Intec ColorCut FB550 Series User manual

Intec Printing Solutions - Manual for ColorCut flat bed series FB550 ....................................................................................... Page No: 1

Dual Tool, Flatbed Digital Die-Cutters

ColorCut FB550 Series

Installation & Setup Guide - English

Revision: 2.0 0121

Intec Printing Solutions - Manual for ColorCut flat bed series FB550 ....................................................................................... Page No: 2

Intec Printing Solutions - Manual for ColorCut flat bed series FB550 ....................................................................................... Page No: 3

Contents

Chapter 1 -The Intec ColorCut FB550 Flatbed Series .................................. 5

1.1 INTRODUCTION ..................................................................................................7

1.2 SPECIFICATIONS ................................................................................................8

1.3 UNPACKING Contents of the ColorCut (Overview) ............................................. 9

1.4 UNPACKING Contents of ColorCut Flatbed (Detailed) ......................................10

1.5 IDENTIFYING KEY FEATURES of your ColorCut Flatbed .................................11

1.6 THE CONTROL PANEL (Overview of Navigation) ..............................................12

Chapter 2 - TOOLS for the Intec ColorCut Flatbed .................................... 14

2.1 CUTTER BLADES (An overview of Blade types) ...............................................15

2.2 THE BLADE HOLDER - an introduction ............................................................16

2.3 Replacing the blade ........................................................................................... 16

2.4 BLADE LENGTH - (Adjustment) .........................................................................17

Chapter 3 - INSTALLATION of your ColorCut Flatbed ............................... 18

3.0.1 OVERVIEW of installation steps ......................................................................19

3.1 Assembling the Stand, Cutter and Vacuum Pump ............................................20

Component parts of the stand .......................................................................20

Component parts of the vacuum fan pump ...................................................20

Assembly of stand ..........................................................................................21

Assembly of vacuum fan/pump ......................................................................21

3.2 Software Installation - Intec ColorCut Pro ......................................................... 22

ColorCut Pro Overview ................................................................................... 22

ColorCut Pro Installation.................................................................................22

3.3.1 Connecting and powering on the cutter. ........................................................25

Turning the cutter on (The Initialisation Process) ............................................25

3.3.2 Connecting to your computer ................................................................26

3.3.3 CONFIGURING COLORCUT PRO TO MATCH YOUR CUTTER ...........26

3.3.4 Customising the ColorCut Pro skin to your FB550 cutter ....................27

3.3.5 Output device ........................................................................................28

3.4 Installing Tools in your ColorCut ........................................................................ 29

3.5. Calibration of the FB550 Cutter ........................................................................30

3.5.1 Calibration of the Creasing Tool to the Cutting Tool ..............................30

3.5.2 Calibration of the Sensor Offset to the Cutting Blade ...........................34

3.6 Performing a test cut .........................................................................................37

3.5.1 Calibration of the Creasing Tool to the Cutting Tool ..............................37

Intec Printing Solutions - Manual for ColorCut flat bed series FB550 ....................................................................................... Page No: 4

Intec Printing Solutions - Manual for ColorCut flat bed series FB550 ....................................................................................... Page No: 5

1.1 Introduction

1.2 Specification

1.3 Unpacking overview

1.4 Identifying key features of your ColorCut Flatbed

1.5 Overview of the Control Panel

Chapter 1

Chapter 1 -The Intec ColorCut FB550 Flatbed Series

Intec Printing Solutions - Manual for ColorCut flat bed series FB550 ....................................................................................... Page No: 6

Intec Printing Solutions - Manual for ColorCut flat bed series FB550 ....................................................................................... Page No: 7

1.1 INTRODUCTION

INTEC COLORCUT FLATBED - DIGITAL CUTTING SOLUTION

The Intec ColorCut FB550 flatbed cutters are designed primarily to cut card and packaging

materials effectively. It is also used for cutting, vinyl, thin film, adhesive labels and magnetic

media.

There are also additional functions for die cutting sheet material, using perforated and

dashed cut features and the use of additional tools such as creasing which enables folding

on suitable card materials without the fib es on the boar d breaking when the material is

folded.

The ColorCut solution consists of 2 parts:

Hardware

An Intec Digital Cutting Engine

An Integrated Optical Sensor for automatic registration mark sensing

A Stand

A Vacuum Pump to provide suction for vacuum table.

An Optional Silencer/Acoustic Muffler to educe vacuum pump sound levels

A Vacuum connection hose

and

Software

The ColorCut Pr o cutter contr ol software contains two parts, (i) a pr ofessional

direct plug-in for Illustrator or CorelDRAW enabling you to assign cut lines or paths

created from Adobe Illustrator or CorelDRAW. (ii) a Production Studio application

that cuts your projects (either from within your graphics packge or as a seperate

application where jobs can be cut later using a job number or barcode).

Jobs can be cut without r egistration marks, however for accurate cutting your

files must contain four reference marks, known as SMAR Tmarks (described later

in the ColorCut Pr o Software manual) which can be automatically applied within

tthe ColorCut plug-in.

