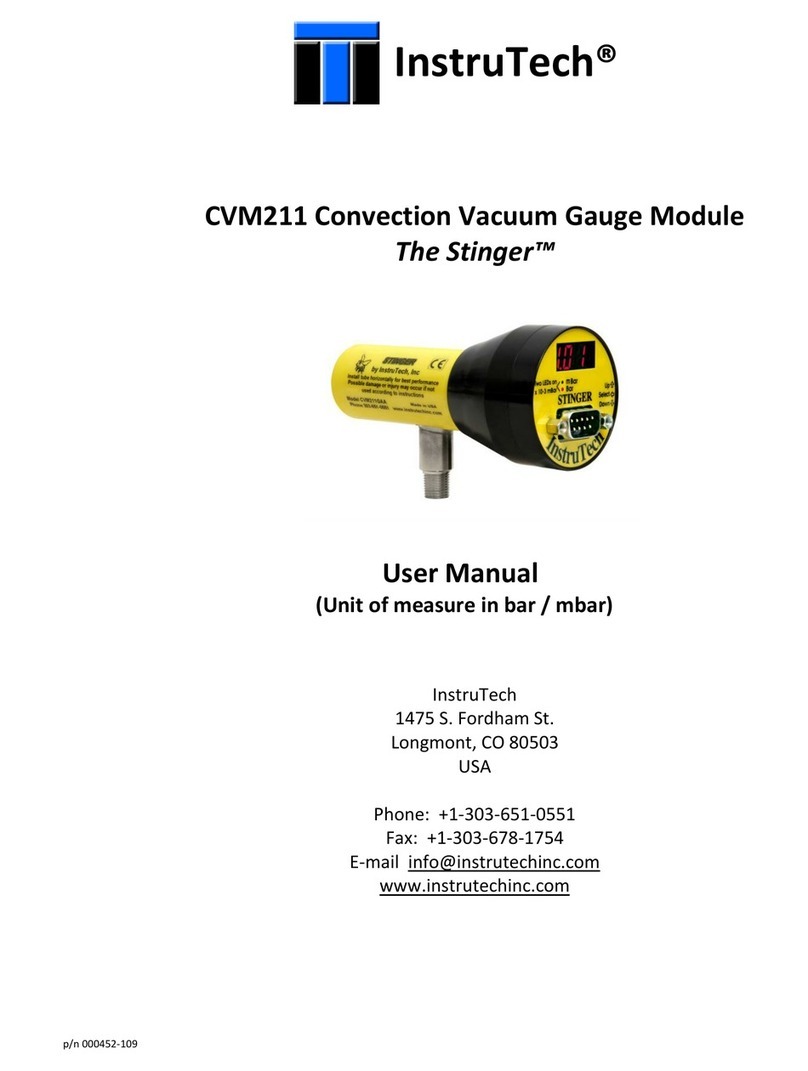

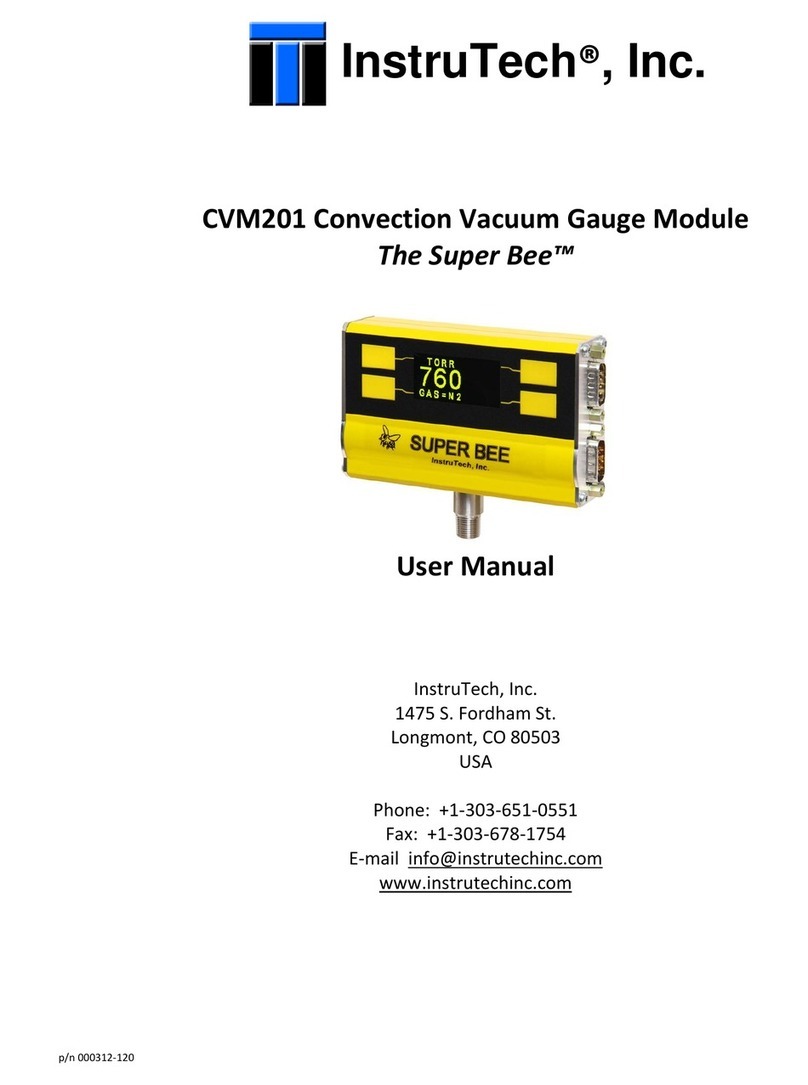

InstruTech Page 1

Table of Contents

1 Introduction / General Information....................................................................................................................3

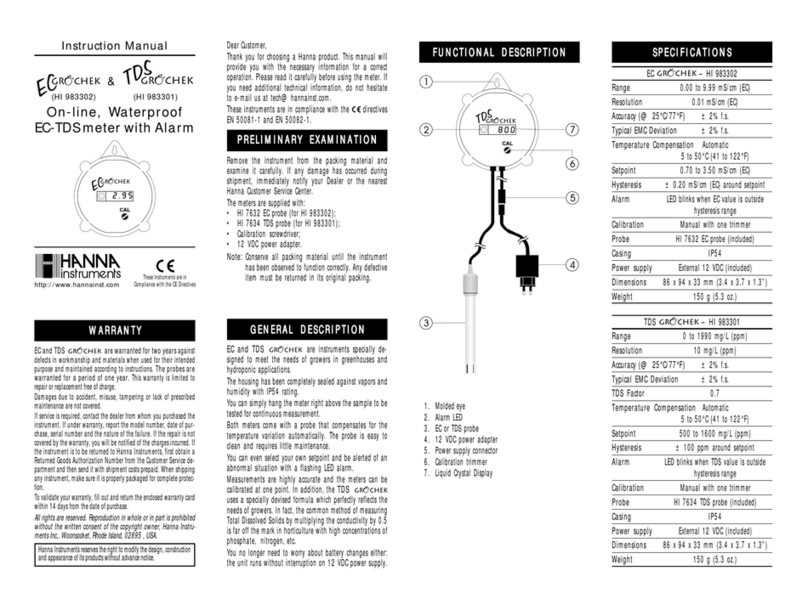

1.1 Description .................................................................................................................................................3

1.2 Specifications .............................................................................................................................................3

1.3 Dimensions.................................................................................................................................................4

1.4 Part Numbers .............................................................................................................................................5

1.5 Options & Accessories................................................................................................................................6

2 Important Safety Information.............................................................................................................................7

2.1 Safety Precautions - General......................................................................................................................7

2.2 Safety Precautions - Service and operation ...............................................................................................8

2.3 Electrical Conditions...................................................................................................................................8

2.3.1 Proper Equipment Grounding............................................................................................................8

2.3.2 Electrical Interface and Control..........................................................................................................9

2.4 Overpressure and use with hazardous gases.............................................................................................9

2.5 Gas Dependency.......................................................................................................................................10

3 Installation ........................................................................................................................................................10

3.1 Mechanical Installation............................................................................................................................10

3.2 Electrical Installation................................................................................................................................11

3.2.1 Grounding.........................................................................................................................................11

3.2.2 Connector.........................................................................................................................................12

3.2.3 Connector pin-out............................................................................................................................12

4 Setup and Operation.........................................................................................................................................13

4.1 Gauge start up and operation..................................................................................................................13

4.2 Gauge Status LEDs....................................................................................................................................13

4.3 Gauge Display...........................................................................................................................................14

4.4 Programming & configuration .................................................................................................................17

4.4.1 Relay setpoint characteristics (setpoint assigned to vacuum system pressure) .............................18

4.4.2 Programming the SP1 & SP2 setpoints with button on the gauge ..................................................20

4.4.3 Relay setpoint characteristics (atmospheric pressure (ATM) setpoint)...........................................21

4.4.4 Zero adjustment...............................................................................................................................22