Interpack ipg RSA 2024-TB/2" User manual

RSA 2024-TB/2”

Serial Numbers TM108 XX X XXX

RANDOM SEMI-AUTOMATIC CASE SEALER

Rapid Packaging, Inc.

763-404-8900 | [email protected]

www.RapidPackaging.com

UDM108-01 2 RSA2024-TB/2”

TABLE OF CONTENT

Description RSA 2024-TB/2"............................................................................................................................5

Important Safeguards..........................................................................................................................................6

Specifications...........................................................................................................................................................9

Power Requirements...........................................................................................................................................9

Operating Speed...................................................................................................................................................9

Operating Conditions........................................................................................................................................10

Tape .......................................................................................................................................................................10

Tape Width..........................................................................................................................................................10

Tape Roll Diameter...........................................................................................................................................10

Tape Application Leg length - Standard.....................................................................................................10

Tape Application Leg Length - Optional....................................................................................................10

Box Board............................................................................................................................................................11

Carton Size Capacities......................................................................................................................................11

Machine Dimensions........................................................................................................................................12

Set-Up Recommendations...............................................................................................................................12

Receiving and Handling...................................................................................................................................13

Table Level..........................................................................................................................................................14

Stop/Start Box.....................................................................................................................................................14

Tape Loading ......................................................................................................................................................15

Tape Threading - Upper Tape Head.............................................................................................................16

Tape Threading - Lower Tape Head............................................................................................................16

Electrical Connection........................................................................................................................................16

Air Connection ...................................................................................................................................................17

Pneumatic Adjustment .....................................................................................................................................17

Operating Instructions......................................................................................................................................18

Troubleshooting...................................................................................................................................................19

Recommended Spare Parts List.....................................................................................................................21

Electrical Schematic...........................................................................................................................................22

Pneumatic Schematic.........................................................................................................................................23

Illustrations and Parts Lists............................................................................................................................24

UDM108-01 3 RSA2024-TB/2”

Service Instructions

Service

This is the Interpack Model RSA 2024-TB/2” Uniform Side Belt Case Sealer you ordered. It has been set

up and tested in our factory with Intertape manufactured pressure sensitive tapes. If any problems occur

when setting up or operating this equipment, please contact the authorized distributor from where you

purchased this item.

Should you need to contact Interpack Technical Support, please have the Case Sealer model number

and serial number available. This information can be found on the nameplate of the side panel of the

machine. Interpack Technical Support is available during normal business hours (Eastern Time).

PHONE 813-621-8410 x101

If you have a technical question that does not require an immediate response, you may contact Interpack

by fax.

FAX 813-621-8449

Replacement Parts

Order parts by item number, part name and quantity required. Replacement parts are available from your

Authorized Interpack Distributor exclusively.

Should you require assistance selecting the correct part, you may call:

Intertape Polymer Group

Interpack Machinery

9940 Currie Davis Drive, Suite 23B

Tampa, FL, 33619

Tel: 1-800-474-8273 Option 3

Fax: 1-800-462-1293

MODEL:

SERIAL NUMBER:

DISTRIBUTOR PURCHASED FROM:

DATE OF PURCHASE:

UDM108-01 4 RSA2024-TB/2”

Service Instructions

EQUIPMENT WARRANTY AND LIMITED REMEDY: The following warranty is made in lieu of all other

warranties, express or implied, including, but not limited to, the implied warranty of merchantability, the

implied warranty of fitness for a particular purpose, and any implied warranty arising out of a course of

dealing, a custom or usage of trade:

Intertape sells its Interpack Tape Heads, Case Tapers and Case Erectors with the following warranties:

1. The HSD2000 Tape Heads' knife blades, springs and wipe down rollers will be free from all

defects for a period of ninety (90) days.

2. All other HSD2000 Tape Head parts will be free from all defects for one (1) year after delivery.

3. Water Activated Tapers’ blades and brushes will be free from defects for ninety (90) days after

delivery

4. Drive Belts will be free from defects for ninety (90) days after delivery

5. The Gear Motors will be free from defects for one (1) year after delivery.

6. All other components for Case Tapers and Case Erectors will be free from defects for one (1)

year after delivery.

If any part is proven defective within its warranty period, then the exclusive remedy and Intertape's and

the seller's sole obligation shall be, at Intertype’s option, to repair or replace the part, provided the

defective part is returned immediately to Intertape's factory or an authorized service station designated by

Intertape.