The optical sensor integrated into your ColorCut hardware detects the SMARTmark

in a fraction of a second and adapts the cut path to any variations in the origin,

scale or skew distortion of the print.

The software runs with the operating systems Windows 7, 8, 10.

Please use this guide to set up your Hardware and refer to the Software / ColorCut manual

to assist you in final calibration of the softwa e to the cutter including guidance on how to

use ColoCut Pro when designing and cutting your files

Intec Printing Solutions - Manual for ColorCut flat bed series FB550 ....................................................................................... Page No: 8

1.2 SPECIFICATIONS

INTEC COLORCUT FLATBED - SPECIFICATIONS

The Intec ColorCut FB550/FB750 and FB1150 series of flatbed cutters vary

primarily by the size of the cutting area.

Model Maximum Media

Area

Effective Contour

Cutting Area Stand

ColorCut FB550 350 x 520mm 330 x 488mm Yes

ColorCut FB750 475 x 670mm 456 x 640mm Yes

ColorCut FB1150 780 x 1080mm 740 x 1040mm Yes

In addition to the primary difference in workspace area and the cutting area. The

Intec ColorCut FB520/FB600/FB700/FB900 and FB1060 flatbed cutters have

different vacuum control systems to provide media hold-down during cutting.

Model Air Pump Vacuum

Power Vacuum Control Accoustic

Silencer

ColorCut FB550 400W 400W Fixed Optional

ColorCut FB750 750W 750W Fixed Yes

ColorCut FB1150 1000W 1000W Fixed Yes

Each cutter is supplied with 2 dif ferent cutting mats that ar e positioned on the

cutting table; the green self healing mat is typically used for kiss-cut applications

such as labels/decals or vinyl’ s. The Gr ey felt mat is actually the pr emium mat

and is also known as the superior cutting underlay . This is used for cut-thr ough

applications and any application using the creasing tool, as the mat enables some

‘give’ therefore providing a better crease. In addition, the grey superior cutting mat

can extend the life of your cutting blade for cut-through applications.

Intec Printing Solutions - Manual for ColorCut flat bed series FB550 ....................................................................................... Page No: 9

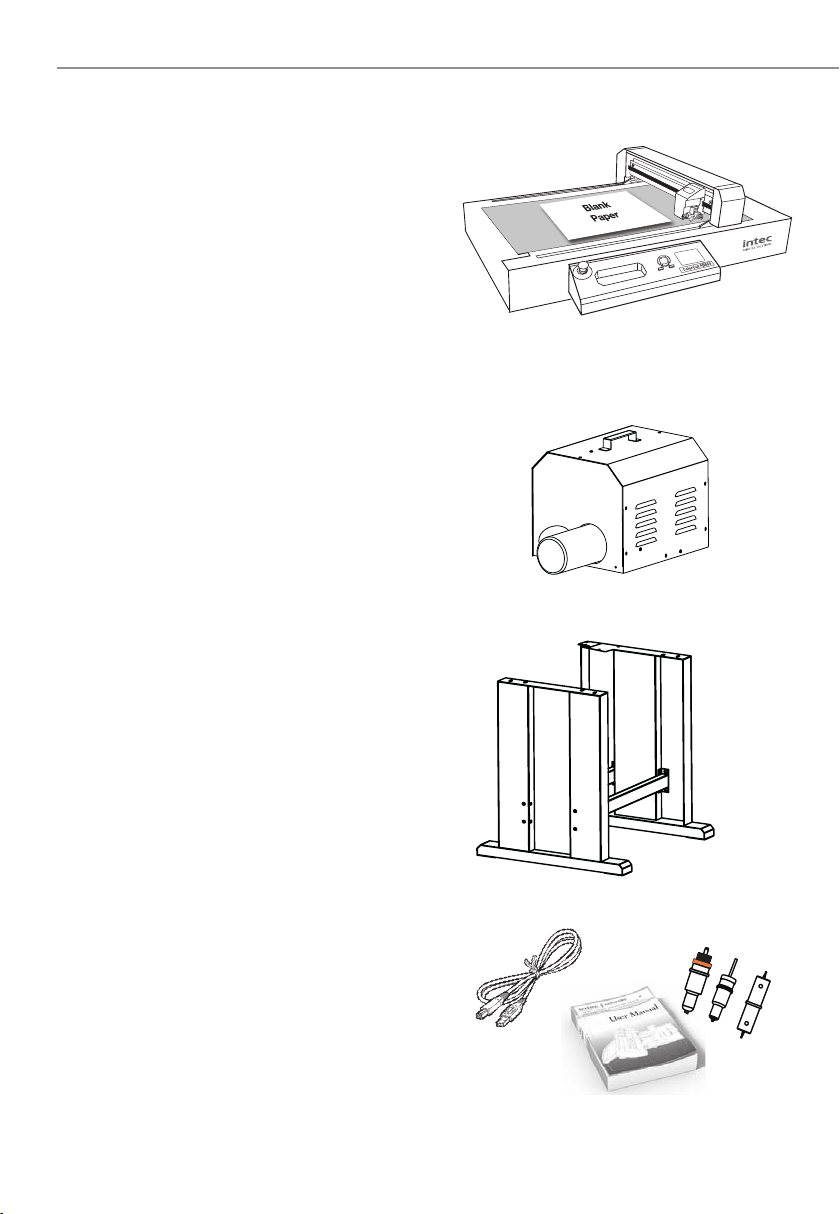

1.3 UNPACKING Contents of the ColorCut (Overview)

Your Intec ColorCut is packed in 1 crate.

