Intamsys Funmat Pro 410 User manual

QUICK START GUIDE PN: 005-0801 REV: E04

1/ 13

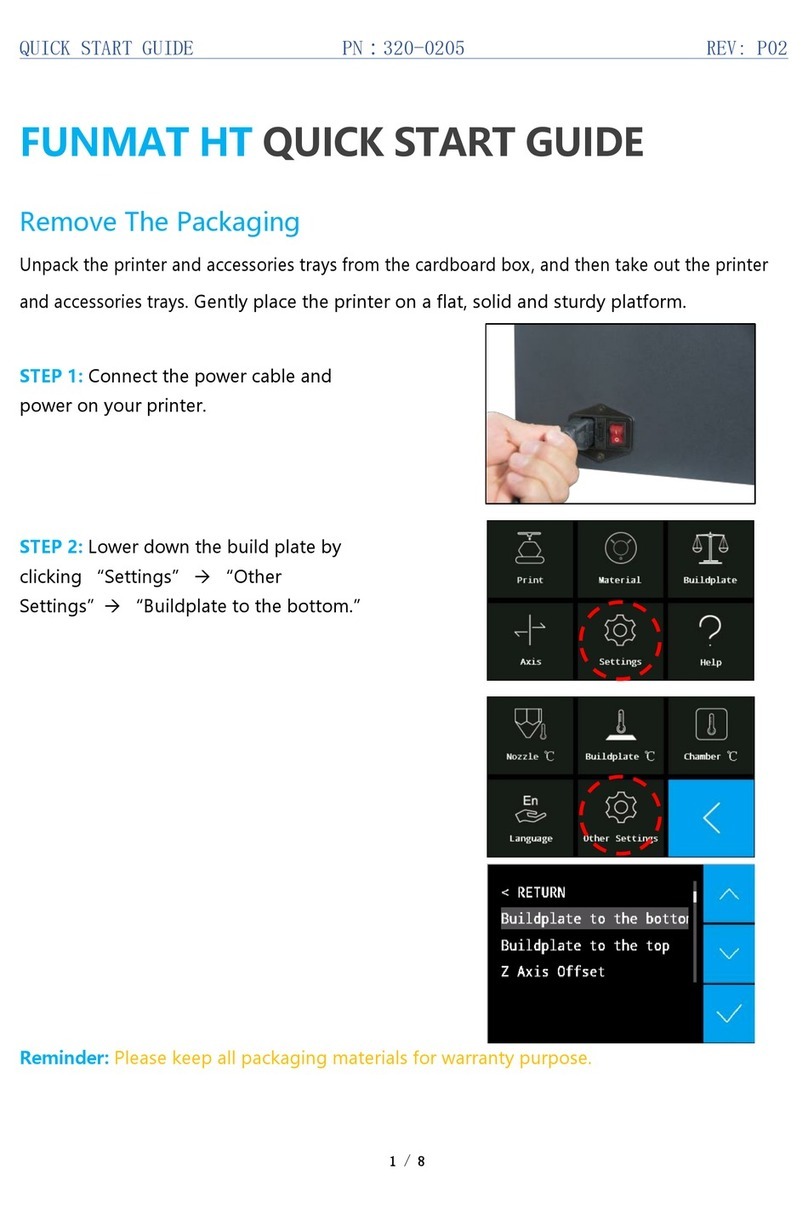

FUNMAT PRO 410 QUICK START GUIDE

Remove The Packaging

STEP 1: Unscrew the wooden box with an 8mm sleeve, remove all the plates, the ties, the

stretch film.

STEP 2: Take out the wooden plates under the printer, use a cross screwdriver to assemble

them into ramps with the nails attached on the plate, then connect the ramps to the

baseplate.

Make sure the ramps are properly and securely mounted together.

STEP 3: Release the caster wheels by rotating clockwise, gently move the printer to a flat,

solid and sturdy ground.

STEP 4: After moving the printer to the right place, remember to tighten the caster wheels

by rotating anti-clockwise.

