Intec ColorCut BC480 User manual

Version 3

BC480

Business

Card Cutting

User Manual

250 CARDS

96 SECS

PRE-SET

SIZES & TEMPLATES

SENSOR

DUAL MODES

180-350gsm

MEDIA RANGE

FEEDER

AUTO SHEETS

Page 1

Version 1 - January 2019 - TW

Version 3 - September 2020 - TW

Page 2 Page 3

Contents

Chapter One

Important Safety Instructions ......................................... 4

1 Safety Precautions ........................................................................ 4

1-1 Security matters......................................................................... 4

1-2 Warning labels............................................................................ 4

2 Safety Features.............................................................................. 4

2-1 Articles ........................................................................................ 4

2-1-1 Articles and operating limits .................................................. 4

2-1-2 Locking lid - stationary lid ...................................................... 5

3 Product Dimensions...................................................................... 5

Chapter Two

Machine specifications and contents............................. 6

1 . Machine Summary....................................................................... 6

1-1 Main purpose for usage.............................................................. 6

1-2. Machine Specifications ............................................................ 6

1-3 Accessories................................................................................. 7

1-4 Description of machine parts ..................................................... 8

Chapter Three

Set up - Operating, maintenance and troubleshooting11

1. Set up.......................................................................................... 11

1-1 Setting up methods and procedures ....................................... 11

1-2 Paper Feed Tray........................................................................ 12

1-3 Waste Paper Tray...................................................................... 12

1-4 Card Collection Tray ................................................................. 13

1-5 Mains Power.............................................................................. 13

1-6 Placement of machine for operation ....................................... 13

2. Operation .................................................................... 14

2-1 Cutting workflow...................................................................... 14

2-2 Operation panel description ................................................... 15

LCD display description.................................................................. 15

Card option...................................................................................... 16

System option - See Section 2-5-5 ................................................ 16

Manual operate ............................................................................... 16

Language ......................................................................................... 16

Test your cutting mode with a sheet of paper/card....................... 17

Number of cards to be cut.............................................................. 17

2-3 Datum selection ....................................................................... 18

2-3-1 ‘MARK’ printing set up ........................................................ 19

2-4 Cutting modes.......................................................................... 20

2-4-1 Selection of rotary knife cassette (longitudinal knife).......... 20

2-4-2 Cutting modes - paper sizes ................................................ 20

2-4-3 Cutting templates .................................................................. 21

2-4-4 Selecting the cutting mode ................................................... 33

2-5 Parameter settings description .............................................. 33

2-5-1 Cutting quantity .................................................................... 33

2-5-2 Datum selection..................................................................... 33

2-5-3 Card error adjustment method ............................................ 33

1. First cutting compensation ......................................................... 34

2. Mark position compensation ...................................................... 34

3. Card length compensation ........................................................ 35

4. Groove width compensation....................................................... 35

2-5-4 System settings ..................................................................... 36

1. System speed .............................................................................. 37

2. System accuracy compensation ................................................ 37

3. Five column blade width ............................................................. 38

4. Three column blade width .......................................................... 38

5. First cutting compensation ......................................................... 39

6. Mark position compensation ...................................................... 39

7. Groove width compensation....................................................... 39

8. Last card compensation ............................................................ 40

9. Penultimate cards compensation............................................... 40

10. Third from last compensation................................................... 41

11. Subtotal clear ............................................................................ 41

12. Restore factory settings............................................................ 41

8. Firmware version......................................................................... 42

2-5-6 CUSTOM mode card settings ............................................... 42

1. Card width ................................................................................... 44

2. Card length .................................................................................. 44

3. Card rows .................................................................................... 44

4. Card columns .............................................................................. 45

5. First cutting length ...................................................................... 45

6. Mark position length.................................................................... 46

7. Groove width ............................................................................... 46

8. First cutting compensation ......................................................... 46

9. Mark position compensation ...................................................... 47

10. Card length compensation ....................................................... 47

9. Groove width compensation....................................................... 48

2-6 Operating methods and processes........................................ 48

1. Input power.................................................................................. 48

2. Paper settings.............................................................................. 48

3. The left or right position setting of paper................................... 49

2. Feed cutting................................................................................. 49

2-7 Changing the longitudinal cutting cassette .......................... 49

Removing the longitudinal cutter (cutting cassette)...................... 49

Installing the longitudinal cutter (cutting cassette)........................ 50

3. Troubleshooting.......................................................... 51

3-1 Safety cover failure ................................................................... 51

3-2 Jam handling............................................................................. 51

3-3 Crosscutting knife cutting failure ............................................. 52

3-4 MARK’ was not detected......................................................... 52

3-5 Paper too narrow ...................................................................... 53

3-6 Poor feed................................................................................... 54

Support contact information ......................................... 55

Page 4 Page 5

2-1-2 Locking lid - stationary lid

1. Top cover

2. Locked-cover-switch

3. Operate side cover (left cover)

4. Right side cover

5. Front cover

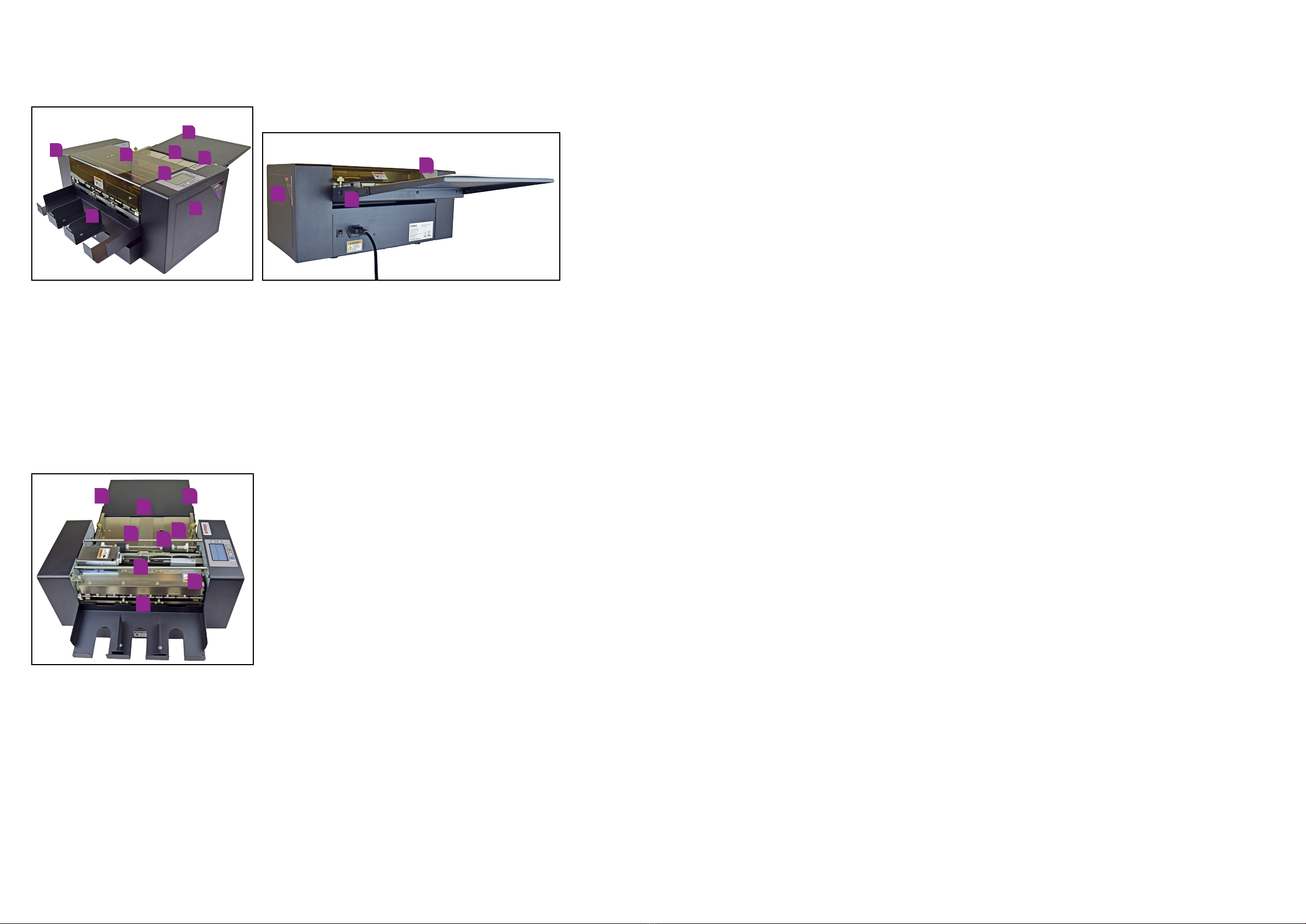

Picture 1-1 front view with feed tray

Picture1-2 back view with catch tray

3 Product Dimensions

Chapter One

Important Safety Instructions

Before installing and using the BC480 please read the following safety insructions. This will help

prevent accidents or loss of equipment and allow you to fully understand the contents and then set

up, operate and maintain the machine in accordance with this.

1 Safety Precautions

1-1 Security matters

In order to prevent accidents, strict compliance with the following matters:

• The machines’s power cord ground wire must be grounded

• Do not connect or disconnect with wet hands, as this will cause an electric shock

• Do not use a damaged plug or lead, as this could cause a fire or an electric shock

• Do not use other voltage and power supply, other than specified, as this will cause a fire and

an electric shock.

• Ensure all hair, neckties, necklaces are kept free of the feeding table to avoid injury

• Do not allow children to use this equipment

• Turn off the power when the machine is not in use

Before any action to remove wate media or to troubleshoot the machine and In exceptional

circumstances, please cut off the power supply.

Please contact your supplier for machine operating instructions should you be unable to follow any

of the manuals instructions or if the machine fails to work.

