Interfacom TAXITRONIC TC60 User manual

INTERFACOM, S.A.

TC60_Install_Manual_en_015.doc 08/05/2013

INSTALLATION MANUAL

TAXITRONIC TC60-TV60

TC60-TV60 INSTALLATION MANUAL INTERFACOM, S.A

TC60_Install_Manual_en_015.doc 2

INDEX

1. Introduction.................................................................................................................. 4

2. Mounting...................................................................................................................... 4

2.1. Mounting TC60..................................................................................................... 4

2.1.1. Placing of TC60............................................................................................................ 4

2.2. Mounting TV60..................................................................................................... 4

2.2.1. Placing of TV60 ............................................................................................................ 5

2.3. Electrical installation............................................................................................. 5

2.4. Characteristics...................................................................................................... 6

2.5. Installation recommendations............................................................................... 7

3. First time turn on.......................................................................................................... 8

3.1. Configuration parameters..................................................................................... 9

3.2. Switch to normal mode....................................................................................... 18

4. Taximeter configuration............................................................................................. 19

4.1. Configuring constant K ....................................................................................... 19

4.1.1. Pull-up configuration................................................................................................... 20

4.1.2. Calculation of the K constant...................................................................................... 21

4.1.3. Entering constant k..................................................................................................... 21

4.2. Programming passwords.................................................................................... 21

4.3. Setting the calendar - clock ................................................................................ 22

4.4. Reset totalizers................................................................................................... 22

4.5. CAN bus CiA447 ................................................................................................ 22

4.6. Record the tariff.................................................................................................. 22

5. Sealing ...................................................................................................................... 23

6. Maintenance.............................................................................................................. 24

6.1. Hardware test..................................................................................................... 24

6.2. Remote test........................................................................................................ 24

6.3. Repairs............................................................................................................... 25

6.4. Repairs of TC60 with 112................................................................................... 25

6.5. Software update ................................................................................................. 26

6.5.1. TC60 in normal mode................................................................................................. 26

6.5.2. TC60 in installation mode........................................................................................... 26

ANNEX I........................................................................................................................... 28

INTERFACOM, S.A

3

DRAWINGS LIST

Drawing 1 TV60 bracket assembly

Drawing 2 TV60 unit drawing

Drawing 3 TC60 connectors

Drawing 4 Installation drawing (*1)

Drawing 5.1 TC60 Plastic sealing

Drawing 5.2 TV60 Plastic sealing

Drawing 6.1 TC60 cable sealing

Drawing 6.2 TV60 cable sealing

Drawing 7 Taximeter with armoured cables

Drawing 8.1 TC60 Sticker seals position

Drawing 8.2 TV60 Sticker seals position

INTERFACOM, S.A

4

1. INTRODUCTION

This document describes the installation and parametrization of TAXITRONIC TC60/TV60.

2. MOUNTING

2.1. MOUNTING TC60

TC60 mounting is prepared for 4 adhesive supports, which can optionally be fixed with

screws, and two cable ties. The supports must be fit rigidly, to avoid vibrations.

All TC60 connectors are on the front of the unit, covered by a sealable cover.

Al other devices are interconnected with TC60. So it can’t be sealed until the whole

installation process is finished.

The tools necessary for the installation are:

Screwdriver with head format Z1

Isopropilic alcohol (if the previous installation seals have to be removed)

2.1.1. PLACING OF TC60

TC60 must be installed so that passengers can’t see or access it. Seals and serial

numbers must be easily visible and accessible upon verification at a verification office.

Standard positions are inside the glovebox or under the passenger seat. Some vehicle

brands have standardised the TC60 position: Find these positions in Annex III

It is necessary that the identification sticker and the seals are easy to inspect. For this

reason it is necessary to take care of the orientation, with the stickers looking to the

outside. Cables cannot cover either the identification sticker nor the seals.

2.2. MOUNTING TV60

The installation of the TV60 is to be done on its certified support (See drawings 1 and 2).

The design of the support allows for 3-dimension orientation of the TV60, so it is adapted

to different dashboard designs.

The adhesive base is ready to be adhered to plastics, and supports the temperature

ranges inside a vehicle.

The connexion is done by only one connector on the back of TV60. The direction the cable

coes out, can optionally be to the back or pointing down.

The tools necessary for installing the TV60 are:

Fixed hexagonal key nº 15.

Allen key nº2, minimum length of the shaft 100mm.

Allen key nº3.

