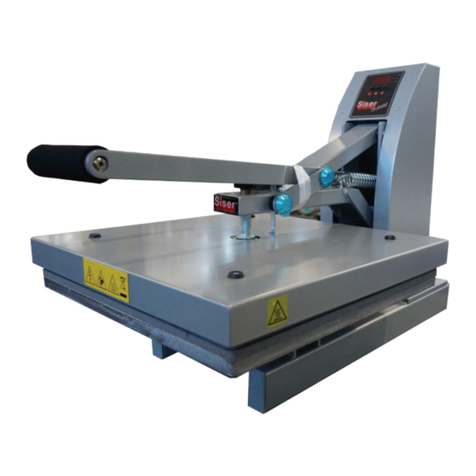

Ge eral Descriptio

The 288 is a manual swing-away machine capable of

generating tremendous pressure that is evenly

distributed across the area of the 20’’ x 25’’ platen.

The 288 machine also features a quick-change

mechanism in the lower platen allowing the lower

platen to be switched or rotated in a matter of

seconds. The heating platen features a cast-in

tubular heating element that is densely coiled to

deliver rapid heating and constant, long-lasting and

uniform temperatures.

Limited Machi e Warra ty

Insta Graphic Systems warrants this heat seal

machine, when operated under normal conditions,

to be free from manufacturing defects in material

and workmanship for a period of one (1) year on

parts and 90 days on labor from the invoice date.

This warranty will be effective only when Insta

authorizes the original purchaser to return the

product to the factory in erritos, alifornia, freight

prepaid, and only when the product upon

examination has proven to be defective.

This warranty does not apply to any machine that

has been subjected to misuse, negligence, or has

been damaged accidentally or intentionally.

Insta shall not be liable for the injury, loss, or

damage, directly or indirectly, arising from the use

or the inability to use the product.

No claim of any kind shall be greater in amount

than the sale price of the product or part to which

claim is made.

See extended warranty information at the end of

the manual.

I stallatio

Please fill out the followi g for future use:

MODEL NO:

SERIAL NO:

MANUFACTURE DATE:

PURCHASE DATE:

PURCHASE VENDOR:

3

FOR USE BY QUALIFIED PERSONNEL ONLY

288 N MODEL, 230 VOLT

Use a desig ated 16 Amp A circuit.

Only industrial extension cords with

proper wire size (2.5 mm

2

) shall be

used.

IMPORTANT

The appliance must be plugged into

a proper receptacle of the proper

size and rating. Equally important,

the line voltage must be able to

accommodate this appliance as well

as other appliances operating on this

circuit.

Specificatio s

Voltage

230 Volts AC

50/60 Hertz

Model 288

230 V

33

00 Watts

14.3

Amps

Machine Weight

(Dry) 145 lbs 65.9 kg

Shipping

Weight

(Box & Pallet)

189 lbs 85.9 kg

Degree of Protectio

The IP (Ingress Protection) rating of this machine

according to IE 60529 is:

IP54 = IP

1

st

Digit = 5 (Dust Protected)

2

nd

Digit = 4 (Splashing Water)

1

st

Digit Protection from

solid objects 2

nd

Digit Protection from

moisture

0 Not protected 0 Not protected

1 Objects greater

than 50 mm 1 Dripping water

2 Objects greater

than 12 mm 2

Dripping water

when tilted up

to 15°

3 Objects greater

than 2.5 mm 3 Spraying water

4 Objects greater

than 1 mm 4 Splashing water

5 Dust protected 5 Water jets

6 Dust tight 6 Heavy seas

-- --- 7 0.15 m – 1 m

immersion

-- --- 8 +1 m

submersion

NOTE:

IEC 60529 does not specify sealing effectiveness against

the following: mechanical damage of the e uipment; the

risk of explosion; certain types of li uid conditions, e.g.

those that are produced by condensation; corrosive

vapor; fungus; vermin.

4

FOR USE BY QUALIFIED PERSONNEL ONLY

Safety a d Da ger Zo e Diagram

Operati g E viro me t

To maximize user safety, ensure that the

following operating conditions are met:

3. The workspace does not restrict access to the main

power switch or power cord.

4. The workspace is free of any forms of liquid.

5. The power cord is not overextended.

6. The machine is connected to a surge protector.

Taking these steps is crucial in maximizing user

safety and ensuring a long, trouble-free life for your

machine!

1. The machine is placed on an even, non-

flammable surface.