1-2 Warning labels

The warning labels are placed so you are aware of areas where caution should be taken.

1. Caution electric shock - do not touch machine with wet hands and remove before servicing.

2. Caution moving parts - do not place hands in machine whilst in operation.

3. Caution nipping hands - do not place hands in machine.

Operators should pay attention to the location of the warning labels shown here.

2 Safety Features

In order to prevent accidents, the machine has a cover interlock feature to avoid anyone operating

the machine.

2-1 Articles

2-1-1 Articles and operating limits

The machine has a locking safety cover that prevents items from getting caught in the working

mechanism of the machine.

If the cover is removed during operation the machine will stop working.

840mm

33"

250mm

9.84"

540mm

21.25"

Page 6 Page 7

Chapter Two

Machine specifications and contents

This chapter covers details about the BC480 card cutter and the standard items delivered with it.

1 . Machine Summary

1-1 Main purpose for usage

The cutting of pre-printed business cards, postcards, inserts and greetings cards to pre-set and

custom specified sizes.

1-2. Machine Specifications

Cutting methods Longitudinal cutter (cutting cassette): cut by roll cutter

Horizontal (cross cutting knife): cut by a lateral long cutter

Paper feeding methods Dual rolling auto-paper feeding

paper size A3+(320×480mm); SRA3(320×450mm);

A3(297×420mm) Custom - Use for American size papers

Paper thickness 0.25mm(180g/m²) - 0.35mm(350g/m²)

Plain good quality paper

Cutting speed 250pcs / 96 seconds for 85x55mm card from SRA3 sheets

Cutting sizes Longitudinal: (85/89/90/95) mm

Horizontal: (50/54)mm or 1 to 600mm adjustable

Paper capacity Max.12pcs card (0.35mm thickness) or a total thickness of 3mm

Name card capacity 180g/m² 90×2 (pcs) 350g/m² 70×2(pcs)

Dimensions (wxlxh) 540mm (21.25") × 840mm (33") × 250mm (9.84")

Operating temperature -15º ~ +40º / humidity 35% ~ 70%

Weight 15Kgs

Power supply AC 110~220V / 150w / 50/60HZ / 0.5A

1-3 Accessories

The below accessories are included in the box with the BC480 card cutter. Please check that you

have received all items listed. If anything is missing please inform your supplier immediately.

No. Description Qty Notes

1 User manual 1 Printed booklet

2 Template download card 1 Details download location

3 Collection tray dividers 2 Magnetic dividers

4 Feed tray 1 Feed tray hooks onto rear

5 Paper feed ring 1 Clear rubber ring

6 Feed roller rubbers 3 Flat, black grooved rubbers

7 Blade sharpening stone 1 Fragile - take care

8 Mains power cable 1 Country specific

9 Waste Paper Collection Bin 1 Removal waste paper collector

10 Collection Tray 1 Hooks onto rear of cutter

BC480

Business

Card Cutting

BC480

Business

Card Cutting

Please find a selection of card templates available for download from our website.

• IncludesAdobe®Illustrator®templatesfor:

85mm,89mm,90mmand95mmcardcuttingcassettes

• Producecardsquicklybyaddingyourdesignstotheprovidedtemplates

Please find a selection of card templates available for download from our website.

• IncludesAdobe®Illustrator®templatesfor:

85mm,89mm,90mmand95mmcardcuttingcassettes

• Producecardsquicklybyaddingyourdesignstotheprovidedtemplates

Template Downloads

Template Downloads

ScantheQRcodeorvisitthelinkbelowtoaccessthecorrectpageandthenclicktherequiredBC480

cassettesizetemplatesicon:

https://intecprinters.com/support-downloads/drivers-downloads/colorcut/

ScantheQRcodeorvisitthelinkbelowtoaccessthecorrectpageandthenclicktherequiredBC480

cassettesizetemplatesicon:

https://intecprinters.com/support-downloads/drivers-downloads/colorcut/

14

7

2

58

3

6

9 10

Page 8 Page 9

1-4 Description of machine parts

1. Rear side cover

2. Front side cover

3. Operating panel

4. Safety cover

5. Paper feed tray

6. Double paper feed ring

7. Start button

8. Power cord

9. Paper thickness adjustable indicator

10. Waste paper collection tray

11. Left paper feed panel - adjustable

12. Right paper feed panel - adjustabe

13. MARK sensor arrow for positioning

14. Paper feed rollers

15. Longitudinal knife - interchangeable cassettes - sizes; 85mm (3.34"), 89mm (3.5"), 90mm (3.54")

and 95mm (3.74")

16. Crosscutting knife

17. Anti-static fur

18. Card collection tray

2

6

8

11 12

14

13

16

15

17

18

5

1

2

4

3

7

10

5

9

Page 10 Page 11

Chapter Three

Set up - Operating, maintenance and troubleshooting

This chapter details operating methods and any required maintenance of the BC480.

1. Set up

1-1 Setting up methods and procedures

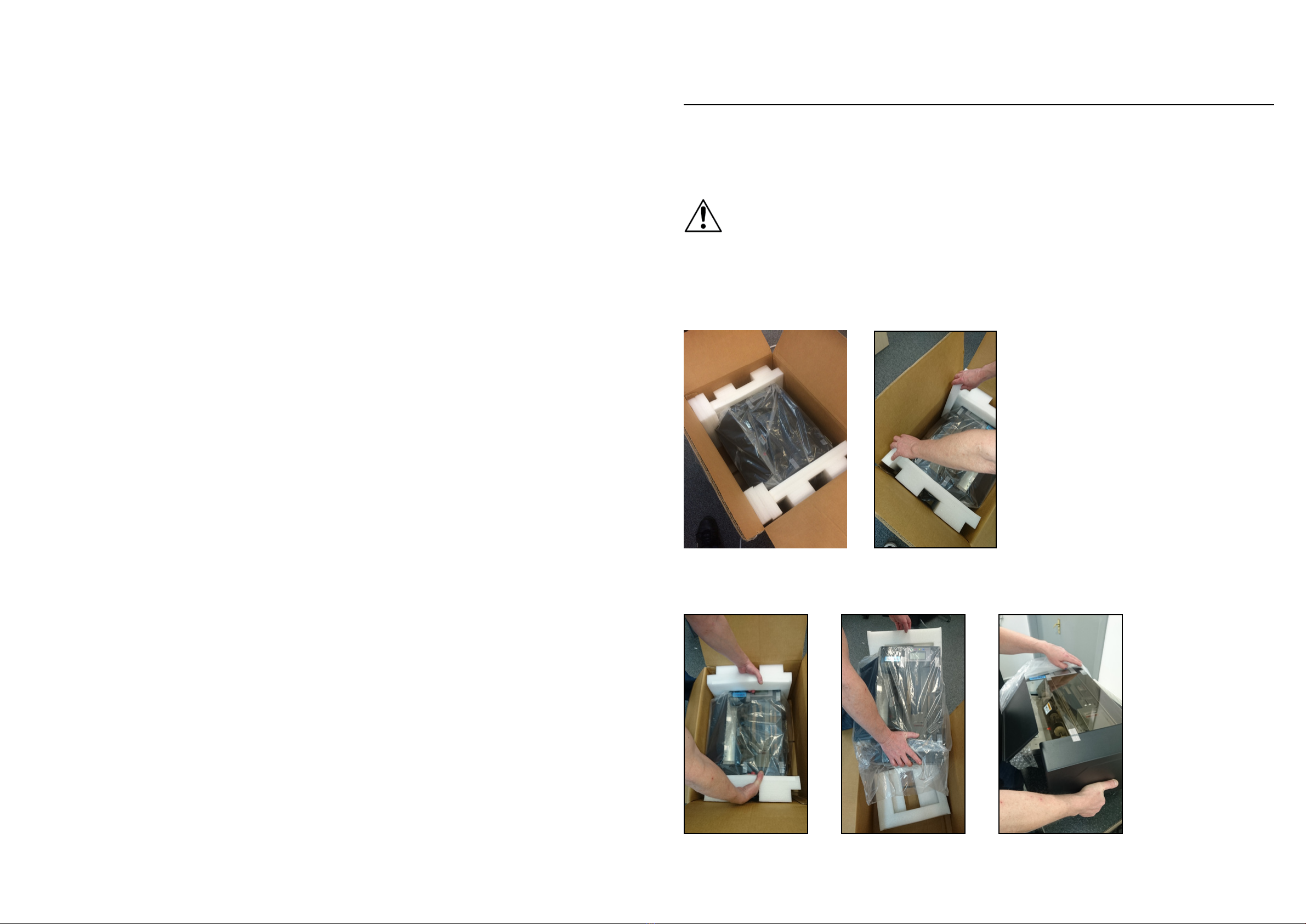

Attention

The BC480 is 15kgs in weight. This can be lifted from its box by one person however, it is advised

that it should be lifted from its box by 2 people.

Remove the BC480 as specified below:

Open the box and remove the top cardboard and foam packing as shown below.

Place you hands either side of the white foam inserts, these should be lifted out with the unit and

remove the unit placing it on a stable surface. Picture 1.

Picture 1 Picture 2 Picture 3

Once out of the box and placed on a stable surface, carefully, and whilst supporting the machine

remove the white foam ends and outer plastic bag. Picture 2 and 3.

Page 12 Page 13

Once in place and on a stable surface check contents.

The machine contains wrapped items, as listed in Chapter 2. 1-3 Accessories section, in the waste

tray.

Remove all the items and check all the contents are there.

Once you have confirmed that all the items are received please put the BC480 together as follows:

1-2 Paper Feed Tray

Find the paper feed tray and hook onto the holding pins.

The tray has adjustable feed guides that can be secured in place by tightening the screws on either

side of the tray - ensure these are closed up to your paper edges but not too tight!

1-3 Waste Paper Tray

Install the waste paper tray in the back of the machine, making sure tray is fully inserted into the

aperture.

