Application note AN-ODV-2-025

AN-ODV-2-025 Remote Push-button Speed Control

Solution One parameter Set-up

The drive should be defaulted back to factory settings prior to set-up. The following parameters are set within the drive to

activate the functionality shown in the control diagram. Check all parameters have been set correctly prior to enabling the drive.

Note that Parameter P1-14 must be set to the value listed in the table before access will be permitted to menu 2 and 9

parameters.

Parameter Changes:

Digital inputs function select

Extended Menu Access code

Menu 9 Reference (Parameter remaining at Default):

Terminal ctrl override source

Speed Source Reference 2 - 8

External Trip input source

The above table is included as a reference so the full configuration of menu 9 can be observed.

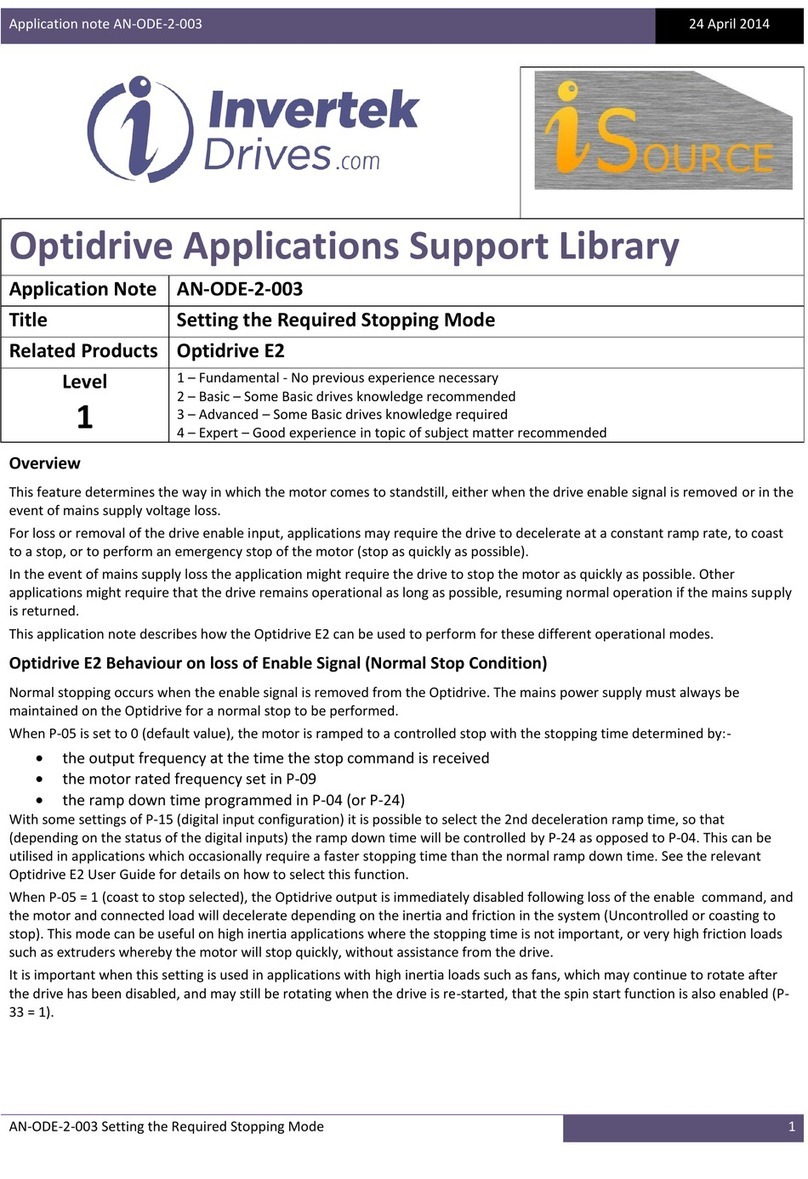

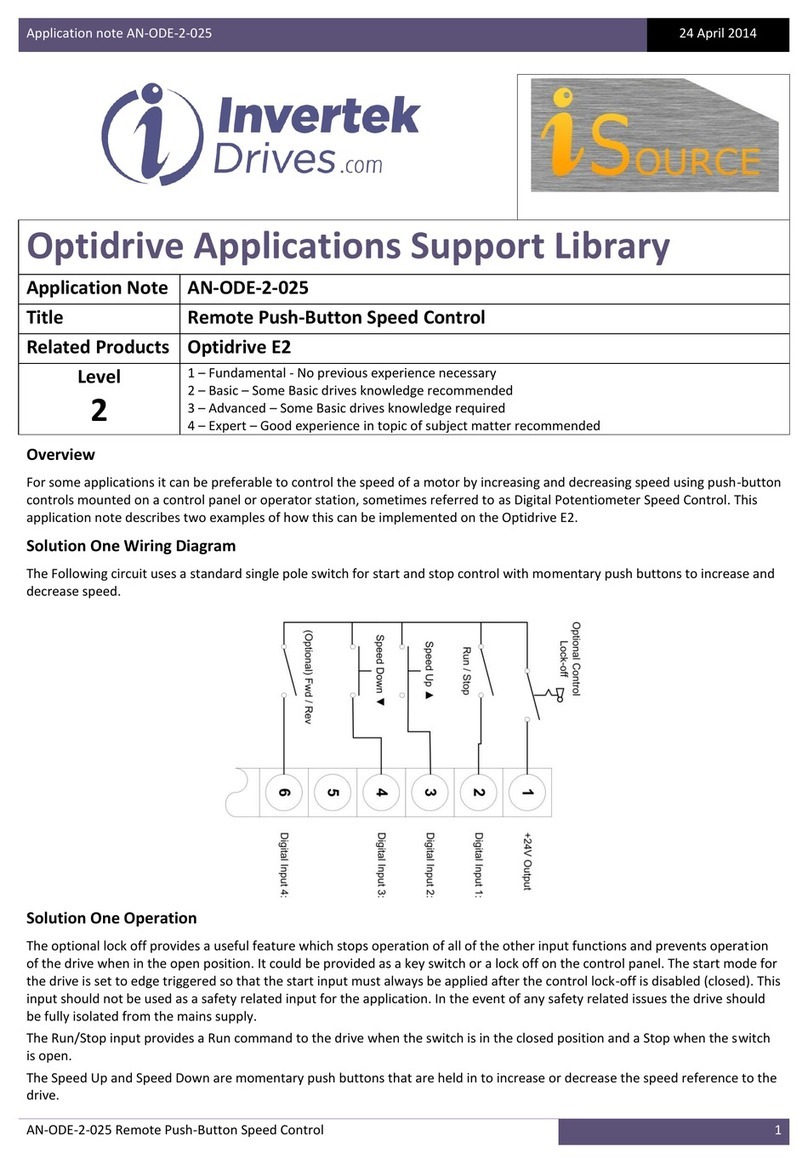

Solution Two Wiring Diagram

The Following circuit uses a standard momentary switches for start and stop control and for the push buttons to increase and

decrease speed.

Solution Two Operation

Fully detail of the optional lock off is provided in solution one operation description.

The Stop input is a normally closed momentary switch that provides a stop command to the drive when opened. The drive will

stop when this switch is activated (opened) and will prevent the drive starting whilst held in the open position. The switch is a

normally closed configuration to help protect against wire-break in the control circuitry.

The Start input is a normally open momentary switch that provides a Run command to the drive when the switch is closed. The

input is latched so that the switch can be released once the drive is started and will continue to run until over-written by a stop

input.

The Speed Up and Speed Down are momentary push buttons that are held in to increase or decrease the speed reference to the

drive.

The Fwd / Rev switch is optional depending on whether bi-directional (forward and reverse) motor rotation is required. The

drive operates in the forward direction when the switch is open and reverses when the switch closes.