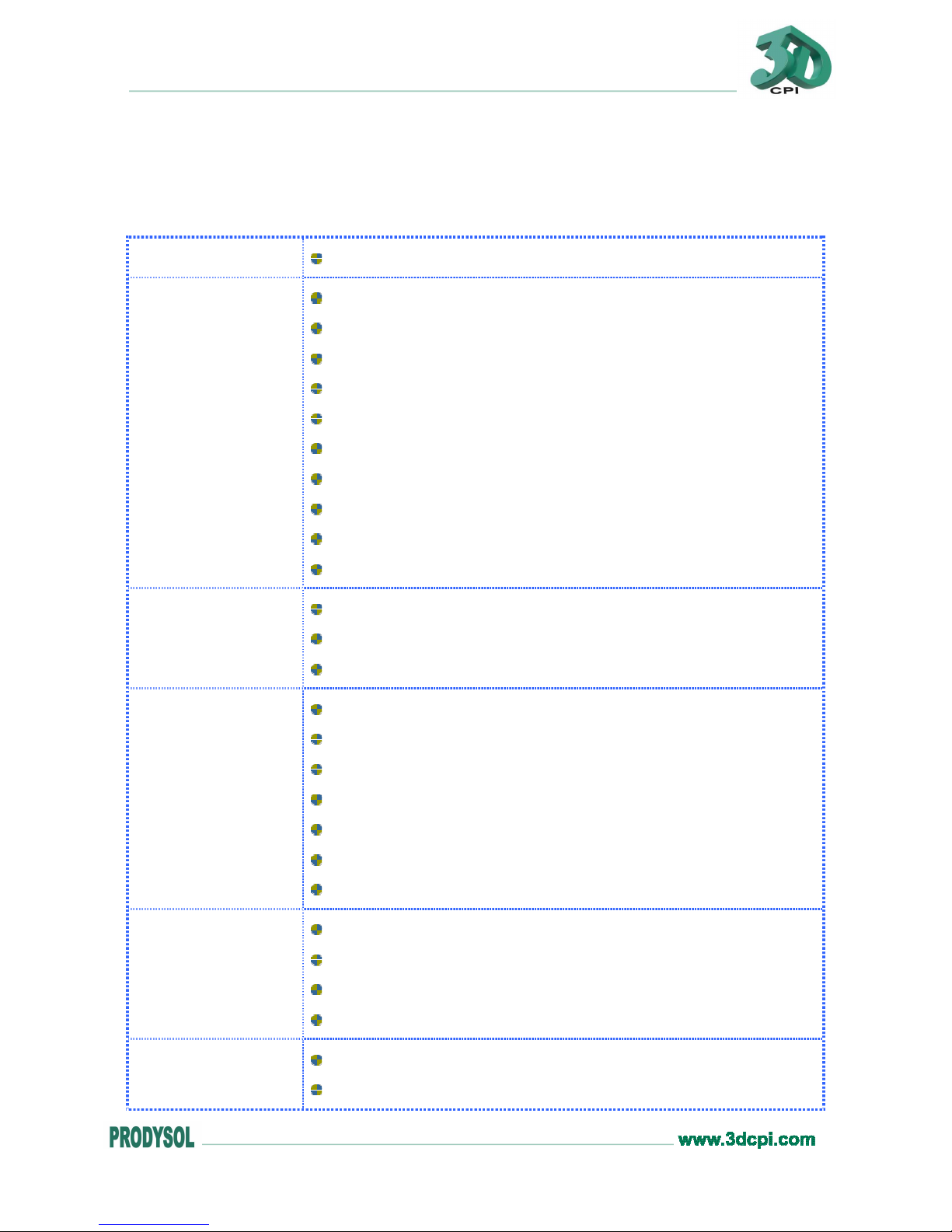

3DCPI-03 START-UP GUIDE

Product Parameters

Forming Tech.: Fused deposition modeling (FDM)

Tech. Parameters: Extrude Number: Dual extruders(Perfect supported)

