Interface T2 User manual

T2, T3, T4, T5, T6, T7, T12 & T15

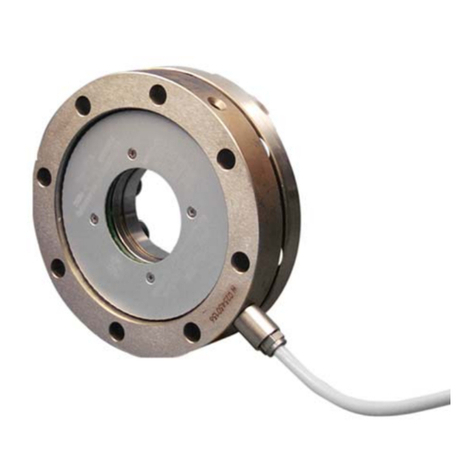

Rotary Torque Transducers

Operation Manual

T2 Precision Rotary &

T4 General Purpose Rotary

Torque Transducers

T6 Dual Range

Rotary Torque Transducer

T3 Precision Rotary &

T5 General Purpose Rotary

Torque Transducers

T7 Dual Range

Rotary Torque Transducer T12 Square Drive

Rotary Torque Transducer T15 Hex Drive

Rotary Torque Transducer

7401 East Butherus Drive • Scottsdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

Valid for... T2, T3, T4, T5, T6, T7, T12 & T15 Rotary Torque

Copyright © 2009 Interface, Inc.

Modification Technical changes reserved.

References in this Text

1.6 Warning Notes; Page 5

Attention must be paid to the accident prevention regulations of the trade associations.

Coverings and casings are necessary before operating the transducer. This is also valid for commissioning,

maintenance and troubleshooting.

Duties of the coverings and casings are:

⇒Protection from detaching parts

⇒Protection from contusion and shear

⇒Prevention from reaching rotating parts

⇒Prevention from being tangled up and/or getting caught by parts

Coverings may:

⇒Not grind

⇒Not rotate

Coverings are also necessary outside of operating and motion travel areas of persons.

These demands can be modified if other sufficient safety devices are available. During operation, the safety

precautions must be operative. By vibrations, damages can occur on the device.

5 Mechanical Assembly; Page 10

During the assembly, the transducer must be supported to protect it from falling down.

5.1.3 Alignment of the Measurement Arrangement; Page 10

For more information please consult factory for details. (800) 947-5598 | (480) 948-5555 or visit

www.interfaceforce.com.

5.2 General; Page 10

Before the assembly, shafts must be cleaned with dissolver (i.e. acetone), no foreign particles may adhere to

them. The hub must fit corresponding to the connection.

Caution: During the assembly inadmissibly large forces may not act on the transducer or the couplings. At small

torques

(< 20 Nm) connect the transducer electrically during the assembly and observe the signal, the measurement

signal may not exceed the limit values.

5.2.1 Torque Transducers of 0.03 Nm to 15 Nm; Page 11

Transducers with nominal torques below 20 Nm are very sensitive to overload, therefore these transducers

need to be handled with greatest caution.

5.3 Free floating Assembly; Page 11

Caution: During the assembly inadmissibly large forces may not act on the transducer or the couplings.

In this installation case, double-jointed couplings cannot be used for both sides.

Risk of Breakage!

5.4 Foot Version Assembly; Page 12

6.1 Engaging; Page 13

6.4.2 Natural Resonances; Page 14

An operation of the device in natural resonance can lead to permanent damages.

Warming-up period of the torque transducer is approx. 5 min.

Caution: During the assembly inadmissibly large forces may not act on the transducer or the couplings.

7401 East Butherus Drive • Scottsdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

1

1.1

1.2

1.3

1.3.1

1.3.2

1.4

1.5

1.6

2

2.1

2.2

3

3.1

3.2

3.2.1

3.2.2

3.2.3

4

4.1

4.2

4.2.1

4.2.2

4.3

4.4

4.5

4.6

4.7

5

5.1

5.1.1

5.1.2

5.1.3

5.2

5.2.1

5.2.2

5.3

5.4

5.5

6

6.1

6.2

6.3

6.4

6.4.1

6.4.2

6.5

6.6

7

7.1

7.2

8

9

9.1

9.2

10

11

11.1

11.2

11.3

Read First……………………………………………………………………………………………………………………...

