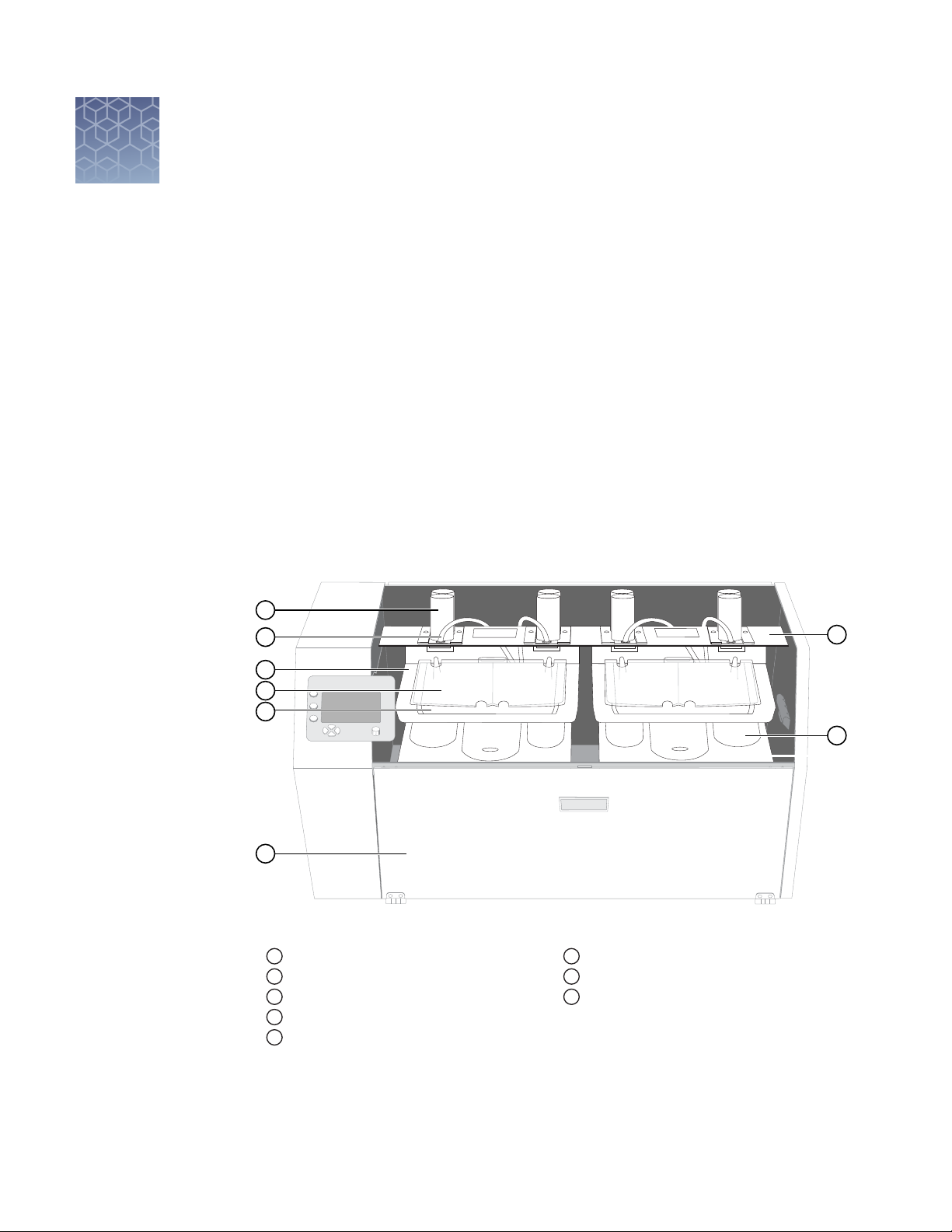

Run the processor

1. Turn the power switch on the back of the unit to the "on" position. The display

will illuminate, and the moving parts will return to their home positions. After a

few seconds, the home screen will display.

2. Program or select your preferred western blot protocol (see “Program the

processor” on page 7).

3. Fill the buer bottle in the back of the processor. Ensure that the hose hanging

from the cap reaches the bottom of the bottle. Leave the cap loose to allow air

into the bottle as liquid is pumped out.

For each wash, 10–75 mL of wash buer can be dispensed for mini gels and

10–150 mL for midi gels. We recommend using 20–30 mL per wash for mini gels

and 30–50 mL for midi gels. Ensure there is enough wash buer to complete the

protocol.