Build Size: 300*250*520mm

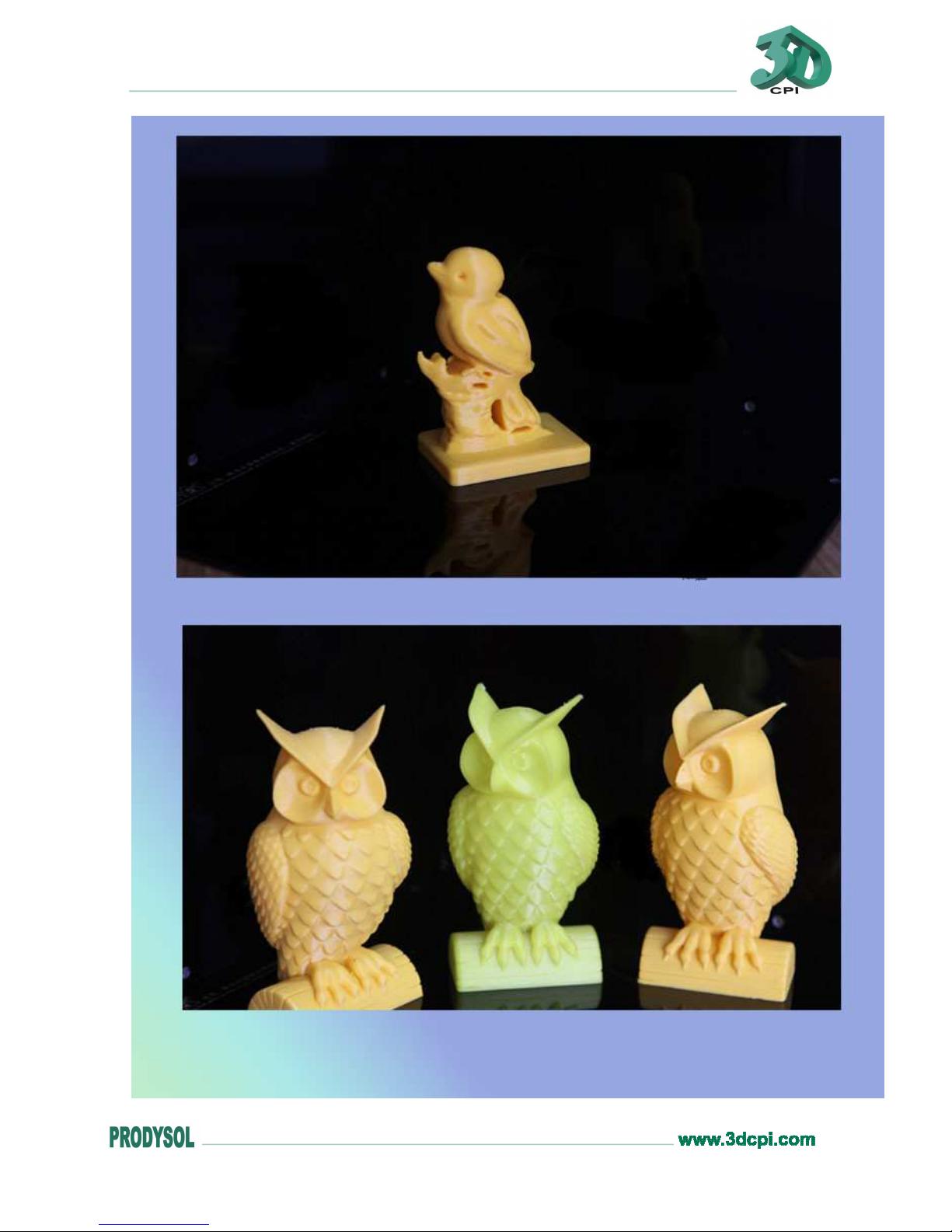

Precision: X, Y 0.01mm, Z 0.015

Min. Layer: 0.04mm

Nozzle Diameter: 0.4mm(0.3、0.5 Optional)

Max. Travel Speed: 250mm/sec.

Max. Print Speed: 180mm/sec

Max. Extruder Temperature: 250Deg.

Max. Hot Bed Temperature: 120Deg.