Safety and Caution Symbols………………………………….……………………………………………………………..

Intended Use………………………………………………………………………………………………………………......

Dangers……………………………………………………………………………………………………………………......

Neglecting of Safety Notes………………………………………………………………………………………………......

Remaining Dangers………………………………………………………………………………………………………......

Reconstructions and Modifications…………………………..…………………………………………………………......

Personnel……………………………………………………….…………………………………………………………......

Warning Notes………………………………………………….…………………………………………………………......

Term Definitions………………………………………………..…………………………………………………………......

Terms………………………………………………………………………………………………………………………......

Definition of the Pictograms on the Torque Tranducer…….…………………………………………………………......

Product Description…………………………………………….………………………………………………………….....

Mechanical Setup…………………………………………………………………………………………………………......

Principle of Operation………………………………………….…………………………………………………………......

Electrical Setup……………………………………………………………………………………………………………......

Transducers with Analog Output……………………………..…………………………………………………………......

Transducers with RS485 Interface…………………………...…………………………………………………………......

The Serial Communication………………………………………………………………………………………………......

Electrical Connection…………………………………………..…………………………………………………………......

Pin Connection……………………………………………………………………………………………………………......

Calibration Control……………………………………………..…………………………………………………………......

Calibration Control and Analog Output…………………………………………………………………………………......

Calibration Control at RS485………………………………….………………………………………………………….....

Cable…………………………………………………………….…………………………………………………………......

Shielding Connection…………………………………………..………………………………………………………….....

Running of Measuring Cables………………………………...………………………………………………………….....

Angle/Speed (Option) ……………………………………………………………………………………………………......

Speed Only (Option) …………………………………………..…………………………………………………………......

Mechanical Assembly………………………………………….…………………………………………………………......

Couplings………………………………………………………..………………………………………………………….....

Misalignment Possibilities of Single-Jointed Couplings………………………………………………………………......

Double-Jointed Couplings……………………………………..………………………………………………………….....

Alignment of the Measurement Arrangement……………….…………………………………………………………......

General………………………………………………………….…………………………………………………………......

Torque Transducers of 0.03 Nm to 15 Nm………………….…………………………………………………………......

Torque Transducers from 20 Nm…………………………….…………………………………………………………......

Freefloating Assembly……………………………………………………………………………………………………......

Foot Version Assembly………………………………………..…………………………………………………………......

Typical Application…….……………………………………….…………………………………………………………......

Measuring……………………………………………………….…………………………………………………………......

Engaging………………………………………………………..…………………………………………………………......

Direction of Torque…………………………………………….…………………………………………………………......

Static/Quasi-Static Torques…………………………………...………………………………………………………….....

Dynamic Torques…………………………………………………………………………………………………………......

General………………………………………………………….…………………………………………………………......

Natural Resonances…………………………………………...…………………………………………………………......

Speed Limits………………………………………………………………………………………………………………......

Disturbance Variables……………………………………………………………………………………………………......

Maintenance…………………………………………………….………………………………………………………….....

Maintenance Schedule………………………………………...………………………………………………………….....

Troubleshooting………………………………………………...………………………………………………………….....

Decommssion…………………………………………………..…………………………………………………………......

Transportation and Storage…………………………………...………………………………………………………….....

Transportation…………………………………………………..………………………………………………………….....

Storage………………………………………………………….…………………………………………………………......

Disposal……………………………………………………………………………………………………………………......

Calibration…………………………………………………………………………………………………………………......

Proprietary Calibration……………………………………………………………………………………………………......

DKD-Calibration………………………………………………..…………………………………………………………......

Recalibration………………………………………………………………………………………………………………......

