Intamsys Funmat Pro 410 User manual

QUICK START GUIDE PN: 005-0801 REV: E08

1/ 20

FUNMAT PRO 410 Quick Start Guide

FUNMAT PRO 410 快速开机向导

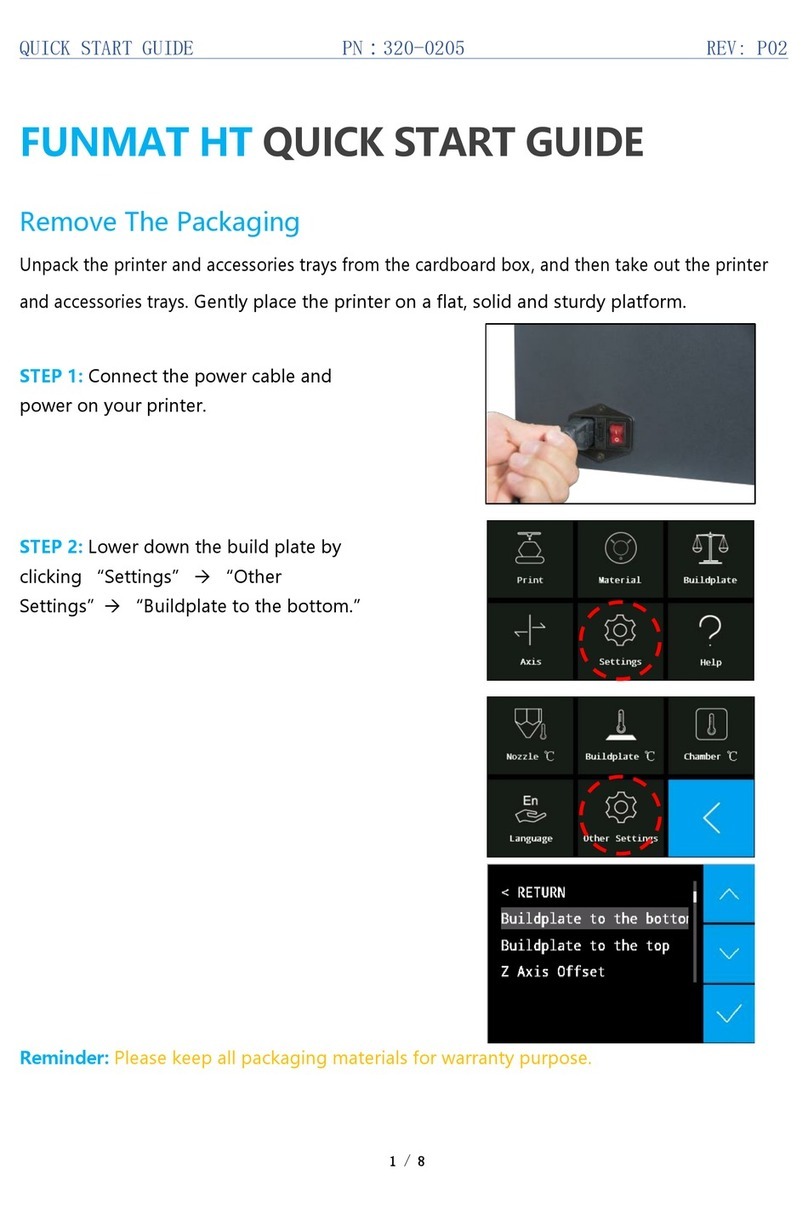

Remove the Packaging

拆除包装

STEP 1:Unhook the latch on the wooden box and slowly open the ramp board

步骤 1:解开木箱上的锁扣,缓慢打开斜坡板

STEP 2: Take out the unboxing tool, unscrew the wooden box with an 8mm sleeve, remove all the

plates, the ties, the stretch film

步骤 2:取出开箱工具,并用装有 8mm 套筒扳手,拆除木箱上的螺丝。移除所有的木板,去掉机器上

的固定带,泡沫和包装膜等外包装物

STEP 3: Use a 17mm open-end wrench, separate the 4 fixed supports from the wooden blocks and

remove the 4 blocks below and the coaming under the machine

步骤 3:使用 17mm 的开口扳手,将 4 个固定脚撑与木块分离,取出下方的 4 块木块和机器下面的围

板

STEP 4: slowly move the machine from the base down the ramp board to the ground(At least

two people needed)

