Intamsys FUNMAT PRO 310 User manual

3D Printer User Manual

FUNMAT PRO 310

Engineering Materials | Desktop Industrial Grade

I

Contents

1 Service and Support ............................................................................................................................1

1.1 Service........................................................................................................................................1

1.2 Safety Instructions......................................................................................................................1

1.2.1 Hazard type .....................................................................................................................1

1.2.2 Areas with potential safety hazard...................................................................................2

1.2.3 Safety door lock ..............................................................................................................3

1.2.4 Environmental requirements ...........................................................................................4

2 Setting and Installation .......................................................................................................................1

2.1 General Information ...................................................................................................................1

2.1.1 Tools that come with the printer ......................................................................................1

2.1.2 Prepare relevant equipment for installation.....................................................................1

2.1.3 Check the printer nameplate............................................................................................5

2.2 Printer Preparation......................................................................................................................5

2.2.1 Unpack ............................................................................................................................5

2.2.2 Remove accessories.........................................................................................................6

2.2.3 Unbuckle X-axis and Y-axis............................................................................................6

2.2.4 Startup .............................................................................................................................7

2.2.5 Installation of Printing Build Plate..................................................................................8

3 System Components ............................................................................................................................9

3.1 Printer Overview ........................................................................................................................9

3.2 Top Door and User Operation Interface ...................................................................................10

3.3 Printing Chamber Components ................................................................................................ 11

3.4 Independent Filament Box ....................................................................................................... 11

3.5 X/Y Axis Components..............................................................................................................13

3.6 Z-axis Components...................................................................................................................16

3.7 Hot Bed Components ...............................................................................................................17

4 User Interface.....................................................................................................................................18

4.1. Overview .................................................................................................................................18

4.1.1 Status bar.......................................................................................................................18

4.1.2 Navigation bar...............................................................................................................19

4.1.3 Display area...................................................................................................................20

4.2 Main Interface ..........................................................................................................................20

4.2.1 Loading print files .........................................................................................................21

4.2.2 Main status area.............................................................................................................22

4.2.3 Auxiliary status area ......................................................................................................23

4.2.4 Control area...................................................................................................................23

4.3 Queue .......................................................................................................................................24

4.4 Materials...................................................................................................................................25

4.4.1 Material selection ..........................................................................................................26

II

4.4.2 Material loading ............................................................................................................27

4.4.3 Material unloading ........................................................................................................28

4.4.4 Material database management .....................................................................................29

4.5 Tools .........................................................................................................................................31

4.5.1 Axis control ...................................................................................................................32

4.5.2 Calibration.....................................................................................................................33

4.5.3 Parameter Settings.........................................................................................................43

4.6 Settings .....................................................................................................................................44

4.6.1 Device information........................................................................................................ 44

4.6.2 Wireless network settings..............................................................................................45

4.6.3 Wired network settings..................................................................................................46

4.6.4 Camera settings .............................................................................................................46

4.6.5 Remote print..................................................................................................................47

4.6.6 Motor enabling ..............................................................................................................48

4.6.7 Screen lock password settings .......................................................................................49

4.7 Other Interfaces ........................................................................................................................50

4.7.1 Warning prompt.............................................................................................................50

4.7.2 Resume print .................................................................................................................50

4.7.3 Command line ...............................................................................................................51

5 Operate Printer..................................................................................................................................52

5.1Startup and Shutdown of Device ...............................................................................................52

5.1.1 Power on the printer ......................................................................................................52

5.1.2 Power off the printer .....................................................................................................53

5.2 Preparation of Print Materials ..................................................................................................53

5.3 Nozzle Replacement and Material Change .............................................................................. 56

5.3.1 Nozzle Replacement......................................................................................................56

5.3.2 Material change before printing ....................................................................................57

5.3.3 Pause to change material ...............................................................................................57

5.3.4 Supply filament after out-of-material warning..............................................................58

5.4 Basic Printing Operations......................................................................................................... 58

5.4.1 Prepare printer...............................................................................................................58

5.4.2 Import print file to the printer........................................................................................59

5.4.3 Load the print file..........................................................................................................60

5.4.4 Printing process.............................................................................................................61

5.4.5 Printing parameter settings............................................................................................62

5.4.6 Printing alarm................................................................................................................63

5.4.7 Pause printing................................................................................................................63

5.4.8 Stop printing..................................................................................................................64

5.4.9 After completion of printing..........................................................................................64