A part will be presumed to have become defective after its warranty period unless the part is received or

Intertape is notified of the problem no later than five (5) calendar days after the warranty period.

If Intertape is unable to repair or replace the part within a reasonable time, then Intertape, at its option,

will replace the equipment or refund the purchase price. Intertape shall have no obligation to install the

repaired or replacement part.

Intertape shall have no obligation to provide or pay for the labor required to install the repaired or

replacement part. Intertape shall have no obligation to repair or replace (1) those parts failing due to:

operator misuse, carelessness, or due to any accidental cause other than equipment failure, or (2) parts

1. Failure or damage is due to misapplication, lack of proper maintenance, abuse, improper

installation or abnormal conditions such as temperature, moisture, dirt or corrosive

matter, etc.

2. Failure due to inadequate cleaning, improper operating environment, improper utilities

or operator error.

3. Failure due to operations above the rated capacities, or in any other improper manner,

either intentional or otherwise.

4. Failure is due to equipment, which has been altered by anyone other than an authorized

representative of Intertape Polymer Group.

5. Failure is due to an attempt by the purchaser to correct alleged defective equipment. In

this event the purchaser is responsible for all expenses incurred.

LIMITTION OF LIABILITY: Intertape and seller shall not be liable for direct, indirect, special, incidental

or consequential damages based upon breach of warranty, breach of contract, negligence, strict liability or

any other legal theory.

The foregoing Equipment Warranty and Limited Remedy and Limitation of Liability may be changed

only by written agreement signed by authorized officers of Intertape and seller.

UDM108-01 5 RSA2024-TB/2”

Description of RSA 2024-TB/2”

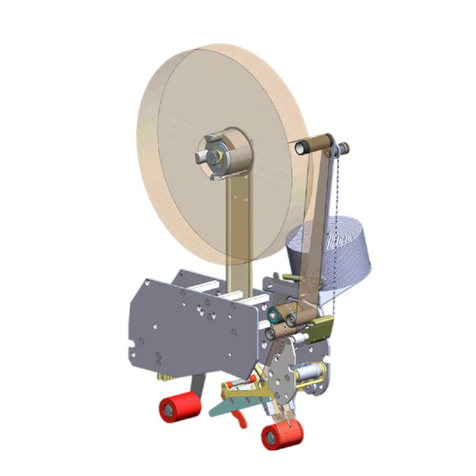

Figure 1

Description RSA 2024-TB/2”

The Interpack RSA 2024-TB/2” Carton Sealing Machine with HSD®2000 ET II Tape

Heads is designed to apply Intertape brand Pressure Sensitive carton sealing tape to the

top and bottom center seam of regular slotted corrugated cartons. The RSA 2024-TB/2”

automatically adjusts to a wide range of carton sizes (see Carton Specifications, Page 11).

UDM108-01 6 RSA2024-TB/2”

Important Safeguards

NOTE: IN THE EVENT THESE SAFETY LABELS SHOWN ON PAGES 6-8 ARE

DAMAGED OR DESTROYED, REPLACEMENTS ARE AVAILABLE.

There are a number of safety labels used on Interpack Carton Sealers.

The illustrated label “WARNING SHARP

CUTTING BLADE”, shown in Figure 2 is

attached to the Knife Guard inside the upper

and lower HSD®2000 Tape Head. The label

warns operators and service personnel of the

very sharp knife used to cut the tape at the

end of the tape application.

The HSD®2000 Tape Heads are equipped with

a Knife guard that covers the blade. The Tape Heads

should never be operated with the blade guards removed.

Turn air and electrical supplies off before servicing the tape heads. Figure 2

The “DANGER HAZARDOUS VOLTAGE” label

shown in Figure 3 is attached to the control box. The

label warns the service personnel to unplug the power

supply before attempting any service work on the carton

sealer.

Figure 3

UDM108-01 7 RSA2024-TB/2”

Important Safeguards

The illustrated label “WARNING MOVING PARTS” shown in Figure

4is located on the “EXIT” end of the Left Hand side cover. The label

warns the operators and service personnel of the pinch point at the exit

ends of the machine.

Figure 4

The illustrated label “WARNING - MOVING

MACHINES PARTS” shown in Figure 5 is located on

the “Bottom Chain Guard” at the end of the Top Belt

Drive assembly. The label warns the operators and service

personnel of the pinch point at the exit ends of the

machine and under the guard.