4

4

4

4

4

4

4

4

5

5

5

5

5

5

6

7

8

8

8

8

8

8

9

9

9

9

9

9

9

10

10

10

10

10

10

11

11

11

12

13

13

13

13

13

13

13

14

14

14

14

14

15

15

15

15

16

16

16

16

16

16

CONTENTS

7401 East Butherus Drive • Scottsdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

1Read First

1.1 Safety and Caution Symbols

Note:

Important points to be considered.

Caution:

Injury Risk for Persons

Damage of the Device is possible.

1.2 Intended Use

Torque transducers are intended for the measurement of torques. This measure is further suitable for control tasks. The valid

safety regulations should be absolutely respected. The torque transducers are not safety components in the sense of the

intended use. The transducers need to be transported and stored appropriately. The assembly, commissioning and

disassembling must take place professionally.

1.3 Dangers

The torque transducer is fail-safe and corresponds to the state of technology.

1.3.1 Neglecting of Safety Notes

At inappropriate use, remaining dangers can emerge (i.e. by untrained personnel). The operation manual must be read and

understood by each person entrusted with the assembly, maintenance, repair, operation and disassembly of the torque

transducer.

1.3.2 Remaining Dangers

The plant designer, the supplier, as well as the operator must plan, realize and take responsibility for safety-related interests for

the transducer. Remaining dangers must be minimized. Remaining dangers of the torque measurement technique must be

pointed out.

Human mistakes must be considered. The construction of the plant must be suitable for the avoidance of dangers. A danger-

analysis for the plant must be carried out.

1.4 Reconstructions and Modifications

Each modification of the transducers without our written approval excludes liability on our part.

1.5 Personnel

4

7401 East Butherus Drive • Scottsdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

2Term Definitions

2.1 Terms

Measuring Side:

Mechanical connection of the torque transducer in which the torque to be measured is applied. Usually this side has the smallest

moment of inertia.

Drive Side:

Mechanical connection of the torque transducer on the opposite side of the measuring side, usually with the largest moment of

inertia. At static torque transducers the housing is fastened on this side.

Low Torque Resistance Side:

The shaft of the arrangement (drive, load) which can be turned considerably smaller with torque than the nominal torque of the

torque transducer M << Mnenn.

2.2 Definition of the Pictograms on the Torque Transducer

The measuring side of the torque transducer is designated as follows:

Measuring side: or M

For more information consult factory (800) 947-5598 or visit www.interfaceforce.com

3Product Description

The transducer measures static and dynamic torques. The mounting position of the torque transducer is horizontally.

Caution: It is differentiated between measuring side and driving side. Consult factory for details.

3.1 Mechanical Setup

The transducers consist of a torsion shaft. Depending on design, the mechanical connection possibilities are executable with

round shafts or feather key connections etc. The torsion shaft, applied with two strain gauge full bridges, is bedded in a housing

through ball bearings. For the signal transmission and/or the supply of the strain gauge full bridges, a rotating transformer,

according to the principle of a transformer, is arranged in the transducer. For supply and measuring signal conditioning,

electronics are integrated in the stator and the rotor.

M

5

7401 East Butherus Drive • Scottsdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

3.2 Principle of Operation

The supply voltage of between 12 and 28V DC is converted to AC in the stator and transferred inductively to the rotor

electronics. The voltage is rectified and stabilized and fed to the strain gage bridge. The output of the bridge is conditioned in an

amplifier and then converted to a digital signal, which is transferred to the stator by another rotating transformer. This digital

signal is much more disturbance-free than an analog signal and is highly immune to noise. This signal is further conditioned in

the stator, comes into a µ-processor and then is converted to the ±5 or ±10V output signal.

These transducers feature internal Shunt Calibration Resistors that can be switched into the bridge. A voltage of greater than

3.5V to pin K causes a control signal to be up-modulated to the supply voltage and transferred to the rotor. There, it is filtered

and evaluated by the µPC, which then activates the internal switch for the connection of the R-Cal resistor.