步骤 4:慢慢将机器从底座沿斜坡向下移动到平稳地面(至少 2 人)

STEP 5: After moving the printer to the mounting position, rotate the four fixed support so that

they land on the ground to ensure that the printer’s stability

步骤 5:将打印机移动到安装位置后,旋转 4 个固定脚撑,使其着地,确保打印机不会晃动

QUICK START GUIDE PN: 005-0801 REV: E08

2/ 20

QUICK START GUIDE PN: 005-0801 REV: E08

3/ 20

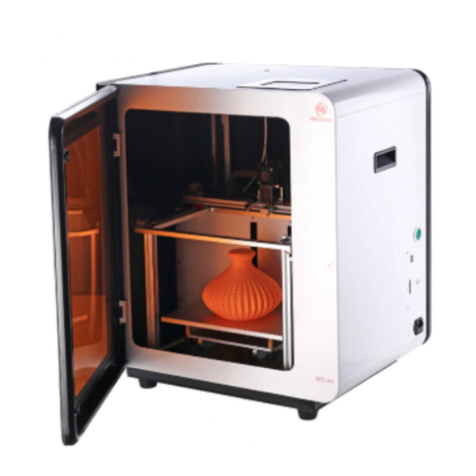

Layout of Printer

机器整体结构

01Smart touch panel/智能触摸屏

02Top cover/机器顶部盖门

03Build plate/打印平台

04Filament chamber/料箱

05Filament shaft/料轴

06Filament chamber door/料箱门

07Liquid cooling unit/液冷系统单元

01

03

04

07

05

06

02

QUICK START GUIDE PN: 005-0801 REV: E08

4/ 20

Prepare the Printer

机器开机前准备

1 Take out the accessory box

取出随机配件

STEP 1:Remove the back door screws with a special printed tool and remove the back door

步骤 1:使用专用工具,移除后门紧固螺丝并拆卸后门

STEP 2:Rotate the z-axis screw clockwise manually to lift the Z-platform about 5cm

步骤 2:手动顺时针旋转 Z 轴丝杆,将打印平台提升约 5cm

STEP 3: Take out the accessory box.

步骤 3:取出随机配件盒

QUICK START GUIDE PN: 005-0801 REV: E08

5/ 20

2 Release extruder and XY modules

解除喷头和 XY 轴固定

STEP 1:Open the top door of the unit.

步骤 1:打开机器前门

STEP 2:Unscrew and take away the stop block on the extruder linear guide.

步骤 2:旋开并移除喷头上方直线导轨上的限位装置块

STEP 3: Takeaway the stop block on the left linear guide.

步骤 3:移除左侧直线导轨上的限位装置块

STEP 4: Move the extruder to the left and take away the stop block on the right linear guide.

步骤 4:移动喷头至最左侧,移除右侧直线导轨上的限位装置块

STEP 5: Remove the front cover of extruder set using 2.5mmallenkey.

步骤 5:使用 2.5mm 内六角扳手拆卸喷头组前盖

QUICK START GUIDE PN: 005-0801 REV: E08

6/ 20

STEP 6:Cut the tie around the nozzle and remove it, then install the front cover back to the original

place.

步骤 6:剪断喷头上的固定扎带并取下,将喷嘴组前盖装回原处

3 Add coolant into the liquid cooling unit

添加冷却液

STEP 1:Unscrew the cover plate on the back of the printer.

步骤 1:拧开机器背面的盖板

QUICK START GUIDE PN: 005-0801 REV: E08

7/ 20

STEP 2: Take out the end of the tube.

步骤 2:将加注冷却液的管子取出

STEP 3: Take out the funnel from the accessory box and fix it on the end of the tube. Then

feed750~950 ml Automotive Engine Anhydrous Coolant (with color preferred) into the liquid

cooling unit.

步骤 3:从随机配件盒中取出漏斗,固定在加注冷却液的管子末端。然后将 750~950 毫升汽车发动机

无水冷却液(带有颜色)注入液冷系统单元

The cap of tube end must be re-tightened after adding liquid.

The volume of the liquid tank of the chiller is 1000ml, and the liquid level sensor will be triggered

when it is lower than 600ml.