2. The surface can support a minimum of

300 lbs (136 kg).

Do not handle the

machinery with

wet hands

This is a hot surface.

Avoid contact with

upper platen shroud

Keep hands clear

between the upper

and lower platens

Machinery should be

operated on a secure

flat surface

Do not disable safety

lock during normal

operation

Always place handle in the

full back position when

machine is not in operation

FOR USE BY QUALIFIED PERSONNEL ONLY

Co figuri g Your Machi e

Once you have correctly installed your machine

will want to

configure the settings of your machine

to match your needs.

1.

Tur the machi e o

Plug

your machine

in

,

turn

power switch on,

and press the

button on the control panel

.

The display will briefly show the

controller program revision

2.

Set the operati g

T

emperature

a.

If the temperature is not shown, press

MODE

to cycle to the temperature

display.

NOTE

:

If the platen temperature is BELOW 2

25

°C, the controller will display “Lo F

” or “

depending on the

units the controller is set to.

b.

Press

SET

to display the current set

temperature.

To raise the temperature, hold

UP.

+

To decrease the temperature, hold

and DOWN.

+

3.

Give the machi e time to heat

FOR USE BY QUALIFIED PERSONNEL ONLY

Co figuri g Your Machi e

Once you have correctly installed your machine

, you

configure the settings of your machine

turn

the

main

and press the

POWER

.

The display will briefly show the

controller program revision

number.

emperature

If the temperature is not shown, press

to cycle to the temperature

25

°F OR 107

” or “

Lo C”

units the controller is set to.

to display the current set

To raise the temperature, hold

SET and

To decrease the temperature, hold

SET

Give the machi e time to heat

1

+

NOTE:

Heating may take between 20

minutes depending on the set

temperature. Do not leave the

machine unattended during t

2

2

2

2

MODEL 288

MODEL 288

MODEL 288

MODEL 288

5

1

1

1

+

Heating may take between 20

to 45

minutes depending on the set

temperature. Do not leave the

d during this time!

MODEL 288

MODEL 288

MODEL 288

MODEL 288

FOR USE BY QUALIFIED PERSONNEL ONLY

4.

Set the desired

P

ressure

Adjust the pressure adjust

crank

behind the top housing.

a.

Turn the

crank

CLOCKWISE

to

the pressure.

b.

Turn the

crank

COUNTER

-

CLOCKWISE

INCREASE the pressure.

NOTE:

Increasing the pressure increases the

force re uired to close the platens. To

avoid user injury or d

amage to the

machine, do not attempt to force the

platens closed at very high pressure

levels.

5.

Set the

A

pplicatio time

a.

Press

MODE

to cycle to the time display.

b.

Press

SET

to display the

application time.

To increase the appli

cation time, hold

SET and UP.

+

To decrease the application time, hold

SET and DOWN.

+

FOR USE BY QUALIFIED PERSONNEL ONLY

crank

located

to

DECREASE

CLOCKWISE

to

Increasing the pressure increases the

force re uired to close the platens. To

amage to the

machine, do not attempt to force the

platens closed at very high pressure

to cycle to the time display.

application time.

cation time, hold

To decrease the application time, hold

Increase pressure

1

2

+

2

2

MODEL 288

MODEL 288

MODEL 288

6

Decrease pressure

1

1

+

MODEL 288

MODEL 288

MODEL 288

7

FOR USE BY QUALIFIED PERSONNEL ONLY

Basic Operatio

1.

Swing the

upper platen

to the right using

the stainless steel handle.

2.

Place the substrate on the lower platen.

3.

Position the

transfer or lettering on the

substrate.

4

.

Swing the

upper platen

bac

k using the

stainless steel handle.

5

.

lose the platens by pulling the handle

down with both hands until the machine

self-locks.

NOTE:

Do not attempt to force the platens

closed. Doing so may result in user

injury or damage to the machine.

6

.

The timer will start automatically when

the platens are closed. A buzzer will

sound when the timer reaches zero.

7

.

Release the handle lock and

bring

the

handle up completely to the back to keep

the platen raised. Swing away the upper

assembly and remove the substrate.

WARNING

:

Use only the stainless steel handle to

swing the upper platen open and

closed. Do not push or pull the upper

platen to swing the top assembly.

WARNING:

When replacing the lower platen, Raise

up and keep the upper platen close to

the center position, Do not lean on

machine to prevent tipping over.