Initial Calibration

1. A preliminary calibration of the strain gaged shaft determines the bridge full scale output in mV/V.

2. A shunt resistor value is created to provide an output equal to the full scale output of the strain gage bridge.

3. The resistor is then hard-wired through a switch into the bridge.

4. Final assembly includes installation of the rotating shaft into the stator housing.

5. After final assembly the complete sensor is calibrated by applying known torques and adjusting the full scale output to

±5V or ±10V.

6. A calibration certificate is generated showing the transducer full scale output in Volts and the R-Cal Calibration Signal

output in both volts and units of torque.

Field R-Cal System Calibration

1. Apply between 3.5V-28V to pin K of the transducer. Pin K should be connected through a switch to either the supply

voltage or another voltage source.

2. A Calibration Signal will be generated equal to the torque value listed on the calibration certificate. The Customer’s

data acquisition system can then be scaled using this signal.

6

7401 East Butherus Drive • Scottsdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

DC/DC Oscillator

4MHz

Signal

Conditioning

Signal Adaption

Analog/Digital

Signal

Conditioning

A/D-Converter

±11 or ±15 bit

µ-Processor

µ-Processor

Rotation Angle (Option)

Supply

voltage

Calibration

Control

Signal

Output

Channel 1

Rotation

Al

A

ngle Output

(Option)

Amplifie

r

Stator Rotor

R

otating Transformer

Serial Data Transmission

A

B

Filter for

Control Signal

Cycle and

Control Signal

Supply and

Control Signal

Rotating Transformer

Signal Adaption

Analog/Digital

Signal

Output

Channel 2

(Option)

A

C

DC

S

GSG

A/D-Converter

±15 bit

A

mplifie

r

2

1

Dual Range

Transducers Onl

y

R-Cal

Resistor

Electrical Setup

Block diagram for serial signal transmission

7

7401 East Butherus Drive • Scottsdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

3.2.1 Transducers with Analog Output

At this output, the digital signal is converted into DC voltage of ±5V or ±10V, proportional to the torque and is available at the

connector output.

3.2.2 Transducers with RS485 Interface

The torque transducer has a digital interface RS485 for the signal output and automatic transducer identification.

The protocol enables high dynamics.

For more information consult factory (800) 947-5598 or visit www.interfaceforce.com.

3.2.3 The Serial Communication

Consult factory (800) 947-5598 or visit www.interfaceforce.com.

4Electrical Connection

4.1 Pin Connection

8

Also see test certificate.

8-pin Analog

1 Excitation + 12 ... 28 VDC

2 Excitation GND 0V

3 Signal ±5V / (±10V)

4 Signal GND 0V

5 Calibration control L<2.0V;

H>3.5V

6 Option angle A TTL For color code of black molded one-piece cable assembly please consult

factory.

7 Option angle B TTL

8 NC View: socket on soldering side

12-pin Analog Digital

A NC NC

B Option angle B TTL Option angle B TTL

C Signal ±5V / (±10V) NC

D Signal GND 0V NC

E Excitation GND 0V Excitation GND 0V

F Excitation + 12 ... 28 VDC Excitation + 12 ... 28 VDC

G Option angle A TTL Option angle A TTL

H* Signal 2 ±5V (±10V) NC

J NC Output B RS485

K Calibration control L<2.0V; H>3.5V NC

L NC Output A RS485

M Housing Housing

*Dual Range Sensors only

4.2 Calibration Control

Only use calibration control in unloaded condition of the torque transducer. Cal control output is approximately equal to

transducer full scale output. Exact value is noted on calibration certificate.

7401 East Butherus Drive • Scottsdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

4.1.1 Calibration Control at Analog Output

Applying voltage of between +3.5V to +28V switches the calibration control on. Voltage below +2.0V switches it off.

3.5V < Ucal < 28V

U

c

a

l

EXC. (+)

CAL

CONTROL

EXC. (-)

OR

CAL

CONTROL

4.1.2 Calibration Control at RS485

The calibration control switch on is carried out by a command.