5.4.10 Locking of front door and top cover............................................................................ 65

5.5 Printer Status ............................................................................................................................66

5.5.1Temperature status..........................................................................................................66

5.5.2 Software version............................................................................................................66

III

6 Maintenance.......................................................................................................................................67

6.1 Inspection Before Each Printing...............................................................................................67

6.1.1 Inspect the printing platform .........................................................................................67

6.1.2 Clean the printing chamber ........................................................................................... 67

6.1.3 Inspect the nozzle .......................................................................................................... 67

6.2 Maintenance after Each Printing ..............................................................................................68

6.2.1 Clean the printing build plate ........................................................................................68

6.2.2 Clean the nozzle ............................................................................................................ 68

6.2.3 Clean the chamber.........................................................................................................68

6.3 Regular Maintenance................................................................................................................68

6.3.1 Clean feeding gears of the extruder...............................................................................68

6.3.2 Maintenance of moving parts ........................................................................................69

6.3.3 Maintenance of chamber filter ...................................................................................... 71

6.3.4 Maintenance and Replacement of Feeding Pipe............................................................71

6.4 Others .......................................................................................................................................73

7 Trouble shooting ................................................................................................................................ 74

IV

Record of Modification and Version Description

Version

Time

Description

E01

July 2023

First version of the Manual

1

1 Service and Support

This chapter provides information on the service and support of FUNMAT PRO 310 desktop

industrial grade 3D printers (hereinafter referred to as "FUNMAT PRO 310", the "printer", the

"machine" or the "device"), as well as safety information and location of safety labels.

1.1 Service

If you have any questions not covered in this manual during the use of the printer, please contact

INTAMSYS Customer Support:

Region

Email

Asia-Pacific

Support_AP[email protected]om

Europe, Middle East and Africa

Support_EME[email protected]om

America

Support_America@intamsys.com

1.2 Safety Instructions

The following basic security tips are intended to ensure safe installation, operation, and maintenance

of INTAMSYS equipment, and shall not be considered as comprehensive safety issues. The machine

is a safe and reliable industrial grade 3D printer. Make sure to inspect for and eliminate potential

hazards, if any, in the printer area before using this printer.

1.2.1 Hazard type

INTAMSYS recommends that all services be provided by qualified personnel. All personnel who

operate this printer or are near it shall understand the meaning of the following hazard classification

signs used in this manual.

[High Voltage Warning]: It indicates that high voltage exists. Keep away from

exposed circuits, and it is recommended to remove all ornaments.

[High Temperature Warning]: It indicates a high printer temperature. Be

cautious when working near components that are exposed to heat. Always wear

the safety gloves that come with the printer.

The temperature of the print head in the printer can reach up to 300℃.

The temperature of the printing platform in the printer can reach up to

160°C.

The temperature in the chamber of the printer can reach up to 100°C.

[Pinching Warning]: It indicates that your hands might be pinched between two

objects. One or more objects are moving in your working area.

2

Please note that changes or modifications without the approval of the responsible party for

compliance may invalidate the user's permission to operate the device.

The device complies with Part 15 of the FCC Rules and the Industry Canada License-exempt

RSS Standard. The following two conditions should be met for operation:

1. The device may not cause harmful interference;

2. The device must accept any interference received, including interference that may lead to

undesired operation.

The device complies with the radiation exposure limits of FCC/IC RSS-102 for uncontrolled

environment. The device shall be installed and operated at a minimum distance of 20 cm from

the radiator and the operator.

1.2.2 Areas with potential safety hazard

The following components and areas have been highlighted as with potential hazards. Failure to

follow the safety regulations might cause system faults or reliability issues.

Extruder

[High Temperature Warning]: Make

sure to wear safety gloves if it is

necessary to maintain the extruder or

work inside the chamber when the

extruder is heated.

Printing platform

[High Temperature Warning]: Make

sure to wear safety gloves if it is

necessary to remove the printing build

plate of the platform or work inside the

chamber when the hot bed is high in

temperature.

Chamber

[High Temperature Warning]: Make

sure to wear safety gloves if you work

inside the chamber at medium and low

temperatures during heating; it is not

recommended to work in the chamber

at high temperatures.

3

XY motion frame

[Pinching Warning]: Do not wear tie,

loose clothing, or hanging ornaments

when working near a moving printer

component.

[Pinching Warning]: Do not click

HOME when there is a model on the

platform.

