2

EN 428001072037 REACH DIPPING MY18

OPERATION MANUAL

1. INSTALLATION .....................................................................3

1.1 Plinth assembly......................................................................3

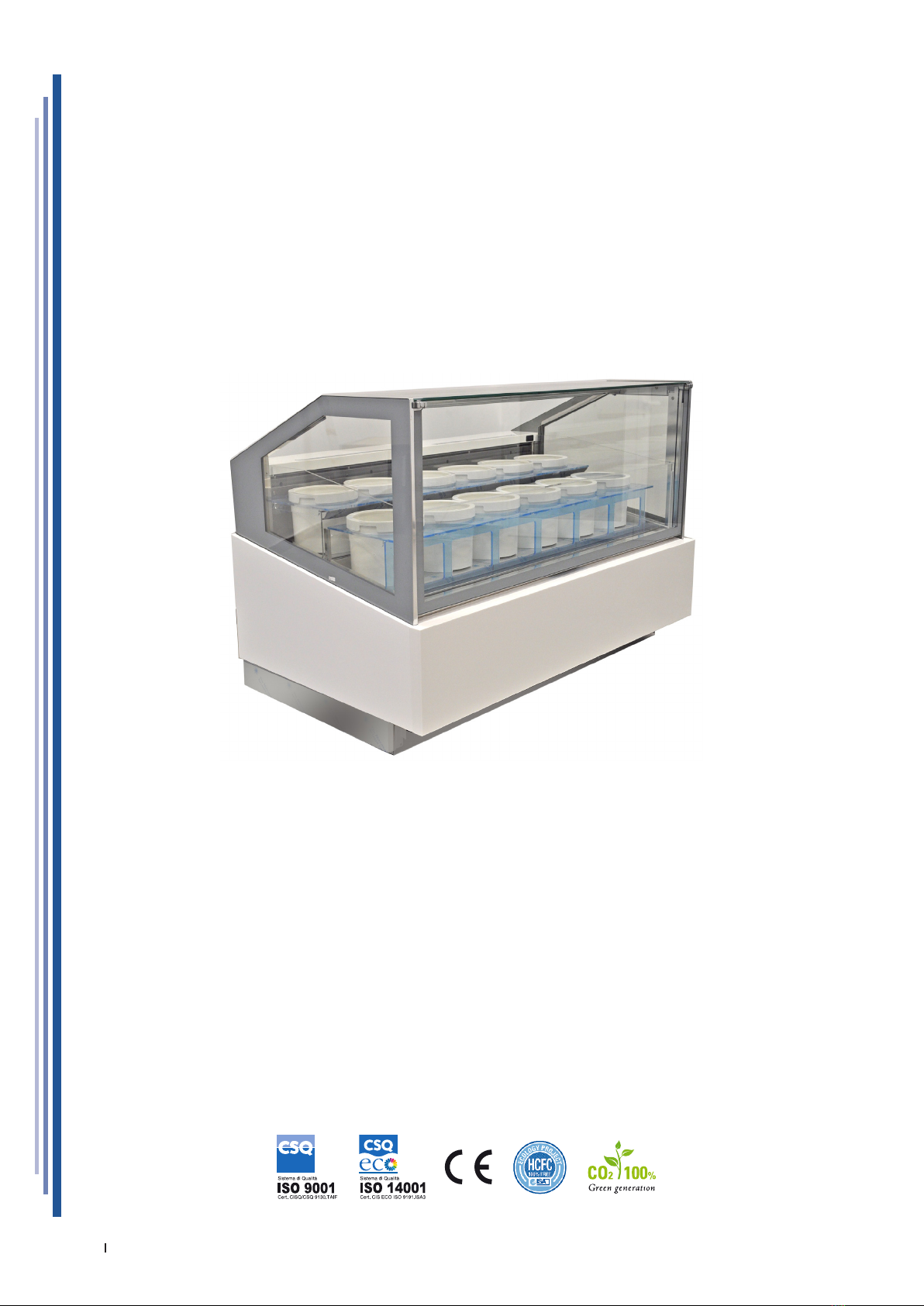

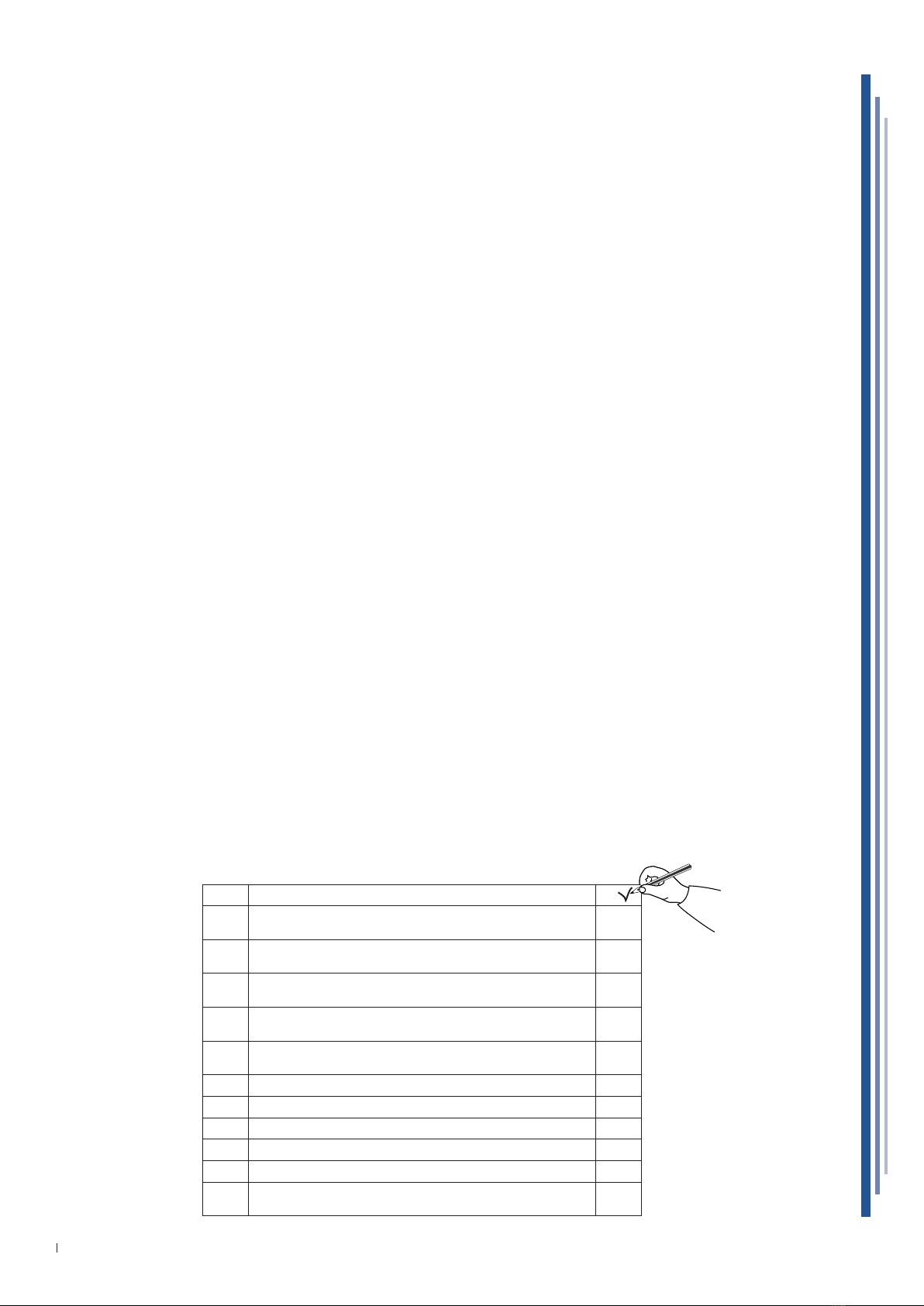

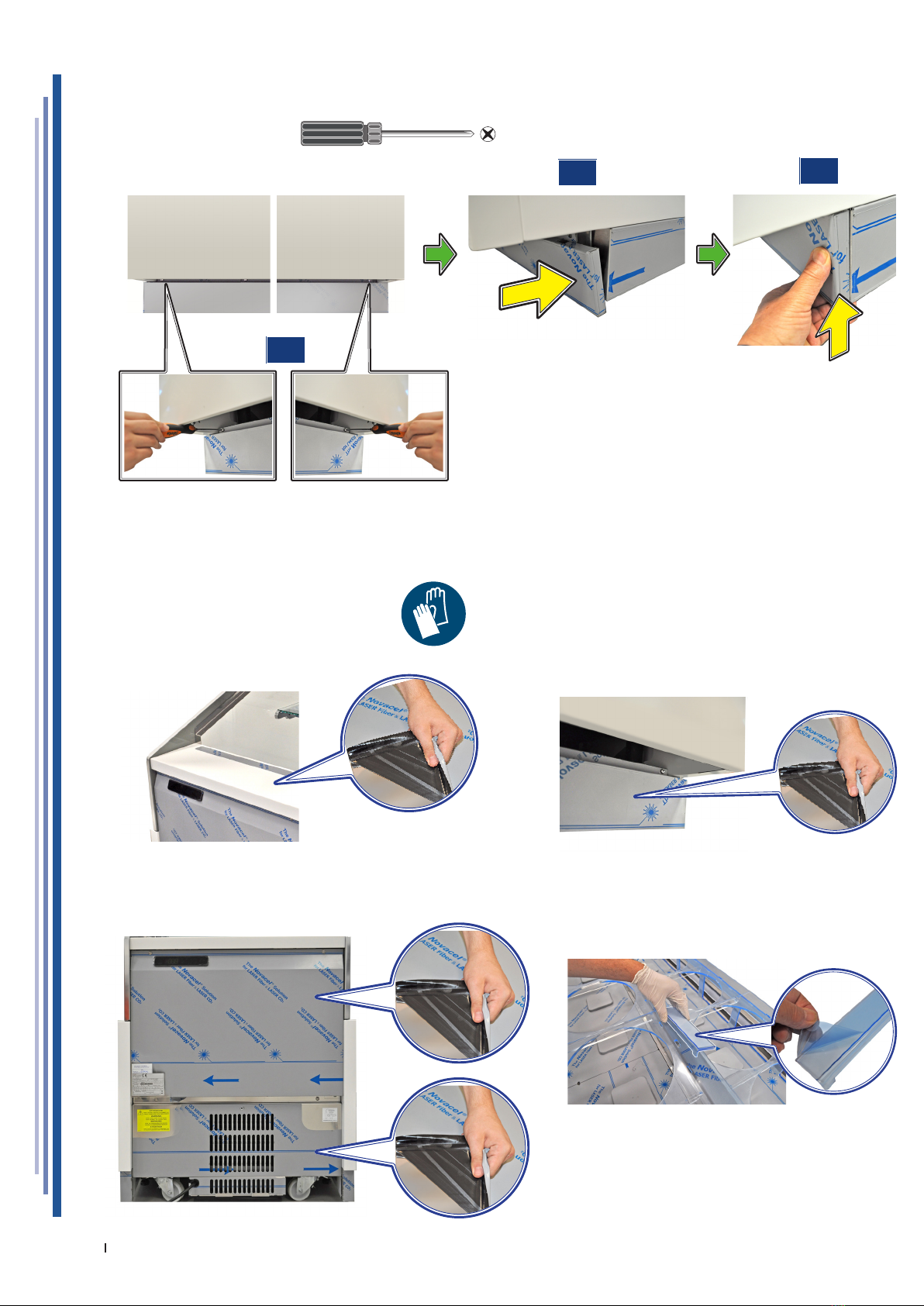