For more information consult factory (800) 947-5598 or visit www.interfaceforce.com.

4.2 Cable

Use only shielded cable with the shortest length possible. We recommend Interface brand cables as they are tested together with our

transducers.

4.3 Shielding Connection

In combination with the transducer and the external electronics, the shield forms a Faraday Cage. By this, electro-magnetic

disturbances do not have any influence on the measurement signal.

4.4 Running of Measuring Cables

Do not run measuring cables together with control or heavy-current cables. Always assure that a large distance is kept to engines,

transformers and contactors, because their stray fields can lead to interferences of the measuring signals.

If troubles occur through the measuring cable, we recommend running the cable in a grounded steel conduit.

4.5 Angle/Speed (Option)

360 pulse/revolution, 2-track, +5V TTL. The second track can be used to

quadruple the number of pulses/revolution, or to determine rotation direction.

Not available on transducers above 1,000 Nm.

4.6 Speed Only (Option)

60 pulse/revolution, single track, +5V TTL. Available on transducers above

1,000 Nm only.

4.7 Speed Only (Option)

60 pulse/revolution, single track, +5V TTL. Available on transducers above

1,000 Nm only.

9

7401 East Butherus Drive • Scottsdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

5Mechanical Assembly

For the assembly of a torque transducer in a shaft line, we always recommend to use couplings, which can be misaligned.

During the assembly, the transducer must be supported to protect if from falling down.

5.1 Couplings

We recommend multi-disc couplings for our torque transducers. Couplings must be able to balance an axial, radial or angular

offset of the shafts and not allow large forces to act on the transducer. The assembly instructions of the respective coupling

manufacturer must be considered.

5.1.1 Misalignment Possibilities of Single-Jointed Couplings

10

Angular misalignments Axial misalignments

Note: Radial misalignments are only possible in the combination of

single-jointed coupling - torque transducer (as adapter) - single-jointed coupling.

Thus, with both single-jointed couplings the torque transducer forms a double-jointed coupling.

Radial misalignments

5.1.2 Double-Jointed Couplings

Double-jointed couplings are used for the balance of inevitable angular, axial and radial misalignments.

5.1.3 Alignment of the Measurement Arrangement

Precisely alignment of the couplings reduces the reaction forces and increases the durability of the couplings. Disturbance

variables are minimized as well.

Due to the multitude of applications, an alignment of the coupling with a straight edge in two levels, vertical to each other, is

sufficient.

However, in drives with high speed, an alignment of the coupling (shaft ends) with a dial gauge or a laser is recommended.

5.2 General

Before the assembly, shafts must be cleaned with dissolver (i.e. acetone); no foreign particles may adhere to them.

The hub must fit corresponding to the connection.

Connections with Clamping Piece:

The indications of the clamping piece manufacturer must be considered. The clamping piece must be

able to transfer the arising torques safely.

Caution: During the assembly inadmissibly large forces may not act on the transducer or the couplings. At small

torques (< 20 Nm) connect the transducer electrically during the assembly and observe the signal, the

measurement signal may not exceed the limit values.

7401 East Butherus Drive • Scottsdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

5.2.1 Torque Transducers of 0.03 Nm to 15 Nm

Transducers with nominal torques below 20 Nm are very sensitive to overload, therefore these transducers need to

be handled with greatest caution.

1. Connect the transducer electrically during the assembly and observe the measuring signal; the limit values may not be

exceeded in any case.

2. Align the arrangement before the parts are connected firmly.

3. Assemble the transducer at the low torque resistance side first, then at the stationary side

(this avoids impermissibly large torques from acting on the transducer).

4. Counter-hold by hand, so that impermissibly large torques or disturbance variables can not act on the torque

transducer.

5.2.2 Torque Transducers from 20 Nm

The hub must fit corresponding to the connection.

5.3 Freefloating Assembly

The transducer is installed between two single-jointed couplings and

contributes to the balance of an inevitable axis offset between the two

mechanical connections.

