Ironmaster IM2000 Quick reference guide

Other Ironmaster Fitness Equipment manuals

Ironmaster

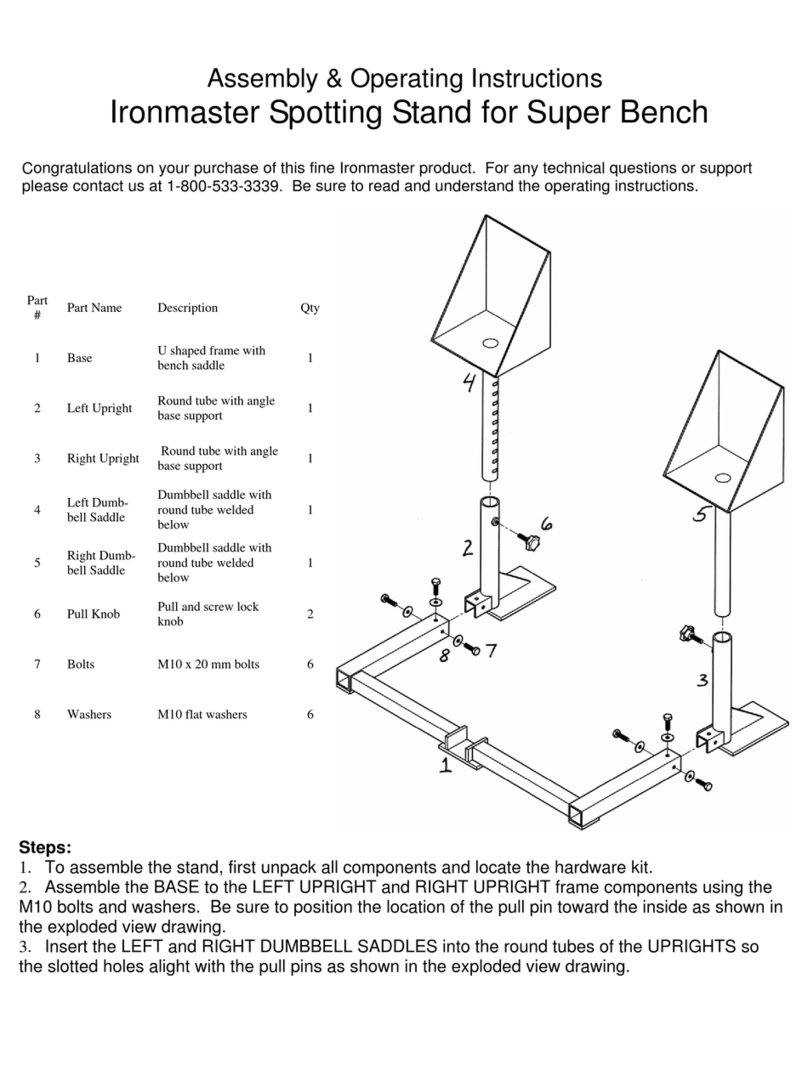

Ironmaster Spotting Stand User manual

Ironmaster

Ironmaster Quick-Lock Kettlebell User manual

Ironmaster

Ironmaster HYBRID BENCH PAD Quick reference guide