Screwdriver with head H1

INTERFACOM, S.A

5

Isopropilic alcohol (If there are previous installation or tariff seals to be removed)

The orientation of TV60 is fixed by screwing the two Allen screws on the sides (points B

and C on drawing 2). The central screw which touches directly on the support ball is not

used (see drawings 1 and 2)

The height of TV60 is fixed by screwing the central hexagonal key (Points A of drawing 2)

2.2.1. PLACING OF TV60

It is normally located on the vehicle dashboard, most times centered, so that both the

passenger and driver can clearly see it.

The version with printer needs space enough to open the printer cover, so that the paper

can be changed. It can’t be too close to the windscreen, so that the magnetic card can be

passed easily. It must not interfere with the vehicle Airbag, and it must be fitted as low as

possible so as to not obstruct the visibility of the road.

The positions established with the vehicle manufacturers are explained in Annex III

2.3. ELECTRICAL INSTALLATION

TC60 admits power supplies between 9 and 30 V, which makes it compatible with the

current 12V and 24V vehicle batteries.

First perform all the connexions with the unit disconnected from the car battery. When all

peripherals are connected, then connect the power supply

If it is necessary to make an intervention in the installation, it is necessary to first

disconnect the main power supply cabling or fuse, and then modify the rest of the

installation.

Drawing 3 details all the TC60 connectors.

Install the cabling and peripherals according to the connexions diagram in drawing 4

Pay attention that the antennae installation is done so that:

-The outside antenna for GPS and GSM is connected to GSM-B

-The inside antenna for GSM is connected to GSM-A

If an emergency button is used: Solder together the brown wire with the yellow wire of the

emergency button, and protect the joint with a thermoretractile cover.

INTERFACOM, S.A

6

2.4. CHARACTERISTICS

The dimensions of the units are:

TC60 174x140x45 mm (length x width x heigth)

Weigth 520 g

TV60 178x70x100 mm

Weigth 630 g

TC60 and TV60 are designed and certified to operate in an environment of

electromagnetic class E3 (instruments powered by a vehicle battery) and in a mechanical

environment class M3 (high and very high vibration level, such as in all type of vehicle).

The units are designed to operate indoors, in an temperature range of -25ºC / 70ºC and

without condensation, such as inside a vehicle

INTERFACOM, S.A

7

2.5. INSTALLATION RECOMMENDATIONS

Disconnect the battery positive contact until the whole electrical installation is finished.

Any work on the terminal or accessory must be done with the device disconnected from

the battery or without the general fuse.

Always use the positive and negative directly from the battery, to get a more filtered

power supply and avoid false contacts.

Always connect the cables to the battery with a terminal, never by direcly rolling the

cables around the battery contact.

If the cables crosses any edges, like metal edges, the cables must be protected with a

rubber protector

If the power supply cables are too long, they have to be cut to measure. They must

never be rolled. Do not cut antenna, microphone nor loudspeaker cables.

In case the vehicle has a radio transmitter, separate the transmitter installation as

much as possible from the terminal and its wiring. The transmitter and the terminal

antennae also are to be as separated as possible.

The interior adhesive GSM antenna, can not be installed under shielded windscreens.

Some vehicles have shielded windscreens that block the antenna transmissions and

coverage. If the windscreen is shielded, locate an unshielded zone or replan the

antenna installation.

Antenna cables must not be cut NOR ROLLED. If the standard antenna cables are too

long, consider asking for shorter cables.

Make the distance between both antennas as large as possible.

Do not connect any element connected to the terminal to the support of the radio

transmitter or radio transmitter antenna.

Install all the units and connect the power. Finally connect the general fuse.

INTERFACOM, S.A

8

3. FIRST TIME TURN ON

Turn on the unit by pressing on the touchscreen.

The unit starts, showing a progress bar. Finally you get a screen with the message

“ENTER A VALID USB”

Connect the USB stick with installer key to the USB connector

A screen requests for the installer password

Enter the password and press OK.