Co troller Features

Basic Co troller Fu ctio s

This controller has two (2) main control features:

1. Temperature – the temperature may be set

from 225 – 425 °F (107 – 218 ° ).

2. Timer – the cycle timer may be set from 1

second to 99:00 minutes.

Temperature Co trol

The temperature control has a range from 225 –

425 °F (107 – 218 ° ). The temperature unit can be

switched between °F and ° , and a temperature

offset can be applied to adjust the temperature

reading (see advanced controller functions on pg.8).

For setting the set temperature, see Configuring

your Machine on pg. 5.

Timer

The controller features an application timer that will

countdown and will start beeping when the timer

has reached 0. The time display is in the

minutes:seconds format, and ranges from 00:00 to

99:00. When the timer is running, the colons (:) will

flash. For setting the application timer, see the basic

operations section.

FOR USE BY QUALIFIED PERSONNEL ONLY

Adva ced Co troller Fu ctio s

Automatic Shut Off

The automatic shut off function is designed to

reduce electrical usage when the Insta heat seal

machine is idle. When active, any user input such as

key presses or starting a h

eat press cycle will reset

the timer for the automatic shut off.

The automatic shut off has a o -

adjustable timer

of 2 hours.

By default, the automatic shut off is

Setti g the Automatic Shut Off

The automatic shut off can be set to

ON

1. Press MODE to cycle to the

TIMER.

→

2. Press and hold UP and DOWN

for 3 to 5

seconds to turn the automatic shut off

or OFF.

a. ONE

beep indicates that the

automatic shut off is

OFF

b. TWO beeps indicate

that the

automatic shut off is

ON

Cha gi g the Tempera

ture Scale

1. Press MODE to cycle to the

TEMPERATURE

→

2. Press and hold UP and

DOWN

seconds to switch the temperature scale.

+ →

FOR USE BY QUALIFIED PERSONNEL ONLY

Adva ced Co troller Fu ctio s

The automatic shut off function is designed to

reduce electrical usage when the Insta heat seal

machine is idle. When active, any user input such as

eat press cycle will reset

adjustable timer

By default, the automatic shut off is

o .

ON

or OFF.

TIMER.

for 3 to 5

seconds to turn the automatic shut off

ON

beep indicates that the

OFF

.

that the

ON

.

ture Scale

TEMPERATURE

.

DOWN

for 3 to 5

seconds to switch the temperature scale.

Setti g the Temperature Offset

1.

Switch the temperature scale to Fahrenheit.

2. Let th

e platen temperature stabilize. Use a

heat-

reading tool such as a

temperature strips to find the temperature

at the center of the platen.

3. Enter the

temperature offset adjust

pressing and holding

MODE

5 seconds.

+

→

4.

XX is the current temperature offset. Press

SET and UP

to increase the offset.

Increasing the offset will increase the

display temperature by the corresponding

amount.

+

→

→

Press SET and DOWN

offset. Decreasing the offset will decrease

the display temperature by the

corresponding amount.

+

→

→

5.

hange the offset so that the display

temperature matches the temperature

measured in step 1.

6. When the des

ired temperature offset has

been reached, press and hold

SET

for 3 to 5 seconds to exit

+

NOTE:

For

the best accuracy, it is suggested

that the temperature offset adjustment

be done in the Fahrenheit scale.

8

Setti g the Temperature Offset

Switch the temperature scale to Fahrenheit.

e platen temperature stabilize. Use a

reading tool such as a

pyrometer or

temperature strips to find the temperature

at the center of the platen.

temperature offset adjust

by

MODE

and SET for 3 to

→

XX is the current temperature offset. Press

to increase the offset.

Increasing the offset will increase the

display temperature by the corresponding

→

to decrease the

offset. Decreasing the offset will decrease

the display temperature by the

corresponding amount.

→

hange the offset so that the display

temperature matches the temperature

ired temperature offset has

been reached, press and hold

MODE and

for 3 to 5 seconds to exit

.

the best accuracy, it is suggested

that the temperature offset adjustment

be done in the Fahrenheit scale.

9

FOR USE BY QUALIFIED PERSONNEL ONLY

Preve tive Mai te a ce Suggestio s

Insta heat seal machines are relatively maintenance

free. For a long, trouble-free life, the following

preventive maintenance should be followed:

1. lean the Teflon-coated upper platen

periodically with a piece of non-abrasive

cloth. Stubborn stains may be removed with

mineral spirits when the platen is cool. Take

care not to rub the Teflon coating off.