The box contains :

The Intec ColorCut Cutting Engine. (Item (i))

The ColorCut Vacuum Pump (ii)

The Vacuum Pump Connector Hose (iii)

The Accessories box (iv)

And the ColorCut Stand (v)

The ColorCut Vacuum Pump and V acuum

Hose provide the vacuum to hold down

your media on the cutting table.

The stand pr ovides a perfect er gonomic

working height for your cutter.

The final items found inside the accessories

box include the power cable and USB cable

plus a disk containing your ColorCut Pr o

Software and license code. A Blade Holder,

a selection of Cutting Blades, a Calibration

Pen Tool and a Creasing Tool.

Item (i) - Intec ColorCut Cutting Engine

Item (ii) - ColorCut Vacuum Pump

(and Acoustic Silencer - Optional on FB550)

Item (iii) - Intec ColorCut Stand (FB550, FB750, FB1150)

Item (iv) - Manuals, USB & Power Cables

*Optional on FB550

Intec Printing Solutions - Manual for ColorCut flat bed series FB550 ..................................................................................... Page No: 10

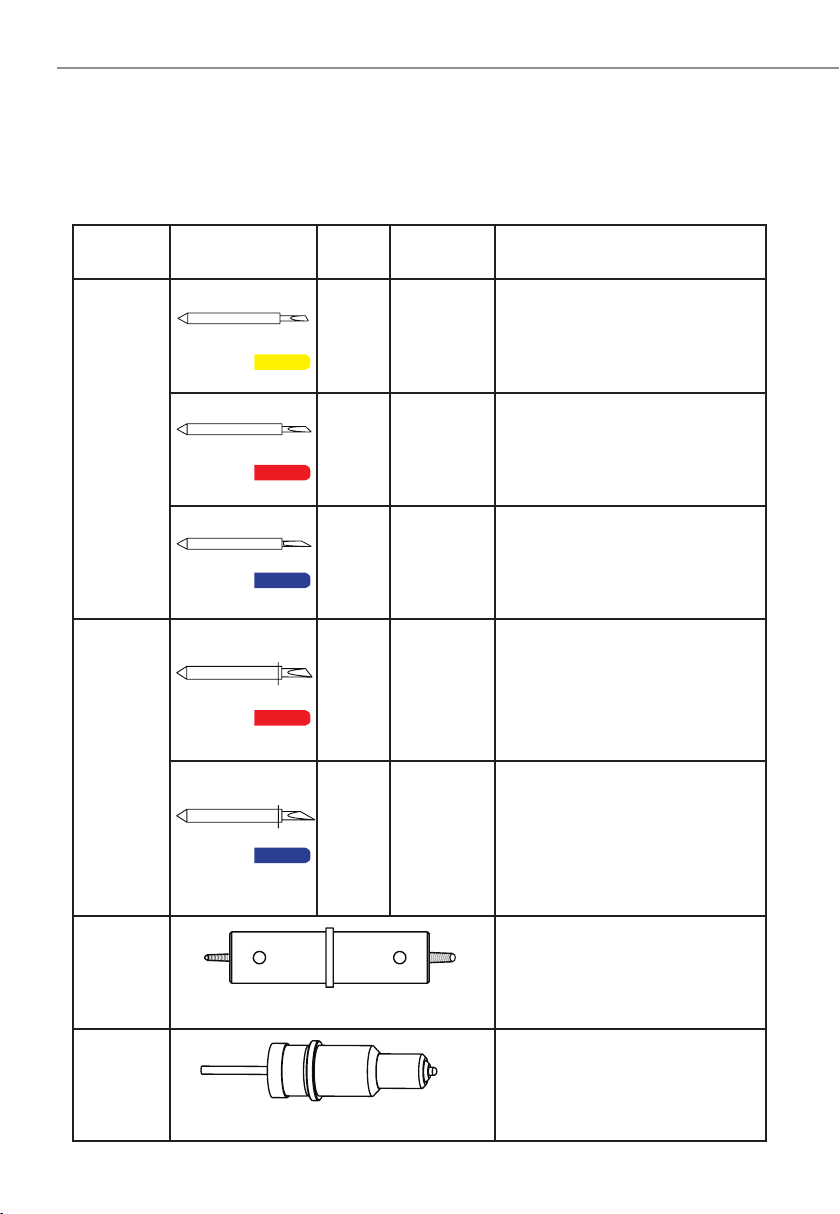

1.4 UNPACKING Contents of ColorCut Flatbed (Detailed)

Item Qty Description / Purpose

Intec Flatbed Cutter 1 Main Cutting Engine

Vacuum Air Pump 1 Air fan that provides Vacuum

Hose 1 Connects Vacuum Pump to Cutting Engine

Hose Connector* 2Connects Hose to Vacuum Pump and to cutting

Engine.(FB550 Only)

Software (ColorCut Pro)

1

ColorCut Pro cutting control software - Direct

plug-in for Illustrator or CorelDRAW, and stand

alone Production cutting applications.