QUICK START GUIDE PN: 005-0801 REV: E04

2/ 13

Layout Of Printer

01 Smart touch panel

02 Top cover

03 Build plate

04 Filament chamber

05 Filament shaft

06 Filament chamber door

07 Liquid cooling unit

01

03

04

07

05

06

02

QUICK START GUIDE PN: 005-0801 REV: E04

3/ 13

Prepare The Printer

1. Power on the printer and take out the

accessory box

STEP 1: Connect the power cord and power on the

printer, touch anywhere on the screen to exit the

screensaver.

STEP 2: Press “Axis”, and then press “Home z”.

STEP 3: Take out the accessory box.

2. Release XY modules

STEP 1: Power off the printer. Pull the door from the

right side of the unit.

STEP 2: Unscrew and take away the stop block on the

extruder linear guide.

1

2

QUICK START GUIDE PN: 005-0801 REV: E04

4/ 13

STEP 3: Pull the buckle upward and take away the

stop block on the left linear guide.

STEP 4: Pull the buckle upward and take away the

stop block on the right linear guide.

3. Add coolant into the liquid cooling unit

STEP 1: Unscrew the cover plate on the back of the

printer.

STEP 2: Take out the end of the tube.

STEP 3: Take out the funnel from the accessory box

and fix it on the end of the tube. Add feed 750~950 ml

Automotive Engine Anhydrous Coolant (with color is

preferred ) into the liquid cooling unit.

The cap of tube end must be re-tightened after adding

liquid.

2

3

1

QUICK START GUIDE PN: 005-0801 REV: E04

5/ 13

The volume of the liquid tank of the chiller is 1000ml,

and the liquid level sensor will be triggered when it is

lower than 600ml.

4. Feeding clamper force adjustment

Take the left extruder for example, the right extruder is

the same.

STEP 1: Open the top door, press down the button of

the one-touch fitting, pull the left filament tube out at

the same time.

STEP 2: Click “System” icon, then press Arrow icon.

STEP 3: Click the“Set”icon. The printer will clear the

former L-Clamper value and enter setting screen.

1

2

QUICK START GUIDE PN: 005-0801 REV: E04

6/ 13

STEP 4: Click the “←”icon to let the two gears

closer and closer. Insert and draw out the calibration

steel bar after every screen click until you feel the

resistance from the gears. After that click “Set”to

save the value. The higher the value, the greater the

clamping force.

Pay attention, the value cannot be too large, if it's

too large it will be loose again.

5. Install the build plate

STEP 1: Press the “Home” icon for X, Y, Z.

STEP 2: Move the heating bed by pressing “Z↓” with

100mm step to a suitable height. (No more than 3

times)

STEP 3: Install the build plate on the heating bed

according to the build plate insertion direction.

2

1

1

2

3

QUICK START GUIDE PN: 005-0801 REV: E04

7/ 13

6. Load material

STEP 1: Press the “Material” icon, and then press

“L” icon to select left extruder. The icon will be

highlighted when it has been selected. (Same with the

right extruder.)

STEP 2: Press the drop-down menu to select material.

Make sure the material you selected is the same with

the one you want to load.

STEP 3: And then press “Load” icon, there are in

total 4 steps to load material, after 120 seconds

loading process ended, press “Finish”. (If the

filament is not extruded out from the nozzle, long

press “E↓” till the filament comes out or redo the

load.)

Unload material by pressing “Unload”icon and then

follow the instructions on the screen.

7. Bed leveling

There are two methods of bed leveling: Manual

Leveling and Auto Leveling. Only need to choose one

method to do the leveling.

Manual Leveling is much recommended because of

higher precision.

1

2

3

4

1

2

3

4

5

6

8

9

7

5

QUICK START GUIDE PN: 005-0801 REV: E04

8/ 13

Manual bed leveling

STEP 1: Press the “Material”icon, and then press

the icon.

STEP 2: Press the leveling icon, and then press

OK.

STEP 3: After the nozzle is heated up, press “Next”.

STEP 4: There are 4 screws which need to be adjusted

one by one for at least twice, by using the leveling

card with 0.2mm thickness ( the leveling card is in the

accessory box) .

