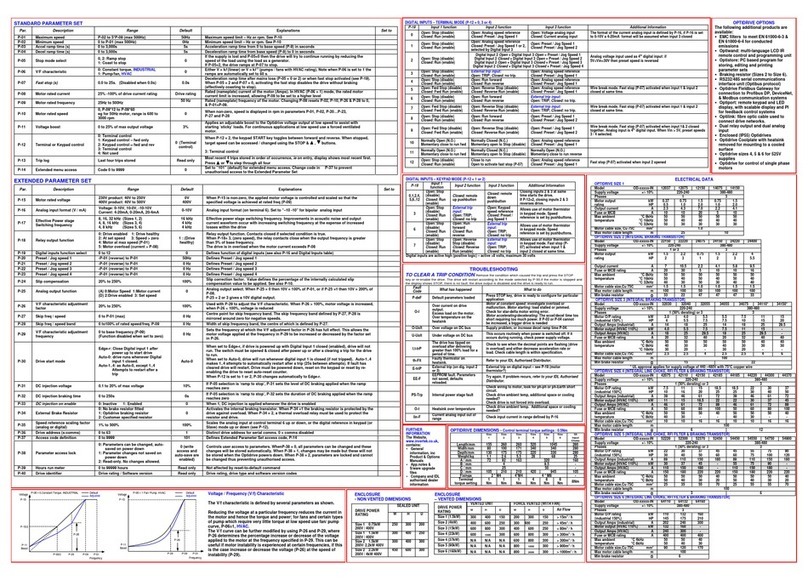

DIGITAL INPUTS – TERMINAL MODE (P-12 = 0, 3 or 4)

P-19 Input 1 function Input 2 function Input 3 function Additional Information

0 Open: Stop (disable)

Closed: Run (enable) Open: Analog input

Closed: Speed Preset 1 Volts / Current analog input

The format of the current analog input is

defined by P-16, if P-16 is set to 0-10V a 4-

20mA format will be assumed when input 3

closed

1 Open: Stop (disable)

Closed: Run (enable)

Open: Analog input

Closed: Speed Preset 1/2,

(Digital Input 3 selects)

Open: Speed Preset 1

Closed: Speed Preset 2

2Open: Stop (disable)

Closed: Run (enable)

Digital Input 2: Open \

Digital Input 3: Open /

Digital Input 3: Open \

Digital Input 2: Closed /

Digital Input 3: Closed \

Digital Input 2: Open /

Digital Input 3: Closed \

Digital Input 2: Closed /

►Selects Speed Preset 1

►Selects Speed Preset 2

►Selects Speed Preset 3

►Selects Speed Preset 4

3 Open: Stop (disable)

Closed: Run (enable) External trip input:

Open: TRIP; Closed: OK Open: Analog Input

Closed: Speed Preset 1

4 Normally Open (N.O.)

Momentarily Close to run

Normally Closed (N.C.)

Momentarily Open to stop Open: Analog Input

Closed: Speed Preset 1

5 Open: Stop (disable)

Closed: Run (enable)

Close to run

Open to fast stop (P-07) Open: Analog Input

Closed: Speed Preset1

Wire break mode. Fast stop (P-07) activated

when input 1 & input 2 closed at same time.

DIGITAL INPUTS – KEYPAD MODE (P-12 = 1 or 2)

P-19 Input 1 function Input 2 function Input 3 function Additional Information

0,1,2,4,5 Open: Stop (disable)

Closed: Run (enable) Closed: remote up pushbutton Closed: remote down pushbutton

Closing inputs 2 & 3 at same time

starts the drive.

3 Open: Stop (disable)

Closed: Run (enable) External trip input:

Open: TRIP; Closed: no trip Open: Keypad speed reference

Closed: Preset / Jog Speed 1

Speed reference is set by

pushbuttons.

TROUBLESHOOTING

TO CLEAR A TRIP CONDITION Remove the condition which caused the trip and press the STOP key or re-enable the drive.

The drive will restart according to the mode selected by P-30.

If the motor is stopped and the display shows STOP, there is no fault; the drive output is disabled and the drive is ready to run.

Fault Code What has happened What to do

P-deF Default parameters loaded Press STOP key, drive is ready to configure for particular application

O-I

Over current on drive output.

Excess load on the motor.

Over temperature on the

heatsink

Motor at constant speed: investigate overload or malfunction.Motor

starting: load stalled or jammed. Check for star-delta motor wiring error.

Motor accelerating/decelerating: The accel/decel time too short

requiring too much power. If P-03 or P-04 cannot be increased, a bigger

drive is needed

O-Uolt Over voltage on DC bus Supply problem, or increase decel ramp time P-04.

