Intamsys FUNMAT PRO 310 User manual

FUNMAT PRO 310 Quick Start Guide

1

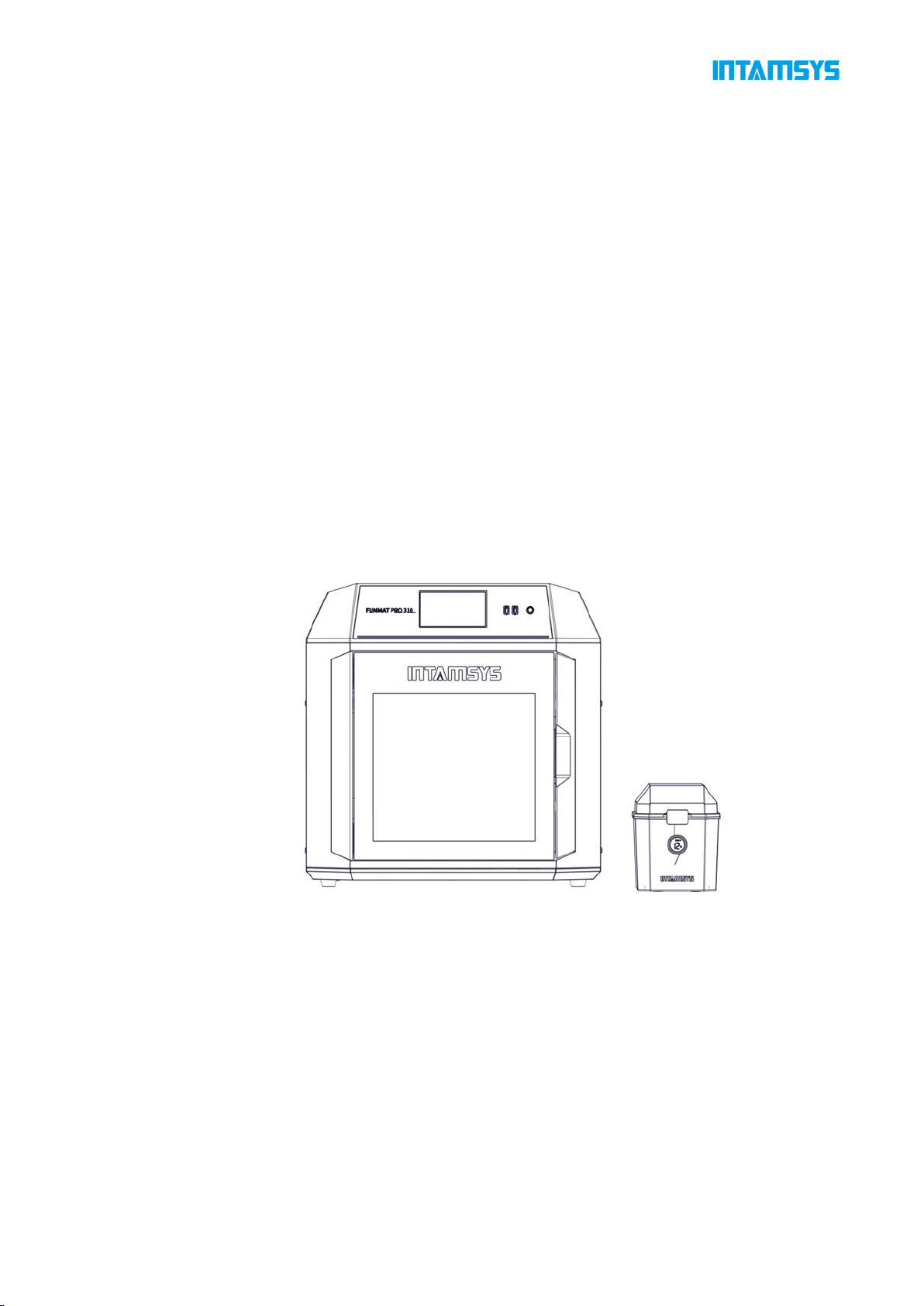

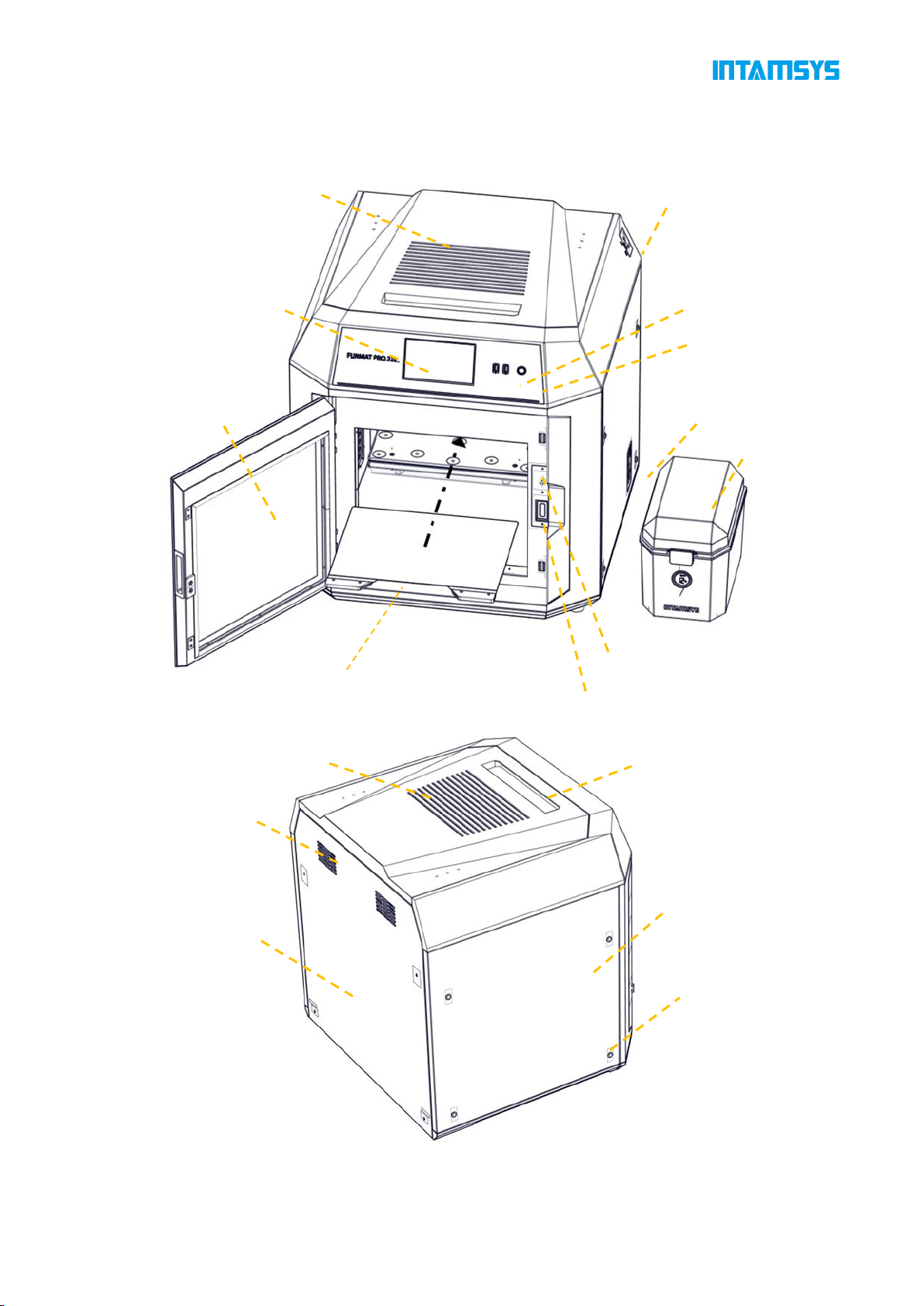

1. Product Appearance

Back side plate

Back air outlet

Top air outlet Top door handle

Left side plate

Outer cover screw

Build plate

Electromagnetic lock

Front door sensor

Power interface

Switch button

USB connection

Feeding entrance

Top cover

Operation interface

Watching window

Independent filament

2

2. Material Selection

Determine the required material for the model. If structural support is needed, select a printing support

material based on the chosen printing material.