2

3

1

QUICK START GUIDE PN: 005-0801 REV: E08

8/ 20

注:加入液体后,必须重新拧紧水管端盖。水冷系统单元液柜体积为 1000ml,低于 600ml 时会触发

液位传感器

4 Power on

启动机器

1. Check the power voltage of the socket: 220VAC

检查供电电源电压,确保满足220VAC要求

2. Insert one section of the power cord into the machine and one section into the socket prepared

将电源线一端接入机器,另一段插入准备好的电源插座

3. Turn on the switch, press the start button, and the machine enters the operation interface

打开电源开关,按下启动按钮,机器进入操作界面

5 Calibrate the feeding clamper force

调整送料夹紧力

Take the left extruder for example, the right extruder is the same.

以左侧喷头为例,右侧喷头以此类推

STEP 1: Open the top door, press down the button of the one-touch fitting, pull the left filament

tube out at the same time.

步骤 1:打开机器顶部盖门,按下接口端快换接头按钮,将左侧送料管拔出

QUICK START GUIDE PN: 005-0801 REV: E08

9/ 20

STEP 2: Click “System” icon, then press Arrow icon.

步骤 2:点击“系统”图标,然后按箭头图标

STEP 3: Click the icon. The printer will clear the former L-Clamper value and enter the setting

screen.

步骤 3:单击 图标。机器将清除之前预设的左侧喷头夹紧力值,并进入设置界面

STEP 4: Click the “←” icon to let the two gears closer and closer. Pull the calibration bar up

and down after every screen click until the calibration bar was just clamped by the gears and can

be hold the position without your hand. Then, click the "←" button one more time to clamp the bar

tighter. At this time, the drive gear just reach its suitable position. After that, click “Set” to save

the value. The higher the value, the greater the clamping force.

2

1

QUICK START GUIDE PN: 005-0801 REV: E08

10 / 20

步骤 4:单击“←”图标,让两个齿轮逐渐靠近。每次点击屏幕后,上下拉动校准棒,直到该校准棒

刚好被齿轮夹住,此时松开手校准棒也可保持该位置而不会下滑。然后,再一次点击“←”按钮,确

保夹得更紧。此时,传动齿轮刚好到达其合适的位置。然后点击“设置”保存值。值越高,夹紧力越

大。

Pay attention, the value cannot be too large, if it's too large it will be loose again.

注意,这个值不能太大,如果太大,又会变松

6 Install the build plate and junk box

安装打印平台和集料盒

6.1 Install the build plate

安装打印平台

STEP 1: Press the “Home” icon for X, Y, Z.

步骤 1:在“Axis”界面中点击 X、Y、Z 轴的“Home”键

STEP 2: Move the heating bed by pressing “Z↓” with 100mm step to a suitable height.(No more

than 3 times)

2

1

1

2

3

QUICK START GUIDE PN: 005-0801 REV: E08

11 / 20

步骤 2:选择上方“Move steps”中的“100mm” 选项后,点击“Z↓”(不多于 3 次)后将热床调

整到一个方便平台拆装的位置

STEP 3: Install the buildplate on the heating bed according to the buildplate insertion direction.

步骤 3:按照热床上标签显示方向插入打印平台

6.2 Install the junk box/安装集料盒

STEP 1:The z-axis is lowered to an appropriate position through screen operation to leave enough

operation space for the installation of the junk box.

步骤 1:通过屏幕操作将 Z 轴降至适当位置,为集料盒的安装留下足够的操作空间。

STEP 2: Install the junk box, the junk box is flush with the front of the nozzle brush assembly.

步骤 2:安装集料盒时,集料盒要与喷嘴刷总成的前端齐平。

7 Load material/材料加载操作

STEP 1: Press the “Material” icon, and then press “L” icon to select left extruder. The icon will

be highlighted when it has been selected. (Same with the right extruder.)

步骤 1:按下“Material”图标,再按“L”图标,选择左侧喷嘴。该图标被选中后将高亮显示。(右侧

的喷嘴也同样操作。)

STEP 2: Press the drop-down menu to select material. Make sure the material you selected is the

磁铁

QUICK START GUIDE PN: 005-0801 REV: E08

12 / 20

same with the one you want to load.