[Pinching Warning]: Be careful when

maintaining this moving component.

Z-axis motion frame

[Pinching Sign]: Do not wear tie, loose

clothing, or hanging ornaments when

working near a moving printer

component.

[Avoid Collision]: If there is a printed

model on the platform, be care to raise

the platform to a proper height to

prevent puncturing the organ cover;

[Avoid Collision]: If there is an object

under the platform, be care to lower

the platform to a proper height to

prevent deformation of drive rod parts

and leveling failure caused by

platform collision.

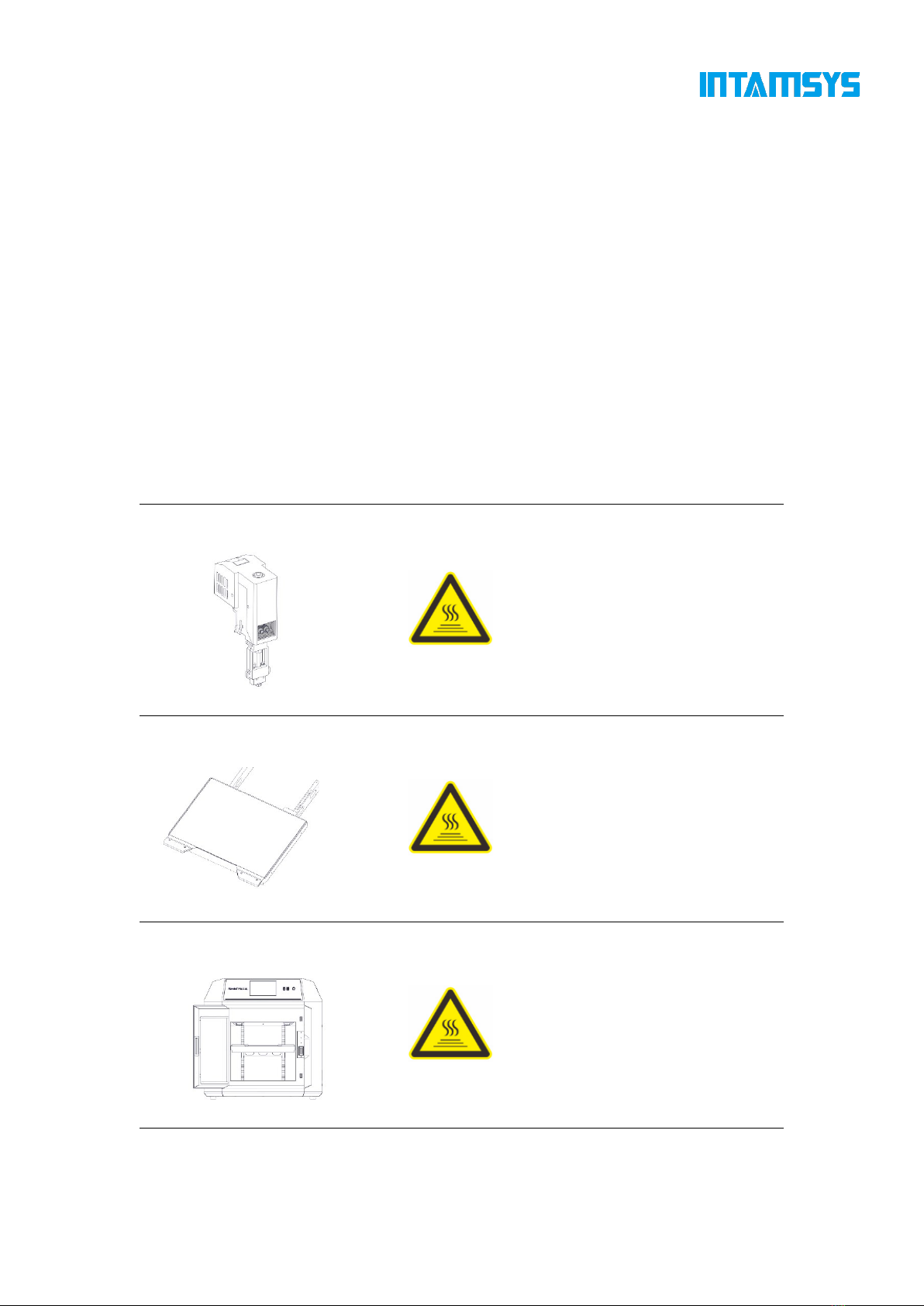

1.2.3 Safety door lock

Sensors are used to monitor the status of the chamber front door and printer top cover. For the

purpose of safety, the chamber door and top cover shall be closed before the XYZ motor can start

working. The electromagnetic lock ensures that the chamber door and top cover remain securely

closed during printing.

