2August 3, 2010

AN1581.0

5. JP1 should be inserted only if the input fault MOSFET

Q1 is not used.

6. Apply input voltage to the VIN and GND post on the

top left corner of the ISL97671IRZ-EVAL Evaluation

Board.

7. Jumper JP3 should be in the right position and EN

signal from a 2.5V/3.3V logic supply connected to

the EN jumper, J5.

8. Jumper JP8A should be in the top position and PWM

signal from a function generator connected to the

PWMI jumper, J6.

9. Insert JP5A, JP6A and J3A.

10.To enable the board in SMBus mode, write a hex 05

in register 01; by writing a hex 01 in register 01 will

enable DPST (see data sheet FN7631 for more

details); writing a hex 03 in register 01 will allow

PWM dimming only.

11.For non-I2C control of ISL97671, remove the I2C

interface board, JP3A and ground J3(SCL post) and

J4 (SDA post). The board can now be controlled via

the EN and PWMI signal.

12.The LED current is calibrated to 20mA/channel,

which can be changed by measuring current across

JP7B and varying POT R15 by Equation 1:

The measured current divided by six is the LED

current per channel. For example, 120mA measured

current will correspond to 20mA/channel.

13.The PWM dimming frequency is calibrated to 200Hz

on this evaluation board but can be adjusted by

varying POT R11 by Equation 2:

14. ISL97671IRZ-EVAL Evaluation Board should be

powering 6P10S or 6P12S LED's.

ISL97672

1. Jumpers JP7B, JP8B, JP9, JP10, JP11, JP12 and JP13

should be inserted for LED's in 6P12S configuration.

2. Jumpers in line 1, plus JP14, JP15, JP16, JP17, JP18

and JP19 should be inserted for LED's in 6P10S

configuration.

3. Jumper JP8A inserted in top position.

4. Jumper JP3 should be in the right position.

5. JP1 should be inserted only if the input fault MOSFET

Q1 is not used.

6. Apply input voltage to the VIN and GND post on the

top left corner of the ISL97672IRZ-EVAL Evaluation

Board.

7. Apply a 2.5/3.3V signal to EN jumper, J5.

8. Apply a PWM signal from a function generator to

PWMI jumper, J6.

9. The LED current is calibrated to 20mA/channel

which can be changed by measuring current across

JP7B and varying POT R15 by Equation 3:

The measured current divided by six is the LED

current per channel. For example, 120mA measured

current will correspond to 20mA/channel.

10.The boost switching frequency is calibrated to

600kHz on this evaluation board but can be

adjusted by varying POT R11 by Equation 4:

11. At this point, the ISL97672IRZ-EVAL Evaluation

Board should be powering 6P10S or 6P12S LED's.

ISL97673

1. Jumpers JP7B, JP8B, JP9, JP10, JP11, JP12 and JP13

should be inserted for LED's in 6P12S configuration.

2. Jumpers in line 1, plus JP14, JP15, JP16, JP17, JP18

and JP19 should be inserted for LED's in 6P10S

configuration.

3. Jumpers JP3A, JP5A and JP6A are inserted.

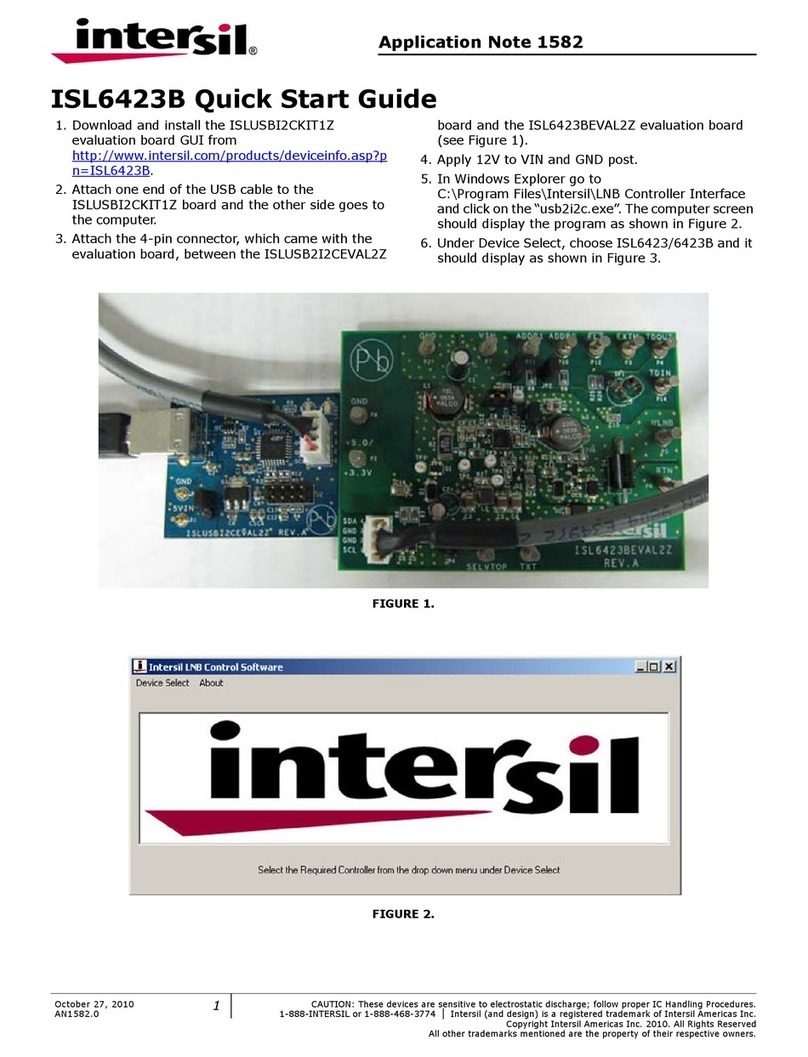

4. Connect the I2C interface board to the ISL97673/4IRZ-

EVAL Evaluation Board, as shown in Figure 3.

ILED 401.8 R15

⁄=(EQ. 1)

FSW 6.66 107

×()R11

⁄=(EQ. 2)

ILED 401.8 R15

⁄=(EQ. 3)

FSW 510

10

×()R11

⁄=(EQ. 4)

FIGURE 3. I2C INTERFACE BOARD CONNECTED TO ISL97673IRZ-EVAL EVALUATION BOARD

Application Note 1581