Model

materials PLA ABS ABS+ ASA PC PC/ABS PA6/66 PA6-CF PA12-CF

Support

materials PVA/SP3030 HIPS SP3030 HIPS HIPS HIPS SP3030 SP3030 SP3050

INTAMSYS recommended model material and support material fit table

Note: Detailed printing process parameters for filaments can be found in the "FUNMAT PRO 310

Printing Process Guide".

3. Printer Preparation

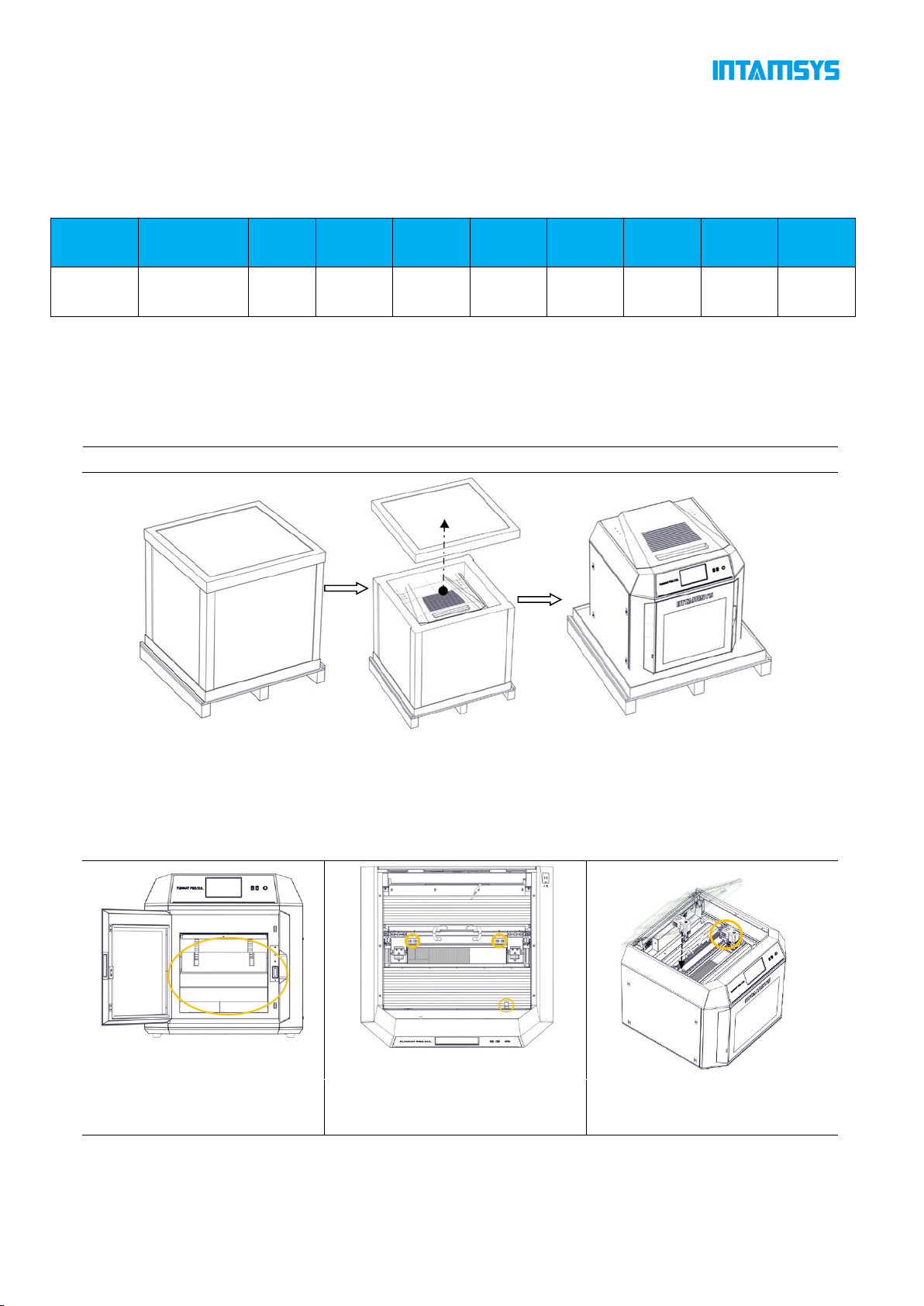

Unpacking

1) Remove the fixed straps from the packaging box and take off the wooden board on top of it;

2) Remove foam and packaging film;

3) Take off the top cover of the packaging box;

4) Remove paperboard and foam around the packaging box;

5) Lift up printer from bottom and move it to a stable working surface (at least two people are required).