Fig. 1.1 Safety Door Lock

Front door sensor

Electromagnetic lock

4

1.2.4 Environmental requirements

The printer is for indoor use only.

Air quality conditions (conductive or non-conductive) with excessive solid particles

might cause damage to the system.

The printer shall operate between 15°C and 30°C (59°F to 86°F) with a relative humidity

range of 30% to 70% (non-condensing).

The printer storage temperature shall be between 0°C and 35°C (32°F to 95°F) with a

relative humidity range of 20% to 90% (non-condensing).

1.2.5 Statement

ce matériel est conforme aux limites de dose d'exposition aux rayonnements, FCC / CNR-102

énoncée dans un autre environnement.cette eqipment devrait être installé et exploité avec distance

minimale de 20 entre le radiateur et votre corps.

1

2 Setting and Installation

This chapter describes the basic settings and installation of FUNMAT PRO 310.

2.1 General Information

2.1.1 Tools that come with the printer

Please check the packing list that comes with the printer. These tools include common tools required

for printer maintenance and various spare parts.

2.1.2 Prepare relevant equipment for installation

The guide for preparation of installation site ensures that relevant equipment for printer installation

can be prepared effectively and safely.

Fig. 2.2 Space required for installation and maintenance (Unit: mm)

5

2.1.3 Check the printer nameplate

Refer to the figure below to identify your printer.

Model information: Product name, model number and power requirements. This nameplate also lists

the relevant certifications and INTAMSYS information.

SKU: Lists the SKU of the printer. Upon a service request, provide this SKU to the agent or

INTAMSYS, so that service personnel can quickly identify your printer configuration.

Fig. 2.3 Printer Nameplate

2.2 Printer Preparation

2.2.1 Unpack

Step 1: Remove the fixing straps from the packing box and remove the wooden board at the

top of the packing box;

Step 2: Remove the foam and packaging film;

Step 3: Remove the top cover of the packing box;

Step 4: Remove the cardboard and foam around the packing box;

Step 5: Lift the printer from the bottom and transfer it to a stable platform (at least two people

are required).

Fig. 2.4 Schematic Diagram of Packaging Removal

6

2.2.2 Remove accessories

Open the front door of the device from the front, and carefully take out the accompanying

accessories and filament boxes from below.