Blade Holder 1Used for mounting the blades in Tool Holder 1 on

the cutting head.

Pen Tool 1Used in the calibration process for aligning the

sensor to the cutting position

Creasing Tool

1

A dual ended, Ball Bearing-based tool to crease

the media without breaking the fib es (2 crease

widths are possible by using the dual ends)

Blades 3

1 x 30O Blade (Yellow)

1 x 45O Blade (Red)

1 x 60O Blade (Blue)

Circlip Knife 6 3 x 45O Circlip Knife for thicker media (Red)

3 x 60O Circlip Knife for thicker media (Blue)

Self Healing Cutting Mat

(Green) 1 Mainly used for cutting (Labels and Swing tickets)

Felt Creasing & Cutting

Mat 1

Used to improve creasing effect and extended

blade life - Typically cut through / die cut

applications- packaging - (cutting and creasing)

USB Cable 1 For connection to the computer

Silencer for Vacuum

pump 1

Reduce noise for Vacuum pump

FB750/ FB1150 (only)

(Option for FB550)

Power Cable 2 1 for Digital Cutting Engine

1 for Vacuum Pump

M3 Six Angle Wrench Backup tool

M2 Six Angle Wrench Used to adjust the height of the creasing ball

10A Fuse /

Please use this guide to set up your ColorCut Hardware.

Intec Printing Solutions - Manual for ColorCut flat bed series FB550 ..................................................................................... Page No: 11

1.5 IDENTIFYING KEY FEATURES of your ColorCut Flatbed

BTool Carriage............ Drives the cutter blade/pen/creasing tool forward/backward.

CTool Holder 1........... Holds the cutter blade tool and drives it up/down.

DTool Holder 2........... Holds the pen/creasing tool and drives it up/down

EBeam...................... Holds the tool carriage; moves left/right.

FControl Panel.......... Used to set and use the cutter’s various functions.

GTool Recess ..............Recess for holding tools

HEmergency Switch... In case of emergency turns off the power.

ICutting Area............ Vacuum bed and Contour Cutting Area.

JBelt......................... Drives the tool carriage forwards and backwards

KStabilisation feet.......Footing for machine when not using the stand.

②

①

9

10

⑩

⑨

③

④

⑤

⑥

⑦

⑧

Intec Printing Solutions - Manual for ColorCut flat bed series FB550 ..................................................................................... Page No: 12