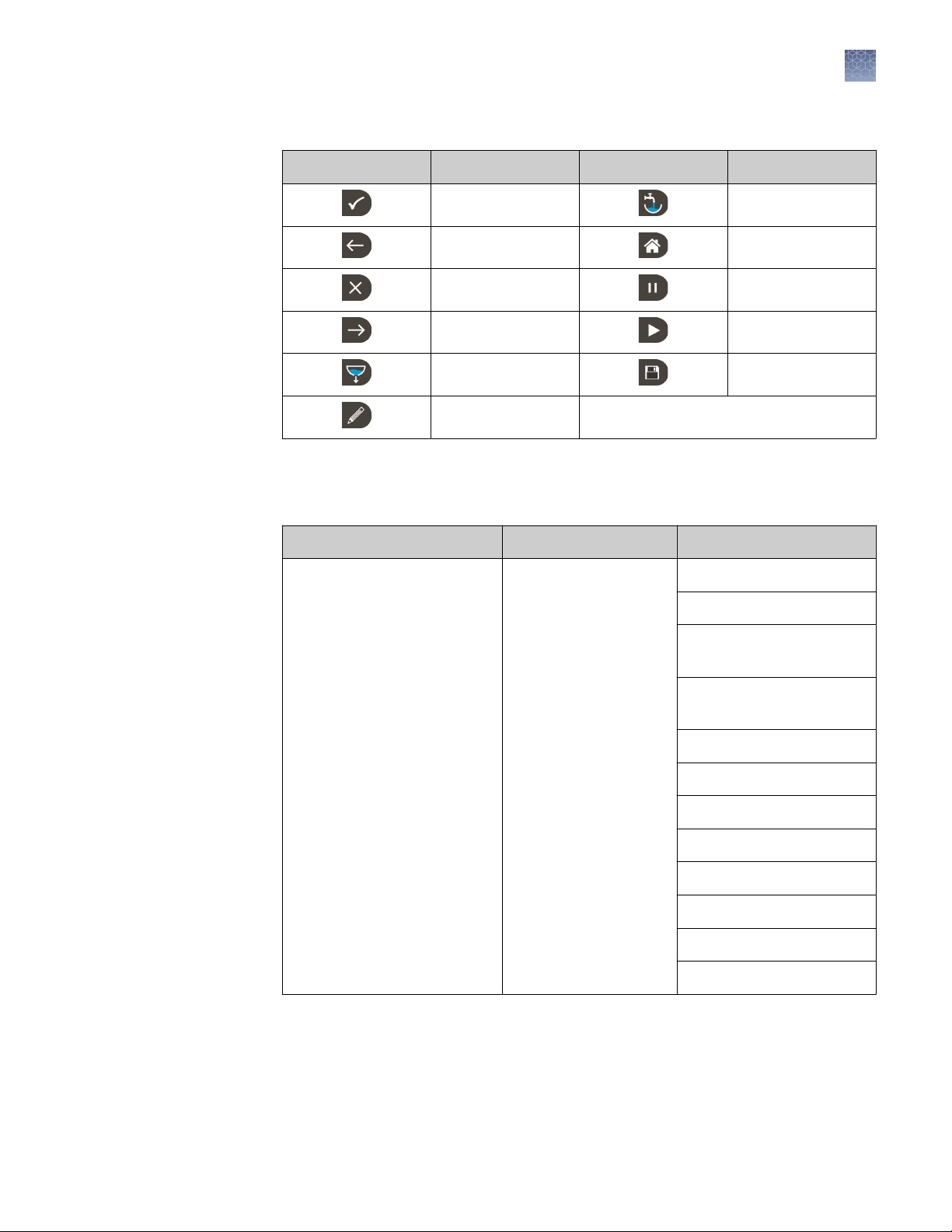

4. Flush the buer lines by selecting Flush from the home screen menu and

then pressing Accept . Press Fill until wash buer is dispensed from

all nozzles. This may take several seconds. The wash buer will dispense into

the waste tray.

5. If using primary and secondary antibodies, 2 reagent tubes will be required

for each blot being processed. Check to ensure the foil on the bottom of the

reagent tubes is not damaged. Screw one reagent tube firmly and completely

into the primary antibody position, noted with the number 1 toward the back of

the slider, and the other into the secondary antibody position, noted with the

number 2, just behind the buer dispensing nozzle.

6. Pipet the appropriate antibody solution into each reagent tube.

A standard-sized mini blot processed in a mini tray requires a minimum of

3.5 mL of each primary antibody and secondary antibody solutions. A standard-

sized midi blot processed in a midi tray requires a minimum of 7.5 mL of each

primary antibody and secondary antibody solutions.