1-4 Card Collection Tray

Install the card collection tray onto the holders for this:

After the card collection tray has been secured in place, add the card dividers - these are magnetic

and adjustable.

1-5 Mains Power

Now put your mains power cable in its input socket and plug into a mains power source.

!

Attention: Make sure the main covers magnetic interlock switch is fully connected

In order to remove the static charge must be grounded.

!

Attention: In case of electric leakage, be careful electric shock

Make sure power switch be turned on.

1-6 Placement of machine for operation

Please use the machine in the following places:

•Onastablesurface

•Inawell-ventilatearea

•Ensureareaaroundthemachineisfreefromdebris

The machine is made of precision machinery and electronic components and therefore needs

to be located in a suitable place for use.

Please avoid the following locations:

•Directsunlight

•Areasofhighhumidity

•Keepawayfromsourcesofignition

•Placesthatcanbecomepronetomoisture

Page 14 Page 15

•Closetoheatingandcoolingsources

•Vibrationofworksurface

!

Attention

•Don’tputanyotherelectricalplug,otherthanwhathasbeenprovided,intoelectricaloutlet

•Pronetostatic-youshouldusestaticshieldandhumidifier

•Don’tputthemachineonatablethatissmallerthanitsfootprint

2. Operation

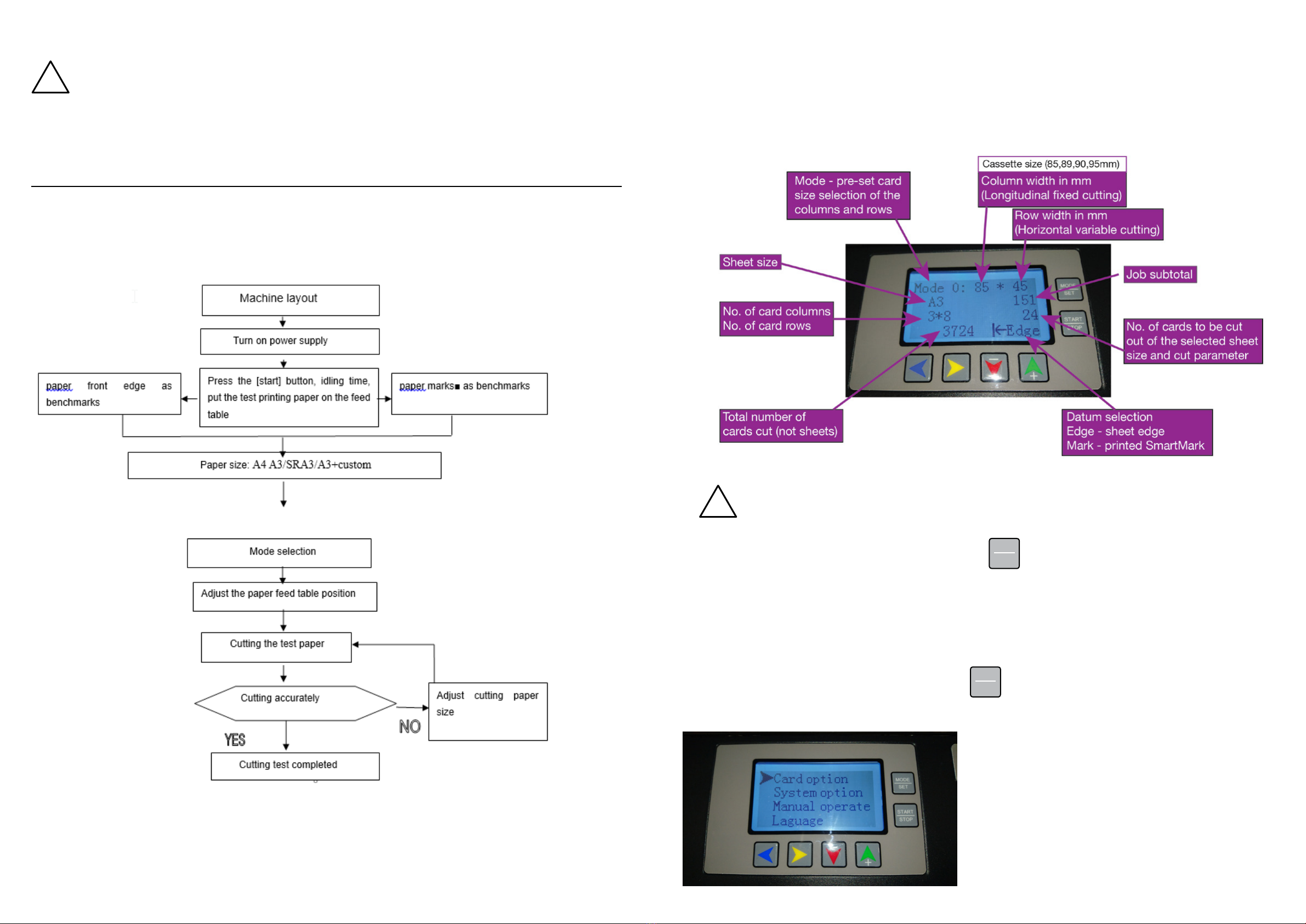

2-1 Cutting workflow

This flowchart shows you the process for machine usage.

2-2 Operation panel description

LCD display description

Initial understanding of the LCD panel is important. Please take a little time to navigate yourself

through the buttons and display before completing any work.

!

When the BC480 is turned on it will go into the last mode used.

With the BC480 turned on and in standby press the

MODE

SET button. This will change your cutting

Mode number (0-9). The cutting mode is the preset COLUMN width size in mm and is defined by the

cassette delivered with the BC480 and ROW length - this figure is variable and dependant on the

card size you would like to cut.

Press this button to understand how the modes change and watch the card sizes change - this does

not change your sheet / paper size. The modes are explained in Section 2-4.

After pressing through the modes now press the

MODE

SET for 3 seconds. This will take you into the

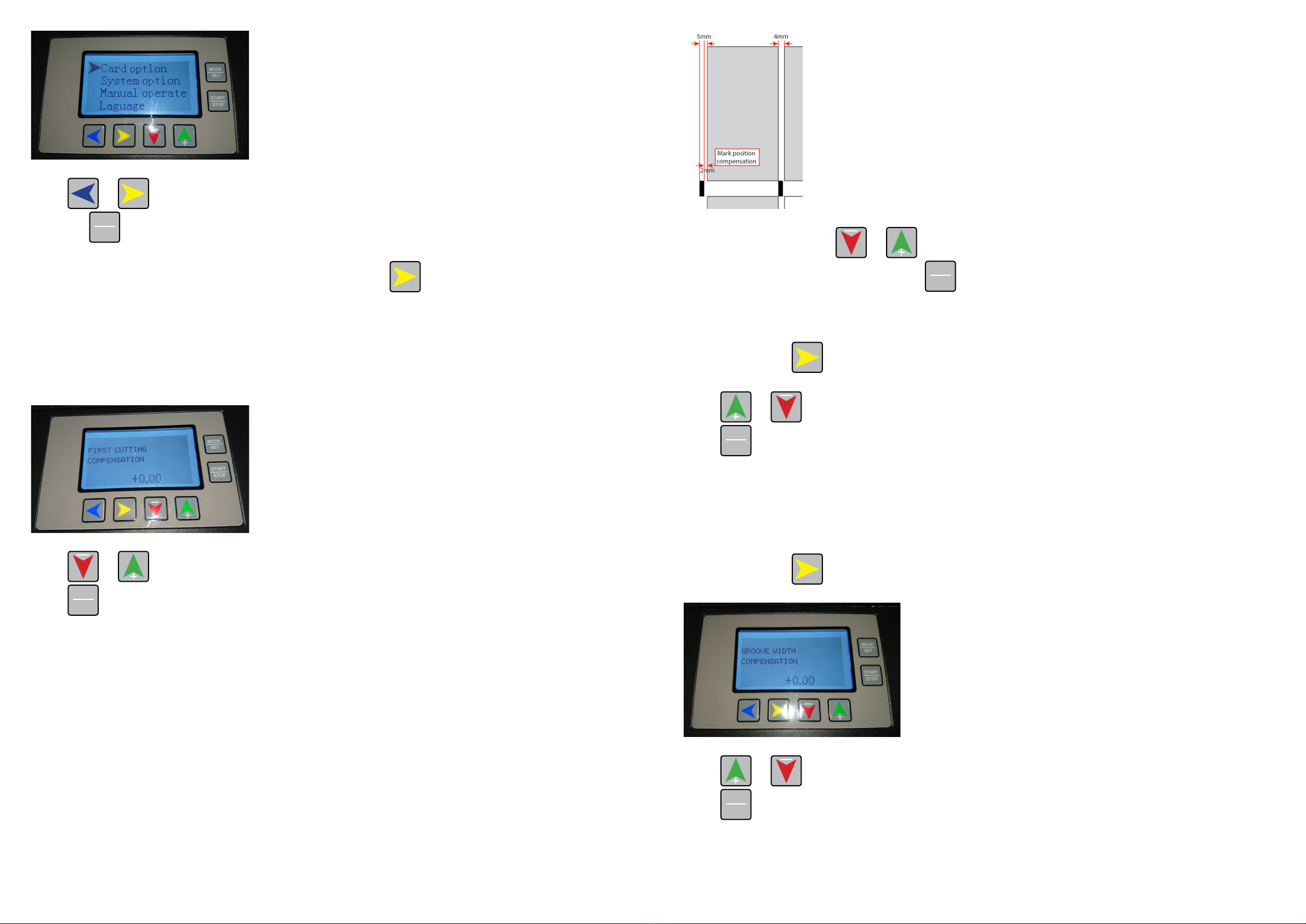

setup menu as shown below:

Page 16 Page 17

DO NOT make any changes here yet - this will be explained later in the chapter.