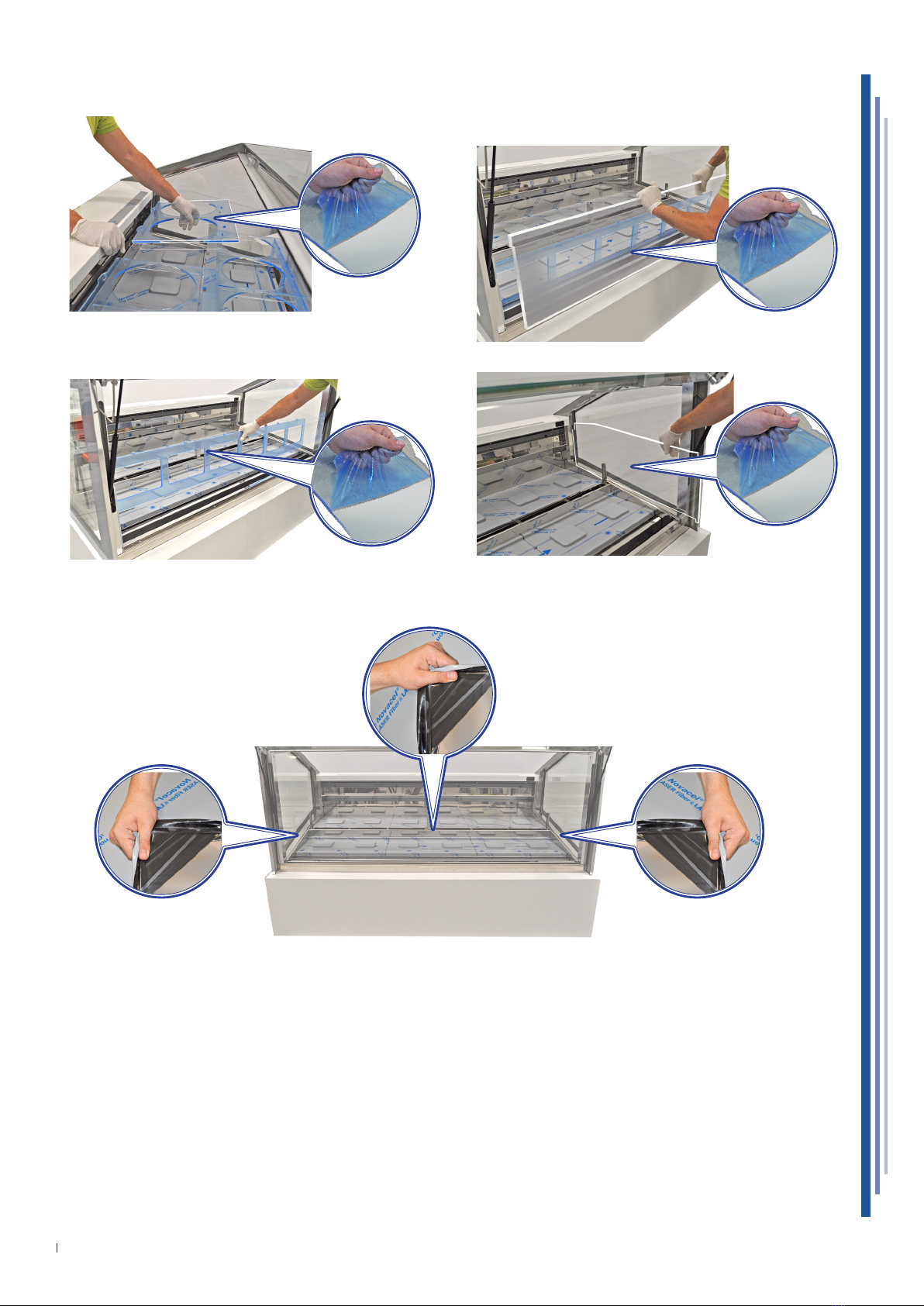

1.2 Removingthelm ..................................................................3

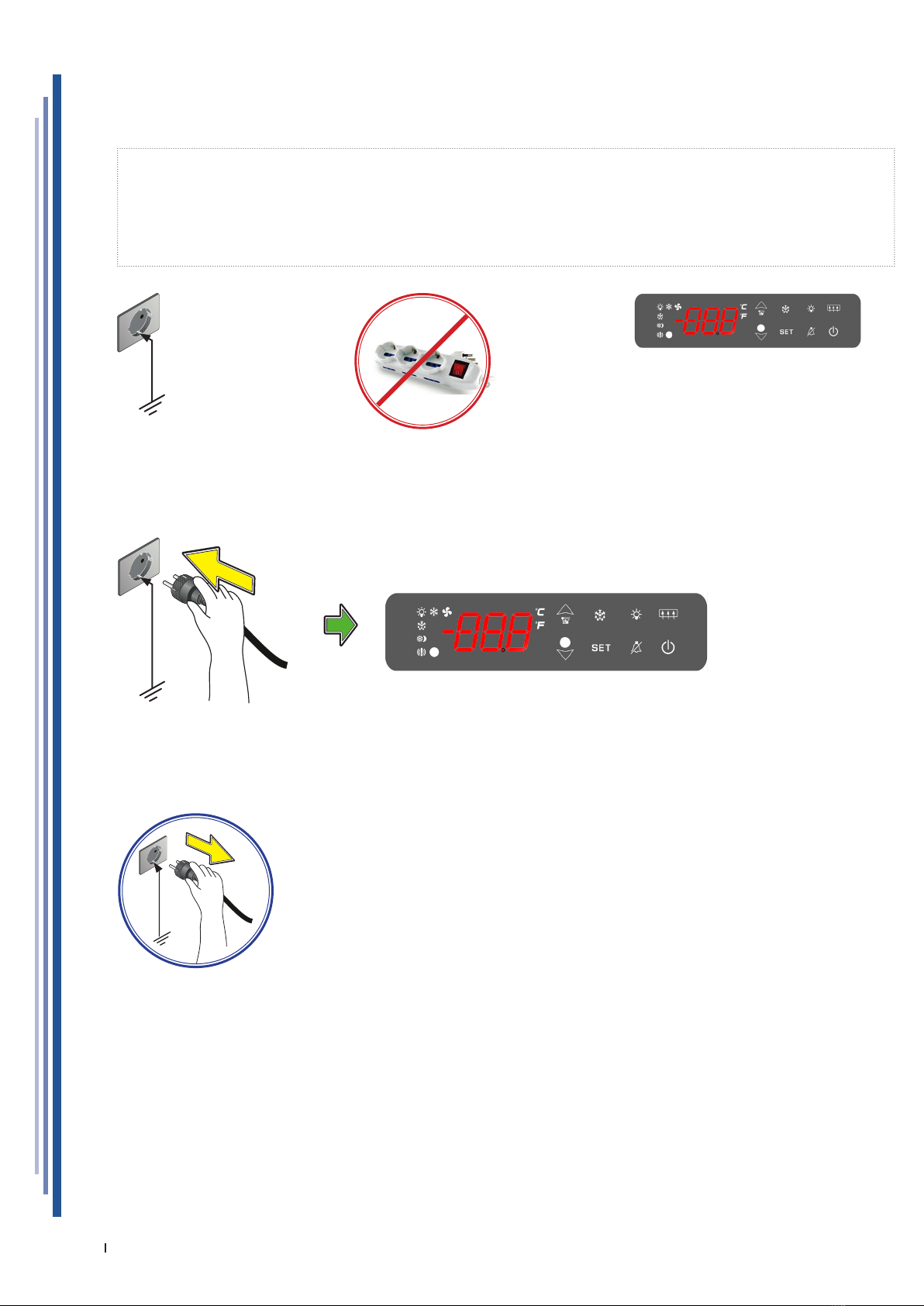