2. To prevent the substrates from becoming

soiled, periodically wipe the entire exterior

of the machine, including the platens, with

a clean rag. If necessary, use mineral spirits

for cleaning a cold machine. Since mineral

spirits are flammable, do not clean with

mineral spirits while the machine is hot.

3. Periodically lubricate the joints and pins of

the machine with a high-temperature, non-

melting grease (MPPL023).

4. Avoid directly pressing items such as

buttons, pins, snaps, or zippers that tend to

cut the silicone rubber pad or scratch the

Teflon-coated heat platen.

Ge eral Mai te a ce

It is recommended that you have the following

items available:

1. Phillips head screw driver

2. Needle nose pliers with insulated handle

3. Set of metric Allen wrenches

4. Special multi-purpose grease MPPL023

5. Grease Gun Kit MAPG010

With the above items you should be able to

accomplish most repairs.

WARNING:

Do not attempt to remove the upper

platen alone.

Replaci g the Silico e Pad

1. Make sure that the lower platen is cool.

Remove the lower platen from the machine

base.

2. Use a mild solve t such as mi eral spirits

to clean the surface of the lower platen.

3. Both the silicone pad and lower platen must

be thoroughly dry and clean (wait at least

45 minutes after using the solvent) before

starting the bonding operation.

4. Use a tube of MPP 006 adhesive to bond

the silicone rubber pad to the lower platen.

Spread a thin and even coat over the lower

platen. lear any excessive adhesive from

the side edges of the lower platen.

5. Quickly apply the silicone pad. Make sure

no air bubbles form.

6. Remove excess glue from the edges of the

platen. Flip the platen over, pad-down, and

allow it to cure for 24 hours at room

temperature.

NOTE:

Read and follow all instructions on the

adhesive package.

A putty knife or similar tool is

recommended for spreading the adhesive

evenly on the lower platen.