When in this menu these are the options available:

Card option

Allows you to make changes to the card preset mode (A3, A3+, SRA3) you have selected:

• First cutting compensation

• Mark position compensation

• Card length compensation

• Groove width compensation

Note: If you are in CUSTOM mode you will also so these options:

• Card width

• Card length

• Card rows

• Card columns

• First cutting length

• Mark position length

• Groove width

• First cutting compensation

• Mark position compensation

• Card length compensation

• Groove width compensation

Note: This is an individual card changes only. The Card Option menu DOES NOT make a universal

change to all set ups.

System option - See Section 2-5-5

Allows you to make changes to the universal set up of the BC480. This will make adjustment to all

the set ups universally and these include:

• System speed - from 1 to 9 but we advise you do not set this to more than 8 as it can have a

detrimental affect on your settings. The default setting is 6.

• System accuracy compensation

• Five column blade (longitudinal) width - for 5 card cassette

• Three column blade (longitudinal) width - for 3 card cassette

• First cutting compensation

• Mark position compensation

• Groove width compensation

• Last card compensation

• Penultimate card compensation

• Third from last card compensation

• Subtotal clear

• Restore factory settings

• Firmware version

Manual operate

This allows you to manually operate the BC480 - use the arrows to move the paper forwards,

backwards and up and down. You can use this mode when you have a paper jam.

Language

This allows you to select either English or Chinese.

To navigate through the 4 options shown above use the and arrows. Once you have

selected the menu the you would like make changes in press the

MODE

SET and this will take you to

the sub menus associated with the main menus (card option, System option, Manual operate,

Language). To come out of the sub menus and back to this main window press the

MODE

SET button

again and then press the

MODE

SET for 3 seconds to return you to standby mode.

Test your cutting mode with a sheet of paper/card

Now take some paper/card and place this in the feed tray.

Note: You can place up to 3mm stack height in the BC480 feed tray (approximately 10 sheets of

250gsm Mondi ColorCopy paper)

Press the button until you see Edge on the LCD panel.

Once in position press the

START

STOP button. This will cut a sheet using the mode you have selected on

the LCD panel.

We will continue to look at the LCD screen description.

To change your sheet / paper size press the arrow. This will take you through the sheet size

options available to you.

• A3 (297mm x 420mm)

• A3+ (320x480mm)

• SRA3 (320 x 450mm)

• A4 (only available in selected territories - do not use)

• CUSTOM (set for American paper sizes if purchased in America only)

Now press the button and this will now provide you with your Datum selection - explained in

section 2-3.

Number of cards to be cut

Take a look at your initial Mode selection and this will tell you how many cards are to be cut from the

sheet size and mode you have selected.

By pressing the and button you can set the amount of cards to be cut.

Note: The Mode you have showing will determine how many cards will be cut from a sheet of

paper.

By continuing to press the button you will incrementally increase the number of cards to be

cut, up to a maximum of 10 and then the system takes you to AUTO mode. To reduce the number of

cards to be cut press the button.

EXAMPLE: If you have 3 sheets of 24 cards to cut press the twice and it will show 72. This is

the amount of cards to be cut from 3 sheets of paper. Place 3 sheets in the feed tray and press the

START

STOP button. The BC480 will cut the 3 sheets and stop after this action.

AUTO - If you leave the BC480 in AUTO it will continue to cut sheets until there are no more sheets

in the tray to feed. The BC480 will try to take sheets for another 2 seconds and will then stop.

Page 18 Page 19

(2) LCD display description

Turn on power supply. The BC480 will initialize and go into standby mode - the LCD display will

show the default mode selection - be sure to change your mode and paper size settings to your

desired card cutting options.

2-3 Datum selection

There are two ways of cutting sheets; using the EDGE of the sheet of paper as your initial guide

point or using a printed ‘MARK’ that the internal mark sensor will read to position its cuts.

Note: The ‘MARK’ option is particularly useful when printing with a digital printing press or copier

because it allows for any sheet printing adjustments.

On the control panel the ‘Datum Selection’ can be selected by pressing the button to choose

which option you would like to use.

Edge Edge: cutting from the front of the sheet as a benchmark

Mark Mark: using a printed ‘MARK’ to position the cuts on sheet

The machine has preset cutting parameters and will always default to EDGE unless you are using

the CUSTOM mode and some of the CUSTOM modes have ‘MARK’ detection set as a default - see

section 2-4 Cutting modes.

i Please be sure to note what Datum option you are using before you press the

START

STOP button to

cut your sheets.

Note: As you scroll through the modes you will need to ensure that you check which datum option

is selected for a particular preset.

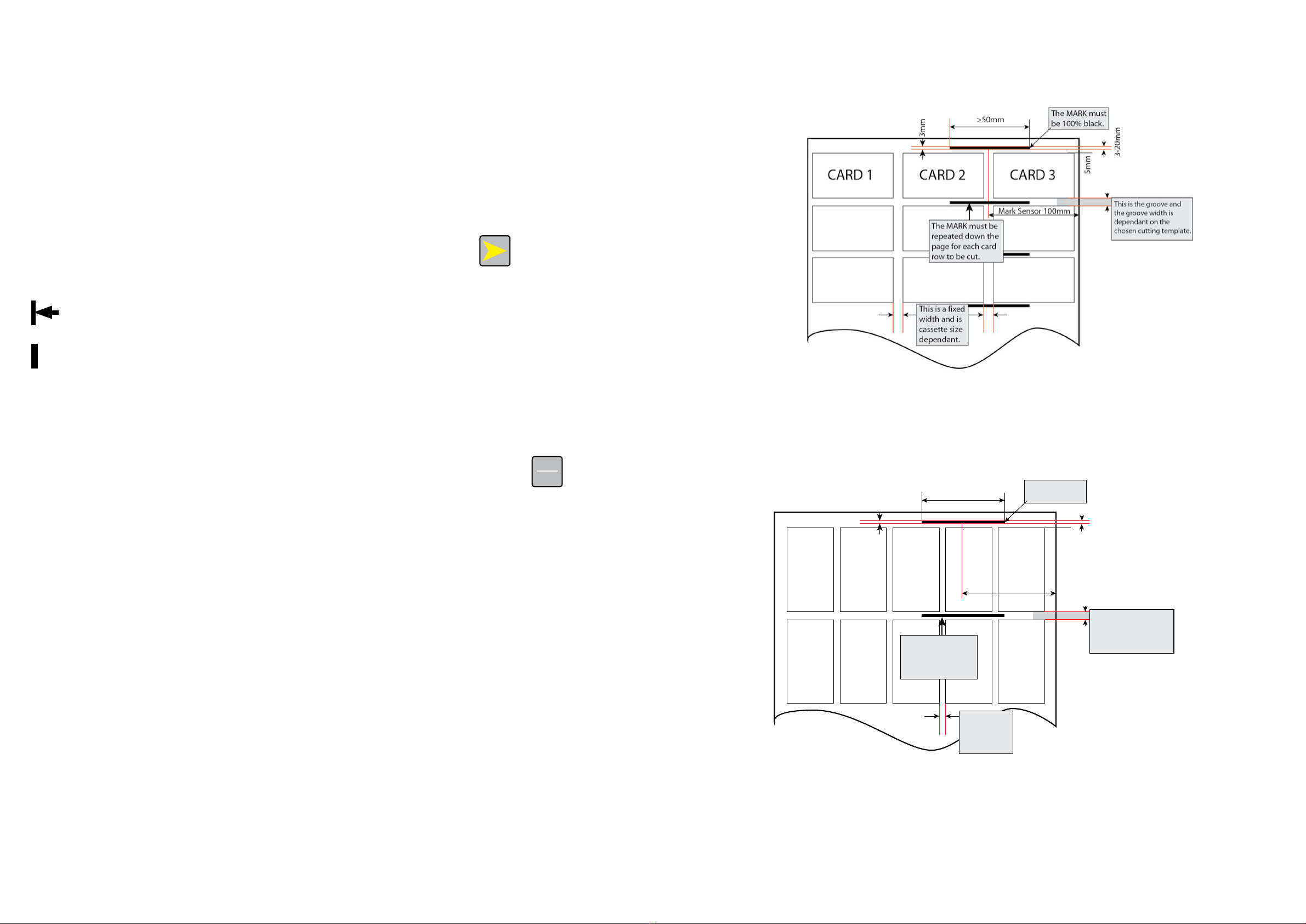

2-3-1 ‘MARK’ printing set up

This is the template set up if you are using A3 paper and have a 3 column cassette:

This is the template set up if you have A3 paper and a 5 column cassette:

Mark Sensor 100mm

>50mm

5mm

3-20mm

This is your groove and

the groove width is

dependant on the

chosen cutting template.

The MARK must be

repeated down the

page for each card

row to be cut.

The MARK must

be 100% black

3mm

CARD 1

CARD 2

CARD 3

CARD 4

CARD 5

This is a fixed

width and is

cassette size

dependant.

The ‘MARK’ on the templates provided are designed to work with the set ups as described in the

manual and those available for download from the Intec website.

If you are creating your own templates be sure to note where the ‘MARK’ falls in relation to the

sensor arrow marks for your chosen cutting cassette on the feed table and in relation to how you

have the paper feed guides set.

Page 20 Page 21

2-4 Cutting modes

2-4-1 Selection of rotary knife cassette (longitudinal knife)

85mm cassette - 3 column cutting widths 85mm - delivered as standard for EMEA countries

89mm cassette - 3 column cutting width 89mm - delivered as standard for the Americas

90mm cassette - 3 column cutting width 90mm - special order

90mm cassette - 3 column cutting width 95mm - special order

55mm cassette - 5 column cutting width 55mm - only available in selected territories

54mm cassette - 5 column cutting width 54mm - only available in selected territories

Indentation cassette - only available selected territories

Perforation cassette - only available selected territories

If you require anything different from the standard cassette provided with the machine, please

specify this at time of order.

