Table of contents

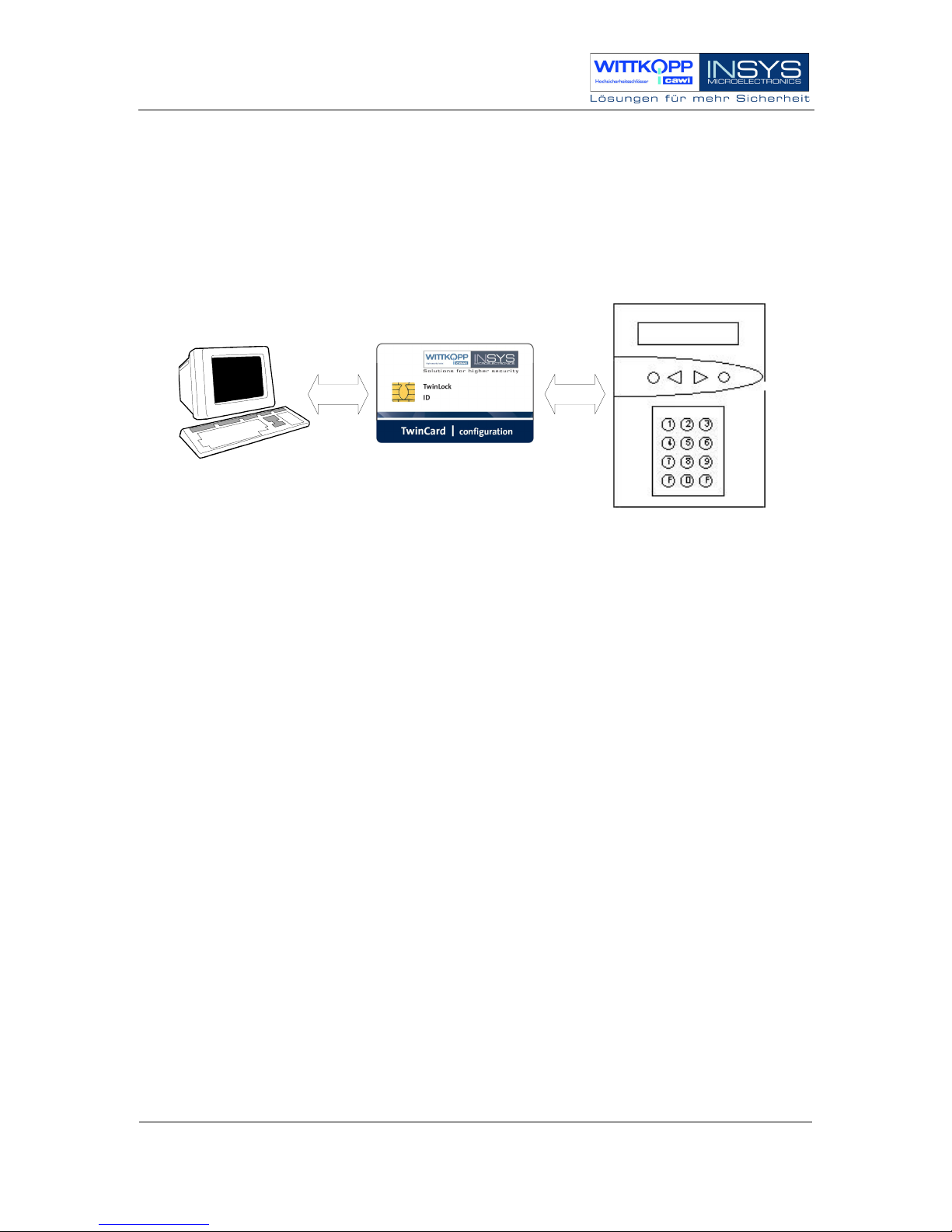

1. SYSTEM DIAGRAM ....................................................................................................................................... 6

2. SYSTEM DESCRIPTION................................................................................................................................ 7

2.1.

I

NPUT

U

NIT

:

F

LAT

C

ONTROL

......................................................................................................................... 7

2.2.

L

OCK

:

T

WIN

L

OCK COMPACT

........................................................................................................................ 7

2.3.

B

US

D

ISTRIBUTOR

:

T

WIN

C

ONNECT

.............................................................................................................. 7

2.4.

E

XTENSION

U

NIT

:

T

WIN

XT.......................................................................................................................... 8

2.5.