U-Uolt Under voltage on DC bus This occurs routinely when power is switched off. If it occurs during

running, check power supply voltage.

I.t-trP

The drive has tipped on

overload after delivering

greater than 100% load for a

period of time.

Check to see when the decimal points are flashing (drive in overload)

and either decrease acceleration rate or load. Check cable length is

within specification.

th-Flt Faulty thermistor on heatsink. Refer to your IDL Authorised Distributor.

E-triP External trip (on dig. input 2 or

3) External trip on digital input – see P-19 (motor thermistor?)

EE-F EEPROM fault. Parameters not

saved, defaults reloaded. Try again. If problem recurs, refer to your IDL Authorised Distributor.

PS-Trp Internal power stage fault Check wiring to motor, look for ph-ph or ph-Earth short circuit.

Check drive ambient temp, additional space or coolingneeded?

Check drive is not forced into overload.

O-t Heatsink over temperature Check drive ambient temp. Additional space or cooling needed?

Iin-F Current analog input out of

range Check input current in range defined by P-16

PARAMETER ZERO

•Provides a read only window into the motor control software

allowing key internal values to be viewed. This is useful for

following signals through the drive control system when

troubleshooting.

•Access, scroll, change and exitare as for any other parameter.

The selected variable is at the left hand side of the display.

•There are 9 different windows listed below:

1 Unscaled analog input (%) 7 Applied motor voltage (V)

2 Speed ref. via scaled analog I/P(Hz) 8 DC bus voltage (V)

3 Pre-ramp speed ref. (Hz) 9 Internal thermistor

4 Post-ramp speed ref. (Hz) (NTC) value

5 Not used

6 Stator field frequency (Hz)

OPTIDRIVE E1/EF1 SIZE 1 - 115V Input Voltage OPTIDRIVE E1/EF1 SIZE 1 - 230V Input Voltage OPTIDRIVE E1/EF1 SIZE 2 - 110V/240V Input Voltage

GENERAL TECHNICAL

DATA

•Supply frequency 48

to 62 Hz.

•Max. permissible 3-

phase supply

imbalance 3%.

•Max. ambient

temperature 50 oC.

•Max. altitude 2000 m.

•Derate above 1000 m,

1% / 100 m.

•Derate output current

5%/oC above max.

ambient temp up to

55oC

•Ix t protection above

100% output current.

•150% overload

protection for 60 sec.

•175% overload

allowable for 2 sec.

•Storage temperature -

40 to +60 oC

OPTIDRIVE DIMENSIONS & TORQUE SETTINGS

Size 1 Size 2

Length mm / in 155 / 6.10” 260 / 10.24”

Width mm / in 80 / 3.15” 100 / 3.98”

Depth mm / in 130 / 5.12” 175 / 6.89”

Weight kg / lb 1.1 / 2.42 2.6 / 5.72

A mm / in 72 / 2.83” 92 / 3.62”

B mm / in 4 / 0.16”

C mm / in 25 / 0.98”

D mm / in 105 / 4.13” 210 / 8.27”

Fixings 2 * M4 (2 x 8-32)

Power terminal torque settings 1 Nm/ 8.86 in.lbs 1 Nm/ 8.86 in.lbs

ENCLOSURE - NON VENTED DIMENSIONS

SEALED UNIT

DRIVE POWER RATING W H D

Size 1 115V / 230V 300/11.81” 400/15.75” 200/9.84”

Size 2 115V / 230V 450/17.72” 600/23.62” 300/11.81”

ENCLOSURE – VENTED DIMENSIONS

VENTED UNIT

DRIVE POWER RATING W H D

Size 1 All ratings 300/

11.81” 400/

15.75” 150/

5.91”

Size 2 All ratings 400/

15.75” 600/

23.62” 250

9.42”

DRIVE

POWER

RATING FORCE VENTED (WITH

FAN)

W H D

Air

Flow

Size 1 All

ratings 200/

7.87” 300/

11.81” 150/

5.91” > 15m3

/ h

Size 2 All

ratings 300

11.81” 400/

15.75” 250/

9.84” > 45m3

/ h

Model ODE1-xxxxx-IN/USA 12037 /

12050 12075 /

12100

Supply voltage +/- 10% 220-240

Phases 1

Motor output rating

kW Hp 0.37

0.5 0.75

1

Output Amps A 4.3 7

Fuse or Circuit Breaker

rating A 10 20

Max ambient temperature

oC 8kHz

oC 16kHz

oC 32kHz

40

30

40

30

Motor cable size, Cu 75C AWG 16 14

Max motor cable length m/ ft 50 / 160’