Figure 5

UDM108-01 8 RSA2024-TB/2”

Important Safeguards

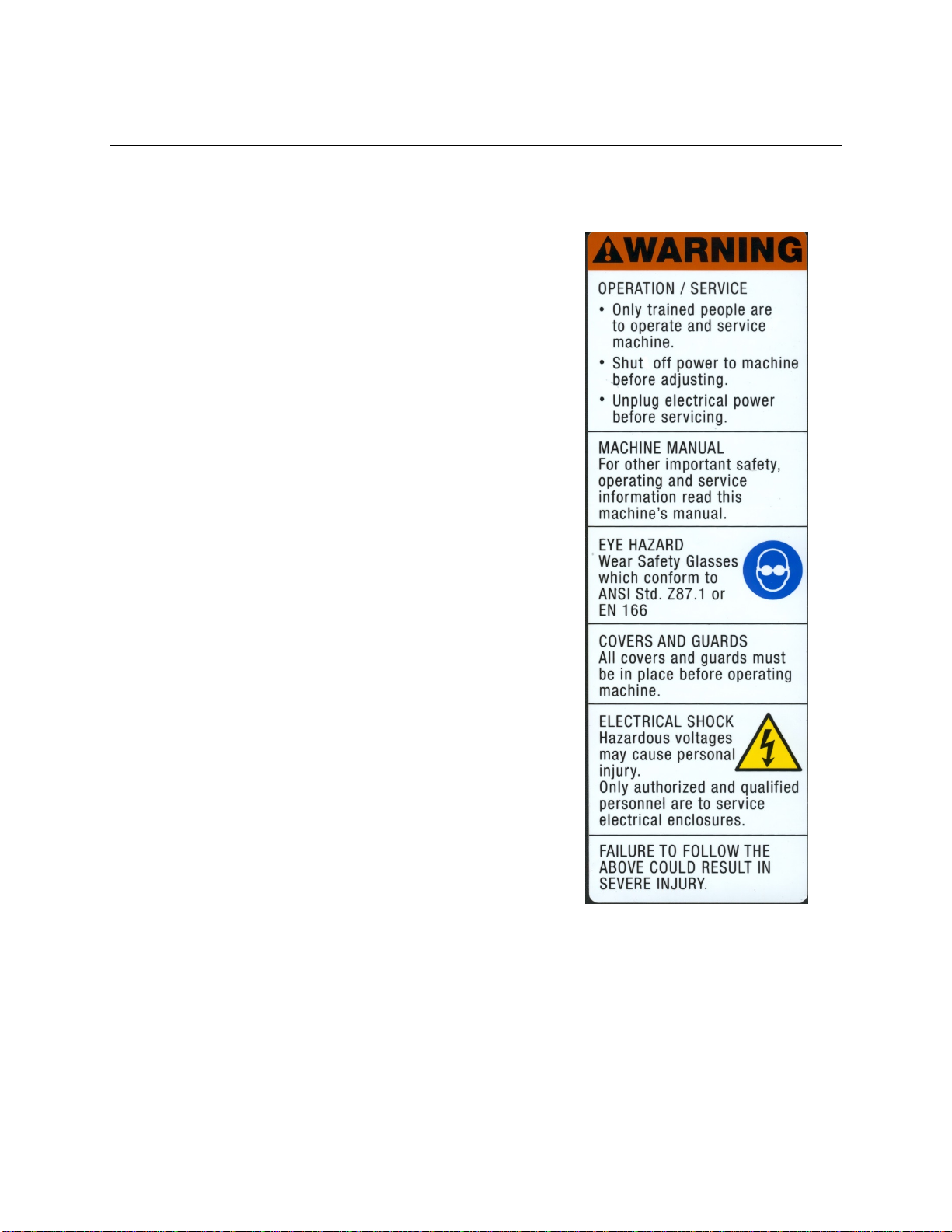

The illustrated label “WARNING - OPERATION /

SERVICE”, shown in Figure 6 is located on the side of the

column. This label provides convenient safety instruction for

the operator and service personnel in the operation of the

Interpack Carton Sealing Equipment.

