9

I.S.E. S.r.l.

Via Dell’artigianato 1/3

00065- Fiano Romano (RM)

Tel. 076540191-Fax 0765455386

www.irritrol.it

7.3 Break-down and elimination of the defects

Break down Cause / reason Elimination

Valve opens / closes only

manual not by electrical, Coil or coil seat is dirty Remove coil and clean it,

see point 7.1.

Control signal Supply voltage is too low

(24VAC/DC) Check supply voltage and

cable connections

Coil is broken Check coil resistance

(must be appr. ca. 30Ω)

Plunger in coil is seated Change coil

Valve does not open, even

not manual Seal of valve insert is

defect Change valve insert (see

point 7.1.)

Exit for control water on

cylinder of the valve is

blocked

Disassembly control pipe

out off connection and

blow through backwards

Valve does not close, even

not manual, Filter for control water is

dirty Disassembly valve insert

and clean filter or change it

(see point 7.1.)

Leakage in the control

water path Check all connections,

control pipe and pressure

regulators units for

leakage’s and eliminate

them.

The pressure on the

sprinkler nozzle is too low. Valve is blocked Disassembly valve and

flush pipes (see point 7.1)

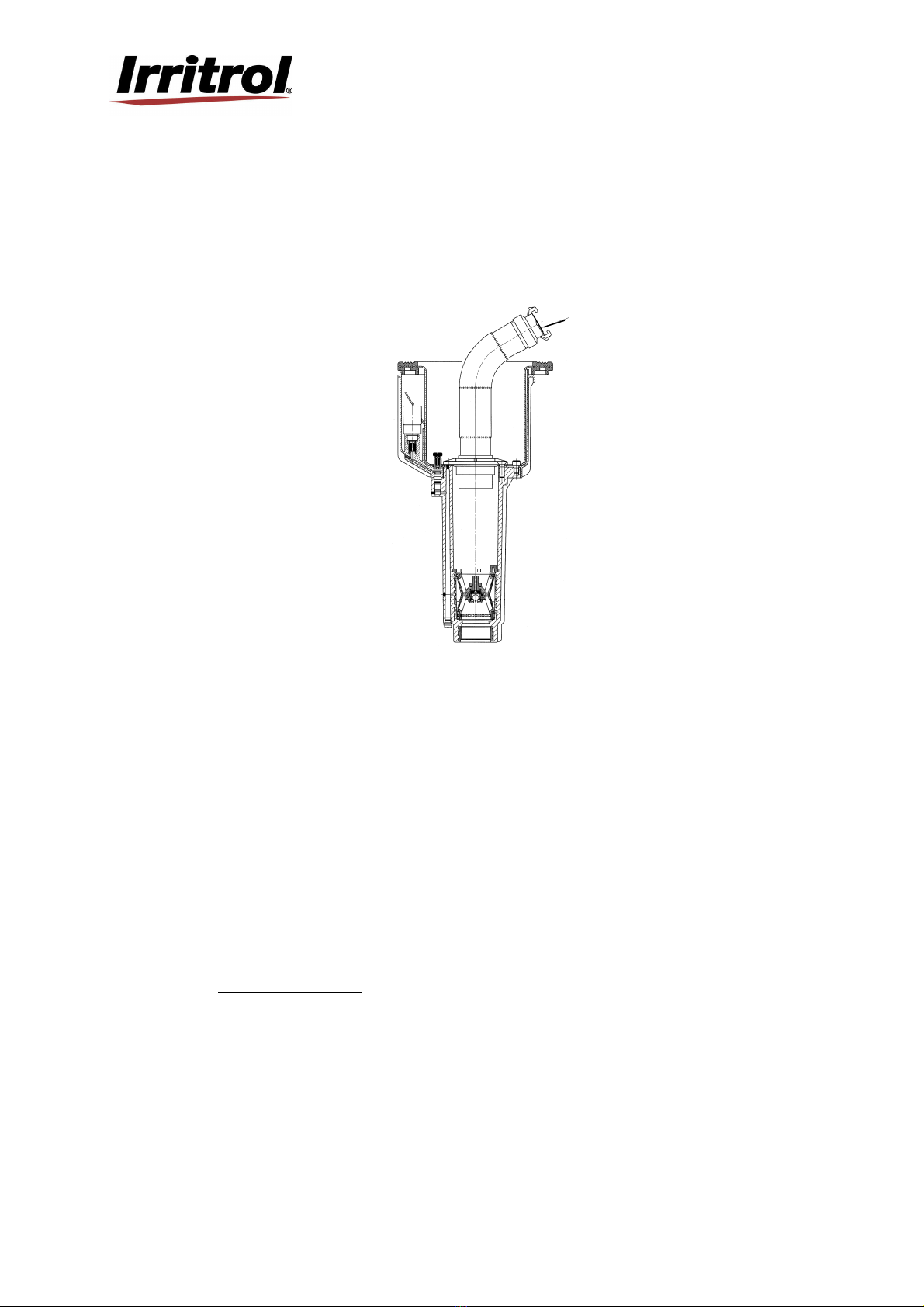

7.3.1 How to check sprinklers, which do not open

Check solenoid in or at the controller for efficient operation.

Engage valve and check at the relief exit of the controller for a brief water splash

to come out

Exchange solenoid at the controller only when there is no pressure in the line

7.3.2 How to check sprinklers, which doesn’t close

Control line has not been ventilated completely.

Foreign particles are blocking the valve

There is a leak in the hydraulic system.

The retaining circlip [9] on top of the valve is not fitted correctly and the valve has

been pushed out of it's seat by the operating pressure.

Check the outlet of the solenoid valve for correct functioning. To implement this,

disconnect the control line. The valve at the controller is normally open (without

current).

Subject to change without prior notice.