If no couplings are used, very large transverse forces can affect the transducer.

In addition, large forces occur on the bearings in drive and output, which limit their

life span very strongly. Shift couplings on shafts (use entire clamping length of the

coupling) and align shafts. Assure absolutely that the data of the couplings (axis

offset, angular offset, tension, compression) are not exceeded.

Caution: During the assembly inadmissibly large forces may not act on the transducer or the couplings.

The housing must be protected from twisting i.e. by a flexible connection. The cable connection may not be used for this.

The cable connection must be placed loosely (form of goose neck), so that it can follow the light movements of the stator.

Threaded holes for fastening a flexible

anti-rotation fixture such as a spring or strap.

Drive Single-jointed coupling Single-jointed coupling Output

Cable connection

Flexible connection for torque

transducer housin

g

fixation

11

7401 East Butherus Drive • Scottsdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

In this case, with both single-jointed couplings, the torque transducer forms a double-jointed coupling.

A single-jointed coupling can only balance axial and angular misalignments.

In this installation case, double-jointed couplings cannot be used for both sides!

Risk of Breakage!

5.4 Foot Version Assembly

The housing of the transducer is designed as a bearing block. A full coupling

must be installed at both shaft ends. By this, inevitable misalignments can

be balanced, which can occur during the period of operation.

If no couplings are used, very large transverse forces can affect the transducer.

In addition, large forces occur on the bearings in drive and output, which limit their

life span very strongly. Furthermore large bending moments occur in the shaft.

At small torques (< 20 Nm) connect the transducer electrically during the assembly

and observe the signal, the measurement signal may not exceed the limit values.

Shafts have to be cleaned with solvent (i.e. acetone) before the assembly

No foreign bodies may adhere to them.

Shift couplings on shaft (use entire clamping length of the coupling) and align shafts.

Absolutely note that the data of the couplings (axis offset, angular offset, tension, compression) are not exceeded.

Torque transducer Double-jointed coupling

Double-jointed coupling

Drive Output

12

7401 East Butherus Drive • Scottsdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

ACCU Schrauber

5.5 Typical Application

Fixation

Cli

p

-on tool

Caution: Do not use impulse or impact screwdrivers!

6Measuring

6.1 Engaging

The warming-up period of the torque transducer is approx. 5 min. Afterwards the measurement can be started.

The warming-up period of the torque transducer is approx. 5 min.

6.2 Direction of Torque

Torque means clockwise or clockwise torque if the torque acts clockwise when facing the shaft end. In this case a positive

electrical signal is obtained at the output.

Torque transducers can measure both, clockwise and counter-clockwise direction.

6.3 Static/Quasi-Static Torques

Static and/or quasi-static torque is a slowly changing torque.

The calibration of the transducers occurs statically on a calibration device.

The applied torque may accept any value up to the nominal torque.

6.4 Dynamic Torques

6.4.1 General

The static calibration procedure of torque transducers is also valid for dynamic applications.

Note: The frequency of torques must be smaller than the natural frequency of the mechanical measurement setup.

The bandwidth of alternating torque must be limited to 70% of the nominal torque.

13

7401 East Butherus Drive • Scottsdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

6.4.2 Natural Resonances

Estimate of the mechanical natural frequencies: c

J1J2

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛+⋅⋅

⋅

=

21

011

21JJ

cf

π

f0= Natural Frequency in Hz

J1, J2= Moment of Inertia in kg*m²

c = Torsional Rigidity in Nm/rad

An operation of the device in natural resonance can lead to permanent damages.

6.5 Speed Limits

The maximum speed indicated in the data sheet may not be exceeded in any operating state.

6.6 Disturbance Variables

By disturbances, measured value falsifications can occur by:

•Vibrations

•Temperature gradients

•Temperature changes

•Arising disturbance variables during operation, i.e. imbalance

•Electrical disturbances

•Magnetic disturbances

•EMC (electromagnetic disturbances)

Therefore avoid these disturbance variables by decoupling of vibrations, covers, etc.