2-4-2 Cutting modes - paper sizes

(1) Paper size: A3+ (320×480mm)

Mode 0: 89x45mm; select 89mm cassette - 3 columns and 9 rows - total 27 cards

Mode 1: 89x50mm; select 89mm cassette - 3 columns and 8 rows - total 24 cards

Mode 2: 89x54mm; select 89mm cassette - 3 columns and 8 rows - total 24 cards

Mode 3: 89x90mm; select 89mm cassette - 3 columns and 5 rows - total 15 cards

Mode 4: 55x85mm; select 55mm cassette - 5 columns and 5 rows - total 25 cards

Mode 5: 55x89mm; select 55mm cassette - 5 columns and 5 rows - total 25 cards

Mode 6: 55x90mm; select 55mm cassette - 5 columns and 5 rows - total 25 cards

Note: These are default presets out of the box. If you have a different cassette size you can

change these presets to suit the cassette size you are using. Please see section 2.5 to do this.

(2) Paper size: SRA3 (320×450mm)

Mode 0: 89x45mm; select 89mm cassette - 3 columns and 8 rows total - 24 cards

Mode 1: 89x50mm; select 89mm cassette - 3 columns and 7 rows - total 21 cards

Mode 2: 89x54mm; select 89mm cassette - 3 columns and 7 rows - total 21 cards

Mode 3: 89x90mm; select 89mm cassette - 3 columns and 4 rows - total 12 cards

Mode 4: 89x95mm; select 89mm cassette - 3 columns and 4 rows - total 12 cards

Mode 5: 89x127mm; select 89mm cassette - 3 columns and 3 rows - total 9 cards

Note: These are default presets out of the box. If you have a different cassette size you can

change these presets to suit the cassette size you are using. Please see section 2.5 to do this.

(3) Paper size: A3 (297×420mm)

Mode 0: 89x45mm; select 89mm cassette - 3 columns 8 rows total 24pcs cards

Mode 1: 89x50mm; select 89mm cassette - 3 columns 7 rows total 21pcs cards

Mode 2: 89x54mm; select 89mm cassette - 3 columns 7 rows total 21pcs cards

Mode 3: 89x90mm; select 89mm cassette - 3 columns 4 rows total 12pcs cards

Mode 4: 89x95mm; select 89mm cassette - 3 columns 4 rows total 12pcs cards

Mode 5: 89x127mm; select 89mm cassette - 3 columns 3 rows total 9pcs cards

Note: These are default presets out of the box. If you have a different cassette size you can

change these presets to suit the cassette size you are using. Please see section 2.5 to do this.

(4) Paper size: CUSTOM - use for American paper sizes 12"x17" and 12"x18"

Mode 0: CUSTOM (EDGE detection set as default)

Note for USA users: Preset - 12"x17" for 3.5" x 2" cards and no groove, so only to be used with

non-bleed. See templates provided.

Mode 1: CUSTOM (EDGE detection set as default)

Note for USA users: Preset - 12"x18" for 3.5" x 2" cards and can be used for non-bleed and cards

with bleed. See templates provided.

Mode 2: CUSTOM (EDGE detection set as default)

Note for USA users: Preset - 12"x18" for 3.5" x 5" cards and can be used for non-bleed and cards

with bleed. See templates provided.

Mode 3: CUSTOM (EDGE detection set as default)

Note for USA users: Preset - 12"x18" for 3.5" x 8" cards and can be used for non-bleed and cards

with bleed. See templates provided.

Mode 4: CUSTOM (MARK detection set as default)

Note for USA users: Preset - 12"x18" for 3.5" x 8.5" cards and can be used for non-bleed and

cards with bleed. ALSO this preset on the unit defaults to MARK datum detection all the time,

so you have to be change to EDGE before you cut. Press the yellow arrow to change the datum

selection. See templates provided.

Mode 5: CUSTOM (MARK detection set as default)

Note for USA users: Preset - 12"x18"for 3.5"x 2"cards and can be used for non-bleed and cards

with bleed.

Mode 6: CUSTOM (MARK detection set as default)

Note for USA users: Preset - 12"x18"for 3.5"x 5"cards and can be used for non-bleed and cards

with bleed. See templates provided.

Mode 7: CUSTOM (MARK detection set as default)

Note for USA users: Preset - 12"x18"for 3.5"x 8"cards and can be used for non-bleed and cards

with bleed. See templates provided.

Mode 8: CUSTOM (MARK detection set as default)

Note for USA users: Preset - 12"x18"for 3.5"x 8.5"cards and can be used for non-bleed and

cards with bleed. See templates provided.

Mode 9: CUSTOM (MARK detection set as default)

Note: There are no presets for this mode - please use this option for testing purposes.

Note: These are default presets out of the box. If you have a different cassette size you can change

these presets to suit the cassette size you are using. Please see section 2.5 to do this.

2-4-3 Cutting templates

Cutting templates for A3+, SRA3, A3 and CUSTOM sheet sizes can be found on the Intec website

in our support and downloads section: https://intecprinters.com/support-downloads/drivers-

downloads/colorcut/

i This information has been provided on a template download card that is shipped with the

BC480.