STANDARD PARAMETER SET

Par. Description Range Default Explanations Set to

P-01 Maximum speed P-02 to 5*P-09 (max 500Hz) 50Hz Maximum speed limit – Hz or rpm. See P-10

P-02 Minimum speed 0 to P-01 (max 500Hz) 10Hz Minimum speed limit – Hz or rpm. See P-10

P-03 Accel ramp time (s) 0 to 3,000s 5s Acceleration ramp time from 0 to base speed (P-9) in seconds

P-04 Decel ramp time (s) 0 to 3,000s 5s Deceleration ramp time from base speed (P-9) to 0 in seconds

P-05 Stop mode select 0, 2: Ramp stop

1: Coast to stop 0 If the supply is lost and P-05=0 then the drive will try to continue running byreducing

the speed of the load using the load as a generator.

If P-05=2, the drive ramps at P-07 to stop.

P-06 V/F characteristic 0: Constant torque, INDUSTRIAL

1..10: Pump/fan, HVAC 0 Either V = kf(linear) or V = kf2(pumps / fans with HVAC rating). Note when P-06 is set

to 1 the ramps are automaticallyset to 60 s.

P-07 Fast stop (s) 0.0 to 25s. (Disabled when 0.0s) 0.0s

Deceleration ramp time after mains loss (P-05 = 0 or 2) or when fast stop activated

(see P-19).

When P-05 = 2 and P-07 = 0, activating the fast stop disables thedrive without braking

(effectively coasting to stop).

P-08 Motor rated current 25% -100% of drive current rating Drive rating Rated (nameplate) current of the motor (Amps). In HVAC (P-06 = 1) mode, the rated

motor current limit is increased, allowing P-08 to be set to a higher level

P-09 Motor rated frequency 25Hz to 500Hz 50 Hz

(60Hz - HP) Rated (nameplate) frequency of the motor. Changing P-09 resets P-02, P-10, P-26 & P-

28 to 0, & P-01=P-09.

P-10 Motor rated speed 0, P-09*12 to P-09*60

eg for 50Hz motor, range is 600 to

3000 rpm 0 When non-zero, speed is displayed in rpm in parameters P-01,P-02, P-20…P-23,

P-27 and P-28

P-11 Voltage boost 0 to 25% of max output voltage 3% Applies an adjustable boost to the Optidrive voltage output at low speed to assist

with starting ‘sticky’ loads. For continuous applications at low speed use a forced

ventilated motor.

P-12 Terminal or Keypad control

0: Terminal control

1: Keypad control – fwd only

2: Keypad control −fwd and rev

3: Terminal control

4: Not used

0 (Terminal

control)

When P-12 = 2, the keypad START key toggles between forward and reverse.When

stopped, target speed can be accessed / changed using the STOP & , buttons.

3: Terminal control

P-13 Trip log Last four trips stored Read only Most recent 4 trips stored in order of occurrence, ie on entry, display shows most

recent first. Press or to step through all four

P-14 Extended menu access Code 0 to 9999 0 Set to “101” (default)for extended menu access. Change code in P-37 to prevent

unauthorised access to the Extended Parameter Set

EXTENDED PARAMETER SET

Par. Description Range Default Explanations Set to

P-15 Motor rated voltage 115V product: 40V to 150V

230V product: 40V to 250V 115V for 115V

230V for 230V When P-15 is non-zero, the applied motor voltage is controlled and scaled so that

the specified voltage is achieved at rated freq (P-09)

P-16 Analog input format (V / mA) Voltage: 0-10V, 10-0V

Current: 4-20mA, 0-20mA, 20-4mA 0-10V Analog input format (on terminal 6). If a current input format is set & P-19=0, Digital

input 3 must be closed for the current input to be configured.

P-17 Switching frequency 8, 16, 32 kHz 16 kHz Effective power stage switching frequency. Improvements in acoustic noise and

output current waveform occur with increasing switching frequency at the expense

of increased losses within the drive

P-18 Relay output function

0: Drive enabled

1: Drive healthy (not tripped)

2: Motor at set speed

3: Motor speed > zero

4: Motor at max speed (P-01)

5: Motor current overload

1

Relay output function. Contacts closed if selected condition is true.

When P-18= 3, (zero speed), the relaycontacts close when the output frequency is

greater than 5% of base frequency.