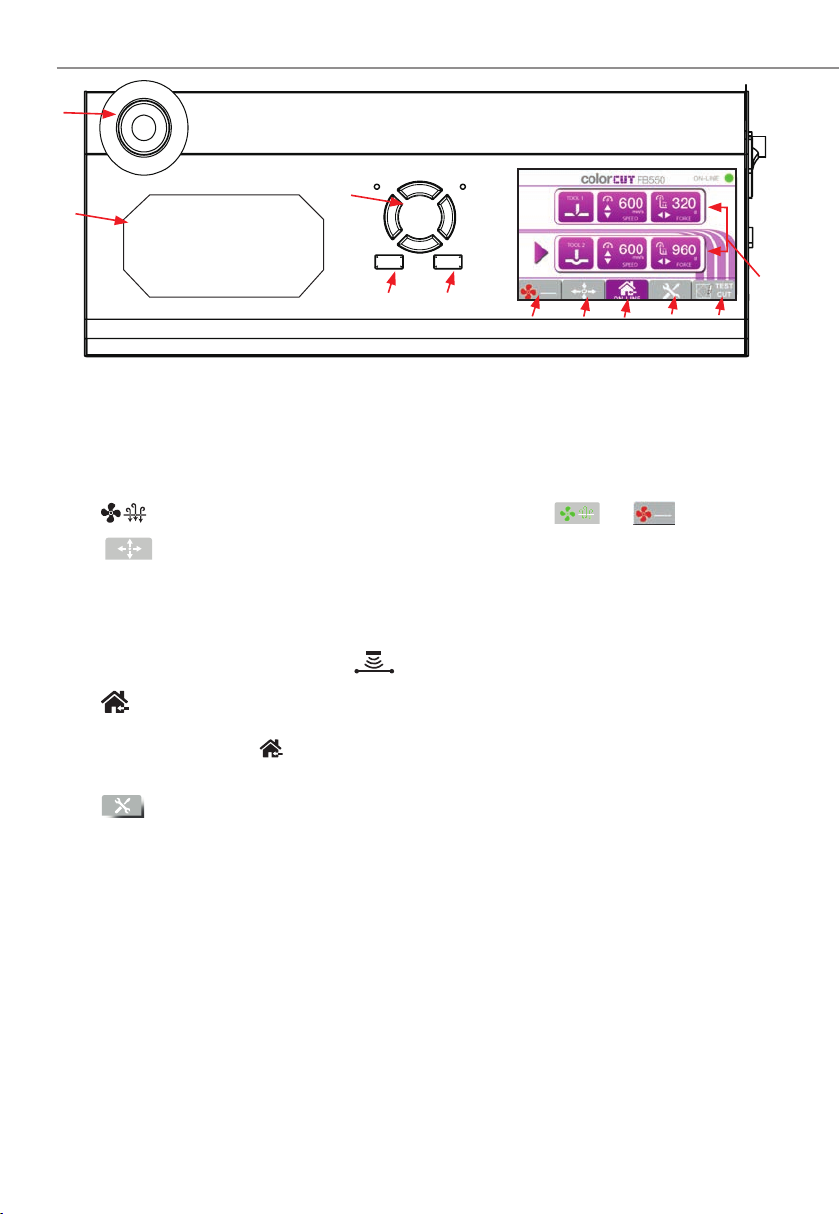

1.6 THE CONTROL PANEL (Overview of Navigation)

①LED Display Displays Tool (Cut/Crease) information and menu parameters.

TOOL 1 - SPEED / FORCE - Controls the speed and force of tool holder 1.

(Generally used to hold the blade for cutting).

TOOL 2 - SPEED / FORCE - Control the speed and force of tool holder 2.

(Generally holds the creasing tool).

Tap on the screen to select each tool, use the HARD keys (left) to adjust values.

② (Fan) Toggles the vacuum fan function on/off [ ] /[ ]

③ /MOVE Takes the Cutter [Of f-Line] and enables your to move the tool

carriage. Used to set the start/origin for cutting and moving the

carriage when placing sheets. After moving the tool carriage, you

must press ENTER twice if you want to define the position as a new

ORIGIN. The MOVE function also enables access to the Sensor light

ON/OFF button (enabling you to see the sensor position).

④ (Home) HOME - Returns back to the main screen.

(When you use the MOVE function or scroll through the menu options, pressing

the [ ](HOME) key leaves the screen and returns to the HOME screen.

(Default Home screen displays: Speed and Force - (for each Tool)

⑤ Menu Scrolls through the machines menu settings/parameters.

Align Tool2 to Tool1 - Sets the distance between tool holder 1 & tool holder 2.

Enabling you to align the CREASE to the CUT . This is not the same as cutting

in the correct position (see SENSOR OFFSET) in your software manual for that!.

Firmware Version - Displays the current installed version of firmwa e.

Menu Mode - Displays the DEFAULT list (above) or ADVANCED list (below)

Work Mode - Cut Plotter - Enables both tool holder 1 and tool holder 2.

- Draw Plotter - Enables tool holder 1 (blade/cut ) only.

Scaling Factor - Scaling for the X direction and Y direction.

- Set at the factory, and typically does not need to be changed.

Factory Reset - Restores ALL factory default settings.

⑥ Test Used to make a Test Cut to check whether the currently selected cutting

conditions are compatible with the media loaded. Tool 2 creases a 45O

rotated square (Like a diamond), then Tool 1 cuts a square around it.

Using a Test Cut you can check Blade Depth and pr essure for cutting

and also confirm if the creasing Tool is perfectly aligned to Cutting Tool.

②

①

⑩

⑤

⑦ ⑧

Offline Enter

⑪

③④⑥

⑨

Intec Printing Solutions - Manual for ColorCut flat bed series FB550 ..................................................................................... Page No: 13