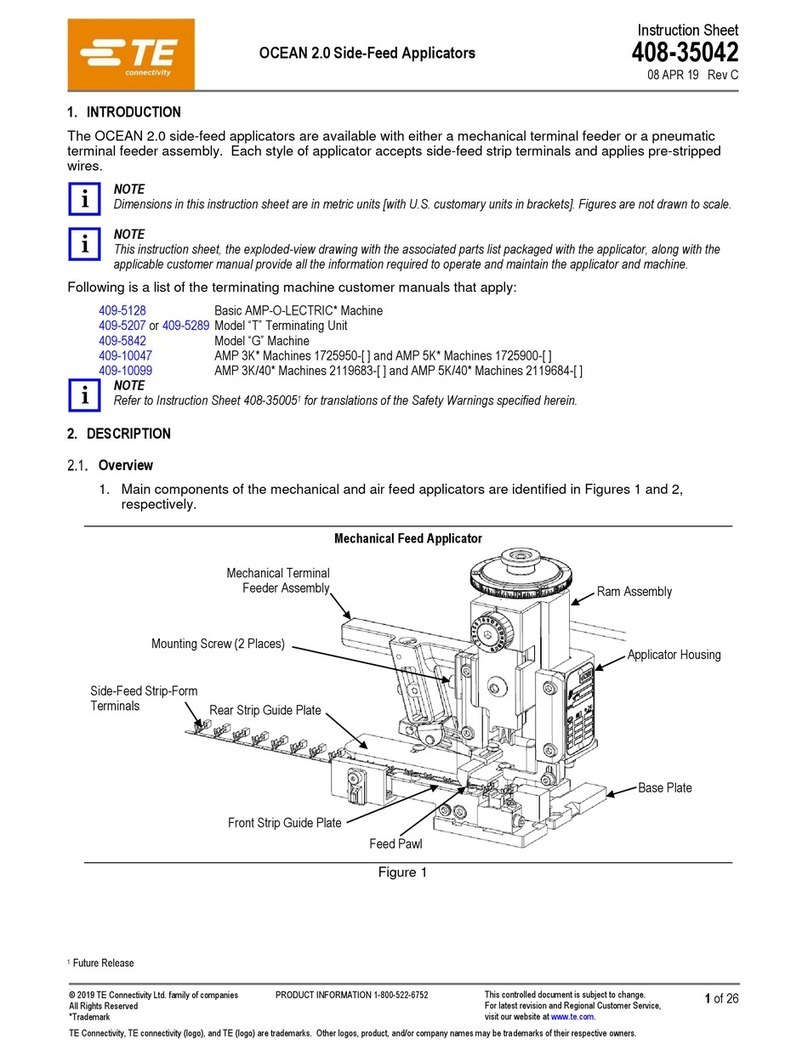

TRANSFORME

R

SSR

1

2

BROWN

GRN/YEL

GRN/YEL

GREEN

GREEN

BLACK

BLACK

WHITE

WHITE

P

OWER

SWITCH

WHITE

GRAY RED

TERMINAL

BLOCK

1

2

3

4

+12V

4

5

3

6

7

TIMER

INPUT

NC

RTD

HEAT PLATEN

AC

INLET

VIO

YELLOW

VIO

COM

NC

Circuit

Breaker

20A

250V

+

-

BLACK

1

2

5

6

12

11

7

SENSOR

RTD

WHITE

GRN/YEL

GREEN

BLACK

MICRO

SWITCH

12 VAC

LIMITE

R

HI TEMP

GRN/YEL

BROWN

WHITE

WHITE

WHITE

WHITE

TAN

TAN

MODEL 288 WIRING DIAGRAM

!

"

#

$!

$!

%

&

'#

'

(

)

"*

""

"#

"

"!

"%

"&

"'

"(

")

#*

#"

$#

$#

$!

$#

$#

$#

##

#

#!

#&

#'

#(

#)

$!

$!

*

"

#

!

%

&

'

(

)

!*

!"

!#

"*

$#

$#

$#

$#

$#

!

!!

!%

!&

!'

"&

$

$%

$%

'*

'"

'#

'

'!

%

'%

(*

("

"**

&%

(# (%

(&

('

'(

(

(!

"*"

"*#

"

%

((

()

)*

!'

$#

$!

$!

$#

$

$#

$#

'(

+

')

+

'&

&%

&&

&'

&(

&)

$#

%&

%'

%(

%)

&*

!'

!&

&!

&

&#

$#

$#

$!

$

&"

)

!(

!)

%*

%"

%

%#

%!

%%

$#

$#

$#

$#

$#

$!

$!

)

)"

)#

)

$!

$!

$!

#%

'#

)!

)%

)&

)'

$#

$#

)(

))

#*"',*(,""