Fig. 2.4 Remove Accessories

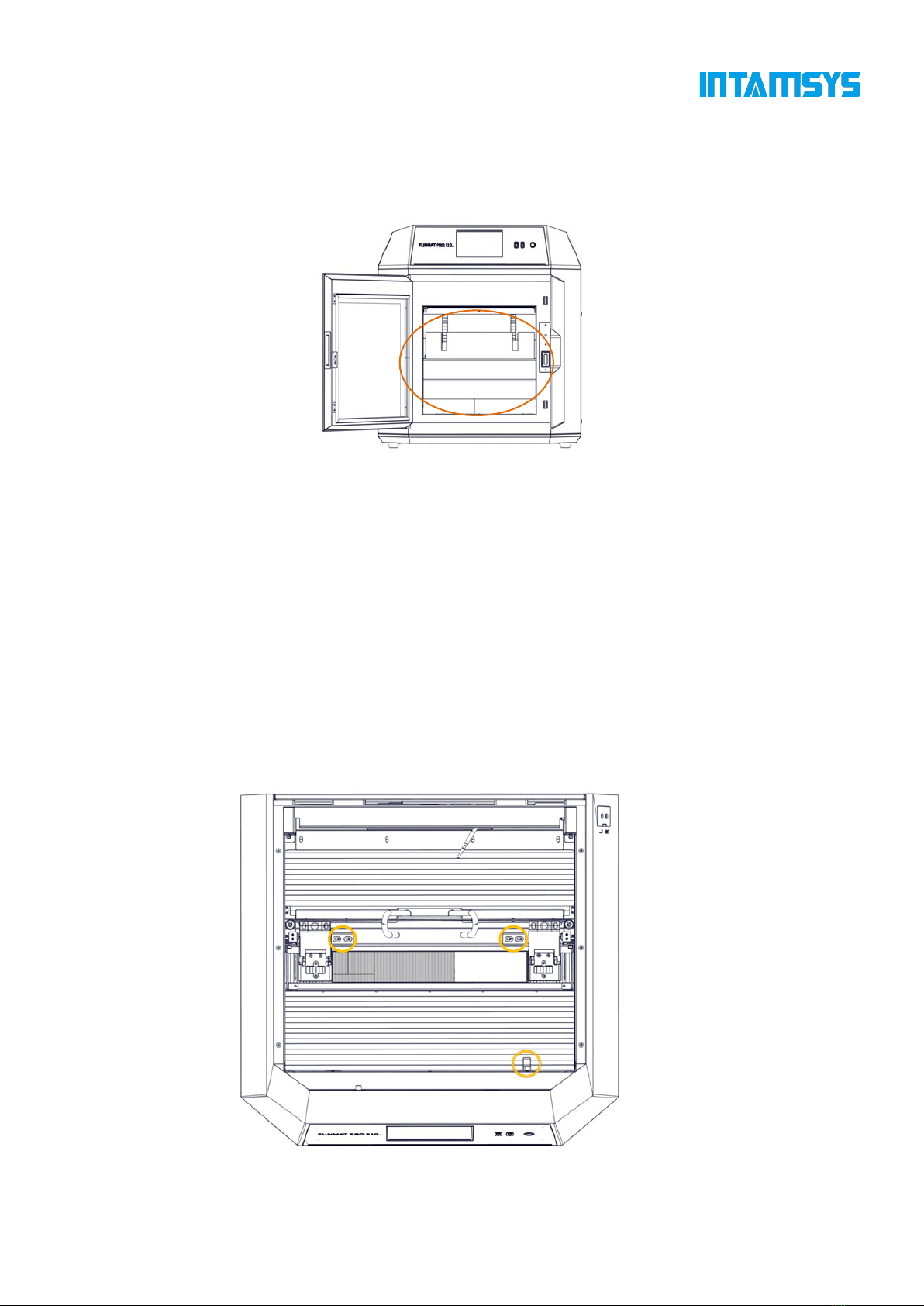

2.2.3 Unbuckle X-axis and Y-axis

Step 1: Open the top cover of the printer;

Step 2: The fixing block on the X-axis guide rail is used to ensure the stability of the extruder

during transportation. Unscrew the two screws on the fixing block with an M4 Allen wrench (the

4mm Allen wrench is placed in the spare parts box), and then remove the X-axis fixing block;

Step 3: Remove the Y-axis fixing block fixed on the front side sheet metal in the same way,

and then install the spare screws in the plastic bag back to their original positions;

Step 4: When the power is off, gently push the print head leftward in X direction to move out

enough operating space, and remove the right fixing block of Y-axis with the same method;