6) Open front door of printer;

carefully remove accessories

7) Flip open printer's top cover.

8) Use an M4 hex wrench to

11) Install left/right nozzles

separately as shown in figure.

3

and material boxes from below. unscrew two screws that fixate X-

axis guide block, then remove X-

axis fixing block.

9) Repeat step 8 to remove Y-axis

fixing block fixed on front side

panel.

10) Turn off power, push printhead

out enough space by moving it

leftward, repeat same method to

remove right-side Y axis fixing

block;

12) Rotate the pressure rods on

both sides of the nozzle, fix the

nozzle and connect the nozzle

cable

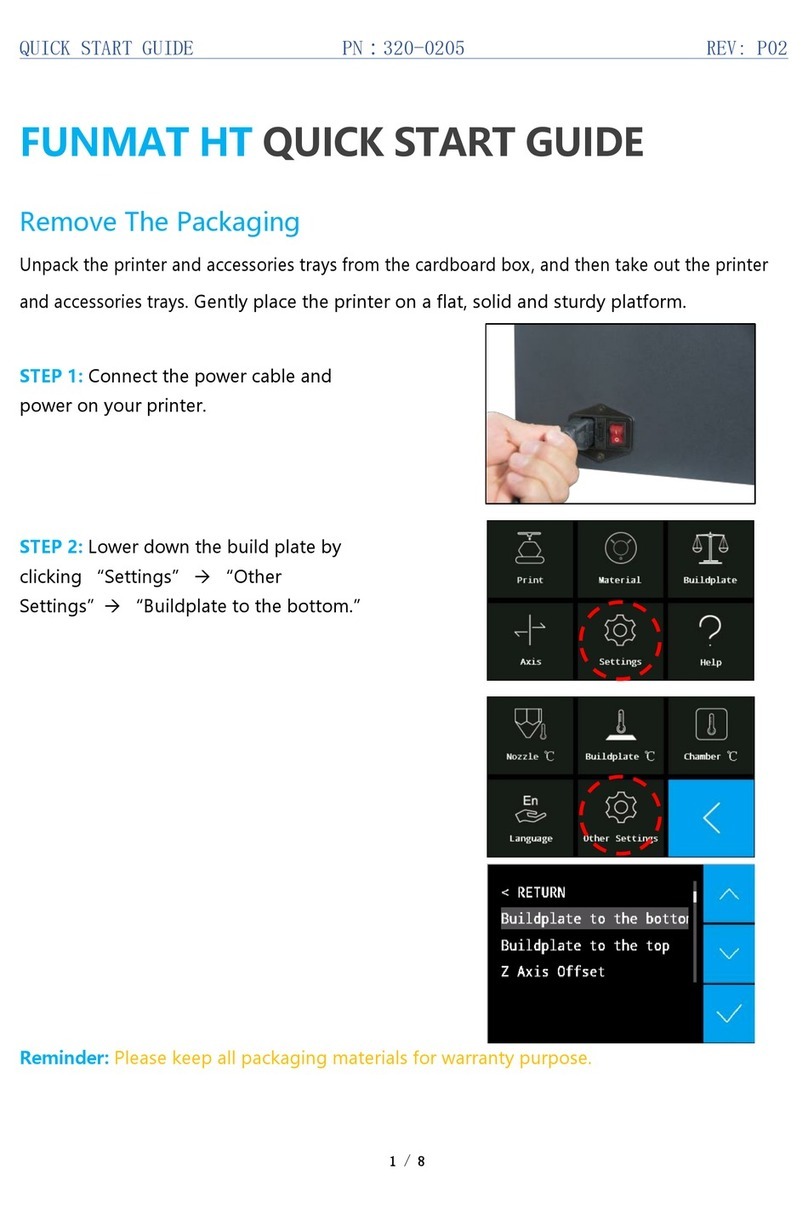

Startup and shutdown

1) The power plug is located at

lower right corner of machine;

connect power cord (two types

available: 110V or 220V), and

turn on power switch next to

printer's power socket so that it

is set at ON(I);

2) Then open front start-stop

switch located at right side of

screen, the indicator light will turn

on while operating screen enters

startup interface, printer starts

booting up;

3) To power off the printer:

Press the power button located

on the front of the printer. Note

that this action only shuts down

the printer. To fully disconnect

the printer, the main power

switch must be turned to the Off.