Max. Extrude Speed: 100mm/sec

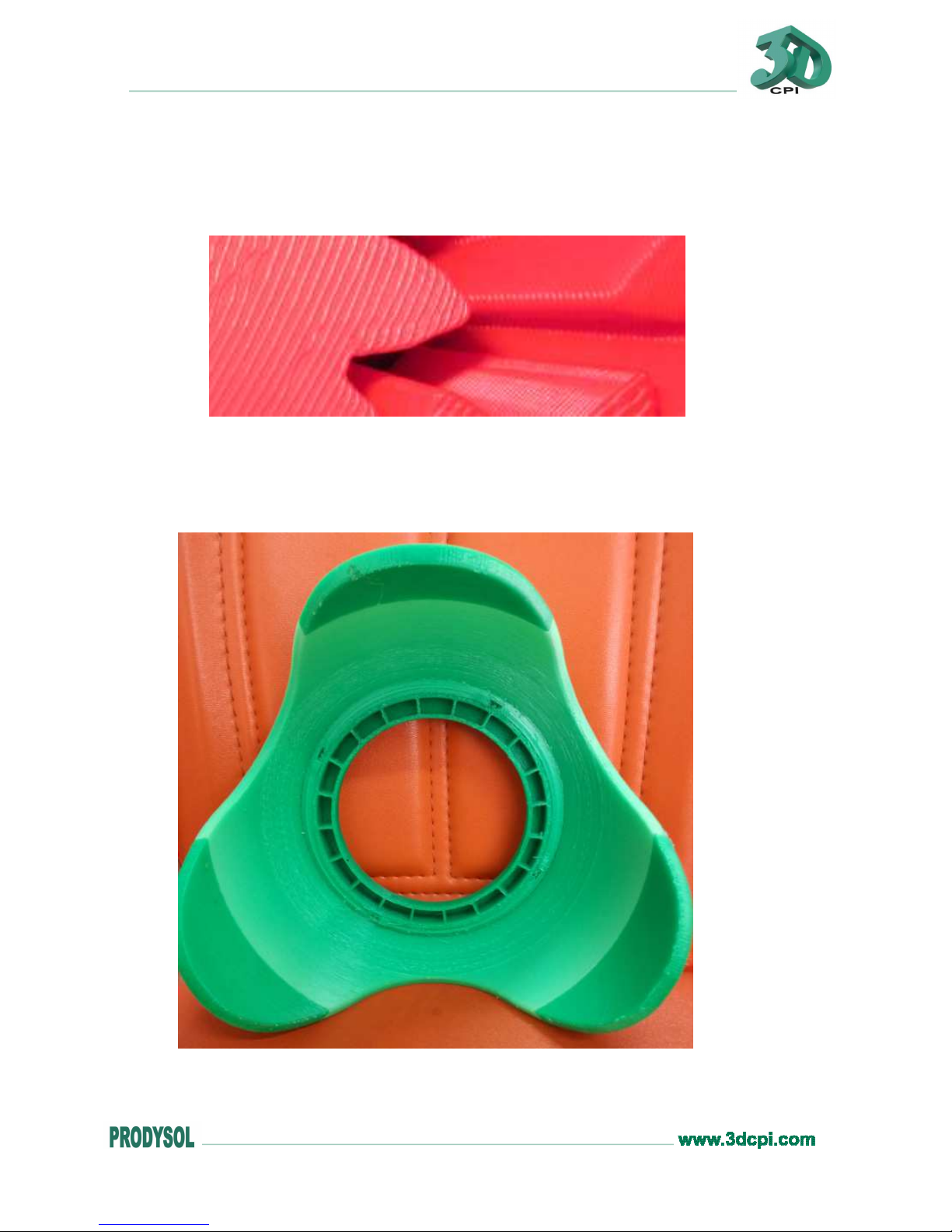

Filament: Filament Type: ABS、PLA(Spec.)、PVA、PS

Filament Temperature: 150~250Deg.

Filament Colors: Black, White, Red, Yellow, Green, Blue

Hardware: Controller: Arduino ATmega2560 R3Micro Controller

Mother Board: CreatBot Stable Main Board V3.x

Stepper Motor: X, Y 42*48, 1.3A

Stepper Motor: Z 42*63, 1.5A

Geared Motor: E 42*42, Ratio 1:10

Power Input: 110~220V, 1.5A

Power Output: 24V, 10.5A

Software: OS: XP, Vista, Win7, Win8

File Format: STL, OBJ, GCode

Slicer: Cura, Slic3r

Print Software: Cura, Printrun, RepetierHost

Machinery: Dimensions: 420*380*790mm

Weight: About 35KG