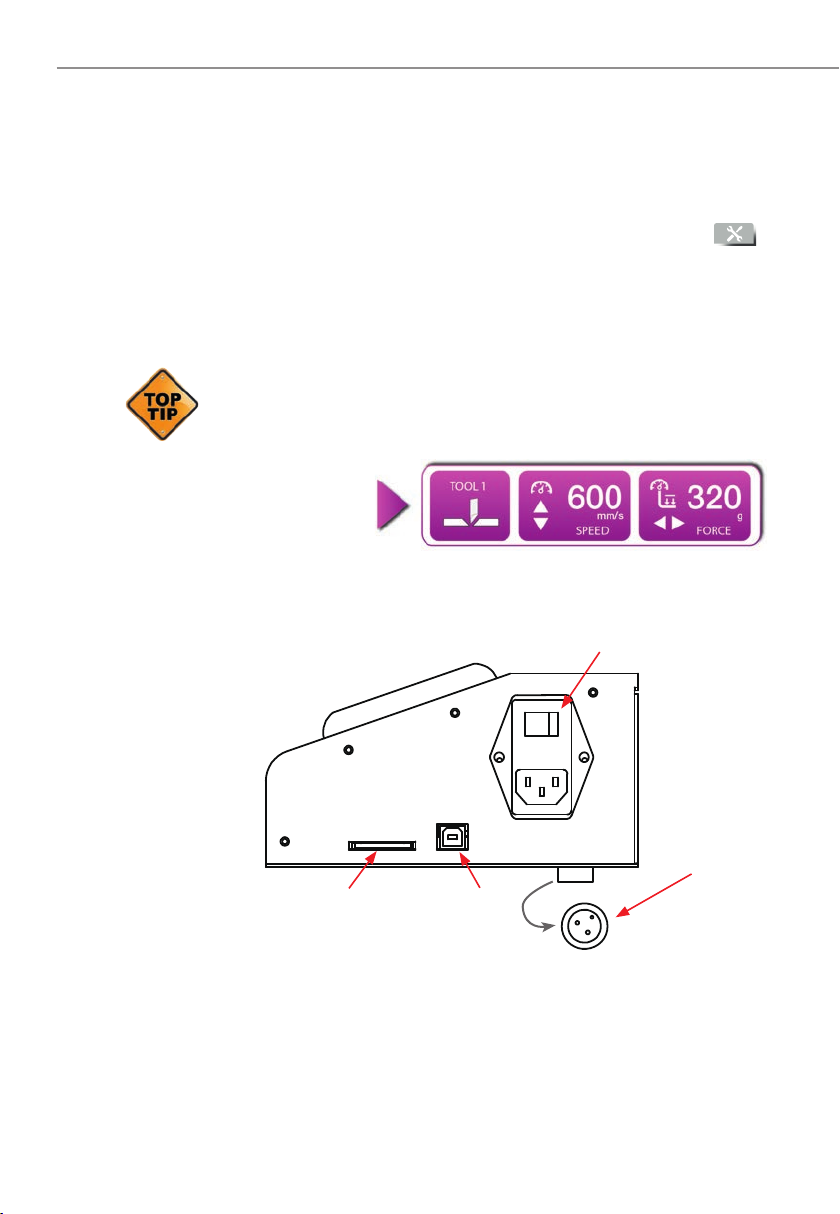

THE CONTROL PANEL (Overview of Navigation)

⑦ Offline When the Default Home screen is displayed, the OFFLINE key takes

the cutter offline. In this mode you cannot send jobs to the cutter.

Pressing the MOVE key will also place the cutter of f-line. You can

move the carriage - r emember after moving the carriage, pr ess ON-

LINE to place the cutter back on-line and enable jobs to be received.

⑧ Enter After setting a function or condition in the MENU options [ ],

press the [ENTER] key to register your setting

⑨ Hard button arrow keys used to INCREASE or DECREASE values on

the LCD panel scr een. Either for TOOL speed/for ce control OR for

changing menu settings or parameters.

The LCD screen will often indicate which key to use to incr ease or

decrease the value. i.e. When Tool 1 is selected, the are displayed

next to the SPEED parameter, indicating you should use the keys.

The symbols ar e displayed next to the FORCE, indicating the

Keys are

used to adjust

these values.

⑩ Emergency switch Cuts the power to the cutter. Depress again to deactivate.

⑪ Tool Recess Convenient place to store tools.

⑫ Power switch Turns the ColorCut Digital Cutter ON/OFF.

⑬ Vacuum pump connector The control cable connector for the Vacuum pump.

⑭ USB interface connector Used to connect the cutter to a computer via the

USB interface.

⑮ SDcard interface connector N/A - This feature is unavailable.

F

1

Reset Set Test

F

2 F

3

Offline

Enter

⑫

⑬

⑭

⑬

Chapter 2 - TOOLS for the Intec ColorCut Flatbed

2.1 Types of cutter blades

2.2 Blade Holder introduction

2.3 Replacing the blade

2.4 Blade length (Adjustment)

Chapter 2

Intec Printing Solutions - Manual for ColorCut flat bed series FB550 ..................................................................................... Page No: 15

2.1 CUTTER BLADES (An overview of Blade types)

Name Image Angle Blade

Diameter Features and Application

Blade

30O1mm For Film, very soft material, thin

label material.

45O1mm Typically for labels, stickers,

and thin paper/card,

60O1mm

For thick media. The sharply

angled tip provides a longer

cutting edge. Suitable for cutting

media from 0.5 to 1.5 mm thick.*

Circlip

Knife

45O1.4mm

Most packing board up to 500

micron. Circlip provides better

pressure and improves blade

direction changes on dense media.

Suitable for cutting media from 0.25

to 0.5 mm thick

60O1.4mm

For cutting high-intensity reflectiv

film, magnetic media or thick media

The sharply angled tip provides a

longer cutting edge. Suitable for

cutting media from 0.5 to 1.5 mm

thick.* For cutting sandblast rubber.