Installation of Printing Build Plate

1) Enter "Tools" interface, click

"Home All" button (make sure

that there are no other sundries

in chamber before operation);

2) After selecting the "Z Build

Plate" option in the upper part,

click "Z-Bottom" to move the

buildplate to the bottom of the

chamber;

3) Flatly adsorb the printing build

plate above the magnetic

platform along the guide grooves

on both sides of the platform, as

shown in the figure.

4

Material loading

1) Insert the feeding pipe in the

accompanying accessories of the

filament box into the quick

connector and the other end into

the quick connector located on

the right side of the printer. The

feeding pipe should be inserted

to the bottom for smooth

feeding.

2) Unbuckle the upper cover of the filament box, place the drying box

in the front slot of the filament box, put the wire rod on the roller of

the filament box as shown in the figure, and then thread the wire rod

through the quick connector at the rear end until the material

protrudes from the feeding pipe of the printer. After manual loading

is completed, buckle the upper cover.

3) Click the "Material" button on

the screen operation interface,

click the left or right spool icon

to select the extruder to be

loaded with materials. The

highlighted icon indicates the

extruder is activated;

4) Pressing the "Material

Database" button will display

INTAMSYS materials and user-

defined materials. Materials that

we used recently and frequently

will be at the top, scroll down to

select available materials. User-

defined materials can be

configured in material database.

5) Specifically, if the material on

the printer is inconsistent with

the material settings in the G-

code print file, the system will

alert the user to check the

material. Click "Apply". Then the

material will be automatically

applied to the L&R Nozzle.

6) After selecting the material,

press the Load button to load the

material step by step according

to the pop-up wizard.

5

Auto-leveling

Cautions:

During the installation of the printing build plate before leveling, it shall be correctly adsorbed on

the hotbed along the guide grooves on both sides of the platform base plate;

Clean the residual materials on the nozzle tip before leveling;

Clean the printing platform before leveling; no foreign matters shall be left;

Clean chamber to prevent the hot bed being lowered from colliding with foreign matters;

1) In the tool interface, click the

Calibrate button, and then click

the leveling button to enter the

automatic leveling

2) Enter the automatic leveling interface, you can choose simple or

full mode, corresponding to the automatic leveling mode of 16

points and 100 points, click "Next", after the leveling is completed, if

the display is successful, the automatic leveling is completed, if the

display fails, you need to manually adjust the level. Manual leveling is

detailed in §6.1/2 of the user manual

Z calibration

1) Click the Z Offset calibration

icon to enter the Z offset

calibration operation. The user

will first be prompted to prepare

the feeler (thickness 0.2mm) and

clean the buildplate. If it has

been cleaned up, click "Finished"

to officially enter the Z-shift

calibration operation

2) After heating, calibrate the left

nozzle first. According to the

prompts on the screen, place the

feeler ruler between the nozzle

and the glass platform, adjust it

roughly by the "Z↑0.05"/" Z↓0.05

"button, and fine-adjust it by the"