STEP 5: Press “Finish”to exit the process after

adjustment is completed.

1

2

3

4

6

7

8

9

10

11

12

5

QUICK START GUIDE PN: 005-0801 REV: E04

9/ 13

Auto bed leveling

STEP 1: Press the “Material”icon, and then press

the icon.

STEP 2: Press the leveling icon, and then press

OK.

STEP 3: After the nozzle is heated up, press the nozzle

upward with the tool as shown in the figure. When

seeing “Triggering succeeded”, press “Next”.

STEP 4: Clean the nozzle and the build plate, then

adjust the Z axis with a leveling card with a thickness

of 0.2mm according to the instruction on screen.

1

2

3

4

5

6

QUICK START GUIDE PN: 005-0801 REV: E04

10 / 13

STEP 5: Remove the leveling card after adjustment is

OK, and then press “Calibrate”. When calibration is

done, press “Next”.

STEP 6: Keep the nozzle and build plate clean, then

press “Auto level”.

STEP 7: The printer will perform a 3-points automatic

leveling.

STEP 8: Press “Finish”after leveling is successful,

the build plate will go downwards and then upwards

to Z home.

7

8

9

11

10

12

QUICK START GUIDE PN: 005-0801 REV: E04

11 / 13

8. Calibrate the printer

1. Z Calibration

STEP 1: Press “Z calibration”icon and confirm with

“OK”.

STEP 2: Press “Z↑” or “Z↓” to perform the left

nozzle calibration by using a leveling card with a

0.2mm thickness, and then press “Next”. (There are

two steps for different adjusting accuracy, 0.05mm

and 0.01mm.)

STEP 3: Perform calibration for the right nozzle by

following the same steps, press “OK”to complete

the total calibration.

2. XY calibration

STEP 1: Press “XY calibration”and then press

“Next”, the printing process starts. After printing is

completed, press “Next”.

STEP 2: Check the printed model. Find the alignment

line in X and Y direction and set the corresponding

offset X and Y values, press “OK”.

1

2

3

4

5

6

1

2

3

4

6

QUICK START GUIDE PN: 005-0801 REV: E04

12 / 13

If there are no lines are aligned with each other, set 15

firstly on the corresponding direction (“+/-”), redo the

printing and reset the offset value.

STEP 3: Press“Finish”to complete the calibration.

If you want to selectively do the specific step, you can click

“Skip”.

Printing Process

STEP 1: Insert the USB flash disk into the right socket

on the panel, then press Open icon.

STEP 2: Select the file, and press “Open”.

5

7

8

1

2

10

9

QUICK START GUIDE PN: 005-0801 REV: E04

13 / 13

STEP 3: Firstly, buildplate and chamber will preheat for

a specific time, then print. After print, the printer will

maintain buildplate and chamber temperature until

you stop it.

Install Software

After successfully setting up the printer, install the INTAM-SUITE software on your

computer,and you can load the Slicing Software from this link:

https://www.intamsys.com/intamsuite/

It is available for Windows.

Warranty

The detail warranty information please refer to user manual.

Support

If you want get more support, please contact the local reseller or regional technical support

as below.

Asia Pacific: Support_APAC@intamsys.com;

Europe, Middle East, & Africa: Support_EMEA@intamsys.com;

North America / Latin America: Support_America@intamsys.com.

3

4

Other manuals for Funmat Pro 410

2

Table of contents

Other Intamsys 3D Printer manuals

Intamsys

Intamsys FUNMAT PRO User manual

Intamsys

Intamsys FUNMAT HT User manual

Intamsys

Intamsys FUNMAT PRO 310 User manual

Intamsys

Intamsys Funmat Pro 410 User manual

Intamsys

Intamsys Funmat Pro 410 User manual

Intamsys

Intamsys FUNMAT HT User manual

Intamsys

Intamsys FUNMAT PRO 310 User manual

Intamsys

Intamsys FUNMAT PRO User manual

Intamsys

Intamsys FUNMAT HT User manual