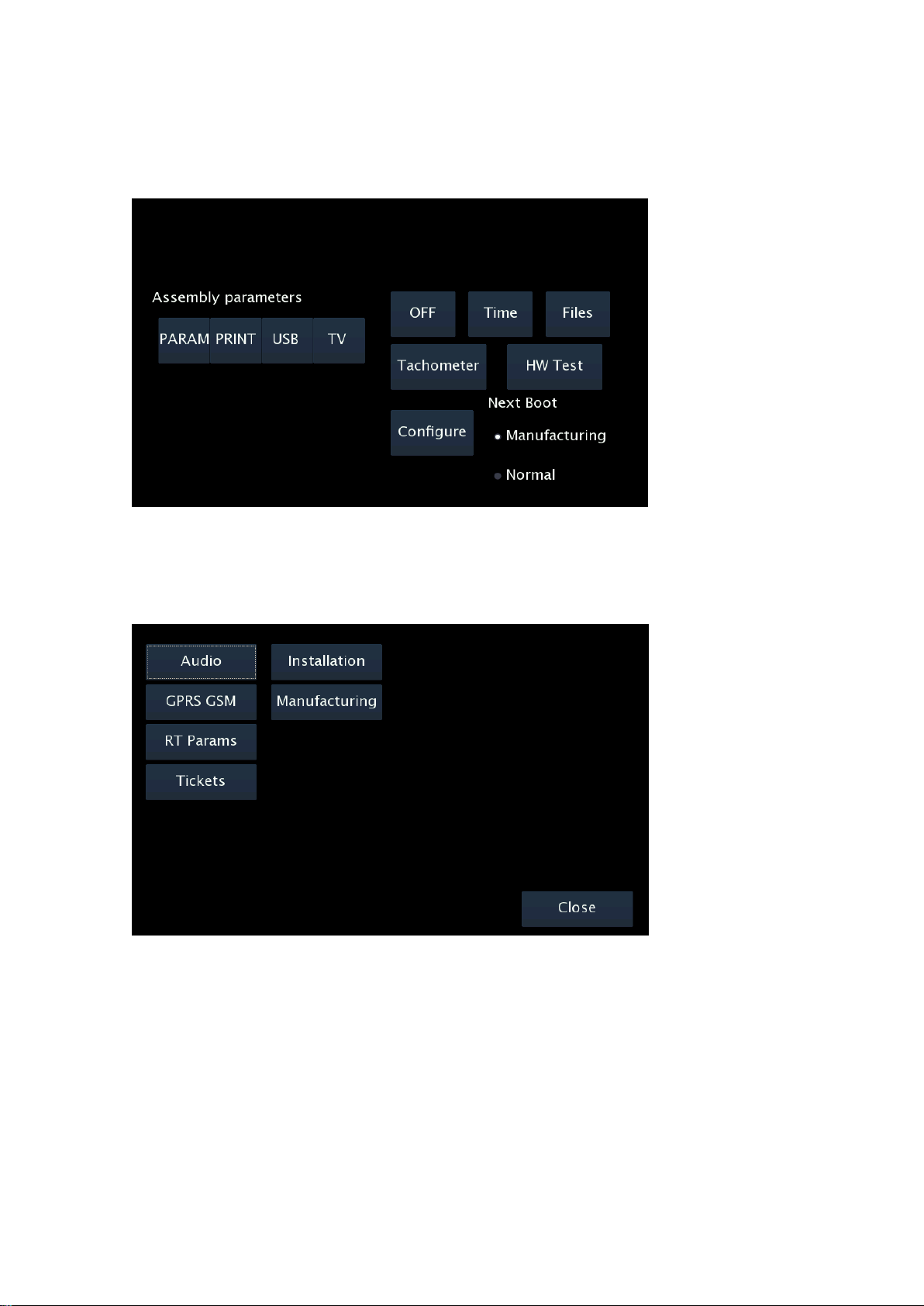

The start installer screen offers the following options:

OFF

Time: It updates the time and date of the terminal. This does not affect the taximeter

time, it is only active in non-taximeter configurations.

Files: Used for software updates

Tachometer: Calibration of the tachometer. This is only used in non-taximeter

configurations. This is not affecting the taximeter tachometer, which is calibrated inside

the taximeter screens.