-./01+2/3#((+45678949+9:1;-.<

FOR USE BY QUALIFIED PERSONNEL ONLY

12

FOR USE BY QUALIFIED PERSONNEL ONLY

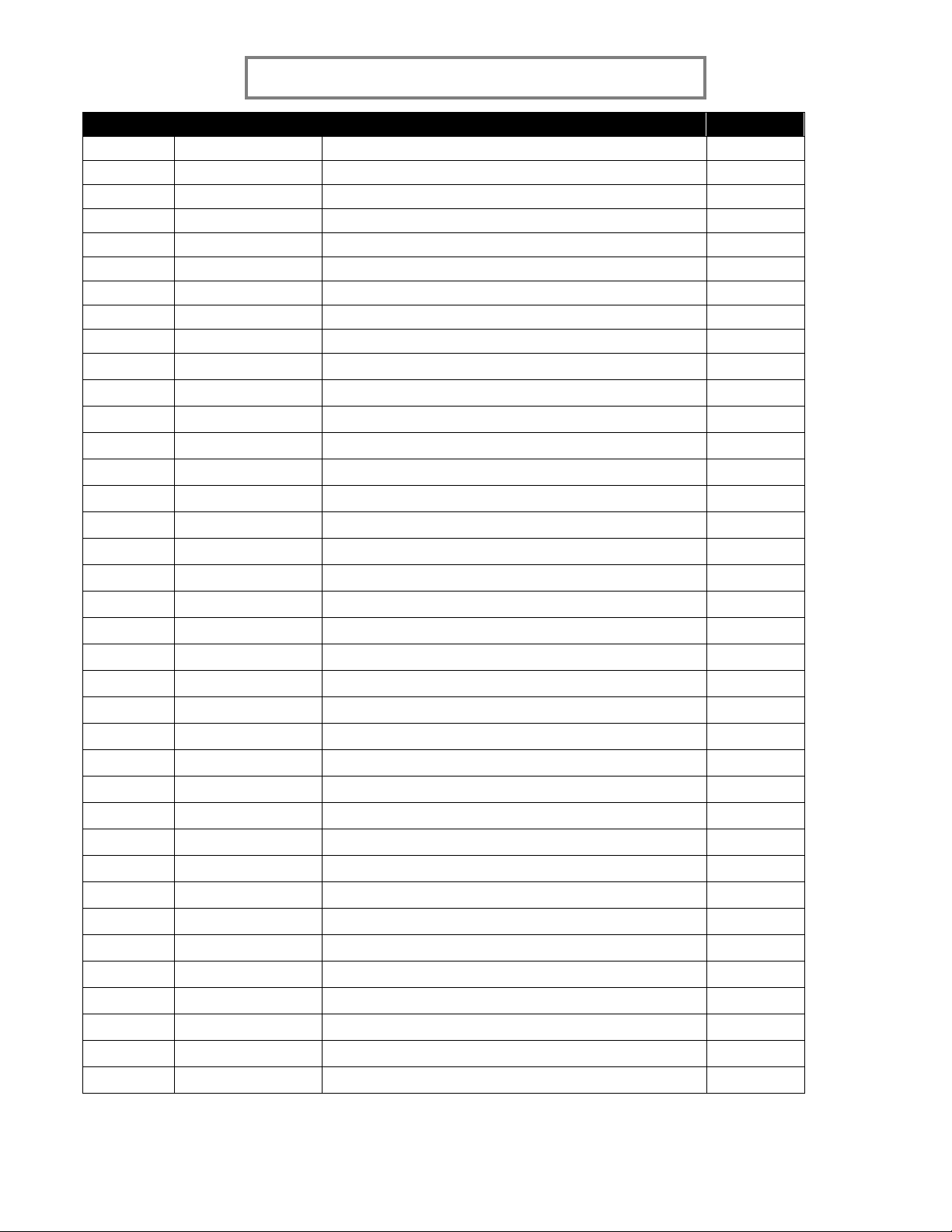

ITEM No. PART NO. DESCRIPTION QTY

1

MH001-M04-009 S REW, PAN HEAD, M4 X 15 4

2

MH007-030 SILI ONE RUBBER FOOT 4

3

MP288-007-011 HEAT SHROUD 1

4

MP288-007-012 FIBERGLASS INSULATION 1

5

MH007-019 -RING, LEVIS PIN 4

6

MP288-007-013 LEVIS, UPPER PLATEN 1

7

MPPT046 HIGH TEMPERATURE LIMITER (230V) 1

8

MP256-003 PLASTI STANDOFF 4

9

MP288-007-013 UPPER PLATEN, 20 X 25 (230V) WITH WIRING 1

10

MH007-054 SILI ONE PAD 20 X 25 1

11

MP288-007-014 LOWER PLATEN, 20 X 25 1

12

MH256-009-001 SENSOR, RTD TEMP 2

13

MH001-M08-010 S REW, HEX HEAD, M8 x 25 6

14

MP256-006 PIN, LEVIS 1

15

MH288-001-001 S REW, HEX,M6x60 1

16

MH288-002-001 NUT, HEX M6 6

17

MP256-004 GUIDE POST 1

18

MH001-M08-013 S REW, SET, M8 x 10 1

19

MP288-007-001 LOADING BAR 2

20

MP256-009 SHAFT, LOWER PLATEN 1

21

MH001-M08-009 S REW, SO KET HEAD, M8 x 20 1

22

MP288-007-015 OVERLAY, ONTROLLER (288) 1

23

MP256-013 ONTROLLER BRA KET 1

24

MH288-003-001 WASHER, FLAT 3.2x10x0.8 4

25

MH288-002-002 NUT, HEX M3 4

26

MH006-003 ONTROLLER 1

27

MH288-001-002 S REW, PAN M3x6 4

28

MP288-004-001 SWIT H, RO KER 250V 20A 1

29

MP256-010 HOUSING 1

30

MP256-029 LEVER ARM HANDLE 2

31

MH001-M10-001 LEVER ARM HANDLE THREADED STUD 1

32

MP288-007-016 LEVER ARM 1

33

MH001-M08-005 S REW, SO KET HEAD, M8 x 28 2

34

MP288-001 BRA KET, ARM (L) 1

35

MP256-027 SAFETY LO K 1

36

MP288-007-017 AM 1

37

MP288-007-002 SPA ER, ARM 2

38

MH288-003-002 WASHER, LO K 8.3x13.6x1.6 2

39

MH002-M08-001 NUT, HEX, M8 8

40

MP288-004 PIN , SPRING 1

13

FOR USE BY QUALIFIED PERSONNEL ONLY

ITEM No. PART NO. DESCRIPTION QTY

41

MP288-005 AP PLASTI ,BLK 1

42

MP288-002 LEVER ARM BRA KET, RIGHT 1

43

MH001-M06-013 S REW, SO KET HEAD, M6 x 14 5

44

MP288-007-018 SWING AWAY ARM ASSEMBLY 1

45

MP288-007-003 BRA KET ASS'Y 299x105x40 1

46

MH288-001-003 S REW M4 22.5x22.5 4

47

MH001-M08-014 S REW, SO KET HEAD, M8 x 10 6

48

MP288-007-004 UPPER PLATE AL 255x200x15 1

49

MH007-059 -RING, LEVIS PIN (288) 2

50

MP288-007-005 TUBE, FRONT 2

51

MH001-M08-005 S REW, SO KET HEAD, M8 x 28 2

52

MH007-060 -RING, LEVIS PIN (288) 1

53

MH003-M08-004 WASHER, 8.5 x 18 x 2 6

54

MP288-007-019 TUBE, REAR 1

55

