2 LearnMode Rate of Rise Heat Sensors Installation Instructions

•Do not mountthe sensorclose to devices that change

temperature rapidly,such as ovens, heatvents, furnaces,

or boilers.

Equipment needed

You will need the following equipmentto install the sensors:

•Phillips and flathead screwdrivers

•Appropriate learn mode control panel documentation (for

programming information)

Programming

The panel must learn (program) the sensor ID code in order to

respond to sensorsignals.For complete programming

information,refer to the specific control panel documentation.

To add the sensor to panel memory,do the following:

1. Separate the sensor from the base by twisting the sensor

counter-clockwise and pulling the sensor offthe base.Set

the base aside.

2. Place the panel in program mode.

3. Proceed to the Learn Sensors menu.When the panel

prompts you for a sensorgroup number,enter the group

number (26).

4. Select the desired sensor number.

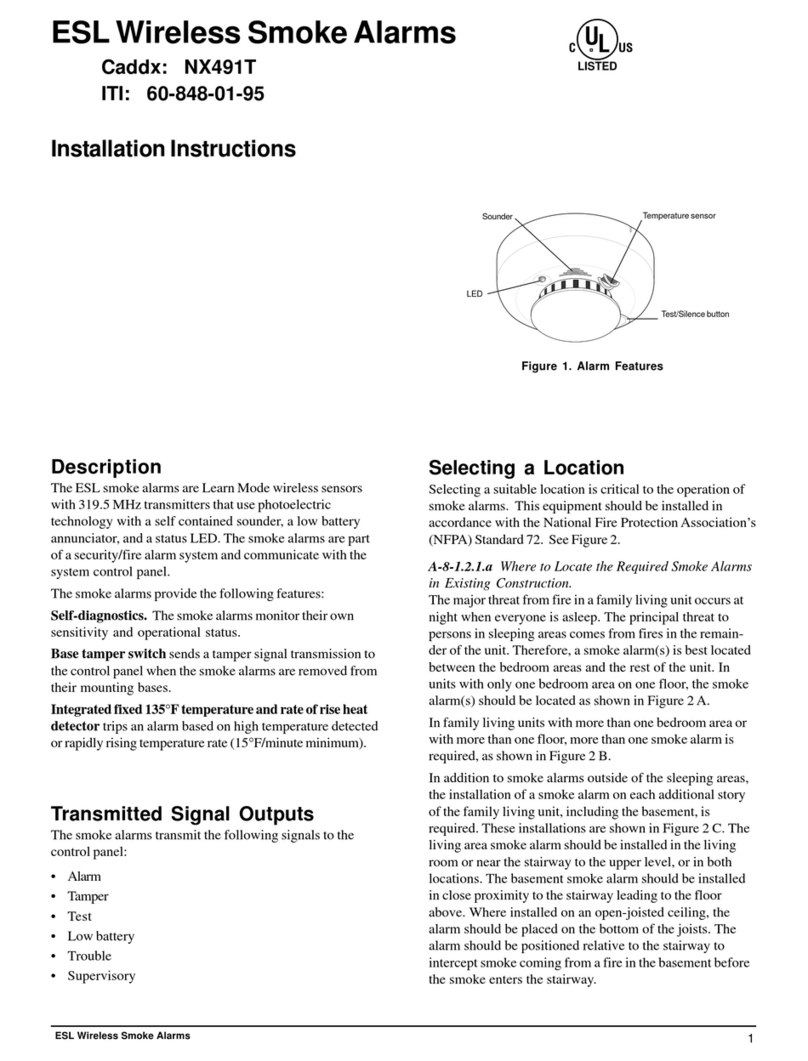

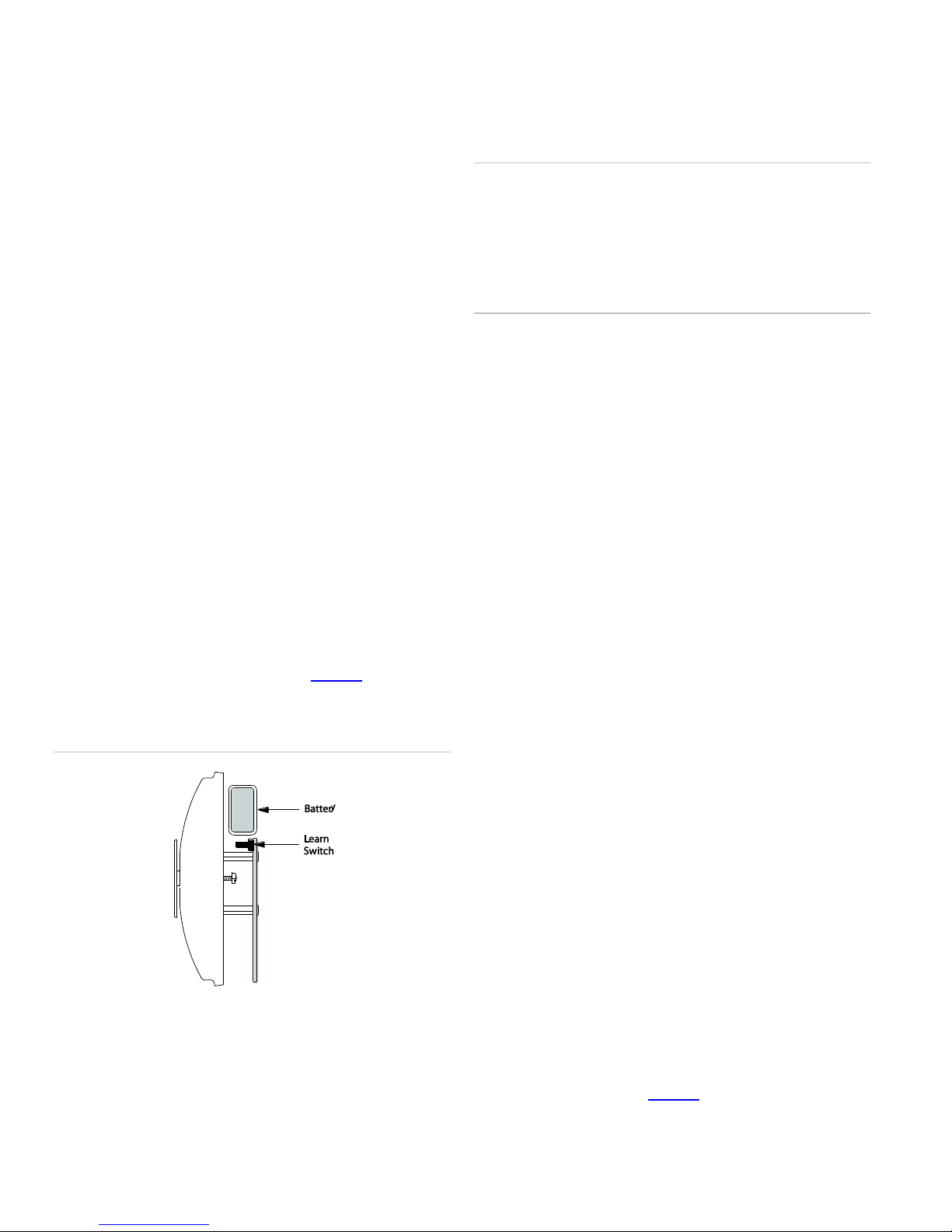

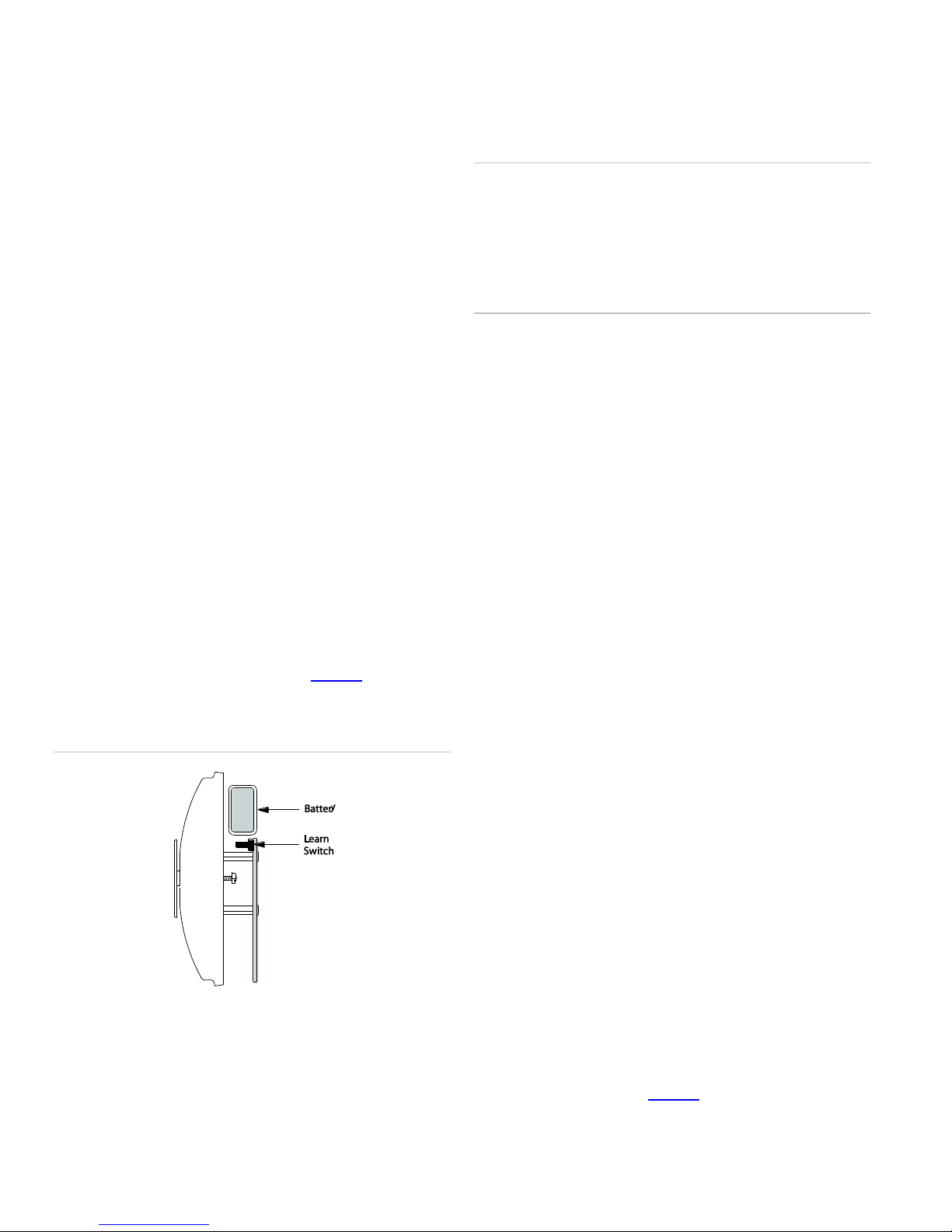

5. When the panel prompts you to trip the sensor,press and

hold the learn switch on the sensor (Figure 2) until the

panel beeps,indicating successful programming.

Figure 2. Learn switch

6. Exit program mode.

Testing

Before permanentlysecuring the sensor to the wall or ceiling,

test the sensor from the installation location using one ofthe

following methods.

Caution: The test method described onlytests rate-of-rise

operation.These sensors cannotbe field tested for their fixed

temperature ratings without being destroyed.When used with

care, the heat from a portable hair dryer (method 2) can be

used for testing.Do not aim the hair dryer directly at the round

disc on the sensor as this can cause itto pop off. If this

happened,the sensor mustbe replaced.