INTERFACOM, S.A

9

3.1. CONFIGURATION PARAMETERS

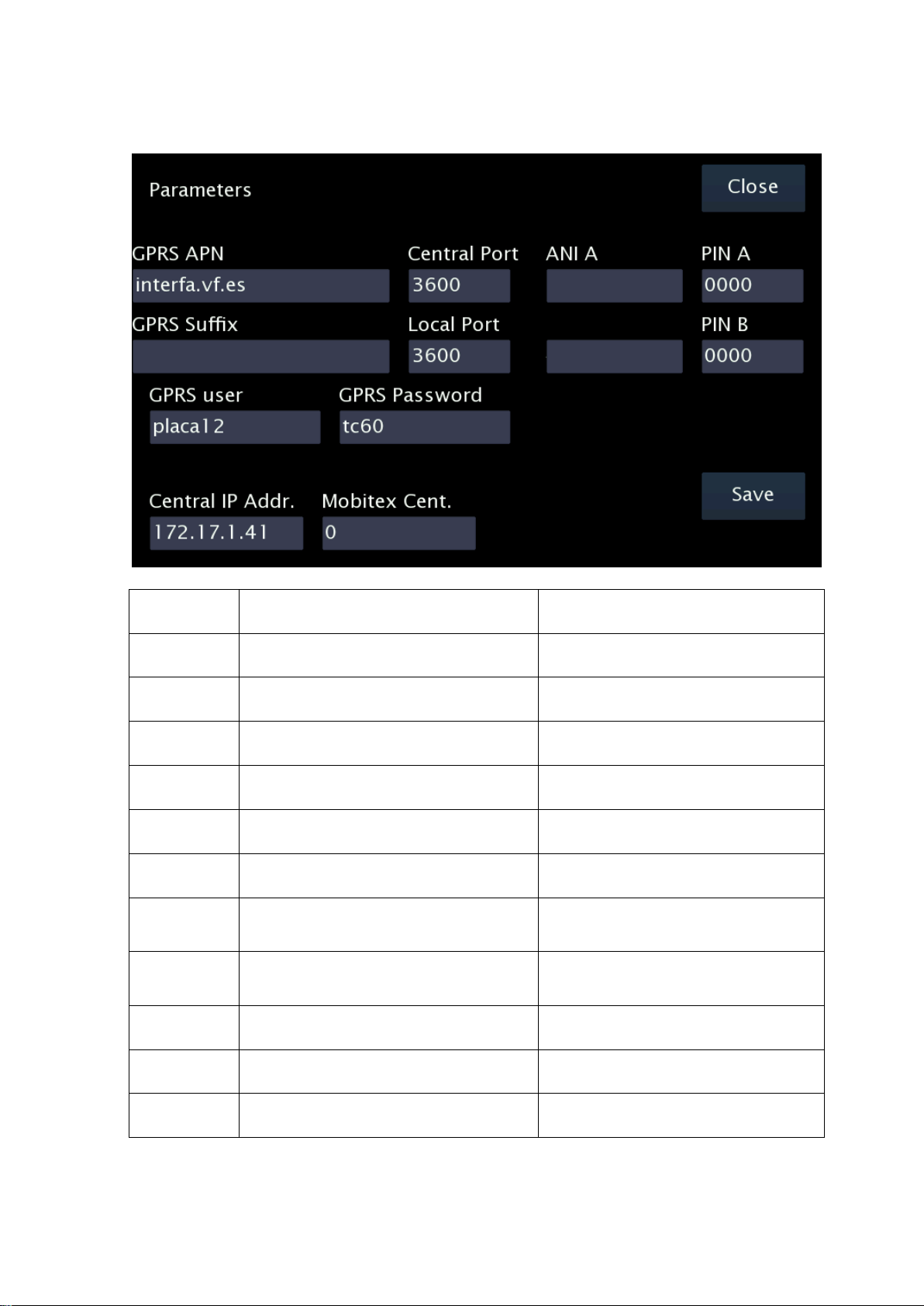

When in the main Manufacturing screen, press “Configure”

The application configuration parameters will open.

These parameters are not metrologic, so they are not subject to legal sealing. This can

also be accessed with an installer magnetic card.

INTERFACOM, S.A

10

Audio

DspEchoCancel

Activates echo cancellation

Normally use this activated

Micr

Choose the used microphone

TC60 External mic connected to TC60

TV60 Internal TV60 mic

Merc Specific Mercedes microphone

Alt

Choose the used loudspeaker

TC60 External loudspeaker

TV60 Internal TV60 loudspeaker

Merc Specific Mercedes loudspeaker

Sounds Volume

Default system sounds volume

Reception of dispatch, messages, etc

Gsm Volume

Default phone calls volume

When you have finished press “Save” to store the new parameters

INTERFACOM, S.A

11

In case of vehicles with excessive echo, which can not be solved with the previously

explained parameters, it is also possible to adjust the microphone gain to reduce the echo.

Echo is not solved by increasing the volume: On the opposite, it is solved by lowering the

output volume or lowering the microphone gain.

The parameters affecting the microphone gain are:

Tel.Mic.Analog

Gain

Tel.Mic.Digital

Gain

Dsp Mic Out

Gain

Phone micro analog gain

Phone micro digital gain

Microphone gain at the

output of the DSP

These parameters are by default adjusted

so that they are valid for a majority of

vehicles. In case it might be necessary t o

adjust them:

- Select the parameter

- Lower with button “<”

- Increase with button “>”

In case the microphone gain is not

adequate, adjust with parameter

“Tel.Mic.Analog Gain” and check the

result. Normally it will be enough with this

only parameter.