Z↑0.01 "/" Z↓0.01 "button until

the thickness of the feeler ruler is

just one. After adjustment, press

the next button

3) Then calibrate the right

printhead in the same way as the

left printhead. After adjustment,

press the "Next" button and click

"OK" to finish

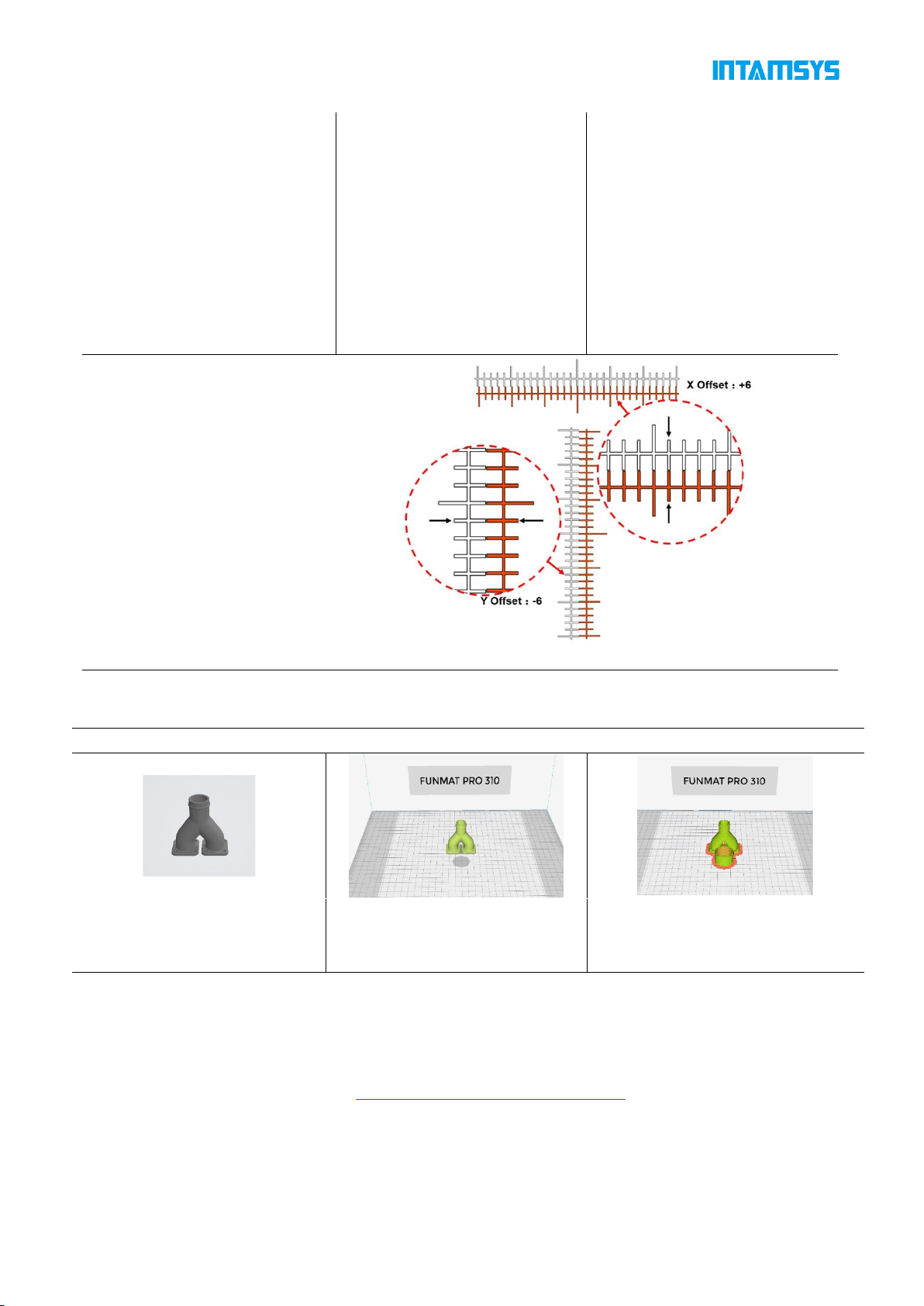

XY calibration

6

1) Click the XY Offset calibration

icon to prompt you to confirm

that the left and right printheads

and buildplate have been cleaned

and the materials have been

loaded. After confirming, click the

"Finished" button and the

calibration model printing will

begin.

2) The printheads and hotbed

will automatically set the

temperature according to the

selected material, and

automatically jump to the next

step after the temperature rises

to target temperature; The

printer will print the ruler with

the left and right nozzle

successively.

3) After printing, read the ruler to

get the X offset value and Y

offset value respectively, click the

"+"/" - "button to enter the value

Read the scale to obtain X offset value

and Y offset value respectively:

(1) Read the scale of the model printed

by the right extruder;

(2) First, read the X offset value to check

whether the center line is to the left or

right. Use the "-" value for the left and

the "+" value for the right;

(3) Find the scale line where the two

models are most aligned, then count

from the center line to this scale line and

record the value as N;

(4) Enter the "N" value into the input box.