The drive is in overload when the motor current exceeds P-08

P-19 Digital inputs function

select 0 to 5, See digital input table 0 Defines function of digital inputs (see also P-16 and Digital Inputs table)

P-20 Preset speed 1 -P-02 (min) to P-01 (max) 50hz/rpm Defines Speed Preset1

P-21 Preset speed 2 -P-02 (min) to P-01 (max) 0 Hz/rpm Defines Speed Preset 2

P-22 Preset speed 3 -P-02 (min) to P-01 (max) 0 Hz/rpm Defines Speed Preset 3

P-23 Preset speed 4 -P-02 (min) to P-01 (max) 0 Hz/rpm Defines Speed Preset 4

P-24 Reserved

P-25

Analog output function

(A) 0:Motor Speed 1:Motor current

(D) 2:Drive enabled 3: Set speed 0

Analog output select. When P-25 = 0 then10V = 100% of P-01, or if P-25 =1 then 10V

= 200% of P-08.

P-25 = 2 or 3 gives a 10V digital output.

P-26 Reserved

P-27 Skip freq / speed P-02 (min) to P-01 (max) 0 (inactive) Centre point for skip frequencyband. The skip frequency band defined by P-27, P-

28 is mirrored around zero for negative speeds.

P-28 Skip freq / speed band 0 to100% of rated speed/freq. P-09 0 Hz / rpm Width of skip frequency band, the center of which is defined by P-27.

P-29 Reserved

P-30 Drive start mode

Edge-r: Close Digital input 1 after

power up to start drive

Auto-0: drive runs whenever

Digital input 1 closed.

Auto-1..4: as Auto-0, except 1..4

Attempts to restart after a

trip

Auto-0

When set to Edge-r, if drive is powered up with Digital Input 1 closed (enabled),

drive will not run. The switch must be opened & closed after power up or after a

clearing a trip for the drive to run.

When set to Auto-0, drive will run whenever digital input 1 is closed (if not tripped).

Auto-1..4 makes 1..4 attempts to automatically restart after a trip (25s between

attempts). If fault has cleared drive will restart. Drive must be powered down, reset

on the keypad or reset by re-enabling the drive to reset auto-reset counter.

When P-12 is set to 1 or 2, P-30 changes automatically to Edge-r.

P-31 Boost frequency 0 to 250Hz 50Hz Optidrive1ph start up frequency maintained during the startup boost period

P-32 Boost duration 0 to 25s 2s Time for which the startup boost period is maintained

P-33 Boost start voltage 0 to 100% 20% % of operational motor voltage applied at start of startup boost period. The applied

voltage is increased to the operational voltage at end of startup boost period.

P-34 Reserved

P-35 Analog input scaling factor 25% to 500% 80% at 50Hz,

84% at 60Hz Scales the analog input at control terminal 6 up or down, or the digital reference in

keypad (or Slave) mode up or down (see P-12).

P-36 Drive address (s-comms) 0 to 63 (0=disable) 1 Distinct drive address for serial comms. 0 = comms disabled

P-37 Access code definition 0 to 9999 101 Defines Extended Parameter Set access code, P-14

P-38 Parameter access lock

0: Parameters can be changed,

auto-saved on power down

1: Parameter changes not saved

on power down

2: Read-only. No changes allowed.

0 (write

access and

auto-save are

enabled)

Controls user access to parameters. WhenP-38 = 0, all parameters can be changed

and these changes will be stored automatically. When P-38 = 1, changes may be

made but these will not be stored when the Optidrive1ph powers down. When P-38

= 2, parameters are locked and cannot be changed thus preventing unauthorised

access.

P-39 Hours run meter 0 to 99999 hours Read only Not affected by reset-to-default command

P-40 Software checksum 0000 to FFFF (hex) Read only Drive rating, drive type and software version codes

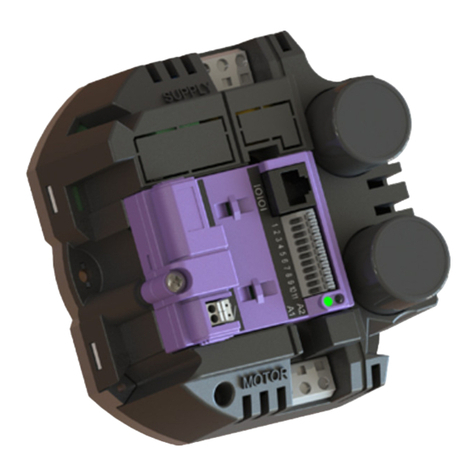

OPTIDRIVE - E OPTIONS

The following additional

products are available:

Internal and external

EMC filters to meet EN

61000-6-3 / -4 for

conducted emissions

Dual relay output and

dual analog input,

2ROUT& 2ANIN

Feedback control card,

PICON

Enclosed (IP55)

Optidrives

Optidrive Coolplate

with heatsink removed

for mounting to a cooled

surface

FURTHER INFORMATION

The Website, www.invertek.co.uk, contains the following

information:

General product information, including Product and Options

Manuals

Application notes and Software product upgrade files

Company and IDL authorised dealer information