These additional microphone gain parameters are not available on TC60 board

version 2, produced between 2007 and 2008

INTERFACOM, S.A

12

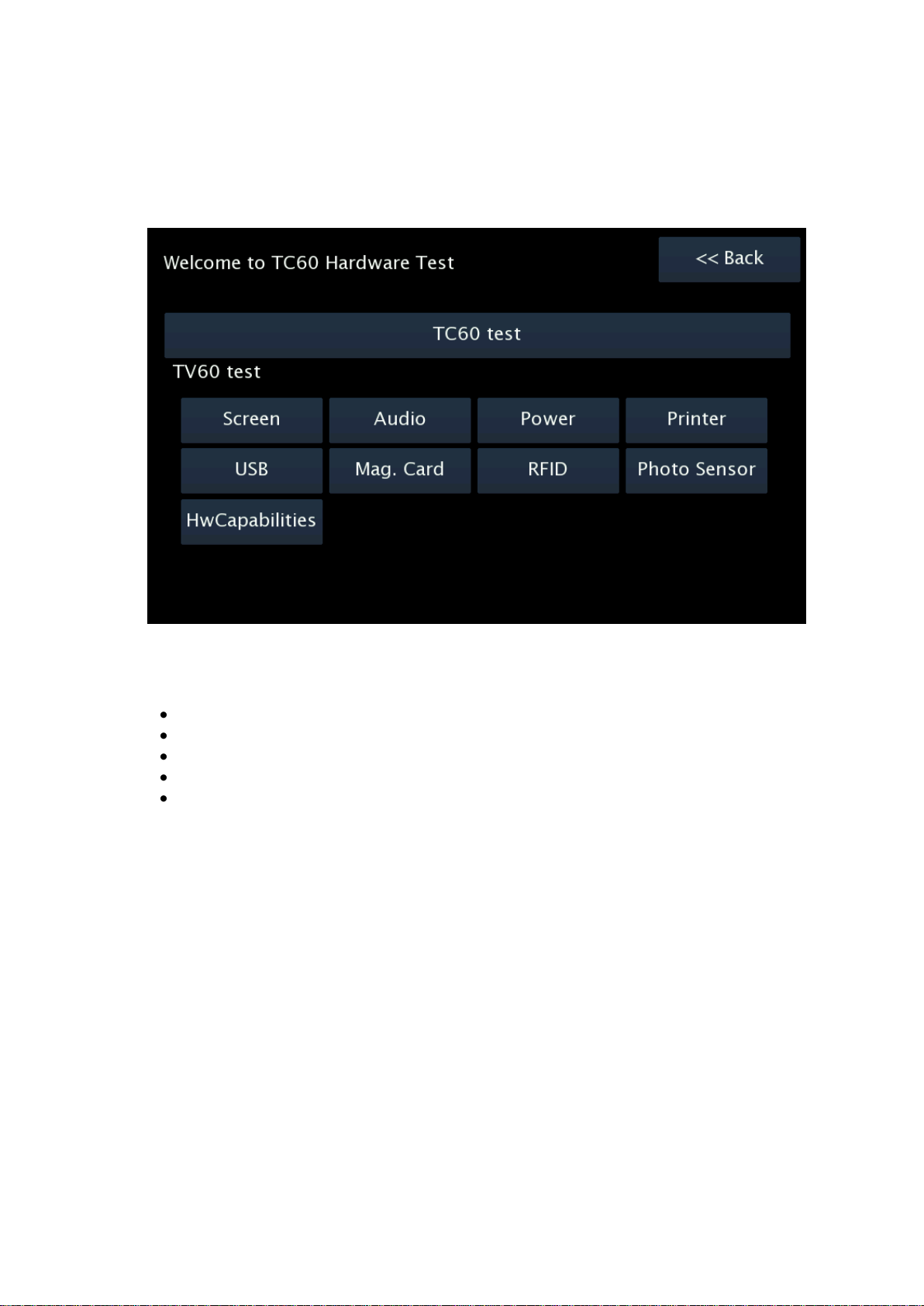

GPRS GSM

GPRS APN

Identification of the GPRS network

Central Port

UDP Port of the central programm

GPRS Sufix

GPRS Sufix, used as a second part of the

GPRS user.