Page 22 Page 23

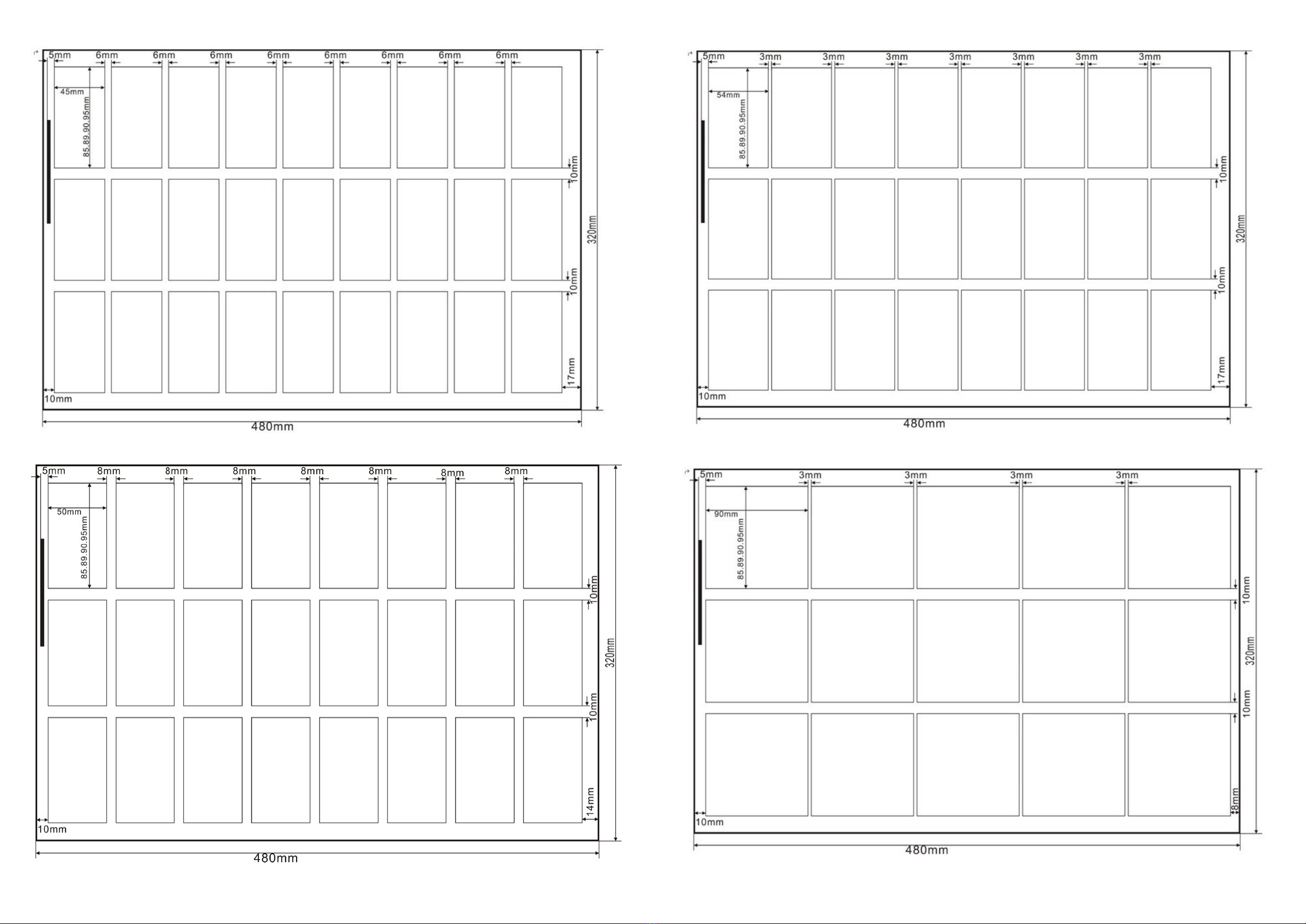

• A3+ MODE 0

• A3+ MODE 1

• A3+ MODE 2

• A3+ MODE 3

Page 24 Page 25

• A3+ MODE 4

• A3+ MODE 5

• A3+ MODE 6

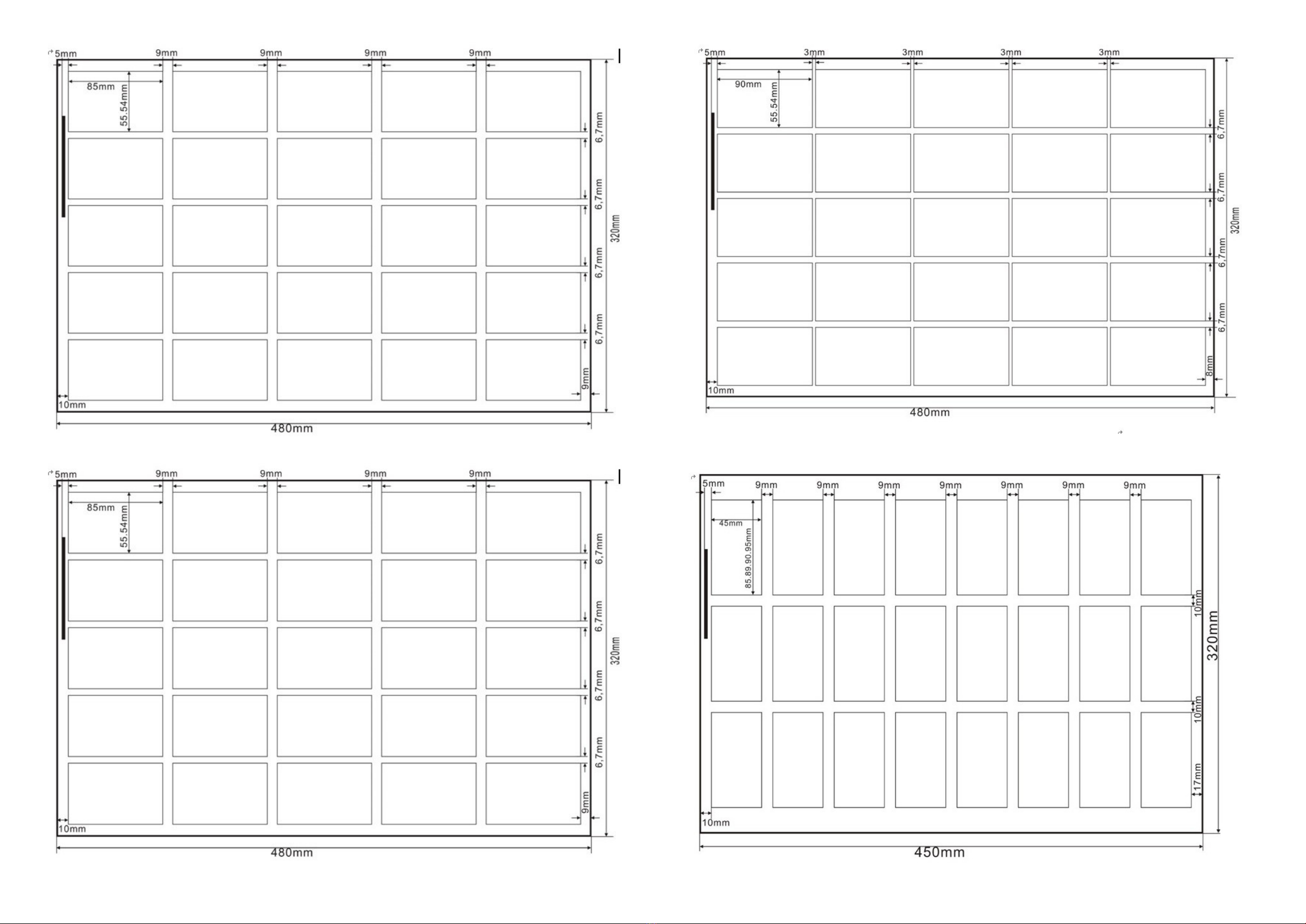

• SRA3 MODE 0

• SRA3 MODE 1

Page 26 Page 27

• SRA3 MODE 2

• SRA3 MODE 3

• SRA3 MODE 4

Page 28 Page 29

• SRA3 MODE 5

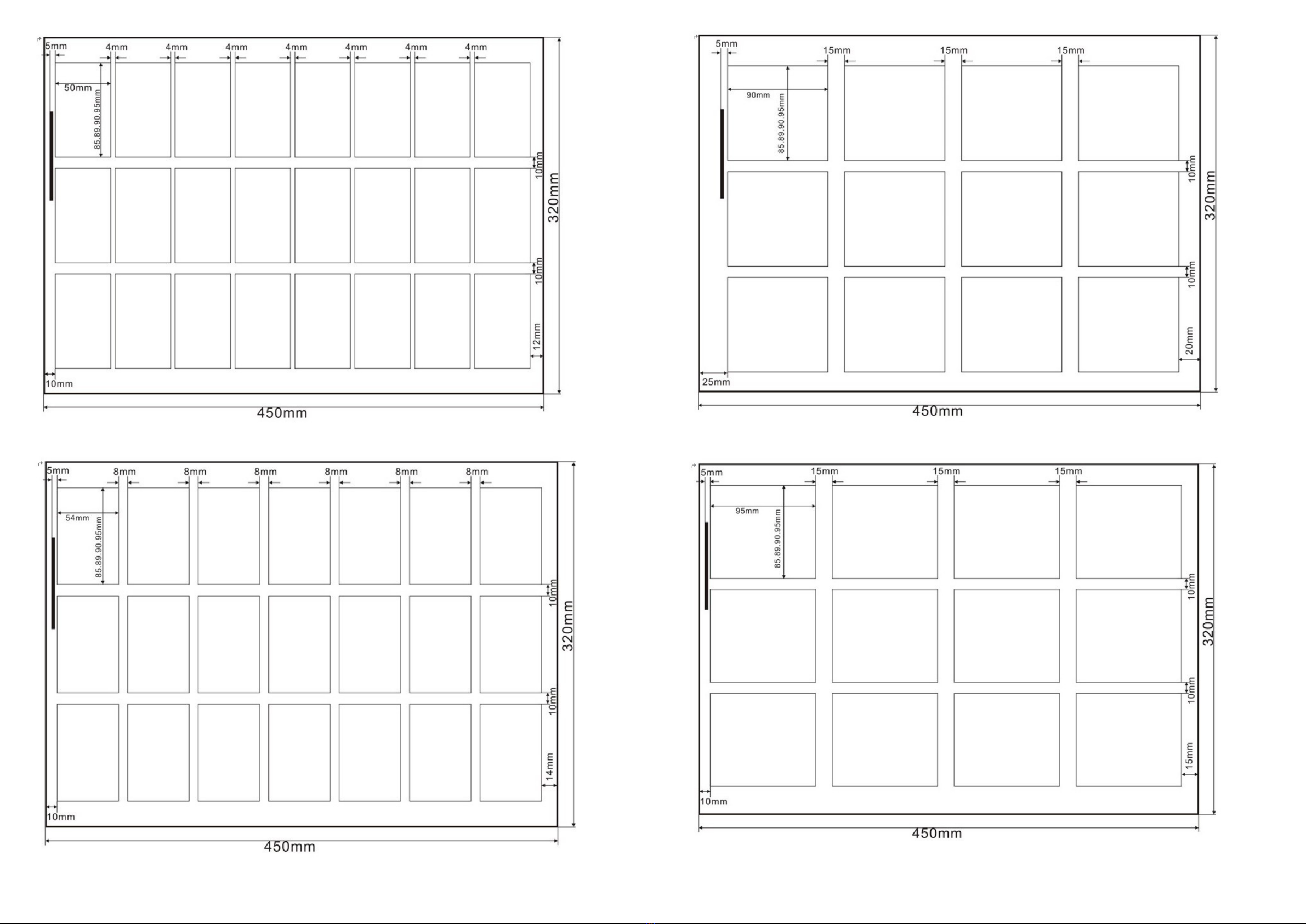

• A3 MODE 0

• A3 MODE 1

• A3 MODE 2

Page 30 Page 31

• A3 MODE 3

• A3 MODE 4

• A3 MODE 5

Page 32 Page 33

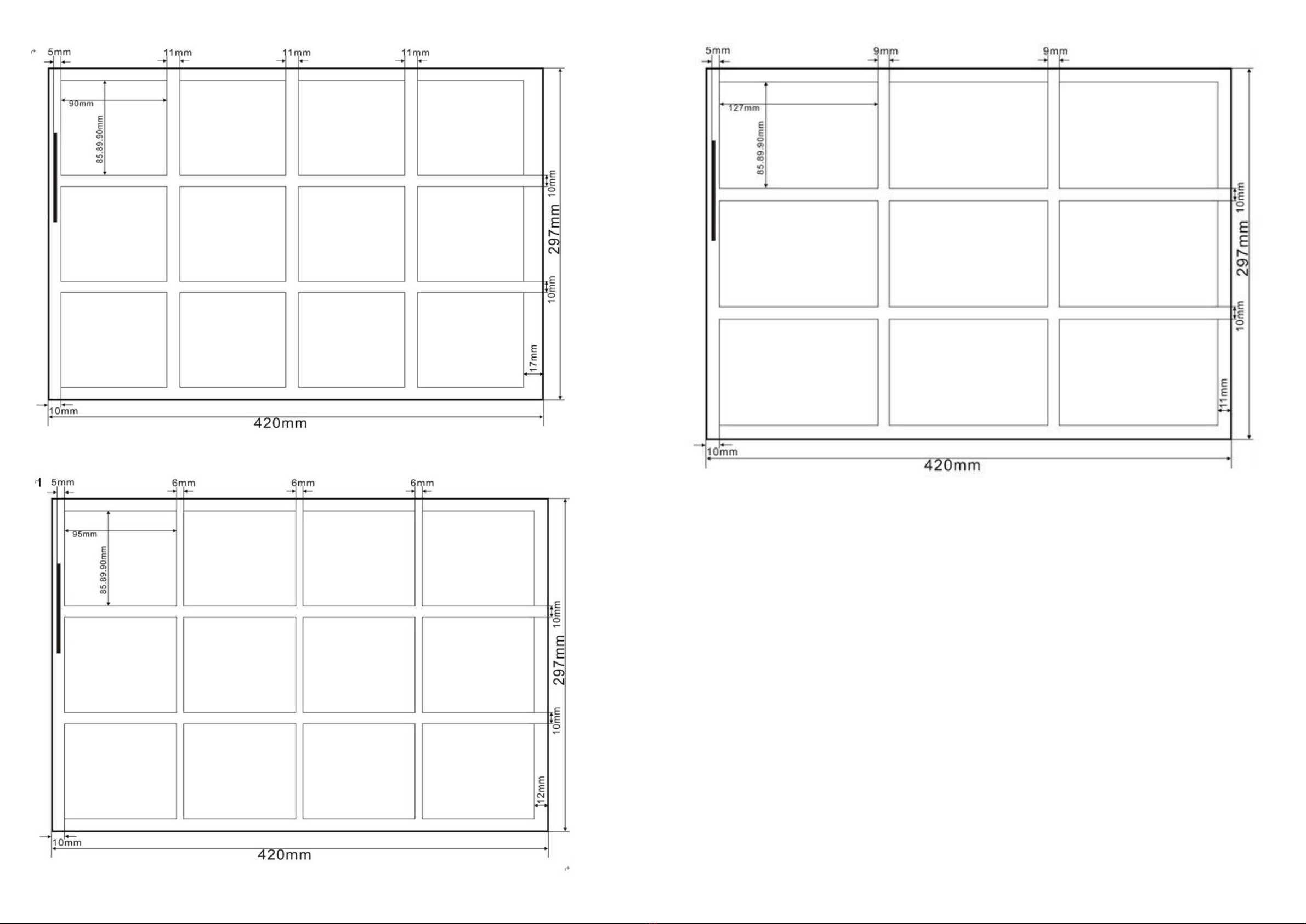

Custom mode,C-3 column cassette -XX rotary knife - paper width: 297--320mm

Custom mode, C-5-column cassette - XX rotary knife - paper width: 297--320mm

Before starting to use the BC480 the following menus are available to you for adjustment of the

machine.

These can be accessed by pressing down the MODE/SET

MODE

SET button for 3 seconds.

The next few pages will explain how these options allow you to adjust the machine settings.

2-4-4 Selecting the cutting mode

This option enables you to access the correct card cutting templates for the sheet / paper size you

are cutting and the number of cards to be cut as detailed in section 2-4-2.

To change the preset card cutting options press the MODE/SET

MODE

SET button this will scroll you

through the cutting options available for the selected paper/ sheet size you have chosen. To change

sheet / paper size use the button. Scroll through until you reach your desired paper sizes and

card preset. This will be displayed on the screen until you change it again or turn the BC480 off.

2-5 Parameter settings description

2-5-1 Cutting quantity

This menu allows you to set the total amount of cards required to be cut.

This option is ideal if you have a stack of sheets that all require the same cutting template as you

can stack these in the feed tray and set the amount of cards to be cut using this function and leave

them to cut automatically.

So if your sheet has 21 cards to be cut multiply this with the amount of sheets you have (up to 3mm