F

Figure 6

UDM108-01 9 RSA2024-TB/2”

Specifications

1. Power Requirements:

Electrical - 115 VAC, 60 HZ, 8.4 A (966 Watts)

This machine comes standard with one (1) 1/6 H.P. and one (1) 1/3 H.P. gear motors and

comes with a standard neoprene covered power cord and a grounded plug. Contact your

Intertape Representative for power requirements not listed above.

2. Operating Speed:

Actual production rate is dependent on operator’s efficiency and the case size mix. Belt

speed is 82’ per minute

UDM108-01 10 RSA2024-TB/2”

Specifications

3. Operating Conditions:

Use in a dry, relatively clean environment at 40to 105F ( 5to 40C) with clean dry

cartons.

IMPORTANT NOTE:

MACHINE SHOULD NOT BE WASHED DOWN OR SUBJECTED TO

CONDITIONS CAUSING CONDENSATION ON COMPONENTS.

4. Tape:

Intertape brand Pressure Sensitive Carton Sealing Tape.

5. Tape Width:

Model RSA2024-TB/2” : 1 ½ inches (36 mm) to 2 inches (48 mm) maximum.

6. Tape Roll Diameter:

Up to 16 inches (405 mm) maximum on a 2 inch (48 mm) diameter core.

(Accommodates all Intertape brand film tape machine roll lengths)

7. Tape Application Leg length - Standard:

2 ½ inches (+1/4”, -0") (63.5 mm, + 6.3 mm, - 0 mm)

8. Tape Application Leg Length - Optional:

2 inches (+1/4”, -0”) ( 50.8 mm, + 6.3 mm, - 0 mm

NOTE: FOR FURTHER SPECIFICATIONS ON HSD®2000 TAPE HEADS,

CONSULT THE HSD®2000 ET II TAPE HEAD MANUAL PROVIDED WITH

THIS MACHINE.

UDM108-01 11 RSA2024-TB/2”

Specifications(Cont’d)

9. Box Board:

Style: regular slotted Containers (RSC)

125 to 275 P.S.I. bursting test, single or double wall B or C flute.

10. Carton Size Capacities:

Height (inches) Width (inches) Length (inches)

Standard

minimum 5 6 6

maximum 24 20 Infinite

Height (inches) Width (inches) Length (inches)

Optional

minimum 2 6 6

maximum 21 20 Infinite

Height (inches) Width (inches) Length (inches)

Optional

minimum 2 8 8

maximum 21 22 Infinite

UDM108-01 12 RSA2024-TB/2”

Specifications(Cont’d)

