1. Introduction ................................................................................................................................................... 7

1.1. Important safety information ..................................................................................................................................................................7

2. General Information and Ratings.................................................................................................................... 8

2.1. Part Number Construction and Definition ...............................................................................................................................................8

2.2. Drive model numbers –IP20....................................................................................................................................................................9

2.3. Drive model numbers –IP55..................................................................................................................................................................10

2.4. Drive model numbers –IP66..................................................................................................................................................................11

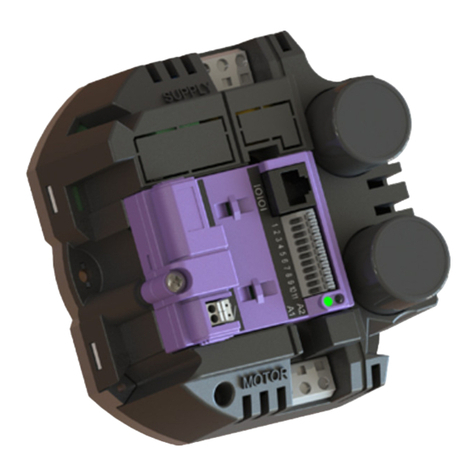

3. Mechanical Installation ................................................................................................................................ 12

3.1. General ..................................................................................................................................................................................................12

3.2. Before Installation..................................................................................................................................................................................12

3.3. UL Compliant Installation.......................................................................................................................................................................12

3.4. Mechanical dimensions and weights .....................................................................................................................................................12

3.5. Guidelines for Enclosure mounting (IP20 Units) ....................................................................................................................................15

3.6. Mounting the Drive –IP20 Units............................................................................................................................................................15

3.7. Guidelines for mounting (IP55 Units).....................................................................................................................................................16

3.8. Guidelines for mounting (IP66 Units).....................................................................................................................................................16

3.9. Removing the Terminal Cover................................................................................................................................................................17

3.10. Routine Maintenance ............................................................................................................................................................................18

4. Electrical Installation .................................................................................................................................... 19

4.1. Grounding the Drive ..............................................................................................................................................................................19

4.2. Wiring Precautions.................................................................................................................................................................................20

4.3. Incoming Power Connection..................................................................................................................................................................20

4.4. Operation of 3 Phase drives from a Single Phase Supply.......................................................................................................................21

4.5. Drive and Motor Connection .................................................................................................................................................................21

4.6. Motor Terminal Box Connections ..........................................................................................................................................................21

4.7. Motor Thermal overload Protection......................................................................................................................................................21

4.8. Control Terminal Wiring.........................................................................................................................................................................22

4.9. Connection Diagram ..............................................................................................................................................................................22

4.10. Safe Torque Off......................................................................................................................................................................................23

4.11. Conecting a Brake Resistor ....................................................................................................................................................................26

5. Managing the Keypad................................................................................................................................... 27

5.1. Keypad Layout and Function –Standard LED Keypad............................................................................................................................27

5.2. Changing Parameters.............................................................................................................................................................................27

5.3. Advanced Keypad Operation Short Cuts................................................................................................................................................28

5.4. Drive Operating Displays........................................................................................................................................................................28

5.5. Keypad Layout and Function –Optional OLED Keypad..........................................................................................................................29

5.6. Drive Operating Displays........................................................................................................................................................................29

5.7. Accessing and Changing Parameter Values............................................................................................................................................29

5.8. Changing the Language on the OLED Display.........................................................................................................................................30

5.9. Resetting Parameters to Factory Default Settings .................................................................................................................................30

5.10. Terminal Control ....................................................................................................................................................................................31

5.11. Keypad Control ......................................................................................................................................................................................32

5.12. Operating in Sensorless Vector Speed Control Mode............................................................................................................................32

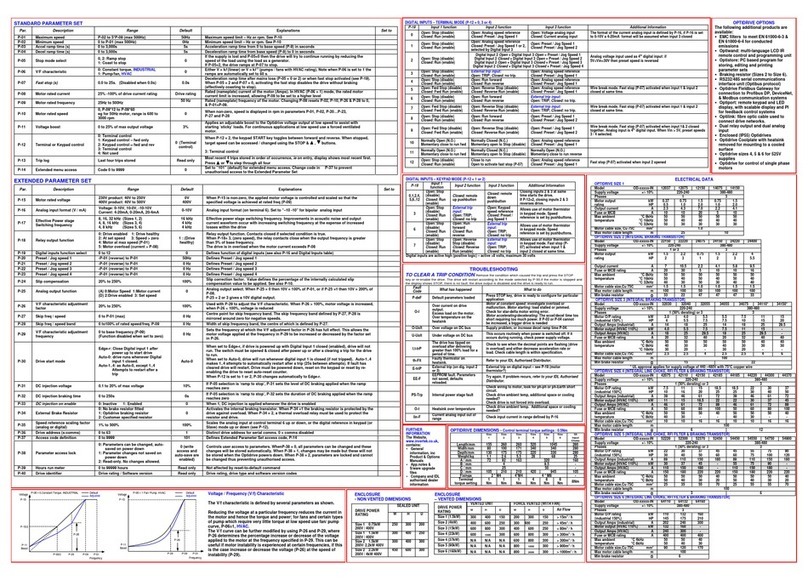

6. Parameters................................................................................................................................................... 33

6.1. Parameter Set Overview ........................................................................................................................................................................33

6.2. Parameter Group 1 –Basic Parameters.................................................................................................................................................33

7. Digital Input Functions.................................................................................................................................. 35

7.1. Digital Input Configuration Parameter P1-13.........................................................................................................................................35

8. Extended Parameters ................................................................................................................................... 37

8.1. Parameter Group 2 - Extended parameters...........................................................................................................................................37

8.2. Parameter Group 3 –PID Control ..........................................................................................................................................................41

8.3. Parameter Group 4 –High Performance Motor Control........................................................................................................................42

8.4. Parameter Group 5 –Communication Parameters................................................................................................................................43

8.5. Parameter Group 0 –Monitoring Parameters (Read Only) ...................................................................................................................44

9. Serial communications ................................................................................................................................. 46

9.1. RJ45 Connector Pin Assignment.............................................................................................................................................................46

9.2. Modbus RTU Communications ..............................................................................................................................................................46

10. Technical Data .............................................................................................................................................. 48

10.1. Environmental........................................................................................................................................................................................48

10.2. Input / Output Power and Current ratings.............................................................................................................................................48

10.3. Additional Information for UL Approved Installations ...........................................................................................................................49

10.4. Derating Information .............................................................................................................................................................................50

11. Troubleshooting ........................................................................................................................................... 51

11.1. Fault messages.......................................................................................................................................................................................51