C

HIP

C

ARDS

(T

WIN

C

ARD

............................................................................................................................ 9

2.6.

C

ONFIGURATION

S

ET

T

WIN

C

OMM

.............................................................................................................. 10

3. FUNCTION DESCRIPTION......................................................................................................................... 11

3.1.

C

ODE AND

L

OCKING

F

UNCTIONS

................................................................................................................ 12

3.2.

T

IMER

F

UNCTIONS

...................................................................................................................................... 15

3.3.

S

ERVICE

F

UNCTIONS

................................................................................................................................... 16

3.4.

O

PERATIONAL

S

AFETY

................................................................................................................................ 17

3.5.

S

ABOTAGE SAFETY

...................................................................................................................................... 19

3.6.

PC

S

UPPORT WITH

C

ONFIGURATION

S

ET

T

WIN

C

OMM

................................................................................ 19

4. OPERATION .................................................................................................................................................. 20

4.1.

D

ISPLAY AND

C

ONTROL

E

LEMENTS OF THE

I

NPUT

E

QUIPMENT

.................................................................. 20

4.3.

G

ENERAL

O

PERATING

I

NSTRUCTIONS

......................................................................................................... 22

5. GENERAL OPERATION PROCESSES...................................................................................................... 24

5.1.

U

NLOCKING A

L

OCK

................................................................................................................................... 24

5.2.

C

LOSING A

L

OCK

........................................................................................................................................ 25

5.3.

S

TATUS

R

EQUEST OF A

L

OCK

/

VERSION REQUEST

....................................................................................... 26

5.4.

R

ESPONSES

.................................................................................................................................................. 27

6. PROGRAMMING THE SYSTEM WITH THE CONTROL UNIT .......................................................... 29

6.1.

R

EPROGRAMMING A

M

ASTER

C

ODE

............................................................................................................ 30

6.2.

R

EPROGRAMMING THE

M

ANAGER

C

ODE

.................................................................................................... 31

6.3.

P

ROGRAMMING AND

R

EPROGRAMMING OF A

U

SER

C

ODE

........................................................................... 32

6.4.

D

ELETE A USER CODE

.................................................................................................................................. 33

6.5.

D

ISPLAY THE

P

ROGRAMMED

U

SER

C

ODES

.................................................................................................. 34

6.6.

S

ETTING THE

D

ATE

,

T

IME AND

W

EEKDAY

.................................................................................................. 35

6.7.

C

ODE

L

INKAGE

P

ROGRAMMING

(F

OUR

-E

YE

-C

ODE

................................................................................... 36

6.8.

P

ROGRAM

U

NLOCKING

T

IME

D

ELAY

.......................................................................................................... 37

6.9.

P

ROGRAM

O

PENING

D

URESS

(F

ORCED

S

EQUENCE

..................................................................................... 38

6.10.

P

ROGRAM SILENT ALARM

.......................................................................................................................... 39

6.11.

P

ROGRAMMING ACTIVATION OF

T

WIN

XT

LOCK

I/O.................................................................................. 40

6.12.

R

ESET THE

I

NPUT

U

NIT

............................................................................................................................. 41

6.13.

L

OCK

M

OTOR

S

ERVICE

............................................................................................................................. 43

6.14.

R

EGISTER

/R

EPLACE

L

OCKS IN THE

S

YSTEM

.............................................................................................. 44

6.15.

W

RITE

L

OG AND

C

ONFIGURATION TO

C

HIP

C

ARD

.................................................................................... 45

6.16.

W

RITE

L

OG AND

C

ONFIGURATION TO

C

HIP

C

ARD

.................................................................................... 46

6.17.

R

EAD

N

EW

S

YSTEM

L

ANGUAGE

............................................................................................................... 47

6.18.

I

GNORE

B

OLT

S

YSTEM

P

OSITION

S

WITCH

................................................................................................. 48

6.19.

A

CTIVATE

P

ARALLEL

C

ODE

...................................................................................................................... 49

6.20.

A

UTOMATIC

L

OCKING

............................................................................................................................... 50

7. PROGRAMMING THE SYSTEM WITH THE PC SOFTWARE TWINCOMM................................... 51

7.1.

G

ENERAL

O

PERATION

................................................................................................................................. 52

7.2.

P

ROGRAMMING OF

G

ENERAL

S

ETTINGS

...................................................................................................... 54

7.3.

P

ROGRAMMING THE

U

NLOCKING

D

ELAY

.................................................................................................... 57