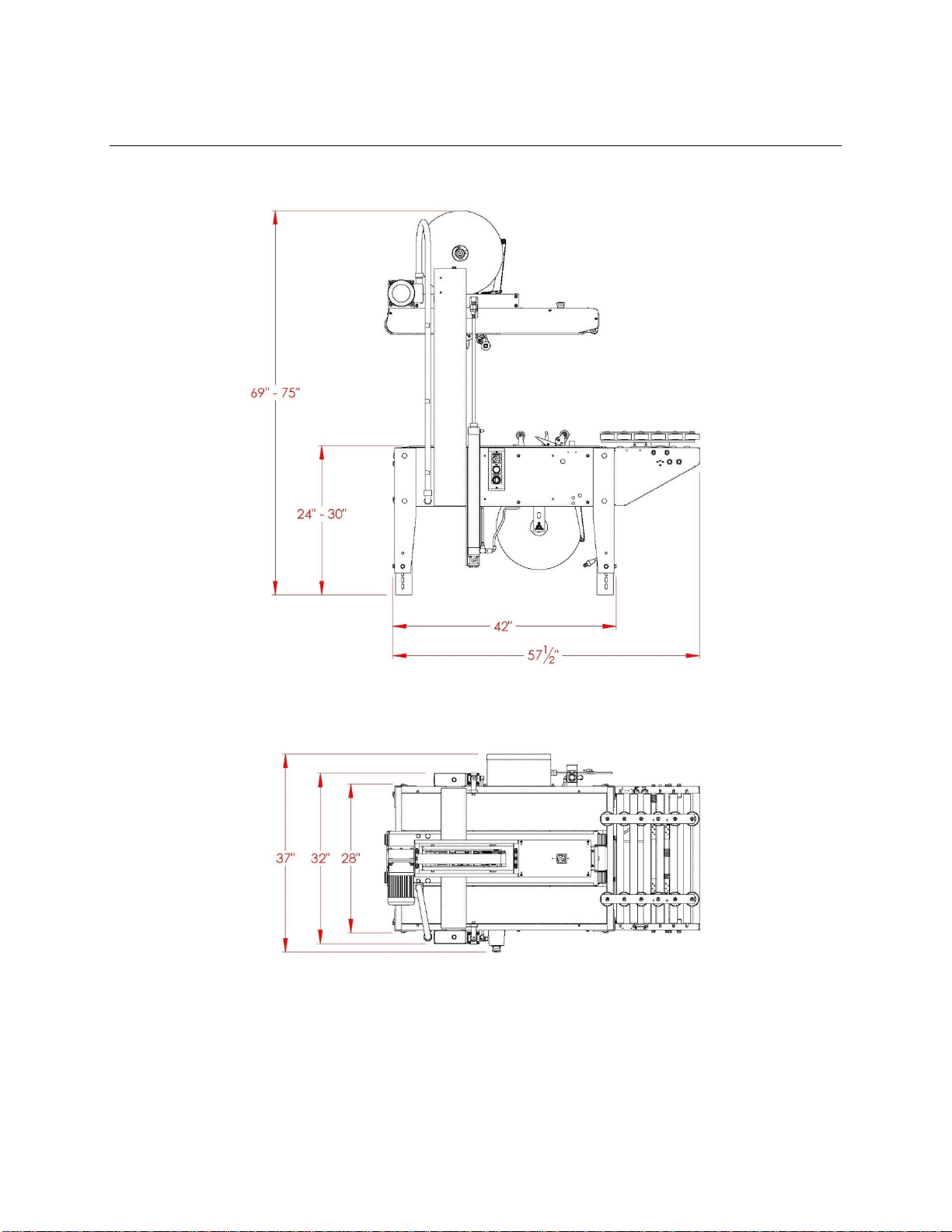

11. Machine Dimensions:

12. Set-Up Recommendations:

The Carton Sealer must be level.

Customer supplied infeed conveyor (if used) should provide straight and level entry.

Customer supplied exit conveyor (if used) should be straight and declined no more

than ¼”/foot away from the machine to convey the sealed cartons away from the

machine.

Figure 7

UDM108-01 13 RSA2024-TB/2”

Set-Up Procedure

Receiving and Handling

After unpacking the machine, look for any damage that may have occurred during shipping.

Should the machine be damaged, file a claim with the transport company and notify your

representative as soon as possible.

The following instructions are presented in the order recommended for setting up and installing

the RSA 2024-TB Carton Sealing machine as well as for learning the operating functions and

adjustments. Following them step by step will result in your thorough understanding of the

machine and an installation in your production line that best utilizes the many features built into

the carton sealer.

1. Lift off cover and sleeve after removing the strapping and staples at bottom.

2. Remove mounting bolts and nuts, which secure the RSA 2024-TB to the shipping pallet

4. Lift machine off pallet and install on your packaging line.

5. Ensure that the machine is level and firmly on the ground (no rocking). Note that the

machines’ roller height can be adjusted with the four (4) adjustment legs to accommodate

conveyor heights from 23 ½" to 29 ½". To adjust the carton sealer, block the machine to

allow adequate leg adjustment. Using a 9/16" box end wrench, loosen and remove the

eight (8) 3/8 hex head bolts, adjust the legs to the desired conveyor height and reinstall

the bolts.

6. Customer supplied infeed and exit conveyors (or rollers) must be level with the machine,

otherwise, the performance of the machine may be affected.

Note: The exit conveyor either gravity fed or driven should be installed with

no more than 1/4" per foot decline.

UDM108-01 14 RSA2024-TB/2”

Set-Up Procedure

Table Level

The Carton Sealer must be installed on a near level ground.

Ensure that the machine is level and firmly on the ground (no rocking). Adjust the roller height

with the four (4) telescopic adjustment legs to accommodate conveyor heights from 24 to 30

inches.

To adjust the Carton Sealer height,

jack up the machine to give ample

room to extend the legs. Using a

3/4" (19 mm) box end wrench, loosen

the eight (8) M10 hex head bolts.

Adjust the legs to the desired

conveyor height and tighten the

bolts. Etched lines on the legs ease

leveling.

Customer supplied infeed and exit conveyors (or rollers) must be level with the machine,

otherwise, the performance of the machine may be affected. The customer-supplied infeed

conveyor (if used) should provide straight and level entry. The customer-supplied exit conveyor

(if used) should be straight and declined no more than 1/4 inch per foot away from the machine.