Your network support will give you this

data if needed

Local Port

UDP Port of the local TC60 application

GPRS User

Identification of the TC60 in the GPRS

network

GPRS

Password

Password of the TC60 in the GPRS

network

Central IP

Address

IP Address of the Radiotaxi central

PIN GSMA

Enter the GSM A PIN

If the SIM is not in:

1.- First enter the PIN

2.- Then the SIM can be entered

PIN GSMB

Enter the GSM B PIN

If the SIM is not in:

1.- First enter the PIN

2.- Then the SIM can be entered

ANI GSMA

Enter the GSM A phone number

Needed for 112 applications

ANI GSMB

Enter the GSM B phone number

Needed for 112 applications

Mobitex Cent

Holland specific

INTERFACOM, S.A

13

RT Params

Name

Name of license owner

Licence

License number

Plate Number

Plate number

NIF

Fiscal ID

Car ID

ID of the car in the Radiotaxi

Driver 1..4

Driver codes of the 4 drivers

Company

Company code

Used by the Prima application

Term SN

TC60 serial number

Used by the Prima application

2 Drivers/Shift

Number of drivers per shift

Used by the Working Time Control application

Pins ShiftNr

To change the Shift number

INTERFACOM, S.A

14

Tickets

These screens are used to set all the data related to tickets. The data are:

Ticket Headers

6 ticket headers

Ticket Footers

8 ticket footers

Extras text

Extras text in the tickets

4 Manual Extras

1 Automatic Extra

Sweden specific

Inspection texts

Control Rapport

Plomb

Used only in Sweden

Sweden specific

TXT 1..4

Used only in Sweden

INTERFACOM, S.A

15

Installation

Operator

Installer who installs the device

Factory

Code of the workshop

Date

Installation date

Format YYYYMMDD

Bat. Calibration

Battery calibration

Touch Calibr.

Touchscreen calibration

EMV Type

Type of EMV payment

EMV SerialPort

Serial port where PinPad is

connected

Port 2 or Port 3 (see drawing ITC600003)

Taximeter type

Type of taximeter

Touchscreen calibration

If it is necessary to calibrate the display touchscreen, select “Touch Calibr”.

A pointer will appear near the left top corner. Press on the pointer, as precisely as possible.

Then the pointer will move to near the bottom right corner. Press on the pointer.

The touchscreen is now calibrated.

INTERFACOM, S.A

16

Battery calibration

This operation is only necessary in case that you have formated the board. Is not

neccesary if you change the battery.

To calibrate the battery:

Open the TC60 box so you can access the battery

Enter Bat. Calibration

Measure the Battery voltage with a tester. The value should be above 8V for a valid

calibration

The TC60 battery is charged up to a maximum between 7,8 and 8,5 V with an

ambient temperature of 25ºC. To calibrate it, wait at least until the value read on the

tester is 7,5 V, otherwise the calibration is wrong and battery may have a

breakdown.

Enter the value in format V.v and Enter

The battery is now calibrated. The voltage will be corrected the next time you reboot the

system.