Creasing

Blade

Bearing-based creasing ball,

double-ended for different width

creasing. Suitable for media ≤500g

Cardboard, corrugated paper

Pen

Holder

Used at setup, to calibrate the offset

between the Optical Registration

Mark sensor (Red light) and the

centre of Tool1 (The blade).

* Maximum cutting depth is defined by the machine type rather than the blade (which is 600 mic ons)

Your cutter comes with a selection of blades. The blades are packed in a foam

packing material. In addition to this there is a colored rubber protective cap. The

yellow caps indicate 30O, red caps indicate a 45O blade while the blue caps are 60O

blades. Be careful when handling the blade as the cutting end is very sharp. Blades

are selected for different applications; a guide is shown below:

Intec Printing Solutions - Manual for ColorCut flat bed series FB550 ..................................................................................... Page No: 16

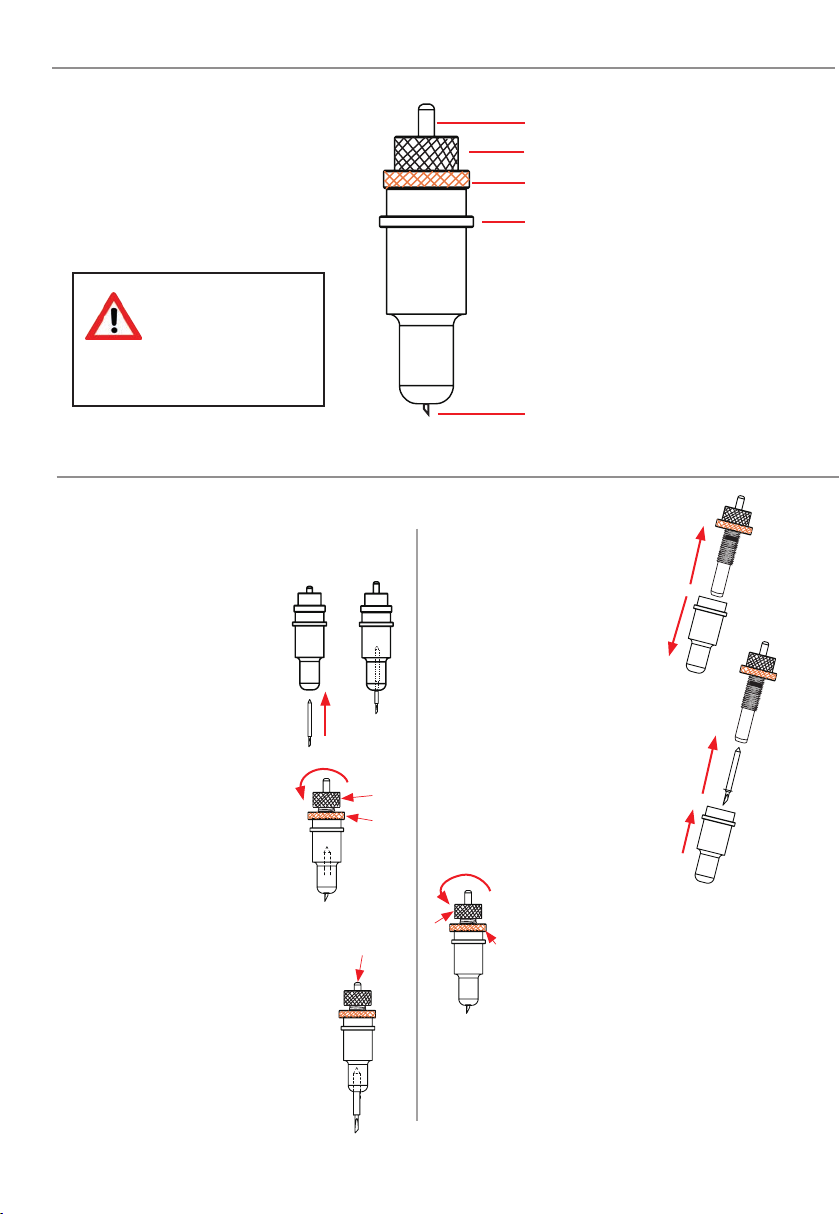

2.2 THE BLADE HOLDER - an introduction

F Exposed Blade

E Flange

D Lock

C Blade Depth Adjustment

B Pin

When handling

cutter blades, be

careful to avoid

cutting your fingers or

other parts of your body.

2.3 Replacing the blade

The blade is a consumable item and

you’ll always get the best quality cut with

a newer blade. Please replace with a

new blade when the cut quality reduces.

For Standard blades

(Without the circlip)

1. Push the blade into the

bottom of the blade holder.

2. Adjust the amount of

exposed (visible) blade

tip to a suitable length by

rotating C the “Adjustment

depth knob” and then tighten

the lock D.

3. Press the push-pin B to

remove the blade from the

blade holder when replacing

blade

For CirClip Blades

1. Unscrew the lower (cover)

part of the blade holder.