Ironmaster

Ironmaster IM1500 Quick setup guide

Ironmaster

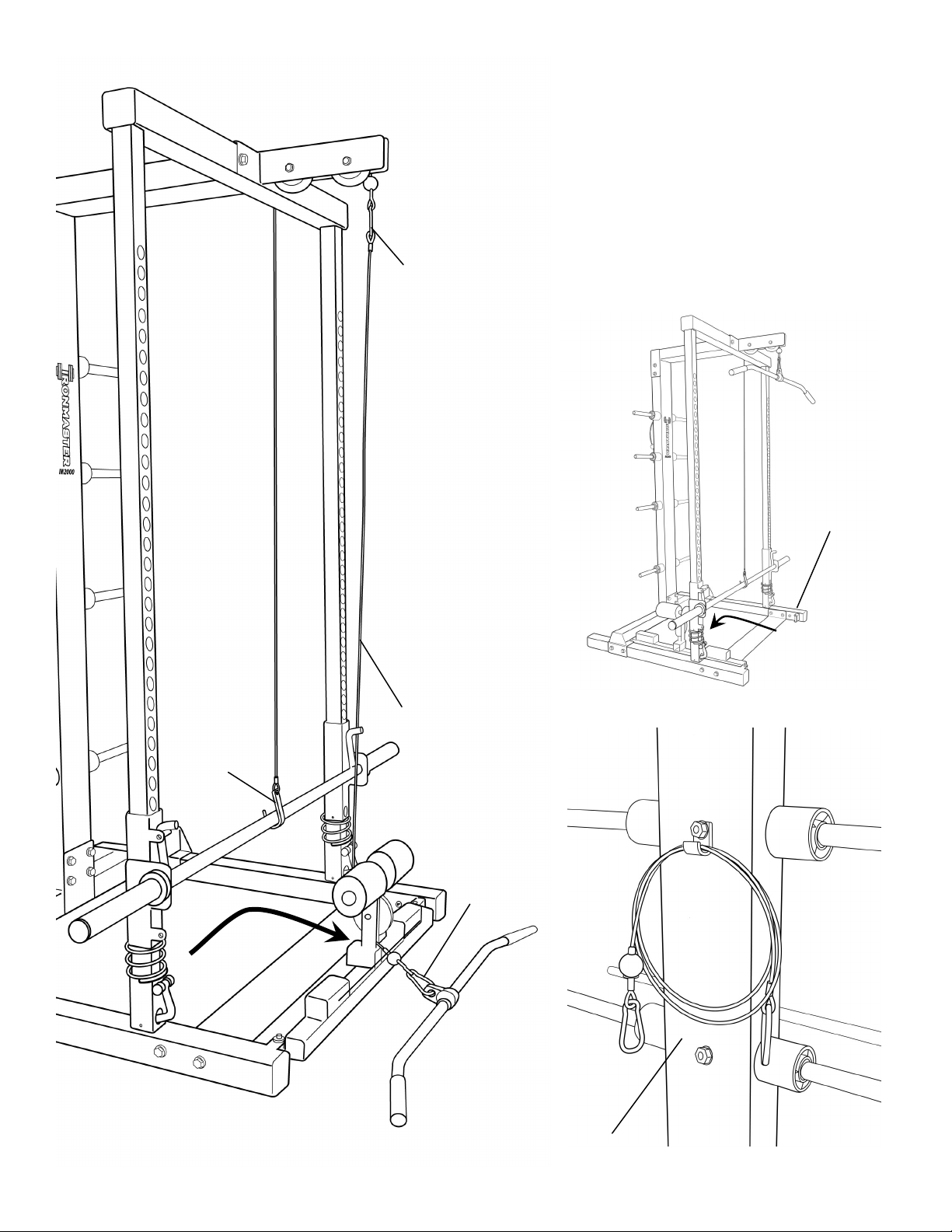

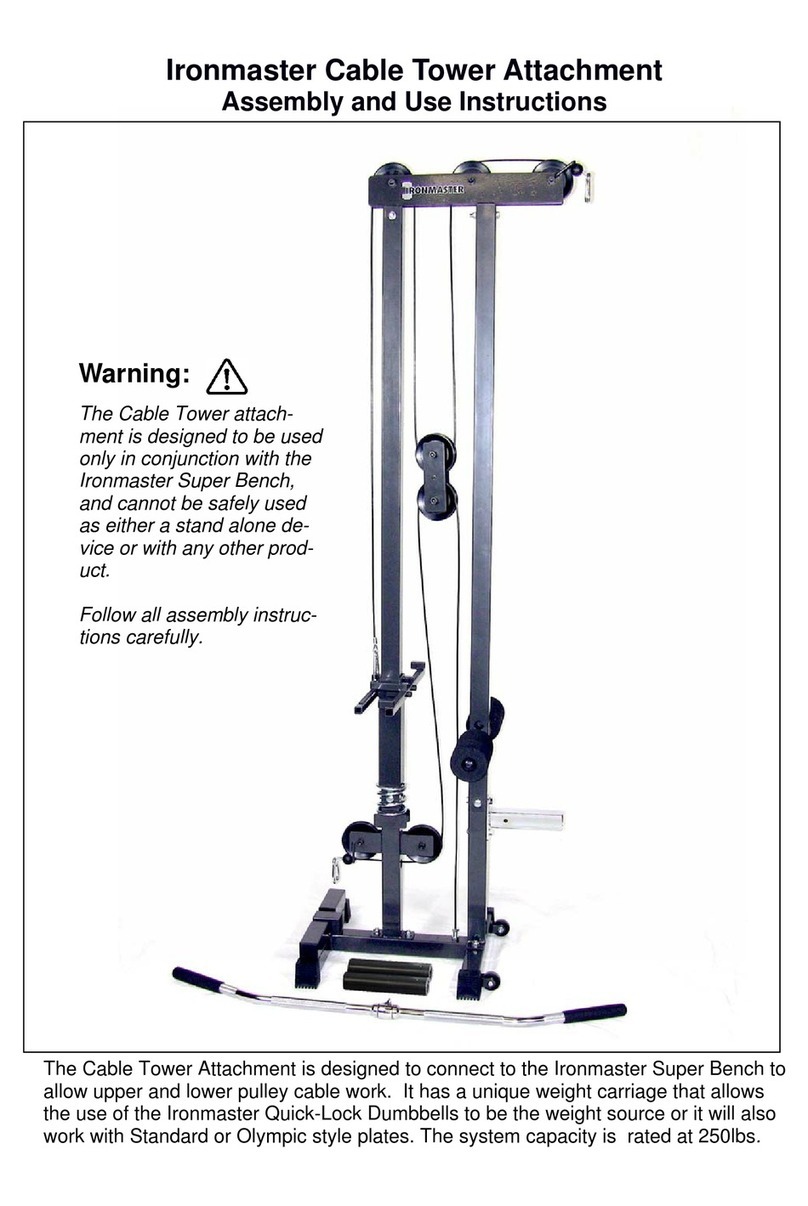

Ironmaster Cable Tower Quick setup guide

Ironmaster

Ironmaster Leg Attachment Quick reference guide

Ironmaster