4. Model 3D printing

Print model slices

1) Get model files

in .stl, .stp, .obj, .3mf, etc

2) Import INTAMSUITE to set

printing parameters.

3) After slicing, you can choose to

generate.gcode or.ifp format file (.ifp

file built-in preview image)

The INTAMSUITE slicing software needs to be installed on the computer(Win OS) in advance. The

software can set the printing parameters of the model and plan the slicing path, then generating a G-

code file that can be run and processed by the 3D printer. For software usage and parameter setting,

please referring to "INTAMSUITE User Manual".

Slicing software download address: https://www.intamsys.cn/software.html

Note: After the G-code file is generated, it will prompt you to estimate the material weight required for

printing the model. The printing wire should be greater than the estimated weight. If the amount of

wire is small, it is necessary to replace the wire during the printing process.

7

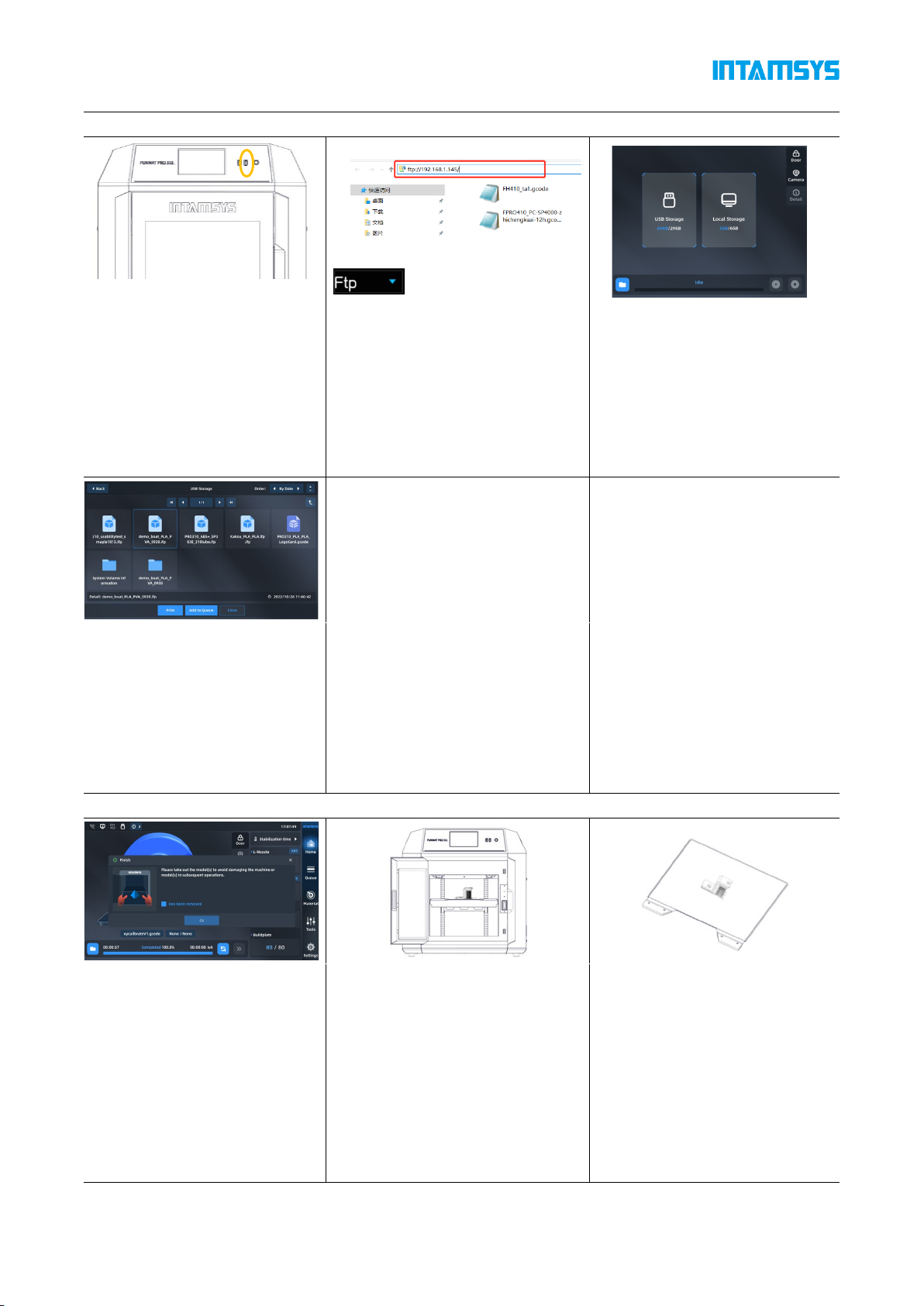

File import and print

1) Use USB storage (USB flash

drive) to import. After copying

through the USB flash drive,

insert it into the USB port on

the right side of the printer's

operation panel for the printer

to read

2) Use the network transmission,

enter the IP address of the printer

in the address bar of the window

folder on the computer side, and

transfer the G-code file to the

printer through the network for the

printer to read

3) Select USB storage or local

storage;

4) Select file and click "Print"

button to load. You can also

select "Add to queue" to add to

the print queue. If use the U

disk (U-disk) import method,

after loading the file, you can

pull out the U disk.

Print sample out

1) After printing, the printhead

will return to zero and stop, the

buildplate will automatically

move to the bottom, the

printing progress on the screen

will display 100%, the model

printing is completed. The

model and buildplate need to

be removed from the printer

2) Unlatch the door and open the

chamber front door, turn off the

heat preservation button in the

"Heat Preservation". At this time,

the front door and top cover will

be unlocked

3) Put on gloves and take out the

flexible plate; Bend the plate up

and down with both hands, and

the part will come away from the

bottom plate. remove support