Fig. 2.5 Position of X-axis and Y-axis Fixing Blocks

7

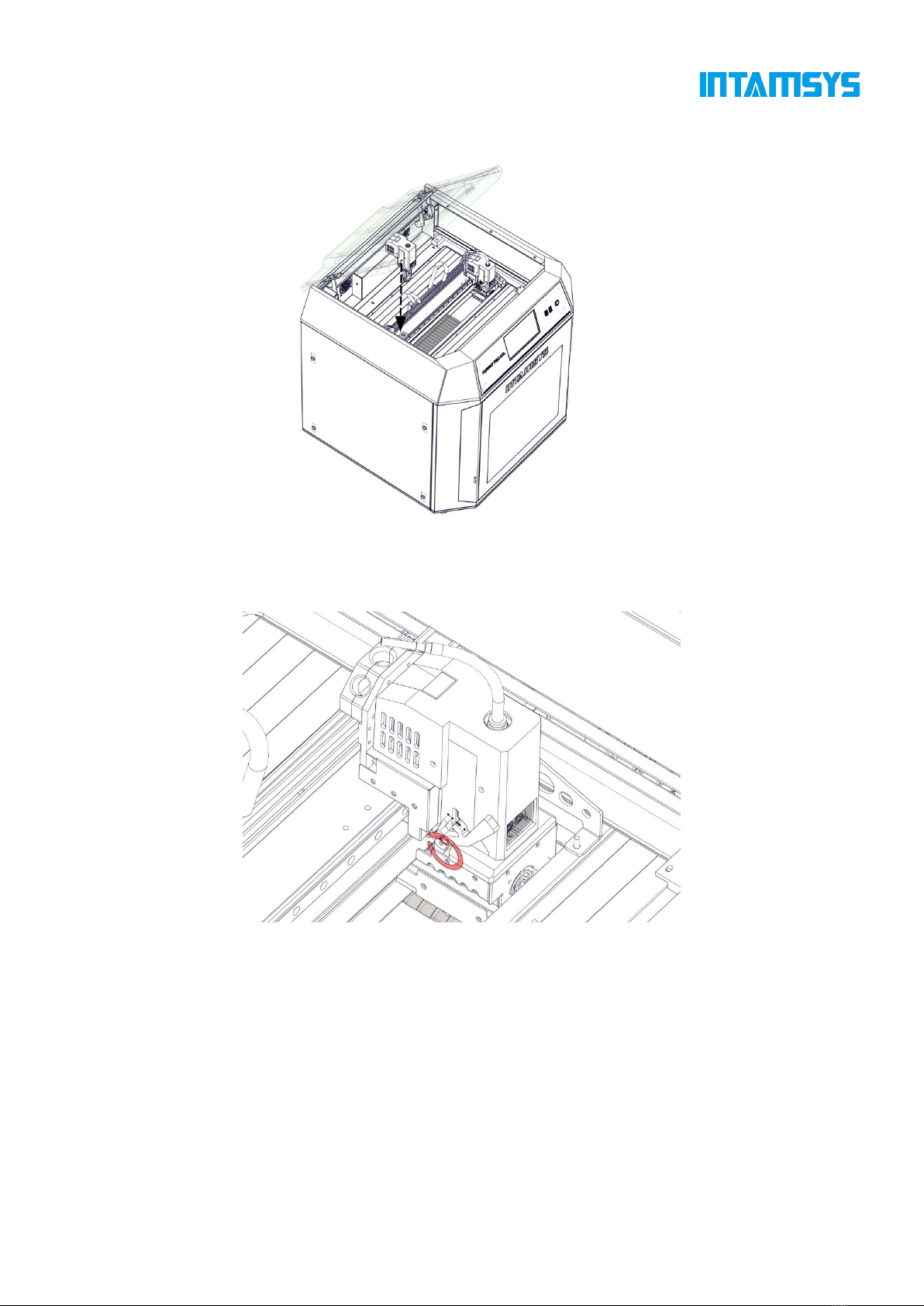

Step 5: Install the left and right extruders in the extruder holder as shown in the figure;

Figure 2.6 Installation of Extruder

Step 6: Rotate the pressure levers on both sides of the extruder holder upward to fix the extruder

in the extruder holder, and plug in the extruder cable.

Fig. 2.7 Securing Extruder

2.2.4 Startup

Step 1: The printer has two power specifications: 110V and 220V. Please make sure to check

whether the socket power supply meets the requirements before use;

Step 2: Insert one end of the power cord into the right power interface of the printer, and insert

the other end into the power socket prepared in advance;

Step 3: Turn on the switch and press the start button at the lower right of the printer to enter

the operation interface;