7. Place blot(s) into the sample tray protein side up with protein lanes

perpendicular to the tray gates. If using a mini tray, which has a central divider,

make sure the blot is on the same side of the divider as the appropriate antibody

reagent tubes.

8. Pour blocking buer of choice in the tray. Use no more than 45 mL of blocking

buer per mini tray and no more than 90 mL blocking buer for midi trays.

Replace the tray cover and make sure it is fully seated.

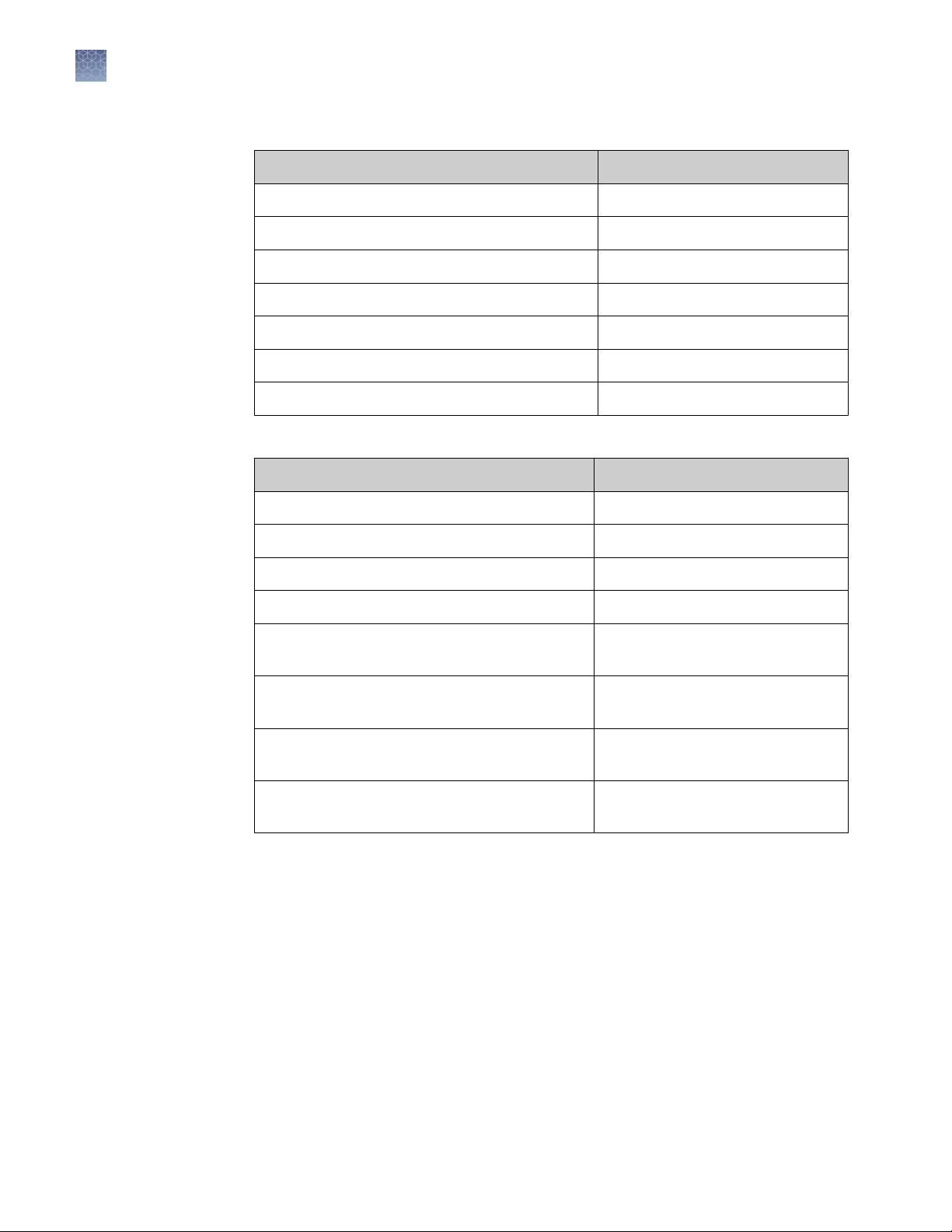

Tray Size Minimum Volume Maximum Volume

Mini 3.5 mL 45 mL

Midi 7.5 mL 90 mL

Bandmate™Automated Western Processor

Operate the Bandmate™Automated Western Blot Processor

Bandmate™Automated Western Blot Processor User Guide 9