material.

8

6 Process after printing

For model parts manufactured by FDM 3D printing, there may be significant lamination after

printing; In addition, some model parts need to add support, which will lead to rough support parts;

And there is deformation of the parts, resulting in differences between the printed solid model and its

digital model. Therefore, the printed sample can be post-processed according to the situation, and the

appearance of the sample can be improved under the premise of ensuring the size, structure and

mechanical properties of the sample. Common post-treatment processes include support material

removal and surface treatment.

Support material Removal Surface treatment

Water-soluble support material: It can be

removed using a high-pressure water gun,

ultrasonic cleaning machine, stirring type

cleaning machine, etc

Sanding: hand sanding, sandblasting, shot

blasting, pearlescent treatment, etc

Chemical polishing: alcohol atomization

polishing, acetone fumigation polishing, etc

Repair: soil, glue, scraping atomic ash

Machining: turning, milling, drilling, etc

Parts back-end process: painting, biting,

electroplating, etc

Peeling support material: need to use hand tools

(such as: diagonal pliers, file, scissors, etc.) to

remove

FOLLOW INTAMSYS ON

www.intamsys.com

info@intamsys.com

HEADQUARTERS:

INTAMSYS Technology Co., LTD

Add: E11, No. 3188 Xiupu Road, Pudong New Area, Shanghai

BRANCH:

INTAMSYS TECHNOLOGY GmbH

35, Zeppelinstr., 73760 Ostfildern Deutschland

BRANCH:

INTAMSYS Technology, Inc.

11479 Valley View Road, Eden Prairie, MN 55344

Copyright ©2023 INTAMSYS Technology. All rights reserved. The information at hand is provided as

available at the time of printing, INTAMSYS reserves the right to change any information without updating

this publication.

Other manuals for FUNMAT PRO 310

1

Table of contents

Other Intamsys 3D Printer manuals

Intamsys

Intamsys FUNMAT PRO User manual

Intamsys

Intamsys Funmat Pro 410 User manual

Intamsys

Intamsys FUNMAT PRO User manual

Intamsys

Intamsys FUNMAT PRO 310 User manual

Intamsys

Intamsys FUNMAT HT User manual

Intamsys

Intamsys FUNMAT HT User manual

Intamsys

Intamsys FUNMAT HT User manual

Intamsys

Intamsys Funmat Pro 410 User manual

Intamsys

Intamsys Funmat Pro 410 User manual