8

Fig. 2.8 Startup of FUNMAT PRO 310 Printer

2.2.5 Installation of Printing Build Plate

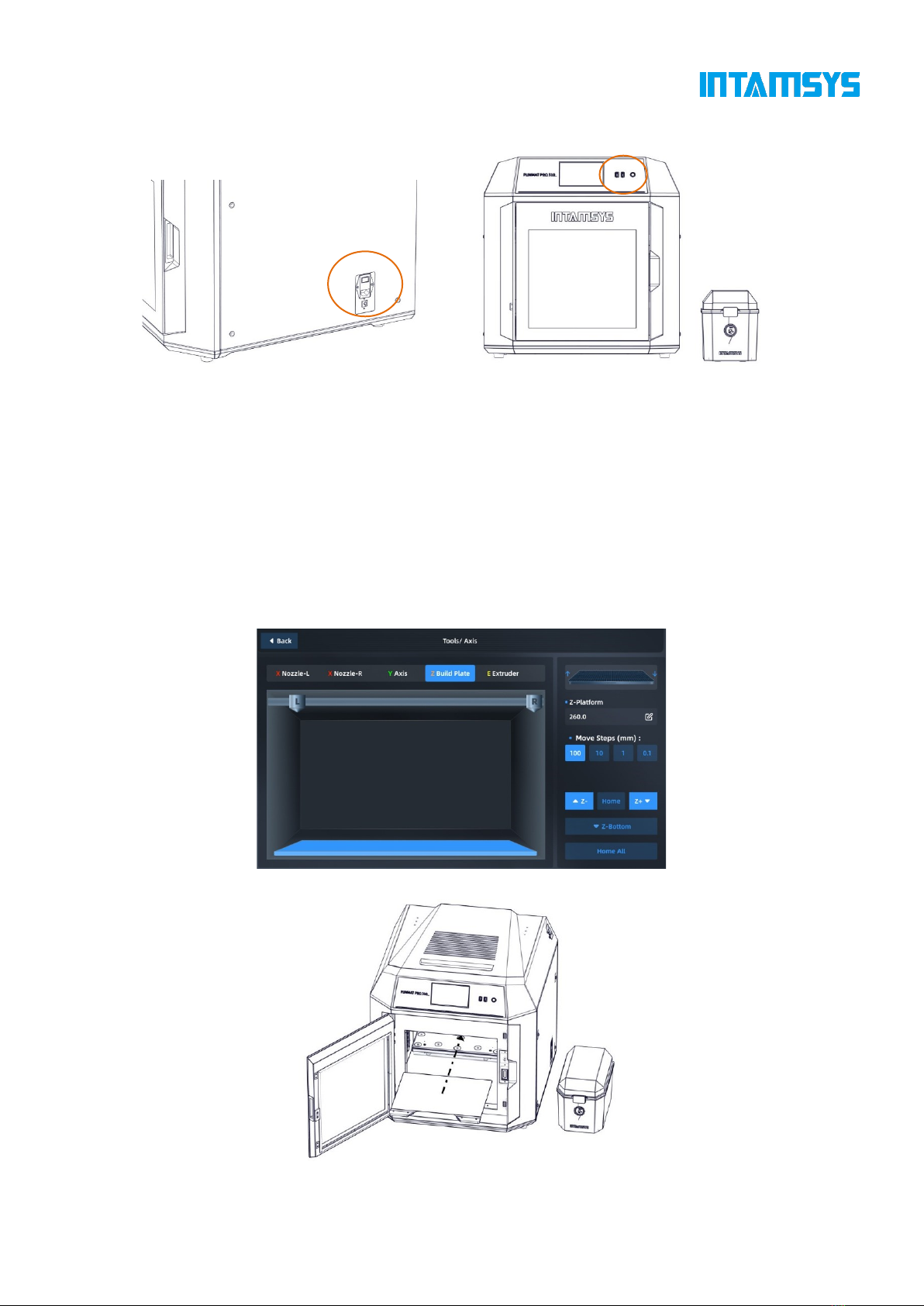

Step 1: Enter the "Tools" interface on the right in the main interface, and click the "Home All"

button (make sure that there are no other sundries in the chamber before operation);

Step 2: After selecting the "Z Build Plate" option in the upper part, click "Z-Bottom" to move

the printing platform to the bottom of the chamber;

Step 3: Flatly adsorb the printing build plate above the magnetic platform along the guide

grooves on both sides of the platform, as shown in the figure.

Fig. 2.9 Platform Lowering Operation Interface

Fig. 2.10 Installation of Printing Build plate

9

3 System Components

This chapter describes the system components of FUNMAT PRO 310, aiming to help users better

understand the mechanism composition of the printer and the functions of each part.

3.1 Printer Overview

The visible parts of the printer is shown in the following figure, where:

The right side plate, left side plate and rear side plate of the housing are removable for access to

internal components; the top door and front door must be closed during printing and locked by

electromagnetic locks.

Fig. 3.1 Front View of Printer

Top cover

Feeding entrance

Switch button

USB connection

Operation interface

Watching window

Build plate

Front door sensor

Electromagnetic lock

Power interface

Independent filament box

10

Fig. 3.2 Rear View of Printer

3.2 Top Door and User Operation Interface

Push the top door upward to observe the movement of extruder from above and for the maintenance

of XY rack and print head assembly.

By releasing the electromagnetic lock through screen operation, the top door can be pushed upward

and supported by damping hinges. The damping hinge can ensure that the top door stops at any

opening or closing position.

Below the top door is the user interaction area, which includes touch screen, USB interface and

ON/OFF switch.

Users can control the print part and obtain the machine status information through the touch screen.

The USB on the left is only used to connect to computers for printing and firmware upgrade, while

the USB on the right is used to insert a U-disk for printing. The ON/OFF switch is used for startup

and shutdown, as well as emergency shutdown.