INTERFACOM, S.A

17

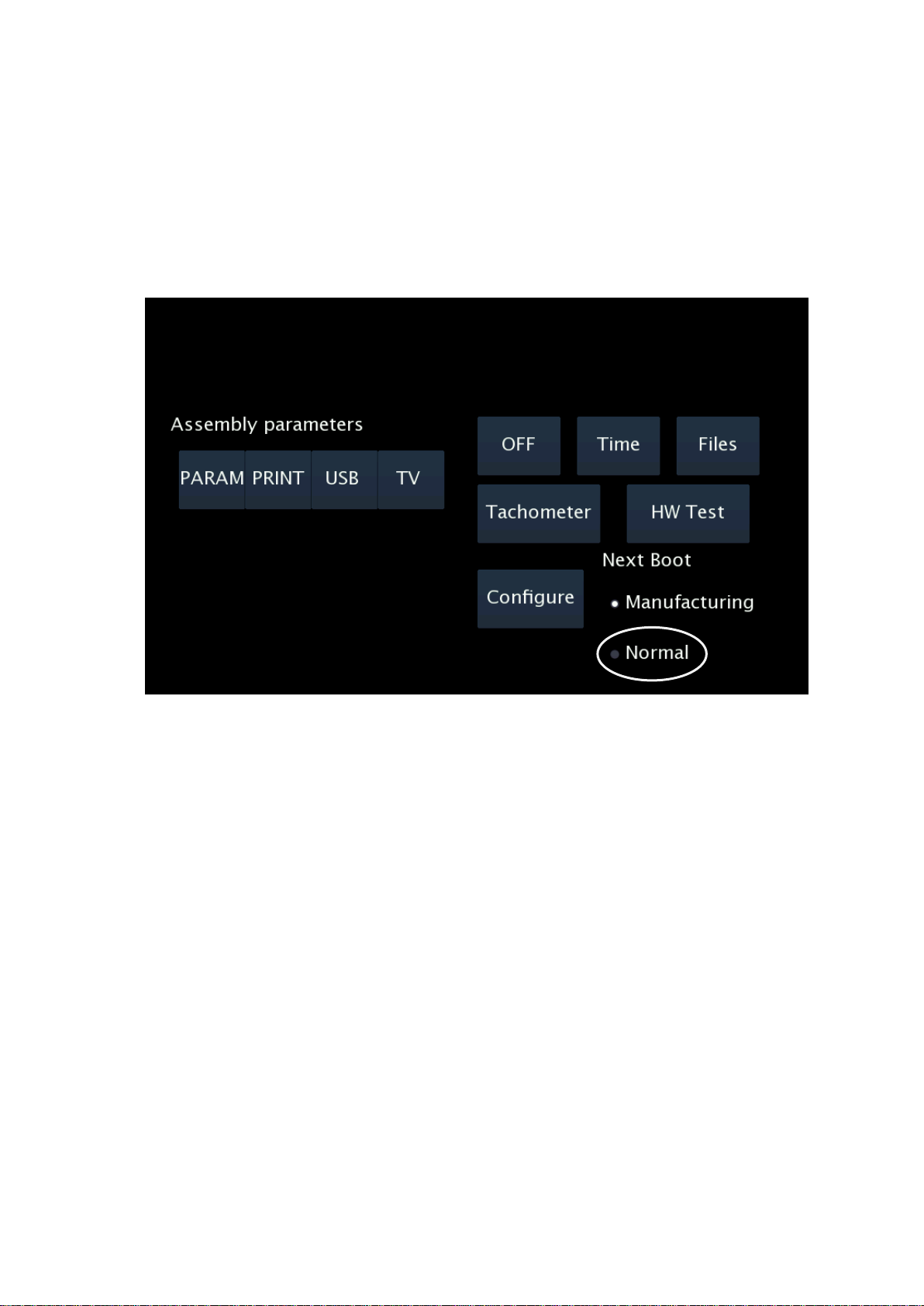

Hardware test

Press HW Test. These screens allow to test the TC60 and TV60. See the summary table

on Annex II to have all the verification options

It is necessary to test the correct connexion of all the elements and peripherals connected

to the TC60. In a typical installation, the verification must include:

Emergency button test

Contact key test

External lights

GSM antenna, coverage of the GSM phones

GPS antenna, GPS coverage

The TC60 installation cannot be considered as finished if the coverages of any of the

phones are not good enough. In that case, recheck the affected antenna. Take into

account that some vehicles have shielded windscreens, which attenuate the coverage.

INTERFACOM, S.A

18

3.2. SWITCH TO NORMAL MODE

Before installation is complete, change the working mode to Normal before the next restart

of the unit.

Select “Normal” in the “Next Boot” frame. Then you can turn the TC60 off. At next startup,

the TC60 will start in Normal mode.

INTERFACOM, S.A

19

4. TAXIMETER CONFIGURATION

With the TC60 in Normal mode, and with the taximeter in Free, open the sealed tariff cover

and connect a USB memory containing a valid tariff and installer key.

The screen will display the tariffs present in the USB. Select the adequate one.

If you have few tariffs in the USB, this will be faster than if you have a large number of

tariffs, so keep the number of tariffs as low as possible.

The taximeter configuration screen is displayed. In this screen the following operations can

be done:

1. Configure the “K” constant

2. Configure passwords

3. Set the clock

4. Reset totalizers

5. Record the tariff to the taximeter

4.1. CONFIGURING CONSTANT K

Press on the button “K”. The K constant configuration screen is entered.

It is possible to enter the K value directly, or to calculate it by doing a distance.

From this screen it is also possible to access:

External light type configuration

0 = Serial channel rooflight

1 = Parallel light

INTERFACOM, S.A

20

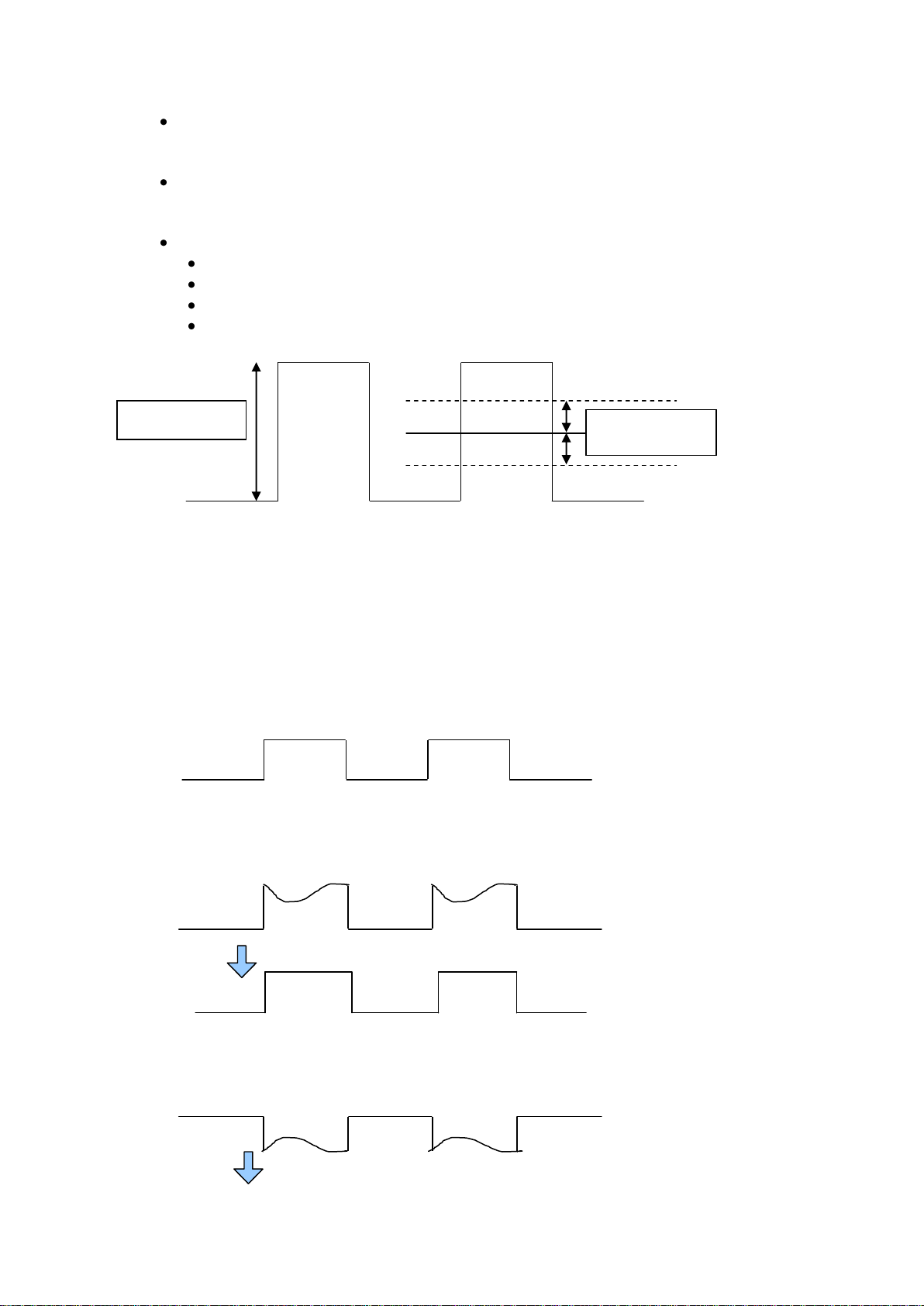

Adjustment of the trigger value for adequation to the car signal. The trigger value

counts from the center value of the signal

Modify Trigger value. The default 1000 mV is compatible with most cars. Change

only if the signal shape is not standard, and test until an adequate value is found.

The value must be in milivolts, without decimals. The default value is 1000

Lower than the vehicle signal amplitude / 2

Higher than a possible noise, so that it does not trigger by noise

Recommended value is the signal amplitude in milivolts / 4.

Valid values are between 400 and 2000.

4.1.1. PULL-UP CONFIGURATION

In some vehicles, the vehicle signal does not provide a high level signal, but an open circuit

instead. In these cases it is necessary to activate the pullup. Modify the value of the field

PULLUP by pressing on it.

Pull-up=0

Use if the vehicle signal has a good level for 0 and for 1

Pull-up=1

Use if the signal has a stable 0 level, but the 1 level given by the vehicle is an open circuit.

Pullup=2

Pull down. Use if the 1 value is stable, but the 0 value is an open circuit.

Signal amplitude

5000 mV

Proposed Trigger

1000 mV

This manual suits for next models

1

Table of contents

Other Interfacom Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

Blaupunkt

Blaupunkt BC OE2 Operating and installation instructions

Tow Tuff

Tow Tuff TTF-2762ACBR owner's manual

VBG

VBG Onspot Mounting instruction/Spare Parts List

SuperATV

SuperATV RBG-P-RZRXPTS installation instructions

Enelion

Enelion Wallbox installation guide

Ridetech

Ridetech MuscleBar 11289100 quick guide