7Maintenance

1

7.1 Maintenance Schedule

Action Frequency Date Date Date

Control of cables and connectors 1x p.a.

Calibration < 26 months

Control of fixation (flanges, shafts) 1x p.a.

Have bearings exchanged by Interface, Inc. 20,000 hrs

operating time

14

7401 East Butherus Drive • Scottsdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

7.2 Troubleshooting

This chart is used for searching for the most frequent errors and their elimination

Problem Possible Cause Troubleshooting

No signal No transducer excitation •Outside of permissible range

•Connect excitation

•Cable defect

•No mains supply

Signal output connected wrong •Connect output correctly

•Evaluation electronics defect

Transducer does not react to torque Shaft not clamped •Clamp correctly

No power supply •Outside of permissible range

•Connect supply

•Cable defect

•No mains supply

Cable defect •Repair cable

Connector connected wrong •Connect correctly

Signal has dropouts Axial position rotor to stator outside of

tolerance •Align rotor

Cable defect •Repair cable

Zero point outside of tolerance Cable defect •Repair cable

Shaft mounted distorted •Mount correctly

Distorted shaft string •Release from distortion

Strong lateral forces •Reduce lateral forces

Distorted flanges •Check evenness of flange-surfaces

Shaft overloaded •Send to manufacturer

Wrong torque indication Calibration not correct •Recalibrate

Transducer defect•Repair by manufacturer

Torque shunt •Eliminate shunt

Oscillations Alignment of shaft not correct •Align correctly

Unbalance •Balance the corresponding parts

8 Decommission

All transducers must be dismantled professionally. Do not strike transducer housings with tools. Do not apply bending moments

on the transducer, i.e. through levers. The torque transducer must be supported to avoid falling down during the dismantling.9

Transportation and Storage

The transportation of the transducers must occur in suitable packing.

For smaller transducers, stable cartons, which are well padded, are sufficient (i.e., air cushion film, epoxy crisps, paper

shavings). The transducer should be tidily packed into film so that no packing material can reach into the transducer (ball

bearings).

Larger transducers should be packed in cases.

9 Transportation and Storage

Only release well packed transducers for transportation. The transducer should not be able to move back and forth in the

packing. The transducers must be protected from moisture.

9.1 Transportation

Only release well packed transducers for transportation. The transducer should not be able to move back and forth in the

packing. The transducers must be protected from moisture.

Only use suitable means of tr

ansportation

15

7401 East Butherus Drive • Scottsdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

9.2 Storage

The storage of the transducers must occur in dry, dust-free rooms, only.

Slightly lubricate shafts and flanges with oil before storing (rust).

10 Disposal

The torque transducers must be disposed according to the valid provisions of law.

For more information consult factory (800) 947-5598 or visit www.interfaceforce.com.

11 Calibration

At the time of delivery, torque transducers have been adjusted and tested with traceable calibrated measuring equipment at

factory side. Optionally, a calibration of the transducers can be carried out.

o

11.1 Proprietar

y

Calibration

Acquisition of measurement points and issuing of a calibration protocol Traceable calibrated measuring equipment is being used

for the calibration. The transducer data are being checked during this calibration.

K

1 11.2 DKD-Calibration

The calibration of the transducer is carried out according to the guidelines of the DKD. The surveillance of the calibrating-

laboratory takes place by the DKD. At this calibration, the uncertainty of measurement of the torque-measuring instrument is

determined. Further information can be obtained from Interface Inc.

11.3 Recalibration

The recalibration of the torque transducer should be carried out after 26 months at the latest.

Shorter intervals are appropriate:

•Overload of the transducer

•After repair

•After inappropriate handling

•Demand of high-quality standards

•Special traceability requirements

16

7401 East Butherus Drive • Scottsdale, Arizona 85260 • 480.948.5555 • www.interfaceforce.com

This manual suits for next models

7

Table of contents