Method 1

To test the sensor,do the following:

1. Place the panel in sensor testmode.

2. Rub your hands together vigorously,until they feel hot.

3. Place the palm of one hand on the round disc of the

sensor,for about7 to 10 seconds.

4. Listen for the appropriate number ofbeeps from interior

sirens and speakers (refer to the specific panel

documentation).

5. Exit sensor test mode.

The sensor should resetin less than one minute.

Method 2

To test the sensor,do the following:

1. Place the panel in sensor testmode.

2. Plug in a portable hair dryer.

3. Hold the hair dryer about12 to 18 in. away from the

sensor,aiming itat the side of the sensor.

4. Listen for the appropriate number ofbeeps from interior

sirens and speakers (refer to the specific panel

documentation).

5. Exit sensor test mode.

The sensor should resetin less than one minute.

Mounting the sensor

To secure the sensor to its permanentlocation,do the

following:

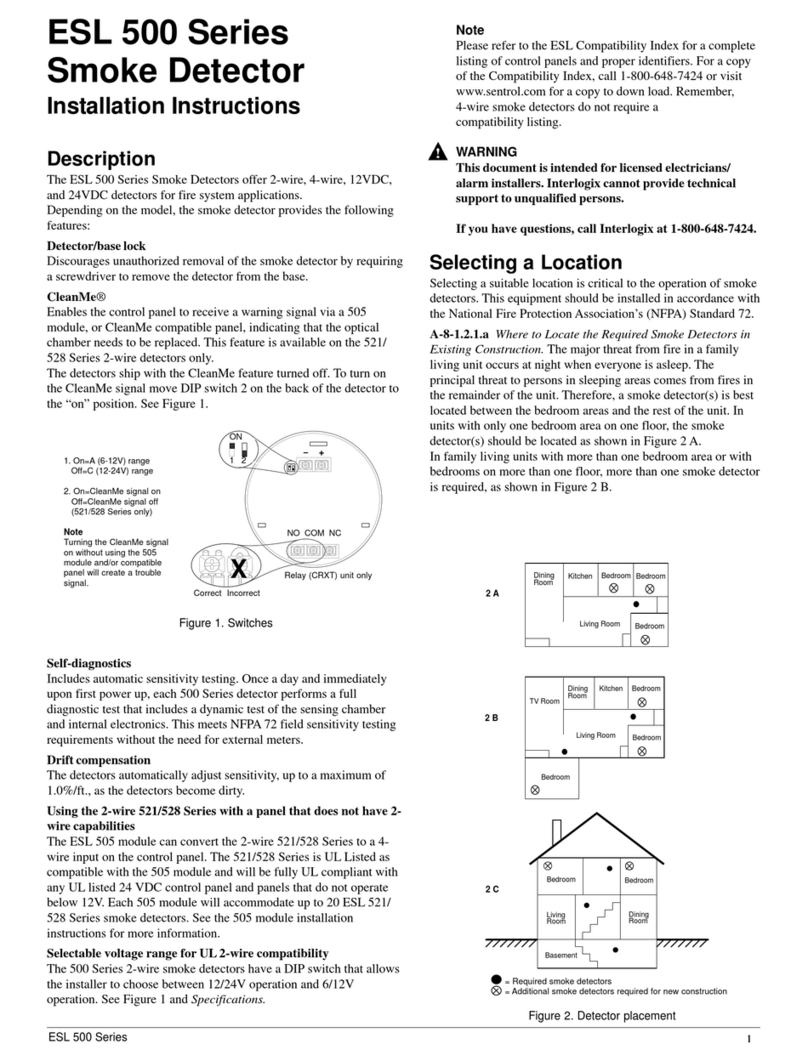

1. Locate the base mounting holes (inner pairand outer pair)

and mountthe base to the wall or ceiling with the

appropriate hardware (Figure 3).

2. Attach the sensorto the base.