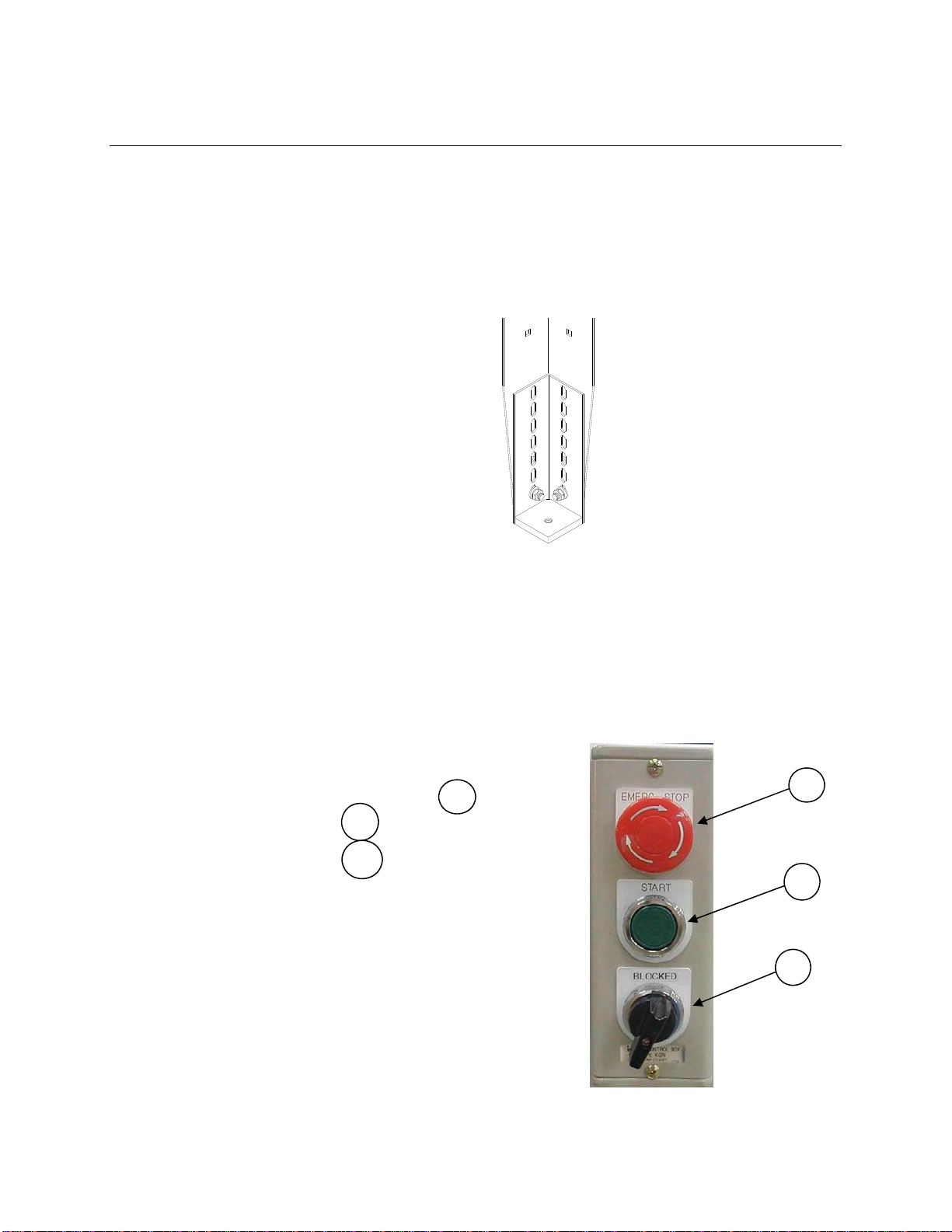

Stop/Start Box

The Stop/Start Box contains :

the red "E-STOP" mushroom push button,

the green "ON" push button,

and the “BLOCKED” button.

The E-Stop is a detented type, when it is pushed

down, it will stay in the down position. In order to

re-start the machine, the operator has to pull up the

E-Stop button and press on the green "on" push

button.