MH288-007-001 O-RING,15.8x2.4 4

56

MH288-001-004 S REW, PAN M4x10 4

57

MH001-M04-010 S REW STD P PAN HD (SP) & FLAT WASHER M4x10 3

58

MH005-003 RELAY, SOLID STATE 40A 24-280VA 1

59

MP288-008-001 POWER TRANSFORMER 1

60

MP256-014 BRA KET ASSEMBLY, ELE TRONI S 1

61

MH288-001-005 S REW, PAN M4x10 1

62

MH256-004-001 ircuit Breaker 1

63

MP288-004-002 TERMINAL BLO K, 20A,250VA 1

64

MH007-026 ABLE LAMP, POWER ORD (230V ONLY) 1

65

MP256-017 PRESSURE TURN KNOB 2

66

MP288-007-006 RANK, PRESSURE 1

67

MH003-M08-004 WASHER, 8.5 x 18 x 2 2

68

MH288-001-006 S REW, HEX 5/16-18x1 1

69

MH001-M06-011 S REW, SO KET HEAD, M6 x 20 1

70

MP256-018 SHAFT, PRESSURE RANK THREADED 1

71

MP256-022 PRESSURE HANDLE OVER 1

72

MH288-001-007 S REW, M4x6 6

73

MH288-001-008 S REW, PAN, M3x16 2

74

MP288-004-003 SWIT H MI RO 250VA 11A 1

75

MP288-007-020 LEVER ARM PIN 1

76

MH256-007-001 PLUNGER 1

78

MH288-001-009 S REW PAN, M5x10 3

14

FOR USE BY QUALIFIED PERSONNEL ONLY

ITEM No. PART NO. DESCRIPTION QTY

79

MH007-025 ABLE LAMP 1

80

MT256-003 BASE 1

81

MB256-001-001 BOLT, QUI K HANGE 1

82

MH288-001-010 S REW, PAN,M4x8 1

83

MP288-007-007 ARM ASS'Y 1

84

MH007-033 RUBBER O-RING SEAL DH75-85-4.5/6 1

85

MP256-020 ADJUSTMENT WASHER 1

86

MH002-M12-001 NUT, HEX, M12 x P1.25 x 8t 1

87

MH002-M12-002 NUT, HEX LO KING, M12 x P1.25 1

88

MH003-M13-001 WASHER, FLAT, 13.5 x 27 x 2 2

89

MP256-019 STEEL SPRING 1

90

MH001-M08-012 S REW, SO KET HEAD, M8 x 16 2

91

MP288-007-021 H-FRAME BASE 1

92

MP288-007-008 FOOT,BLK 4

93

MH007-028 OVER, TUBE END 4

94

MP288-007-009 GROMMET, SILI ON RUBBER 1

95

MH288-001-011 S REW, M3x6 2

96

MP288-004-004 A INLET 15A 250V 1

97

MB256-007-003 POWER BOX (230V ONLY) 1

98

MH007-029 RUBBER ADJUSTMENT FOOTING 2

99

MP288-007-010 PLATE, SUPPORT 1

100

MH256-001-002 S REW, SO KET HEAD 5/16-18x1"L 1

101

MP288-007-022 PLATE, SPRING 1

102

MH001-M04-010 S REW, TRUSS HEAD M4 X 6 (288) 2

103

MP288-007-023 S REW, LO KING BOLT D10X28.3 1

15

FOR USE BY QUALIFIED PERSONNEL ONLY

INSTA GRAPHIC SYSTEMS

Heat Press Limited Warranty

This limited warranty (“warranty”) is given only to the original end-user/retail purchaser

(referred to in this warranty as “Original Purchaser”) of the accompanying product and

accessories (collectively referred to in this warranty as “The Product”).