stack height) and set that number on the machine.

In the standby mode, press the or to reach the required quantity up to a multiple of 10.

21 cards x 10 sheets = 210. After which if will go to AUTO.

AUTO allows for continuous feed of all stacked sheets in the tray and until the tray is empty. When

there are no more sheets to present to the cutter, and the tray becomes empty, the cutter will stop.

2-5-2 Datum selection

Press button in standby mode, to switch between Edge or Mark detection. This is

dependent on the template you have chosen to use.

2-5-3 Card error adjustment method

When you receive an error in the size of you cut cards (preset modes), you have a number of

adjustable options to help with the accuracy of these sizes. These include;

• First cutting compensation

• Mark position compensation

• Card length compensation

• Groove width compensation

These menus can be found under the CARD OPTION menu and is specific to the preset (not

custom) card mode you have selected at the time.

To access these menus, press and hold the

MODE

SET button for 3 seconds. This will enter the setup

menu, the LCD display:

Page 34 Page 35

Press or button to move the arrow selection cursor to the CARD OPTION menu and

press the

MODE

SET button to enter the sub menus as listed.

To navigate through the sub menus for card option press the button.

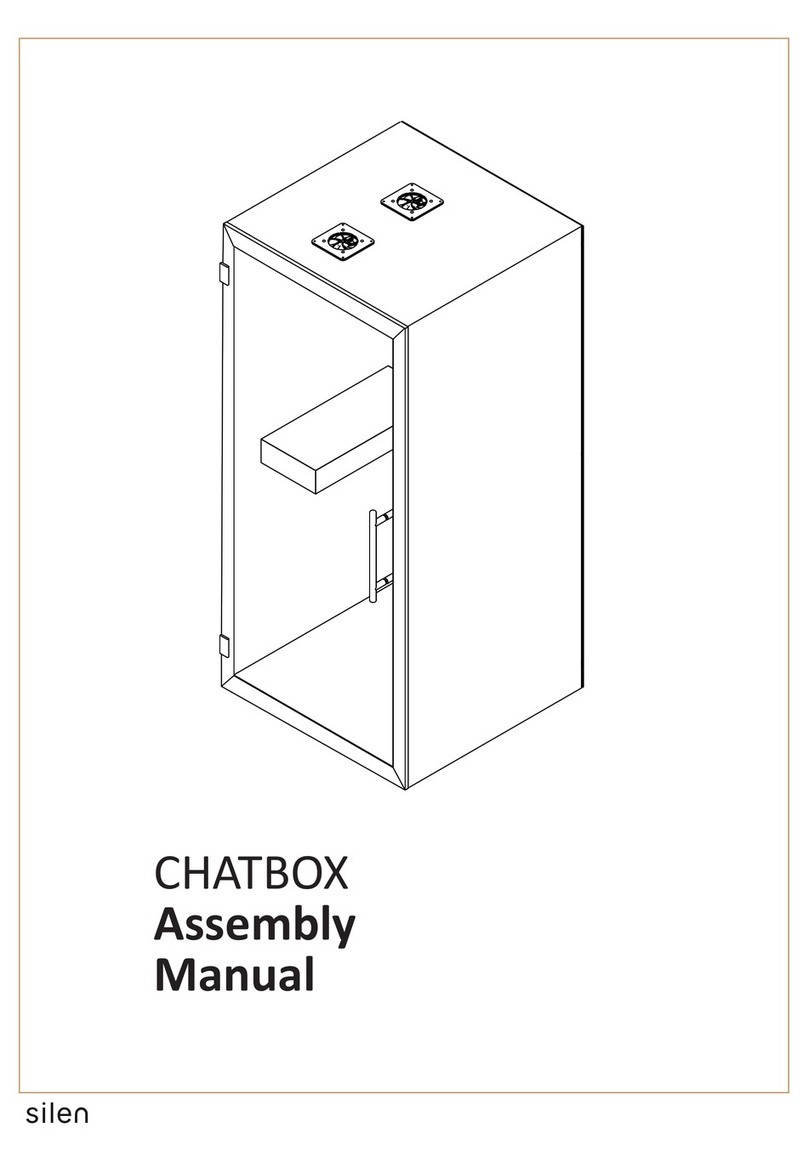

1. First cutting compensation

This is where the first cut is placed on your card.

All the card presets (except CUSTOM) default to Edge cutting. Datum selection is chosen our

templates will have this set to 10mm as a default.

LCD display:

Press or buttontochangethecompensationvalue(-5.0—+5.0mm(

Press

MODE

SET button and return to previous menu.

2. Mark position compensation

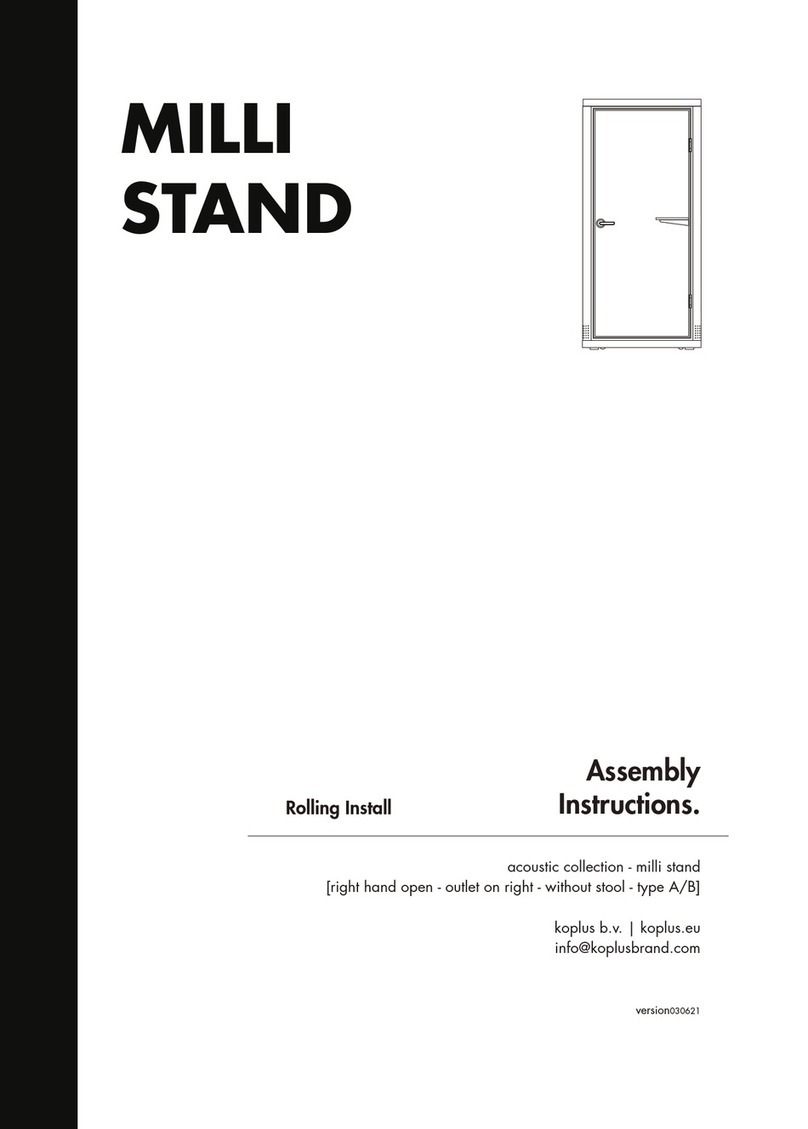

This refers to the gap between the bottom of the ‘MARK’ and the edge of where the next card is to

be cut.