1

2

3

3

1

2

Figure 8

Figure 9

UDM108-01 15 RSA2024-TB/2”

Set-Up Procedure

Tape Loading

The HSD®2000-ET II /2’’Tape Heads accommodate 2" wide Tape rolls and HSD®2000-ET II

/3’’Tape Heads accommodate 3" wide rolls. Check the Tape Head Manual included with your

Carton Sealer or the Tape Head label on the side of the HSD®2000 ET II Tape Head to

determine which Tape Head you are using. Push the roll of tape onto the Mandrel with the

adhesive side up (refer to Threading Diagram on the HSD® 2000 ET II tape head) until the

core seats against the Mandrel flange. This ensures the tape will be centered when feeding into

the tape head.

UDM108-01 16 RSA2024-TB/2”

Set-Up Procedure

Tape Threading - Upper Tape Head

Remove the blade guard from the knife in the Tape head. NOTE: TURN OFF ELECTRICAL

POWER SUPPLY AND DISCONNECT THE POWER CORD FROM THE

ELECTRICAL SUPPLY BEFORE BEGINNING TO WORK ON THE TAPE HEADS OR

TO LOAD TAPE. IF POWER CORDS ARE NOT DISCONNECTED, SEVERE INJURY

TO PERSONNEL COULD RESULT. THE KNIFE CONTAINED IN THE TAPE HEAD

IS EXTREMELY SHARP. USE CAUTION WHEN REMOVING THE BLADE GUARD

AND THREADING THE TAPE TO AVOID PERSONNEL INJURY. To thread the tape

into the Upper Tape Head you do not require any special tools. Pull approximately 12" of tape

from the roll and fold in half. This allows you to thread the tape without it adhering to the guide

and clutch rollers inside the tape head. Follow the Tape Threading Diagram on the side plate of

the HSD

®

2000 Tape Head. See your Tape Head manual for further information if required.

Tape Threading - Lower Tape Head

Lift Top tape Head Box to the uppermost position by activating the “BLOCKED” selector

switch on the control box. Remove the Lower tape Head by grasping the tape application rollers

and lifting straight up. Remove the blade guard from the knife in the Tape head. NOTE: THE

KNIFE CONTAINED IN THE TAPE HEAD IS EXTREMELY SHARP. USE CAUTION

WHEN REMOVING THE BLADE GUARD AND THREADING THE TAPE TO AVOID

PERSONNEL INJURY. To thread the tape into the Lower Tape Head you do not require any

special tools. Pull approximately 12" of tape from the roll and fold in half. This allows you to

thread the tape without it adhering to the guide and clutch rollers inside the tape head. Follow the

Tape threading diagram on the side plate of the HSD

®

2000 Tape Head. See your Tape Head

manual for further information if required. Replace the Lower tape head in the machine. Turn off

the “BLOCKED” selector switch.

Electrical Connection

A twelve (12) foot standard three conductor power cord with plug is provided for 115 V, 60 Hz,

15 amp electrical service. The servicing receptacle must be properly grounded. Before the

machine is plugged into the receptacle, ensure that all materials are removed from the machine.

Note: Use of an extension cord is not recommended because of voltage drop.

The electrical control is protected with an

automatic circuit breaker with re-settable

overload. This reset is located in the electrical

box in the lower left quadrant (Fig. 9). Push

on the blue button to reset.

Figure 10

UDM108-01 17 RSA2024-TB/2”

Air Connection

The regulator has a male "quick disconnect" adaptor. Connect clean dry compressed air to this

adapter. The RSA2024-TB requires a minimum of 3 C.F.M. at 75 psi maximum.

To regulate the air pressure, pull on the

green knob located on the side of the

machine. Turn the knob clockwise for

more pressure and counter clockwise for

less. When the air pressure is at 75 psi,

push back down on the button until a

"click" is felt. The threading size is 3/8

NPT.

Pneumatic Adjustment

The main air filter/regulator controls the air pressure going inside the machine. It also controls

the air pressure inside the cylinders that rise the Top Belt Drive Assembly and open the infeed

guides. The recommended pressure setting for the main air filter/regulator is between 60

and 70 PSI.