Top door handle

Top air outlet

Back air outlet

Back side plate

Left side plate

Outer cover screw

11

Fig. 3.3 Schematic Diagram of Top Door Opening Fig. 3.4 Schematic Diagram of User Operation Area

3.3 Printing Chamber Components

The front door can be pulled open from the right side by the release of the electromagnetic suction

of the front door through screen operation, and then it can be seen that the printing chamber contains

front door, hot bed, double extruder assembly, electromagnetic suction, magnetic suction and door

sensor.

When the printing chamber is heated, its stainless steel build plate and side plates are hot. Please do

not touch them to avoid scalding.

The four leveling knobs under the hot bed are used to manually level the printing platform.

Fig. 3.5 Schematic Diagram of Front Door Opening Mode Fig.3.6 Printing Chamber

3.4 Independent Filament Box

The printer is supplied with an external INTAMBox Sealed Drying Filament box that can hold up

to two rolls of 1 kg material. Seal rings and buckles are provided around the filament box to ensure

its sealing performance. The filament box is supplied with a drying box filled with 4A molecular

sieve desiccant, which can ensure the low humidity environment inside the filament box. The upper

cover of the filament box is equipped with a charging tray tension device to ensure that the printing

wire rod will not be loosen during printing and that the wire coil will not topple when the wire rod

Front door

Extruder assembly

Front door sensor

Hot bed printing platform

Front door magnetic suction

Front door

handle position

Front door electromagnetic suction

Front panel

Firmware

upgrade

USB port

Printing file

transfer

USB port

Switch button

Damping hinge

12

in the wire coil are used up. Please refer to the Operation Manual of INTAMBox Sealed Drying

Filament box for details.

Fig. 3.7 Schematic Diagram of Filament box

Fig. 3.8 Top View of Filament box

Upper cover

Temperature and humidity indicator

Lower cover

Charging tray tension device

Printing wire rod

Buckle

Seal ring

Quick connector x2

Drying box

Bearing x8

Feeding pipe plug x2

Rotating shaft x4

Handle

13

Fig. 3.9 Working Diagram of Tension Device

3.5 Print head Assembly

The print head assembly is used to melt the wire and form a desired model on the printing build

plate in combination with the movement of X-axis, Y-axis and Z-axis. A machine contains two

separate print heads, generally the left extruder for printing model material and the right extruder

for printing support material. Generally, there's only one extruder performing printing at the same

time point, while the other extruder stands by at the end of X-axis. When copying or mirror printing

is carried out, the two extruders move simultaneously.

Refer to Chapter 5 for loading and unloading of materials.

Fig. 3.10 Extruder Assembly

3.5 X/Y Axis Components

X-axis and Y-axis components drive the double-extruder to move within the XY plane according to

commands.

X-axis and Y-axis are driven by the synchronous belts, whose tension has been properly adjusted at

Rotating shaft x4

Shaft pressing x8

Torsion spring x4

Hold-down bracket x4

14

factory and does not need to be re-adjusted during use. After a period of use, if the printing quality

is found to have degraded significantly, the likely cause is the synchronous belts becoming loose

due to various reasons. In this case, remove the left and right lateral plates of the printer and check

the tension of the left and right synchronous belts of Y-axis; After removing the rear housing, you

can adjust the tension of the Y-direction synchronous belt. Open the top door to see and check the

tension of the synchronous belt of X-axis. If the tension of a synchronous belt is found too small,

you can increase the tension using the method shown in the figure below. The left and right

synchronous belts of Y-axis shall keep a consistent tension.

Fig. 3.11 X-axis and Y-axis Components

Y-direction motor

Y-direction synchronous belt

X-direction synchronous belt

Y-direction organ

X-direction motor

X-direction organ

Other manuals for FUNMAT PRO 310

1

Table of contents

Other Intamsys 3D Printer manuals

Intamsys

Intamsys Funmat Pro 410 User manual

Intamsys

Intamsys FUNMAT HT User manual

Intamsys

Intamsys FUNMAT HT User manual

Intamsys

Intamsys FUNMAT PRO 310 User manual

Intamsys

Intamsys FUNMAT PRO User manual

Intamsys

Intamsys Funmat Pro 410 User manual

Intamsys

Intamsys Funmat Pro 410 User manual

Intamsys

Intamsys FUNMAT PRO User manual

Intamsys

Intamsys FUNMAT HT User manual