Here our example shows a 2mm gap between the ‘MARK’ and the edge of card to be cut.

To adjust this value press or button, until the LCD displays your required measurement.

Once your measurement is set press the

MODE

SET button to return to previous menu.

3. Card length compensation

Continue to press button, until you see Card length compensation in the LCD display.

Press or buttonforcompensationsettingof-3.0—+3.0mm(

Press

MODE

SET button and return to previous menu.

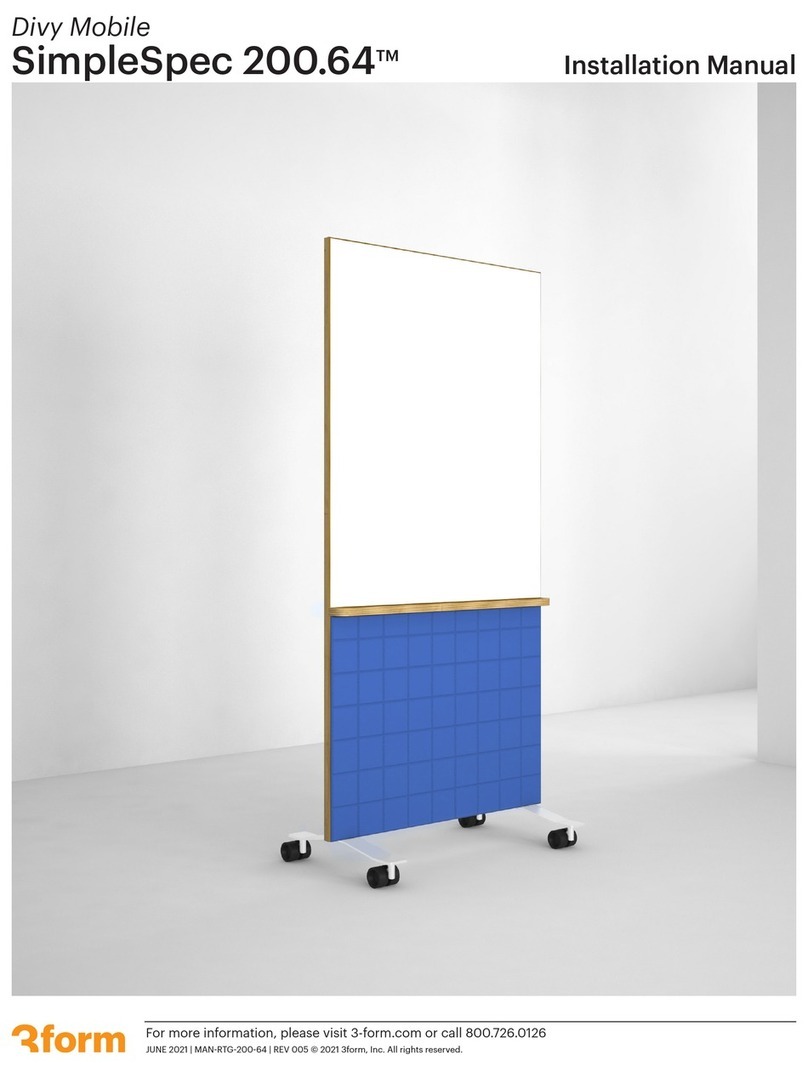

4. Groove width compensation

Your groove width is the gap (measurement in mm) between you card rows. You can apply a

compensation to your width. This is a variable measurement and is dependant on the card template

you have selected and the therefore the card mode.

Continue to press button, until the LCD display:

Press or buttonforCompensationsetting(-3.0—+3.0mm(

Press

MODE

SET button and return to previous menu

Page 36 Page 37

2-5-4 System settings

Under normal circumstances the BC480 will have been set up prior to shipping and you will not have

to make any changes under the system settings.

Should you wish to only change an individual card setting please do this under the CARD OPTION

menu specific to the card mode selected.

!

Attention:

Any changes made under the system settings will change the values for all preset card modes.

These are universal changes.

The options available under the system settings are:

• System speed

• System accuracy compensation

• Five column blade (longitudinal) width - for 5 card cutting cassettes

• Three column blade (longitudinal) width - for 3 card cutting cassettes

• First cutting compensation

• Mark position compensation

• Groove width compensation

• Last card compensation

• Penultimate card compensation

• Third from last card compensation

• Subtotal clear

• Restore factory settings

• Firmware version

From standby mode, press

MODE

SET and hold the button for 3 seconds to enter the setup menu, the

LCD will display:

To navigate around the menus press the or buttons to move the cursor to system

selection. Once you have selected the System option menu press the

MODE

SET button which will take

you to the sub menus.

To navigate around the following sub menus use the button.

i To easily make changes to a measurement values and when in the menu you would like to

change, press the

START

STOP and this will add a small arrow above the measurement values as shown

below. Keep pressing until the arrow falls above the measurement you want to change and use the

or buttons to change the value until you are finished.

1. System speed

This menu sets the speed of cutting of your sheets.

Changing the system speed can affect the cutting accuracy and positioning of your cuts.

The selectable options are 1-9 . 1 being the slowest and 9 the fastest setting.

As an example and using an SRA3 sheet for 85mm x 54mm cards (21 cards to cut) the system on

setting 1 will take 9 seconds to cut the sheet and on 9 it takes 7 seconds to cut the sheet.

The BC480 will have been programmed and tested prior to shipping and so the value set in this

menu should not be changed. However, if it has to be changed, we advise you do not set this to

more than 8.

If you need to change the speed setting this can be done by using the or buttons.

2. System accuracy compensation

This refers to the scaling

This is set prior to shipping and should not be adjusted.

Table of contents

Popular Office Equipment manuals by other brands

Koplus

Koplus MILLI STAND Assembly instructions

silen

silen CHATBOX Assembly manual

LDI Spaces

LDI Spaces Safco Onyx 6453 Assembly instructions

Reiner

Reiner P1-MP2-RD instructions

3-form

3-form SimpleSpec 200.64 installation manual

Herman Miller

Herman Miller FT194.A Installation and Disassembly for Recycling Instructions

PG BISON

PG BISON OFFICE FURNITURE BLUM FLATPAX Assembly guide

J.Burrows

J.Burrows Stilford JBSHBB18WW Assembly instructions

Epson

Epson SC-F9300 series Setup guide

Uplift Desk

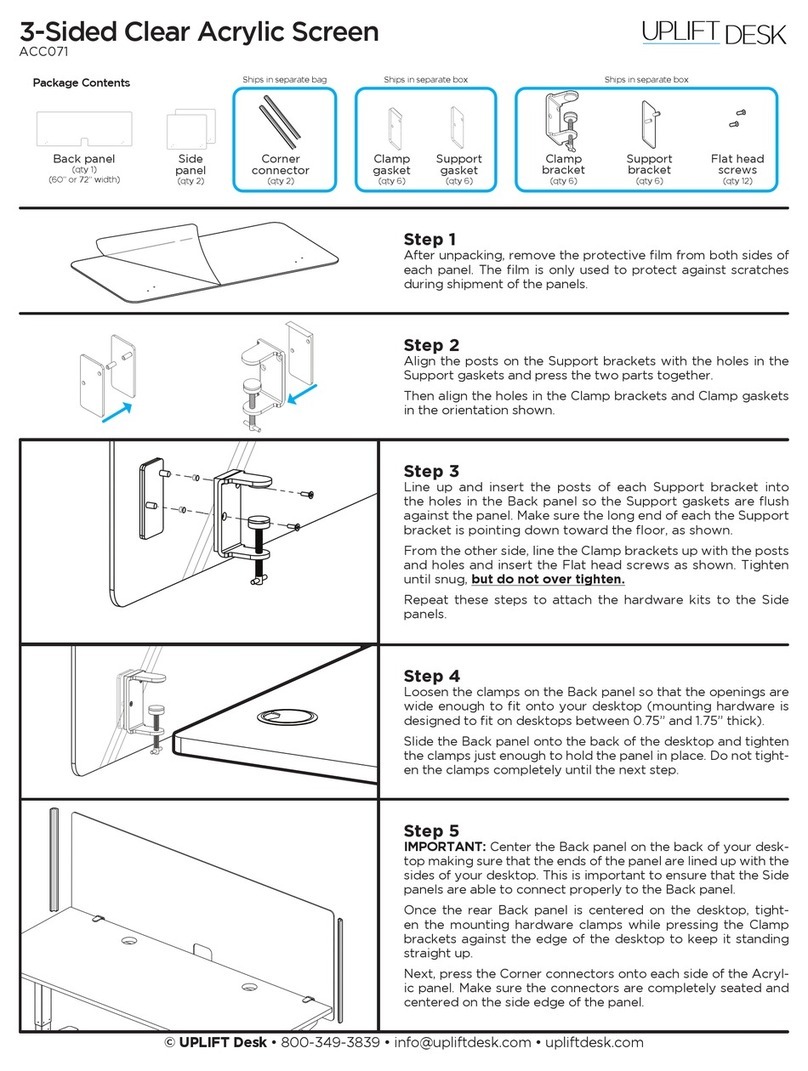

Uplift Desk ACC071 quick start guide

hushoffice

hushoffice hushfree.M HUS-AP-002 Maintenance and safety manual

Koplus

Koplus HOP DESK Assembly instructions