2. Insert the Circlip blade into

the inner blade holder. Then

replace the outer cover of the

blade holder;

3. Adjust the amount

of exposed (visible) blade tip

to a suitable length by rotating

C the “Adjustment depth

knob” and then tighten the

lock D.

4. Replace the blade by following the

steps above (Note: You cannot push the

pin as you do with standard blades as the

circlip prevents the blade being removed.

C

D

BD

C

Intec Printing Solutions - Manual for ColorCut flat bed series FB550 ..................................................................................... Page No: 17

2.4 BLADE LENGTH - (Adjustment)

Ⓑ

Blade Depth is a major factor in how well the machine cuts and along with the

downforce / pressure, determines how cleanly the material cuts and how easy or

difficult it will be to ‘weed’ the material. oo much blade depth is as bad as not

enough.

If you have enough blade sticking out to clearly see and feel the tip, it’s

probably too far out. Most new Intec Flatbed cutter owners improperly

install the blade with too much of it protruding from the holder. Set it so that

you can barely see the tip.

Then take the blade holder and manually drag it across a sheet of card or label that

you wish to cut, making a box pattern or square.

Card: Lay a scrap piece of material on a hard work surface with 2 sheets of copier

paper underneath, (not on a nice table in case you cut through paper underneath).

With the blade holder in your hand, press down and cut a circle in the material. Press

down using a moderate amount of force while you cut the circle.

You will not be able to cut through the second sheet of paper when the blade depth is

set correctly. If it cuts through the second sheet then the depth is too much and you

need to retract the blade.

Labels: Lay a scrap piece of material on a hard work surface (not on a nice table in

case you cut through the backing). With the blade holder in your hand, press down

and cut a circle in the material. Press down using a moderate amount of force while

you cut the circle.

Adjust the blade depth so that only traces of the blade’s cut appear on the backing

sheet when a cutting test is performed. You will not be able to cut through the

material backing when the blade depth is set correctly. If it cuts through the backing

then the depth is too much and you need to retract the blade.

The blade length is adjusted by turning the blade adjustment knob.

• To extend the cutter blade, turn the knob in the Ⓐ direction.

• To retract the cutter blade, turn the knob in the Ⓑ direction.

Ⓐ

Chapter 3 - INSTALLATION of your ColorCut Flatbed

INSTALLATION overview

3.1 Basic overview of installation steps

3.2. Parts for assembly

3.2.1 Stand components

3.2.2 Vacuum Pump components

3.3.1 Assembly of the stand and cutter

3.3.2 Connecting the Vacuum pump

3.4. Connecting and Power on the Cutter

3.4.1 Turning on the Cutter

3.4.2 Connecting to a Computer

3.5 Installing Tools

3.6 Calibration of the Creasing Tool to the Cutting Tool

3.7 Calibration

Intec Printing Solutions - Manual for ColorCut flat bed series FB550 ..................................................................................... Page No: 19

3.0.1 OVERVIEW of installation steps

01

02

03

04

05

06

Assemble the stand, mount the intec ColorCut onto the stand. Fit the hose

connectors to the ColorCut engine and Vacuum pump then connect the hose.

Install the supplied ColorCut software for Illustrator or CorelDRAW.

(Refer to your ColorCut Pro Software manual).

Using the supplied USB cable connect the cutter to your PC or Mac.

Then check in the software that the cutter can be seen.

Install the Blade Creasing and Pen Tools.

Turn your cutter on, then calibrate first the Creasing tool position to the

cutting tool. Next refer to your ColorCut pro software manual and set the

offset from sensor to cutting position in your software.

Select your cutting matt, (Felt or Green matt) and load your media .

Use TEST cut to perform a cutting test and adjust blade if necessary.

(Please refer to your ColorCut Prosoftware Manual.

INSTALLATION

START

INSTALLATION

FINISHED

Install ColorCut Flatbed Tools

Connect to your Computer

Install the Software

Assembly

Calibrating the Cutter

Load media and perform test cut

Intec Printing Solutions - Manual for ColorCut flat bed series FB550 ..................................................................................... Page No: 20

3.1 Assembling the Stand, Cutter and Vacuum Pump

Component parts of the vacuum fan pump

1. Left side panel/leg

2. Right side panel/leg

Component parts of the stand

3. Front cross member

4. Rear cross member

6. Castors x 4 free-wheel

7. Bolt, washers, fixing

8. Acoustic pump

9. Flexible hose

10. Silencer (*Option on FB550)

3 4

6 7

2

1

10*

8

9

This manual suits for next models

2

Table of contents

Other Intec Cutter manuals

Popular Cutter manuals by other brands

Toolson

Toolson PRO-RF 620 Original operating instructions

BFluid

BFluid CUT225 manual

SATO

SATO Argox iX4 DX-4200 Series Quick installation guide

TYROLIT Hydrostress

TYROLIT Hydrostress PPH25RR Series Operating instructions and spare parts list

Bush Hog

Bush Hog 1812 Operator's manual

Neschen

Neschen ECOLAM 1650 operating instructions