Ironmaster Quick-Lock Ultimate Training Vest User manual

Ironmaster

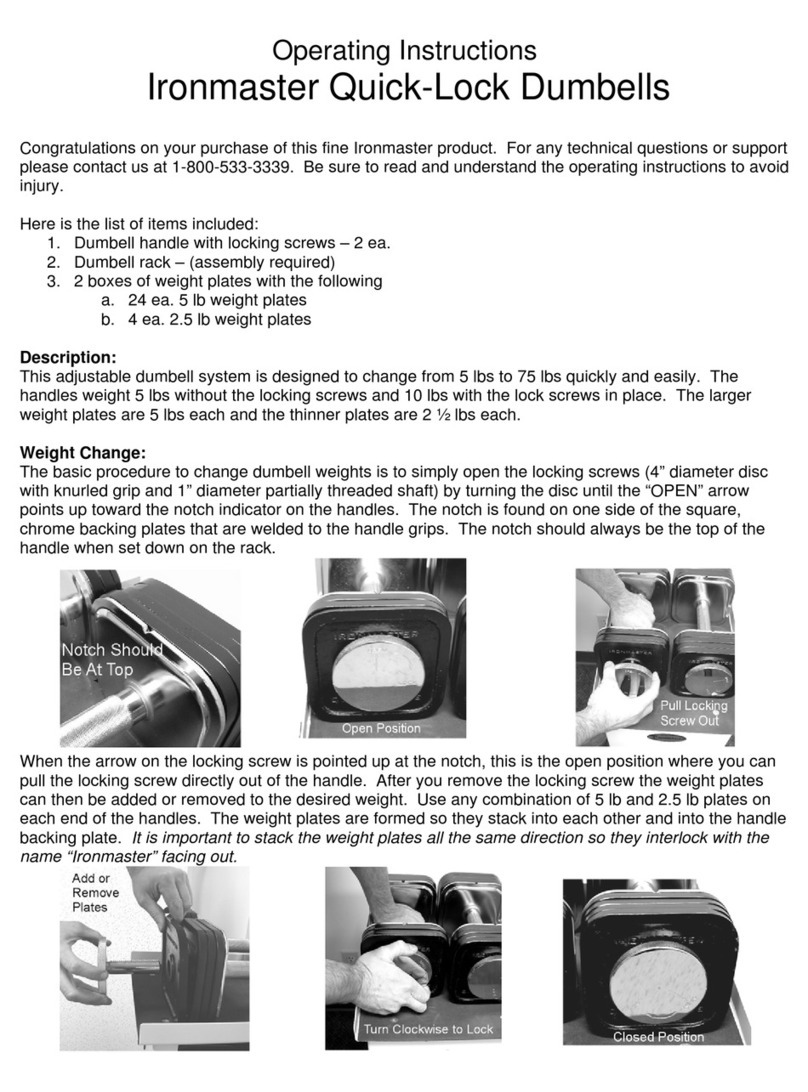

Ironmaster Quick-Lock User manual

Ironmaster

Ironmaster Leg Attachment for SuperBench Quick reference guide

Ironmaster

Ironmaster PRO Stand Quick reference guide