What is covered?

•“The Product” includes Machines, Parts and/or Accessories.

•Except as otherwise provided herein, Insta Graphic Systems (“Insta”) warrants that The

Product will be free from defects in materials and workmanship when used under

normal conditions.

What is the length of the Warranty Periods?

•Machines: Lifetime on the heating element, one year parts and 90 days labor from the

original purchase date (end-user).

•Additional Parts and Accessory Items: 90 days from the original purchase date.

This warranty does not cover:

•Physical damage to the Product;

•Damage caused by improper installation, improper or abnormal use, misuse, neglect or

accident (including but not limited to transporting The Product without the proper

preparation and/or packaging);

This limited warranty is VOID, if

•the Product has been altered or modified in any way (including but not limited to

attempted warranty repair without authorization from Insta and/or alteration/removal of

the serial number).

•the warranty period is expired,

•the serial number label is missing or unrecognizable,

•the defect was subject to abuse, improper use not conforming to product manual

instructions

•the defect was subject to Force Majeure, such as acts of God, flood, lightning,

earthquake, war, vandalism, theft, brownouts or sags (damage due to low voltage

disturbances)

What to do if you think your Product is eligible for warranty service: Immediately report your

model, serial number and purchase date of the equipment.

What Insta will ask you to do?

After contacting Insta you may be asked to deliver (by hand if you prefer) or send The Product

properly packaged, freight prepaid, to Insta or Insta’s service center together with your bill of

16

FOR USE BY QUALIFIED PERSONNEL ONLY

sale. A Return Authorization is required for all returned goods. Failure to obtain the RA will

result in the refusal of the shipment.

You are responsible for the cost of shipping, packing of The Product and insurance (if

you desire). You are also responsible for loss or damage to The Product in shipping.

If The Product does not operate as warranted above during the applicable warranty period,

Insta shall, at its option and expense (except for shipping cost), repair the defective product or

part, deliver to the customer an equivalent product or part to replace the defective item. All

products that are replaced will become the property of Insta.

If The Product is not covered by this warranty, you will be charged for any service and/or

replacement parts/products at Insta’s then current published rates, as well as, for the freight.

What happens when Insta elects to replace your Machine?

When a replacement Machine is authorized by Insta, Insta will send a replacement Machine

and issue a Return Authorization for the return of the Product. The Purchaser will be charged

for the new machine at the time of the shipment. Once the machine is returned and the

warranty confirmed, The Purchaser will receive a credit/refund. The replacement machine you

receive (will be covered by the balance of the limited warranty period remaining on the original

product, plus an additional thirty (30) days. You will keep the replacement machine that is sent

to you and your original machine shall become the property of Insta.

THIS WARRANTY IS GIVEN IN LIEU OF ALL OTHER WARRANTIES, WRITTEN OR ORAL,

WHETHER EXPRESSED BY AFFIRMATION, PROMISE, DESCRIPTION, DRAWING,

MODEL OR SAMPLE. ANY AND ALL WARRANTIES OTHER THAN THIS ONE, WHETHER

EXPRESSED OR IMPLIED INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, ARE HEREBY DISCLAIMED. INSTA

SHALL HAVE NO LIABILITY FOR DEFECTS OF ANY NATURE WHATSOEVER EXCEPT AS

PROVIDED FOR HEREIN.

This Limited Warranty (and Insta’s obligation to you) may not be changed in any way unless

you and Insta sign the same piece of paper in which we (1) refer to The Product and your bill

of sale date, (2) describe the change to this warranty and (3) agree to make that change.

Important:

We recommend that you keep all original packing materials, in the event that you need to ship

the Product.

17

FOR USE BY QUALIFIED PERSONNEL ONLY

NOTES:

18

FOR USE BY QUALIFIED PERSONNEL ONLY

NOTES:

13925 E. 166

th

St. ● erritos, A USA 90702 ● (800) 421-6971 ● Fax (562) 404-3010

Parts Orders ● (800) 426-3609 ● (562) 404-3000 Ext. 215

Technical Support ● (800) 426-3609 ● (562) 404-3000 Ext. 208

In-House Repair ● (800) 426-3609

Table of contents

Other Insta Power Tools manuals