The Infeed Guide Pressure is controlled with the pressure regulator located at the infeed end of

the machine, under the left hand Side Cover (Item 24 on the Bottom Belt Drive Structural

drawing). By increasing the air pressure, you increase the centring force of the guides on the

box. The recommended pressure setting for the Infeed Guide regulator is between 30 and

40 PSI.

The weight of the Top Belt Drive Assembly on the box is controlled by the High Flow Pressure

Control located at the discharge end of the machine, under the left hand Side Cover. This

controls the air pressure at the bottom of the cylinder and counterbalance for the weight of the

Top Belt Drive Assembly. Therefore, to reduce the weight applied on the top of the box, you

have to increase the air pressure. . The recommended pressure setting for the High Flow

Pressure Control is between 35 and 45 PSI.

Figure 11

UDM108-01 18 RSA2024-TB/2”

Operating Instructions

Once the HSD®2000 Tape Heads, (both bottom and top) have been loaded with tape and

threaded the machine is ready to process RCS cartons. The following instructions are presented

in the order recommended for processing cartons successfully through the RSA 2024-TB

Carton Sealing machine.

1- Activate air Supply (3 C.F.M. at 80 P.S.I.).

2- Switch the machine on with start push button.

3- Place carton with flaps held in closed position on the Infeed Table up to sensor #1.(Item

45 or 49 on the “Infeed Table W/ Guide” drawing)) Sensor will detect carton and the

Infeed Guides will center the carton.

Warning:

Ensure that the operator’s hands are away from the contact area between the Infeed

Guides and the carton.

4- Push carton with flaps held in closed position against the Front Sensing Paddle at the

front of the Top Belt Drive Assembly. This will raise the Top Belt Drive Assembly. Push

the rear of the carton until it is between the top and bottom drive belts.

WARNING!!

Ensure That The Operator’s Hands Are Away From The Moving Belts Of The Top And

Bottom Drive Assemblies

5- When the carton exits the Carton Sealer, the Top Belt Drive Assembly will go down to

his initial position.

6- The Carton Sealer is now ready to process the next carton..

UDM108-01 19 RSA2024-TB/2”

Troubleshooting

Interpack Carton Sealers are fabricated with high quality components that provide trouble-free

operation for a long period. However, if a problem should occur we recommend that you always

look for simple things first, then more complex problems. This is exactly how this table is

constructed, as the numbers increase, complexity increases.

TROUBLE POSSIBLE CAUSES SOLUTIONS

The main power

is turned on and

nothing happens

1- One of the fuses is burned.

1- Verify all fuses in the electric

box.

The machine is

ON but the

Infeed Guides do

not center the

carton on the

Infeed Table.

1- Compressed air supply is not

connected.

2- The air tubing or the valve is

obstructed or defective.

1- Inspect air connection and

operating pressure

2- Inspect the air tubing and the

valve for leaks or obstructions.

The Infeed

Guides closes

when the

machine is

powered up even

when there is no

carton on the

Infeed Table.

1- The Infeed Table’s Sensor is

not aligned with his reflector. 1- Check the alignment of the

Infeed Sensor with his reflector.

The Top Belt

Drive Assembly

stays up or goes

down too slowly.

1- The High Flow Pressure

Regulator is adjusted too

high.

1- Reduce the air pressure setting

of the High Flow Pressure

Regulator, located at the infeed

end of the machine, under the

left hand Side Cover.

The Top Belt

Drive Assembly

goes down too

quickly or

crushes the

carton.

1- The High Flow Pressure

Regulator is adjusted too low. 1- Increase the air pressure setting

of the High Flow Pressure

Regulator, located at the infeed

end of the machine, under the

left hand Side Cover.

UDM108-01 20 RSA2024-TB/2”

The Top Belt

Drive Assembly

raises too slowly.

1- The inlet pressure is too low.

2- The moving parts are rubbing

on something.

1- Adjust the inlet pressure on the

main regulator to 80 psi and

make sure that the pressure

doesn't fall below 70 psi while

it is operating.

2- Inspect the Top Belt Drive

Assembly to make sure that

noting interferes with them.

The Top Belt

Drive Assembly

does not rise

when the carton

pushes the Front

Sensor Plate.

1- The Proxy Sensor behind the

sensor plate is too far from

the Front Sensor Plate.

1- Remove the Front Sensor Plate

and adjust the position of the

Proxy Sensor by moving it by

1/16”, then replace the Front

Sensor Plate and verify proper

operation. Make sure that the

sensor does not touch the Front

Sensor Plate.

The cartons are

not taped

properly.

1- The tape head is not adjusted

correctly 1- Refer to the tape head manual.

Table of contents

Other Interpack Food Saver manuals