步骤 2:按下拉菜单选择材料。确保您选择的材料与您想要加载的材料相同。

STEP 3:And then press “Load” icon, there are in total 4 steps to load material, after 120 seconds

loading process ended, press “Finish”. (If the filament is not extruded out from the nozzle, long

press “E↓” till the filament comes out or redo the load.)

步骤 3:然后按“Load”图标,加载材料共有 4 个步骤,120 秒加载结束后按“完成”。(如果材料没

有从喷嘴中挤出,则长按“E↓”,直到材料挤出或者重新加载。)

Unload material by pressing “Unload” icon and then follow the instructions on the screen.

按“卸载”图标卸载材料,然后按照屏幕上的提示说明操作。

8 Bed leveling

打印平台调平

There are two methods of bed leveling: Manual Leveling and Auto Leveling. Only need to choose

one method to do the leveling.

打印平台调平有手动调平和自动调平两种方式。只需要选择一种方法来做调平即可。

Manual Leveling is much recommended because of higher precision.

由于调平精度较高,推荐使用手动调平。

6

8

9

7

5

1

2

3

4

2 3

4

5

1

QUICK START GUIDE PN: 005-0801 REV: E08

13 / 20

8.1 Manual bed leveling/手动调平

STEP 1:Press the “Material” icon, and then press the icon.

步骤 1:点 击“Material”图标,再点击图标。

1

2

STEP 2: Press the leveling icon , and then press Ok.

步骤 2:点击调平图标 ,再点击 OK

3

4

STEP 3: After the nozzle is heated up, press “Next”.

步骤 3:待喷嘴加热后,点击“Next”键

STEP 4: There are 4 screws which need to be adjusted one by one for at least twice, by using the

leveling card with 0.2mm thickness (the leveling card is in the accessory box).

步骤 4:有 4 个螺丝需要用 0.2mm 厚的调平卡依次调整至少 2 次(调平卡在附件箱内)

6

5

QUICK START GUIDE PN: 005-0801 REV: E08

14 / 20

STEP 5: Press “Finish” to exit the process after adjustment is completed.

步骤 5:调平完成后,点击“Finish”键退出,结束调平过程。

12

8.2 Auto bed leveling

自动调平

STEP 1: Press the “Material” icon, and then press the icon.

步骤 1:点击“Material”图标,再点击 图标

1

2

STEP 2: Press the leveling icon, and then press OK.

步骤 2:点击调平图标 ,再点击“OK”键

7 8

9 10

1

QUICK START GUIDE PN: 005-0801 REV: E08

15 / 20

3

4

STEP 3: After the nozzle is heated up, the printer will test the leveling sensor. When seeing

“Triggering succeeded”, then press “Next”.

步骤 3:待喷嘴加热后,机器将检测调平传感器。看到 “Triggering succeeded”提示信息后,点击

“Next”按钮确认。

5

6

STEP 4: Clean the nozzle and the buildplate, then adjust the Z axis with a leveling card with a

thickness of 0.2mm according to the instruction on screen.

步骤 4:清洁喷嘴和打印平台后,用厚度为 0.2mm 的调平卡,根据屏幕指示调整 Z 轴

STEP 5: Remove the leveling card after adjustment is OK, and then press “Calibrate”. When

calibration is done, press “Next”.

步骤 5:调整好后取下调平卡,然后点击“Calibrate”键。校正完成后,点击“Next”键。

7

8

9

STEP 6: Keep the nozzle and buildplate clean, then press “Auto level”.

步骤 6:保持喷嘴和打印平台清洁,然后点击“Auto level”键。

QUICK START GUIDE PN: 005-0801 REV: E08

16 / 20

10

STEP 7: The printer will perform a 3-points automatic leveling.

步骤 7:机器将进行三点自动调平

STEP 8: Press “Finish” after leveling is successful, the buildplate will move to the bottom of the

chamber and then move upwards.

步骤 8:自动调平成功后,点击“Finish”按钮,打印平台将移至打印腔室底部,然后向上移动

11

/

12

9Calibrate the printer

机器校准

9.1 Z Calibration

Z 轴校准

STEP 1: Press “Z calibration” icon and confirm with “OK”.

步骤 1:点击“Z calibration”图标,再点击“OK”按钮

QUICK START GUIDE PN: 005-0801 REV: E08

17 / 20

/

1

/

2

STEP 2:Press “Z↑” or “Z↓” to perform the left nozzle calibration by using a leveling card

with a 0.2mm thickness, and then press “Next”. (There are two steps for different adjusting

accuracy, 0.05mm and 0.01mm.)

步骤 2:使用 0.2mm 厚的水准卡,按“Z↑”或“Z↓”对左侧喷嘴进行校准,然后按“Next”。(调

节精度分为 0.05mm 和0.01mm 两步。)

3

/

4

STEP 3:Perform calibration for the right nozzle by following the same steps, press “Ok” to

complete the total calibration.

步骤 3:对右侧喷嘴按相同步骤进行校准,按“OK”键完成总校准。

5

/

6

9.2 XY calibration

XY 轴校准

STEP 1: Press “XY calibration” and then press “Next”, the printing process starts. After

printing is completed, press “Next”.

步骤 1:按“XY calibration”,再按“Next”,开始打印。打印完成后,按“Next”。

QUICK START GUIDE PN: 005-0801 REV: E08

18 / 20

STEP 2:Check the printed model. Find the alignment line in X and Y direction and set the

corresponding offset X and Y values, press “OK”.

步骤 3:检查打印的模型。查找 X、Y 方向的对齐线,设置对应的偏移量 X、Y 值,按“OK”键。

If there are no lines are aligned with each other, set 15 first Lyon the corresponding direction (“+/-”), redo

the printing and reset the offset value.

如果没有对齐,先在对应的方向(“+/-”)上设置 15,重做打印并重置偏移值。

STEP 3: Press “Finish” to complete the calibration.

步骤 3:按“Finish”键完成校准

If you want to selectively do the specific step, you can click “Skip”.

您也可以选择性地做特定的步骤,点击“skip”键确认跳过这一步骤。

1 2

3

4

6 5 7 8

10

9

QUICK START GUIDE PN: 005-0801 REV: E08

19 / 20

Printing Process

打印过程

STEP 1: Insert the USB flash disk into the right socket on the panel, then press icon.

步骤 1:将 U 盘插入面板上正确的位置,然后点击 图标

STEP 2: Select the file, and then press “Open”.

步骤 2:选择对应文件,然后点击“Open”键

STEP 3: Firstly, buildplate and chamber will preheat for a specific time, then print. After print, the

printer will maintain buildplate and chamber temperature until you stop it.

步骤 3:打印平台和打印腔室会预热一段时间,然后进行打印。打印完成后,机器将保持打印平台和

打印腔室温度直到接受停止命令

21

1

3

4

QUICK START GUIDE PN: 005-0801 REV: E08

20 / 20

Install Software

安装软件

After successfully setting up the printer, install the INTAM-SUITE software on your computer,and

you can load the Slicing Software from this link:

机器设置成功后,需要在您的电脑上安装 INTAM-SUITE 切片软件,您可以从这个链接下载该软件:

https://www.intamsys.com/intamsuite/

It is available for Windows.

该软件只支持 Windows 系统

Warranty

保修

The detail warranty information please refer to user manual.

详细保修信息请参阅用户手册。

Support

技术支持

If you want to get more support, please contact the local reseller or regional technical support as

below.

如果您想获得更多的支持,请联系当地经销商或 INTAMSYS 对应区域的技术支持:

Asia Pacific: Support_APAC@intamsys.com;

Europe, Middle East, & Africa:Support_EMEA@intamsys.com;

North America /Latin America:Support_America@intamsys.com.

Other manuals for Funmat Pro 410

2

Table of contents

Other Intamsys 3D Printer manuals

Intamsys

Intamsys FUNMAT PRO 310 User manual

Intamsys

Intamsys Funmat Pro 410 User manual

Intamsys

Intamsys FUNMAT PRO User manual

Intamsys

Intamsys Funmat Pro 410 User manual

Intamsys

Intamsys FUNMAT HT User manual

Intamsys

Intamsys FUNMAT PRO 310 User manual

Intamsys

Intamsys FUNMAT HT User manual

Intamsys

Intamsys FUNMAT HT User manual

Intamsys

Intamsys FUNMAT PRO User manual