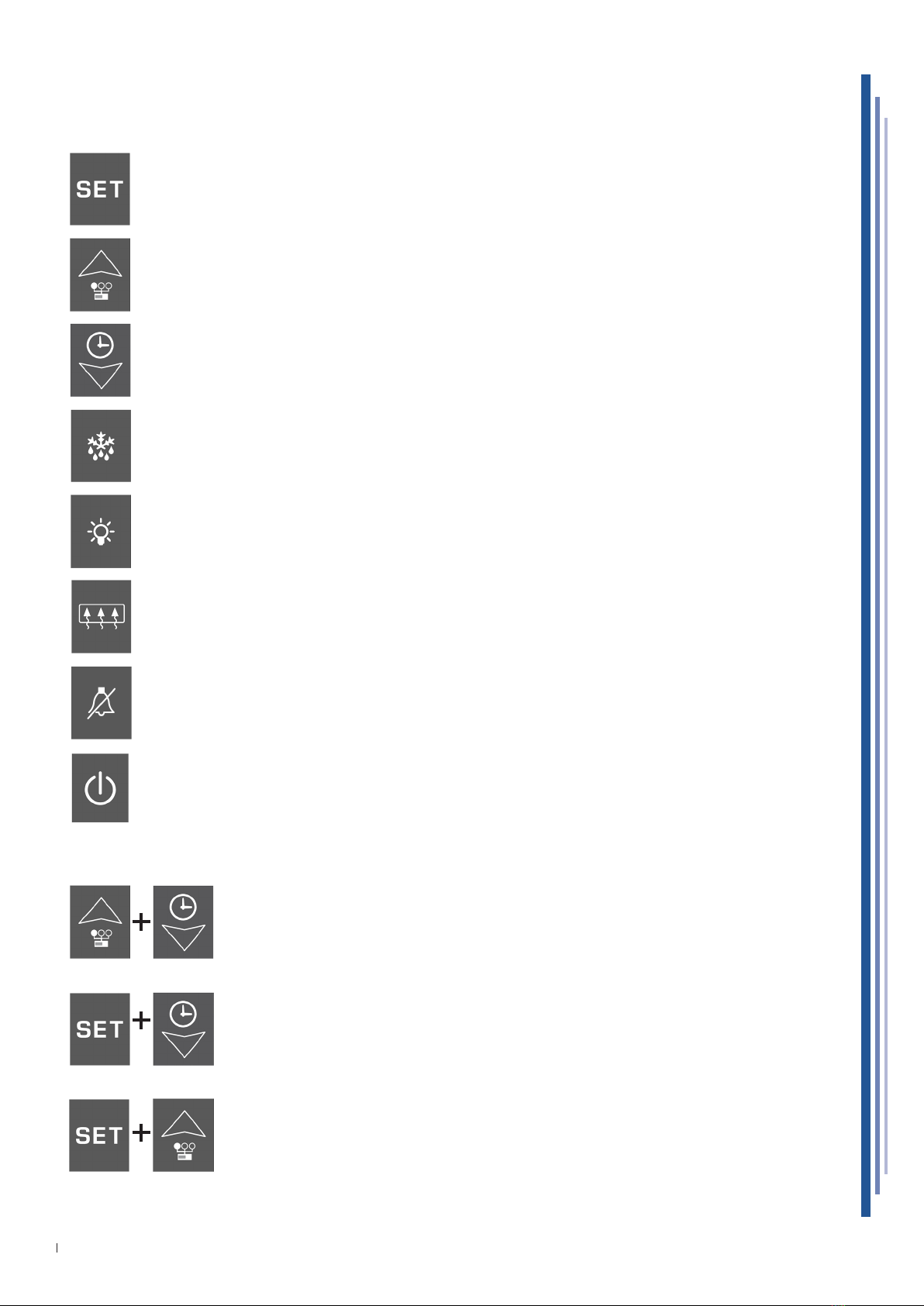

2. CONTROL PANEL.................................................................5

2.1 Informations ...........................................................................5

2.2 Start-up (on)...........................................................................5

2.3 Switcho................................................................................5

2.4 User interface.........................................................................6

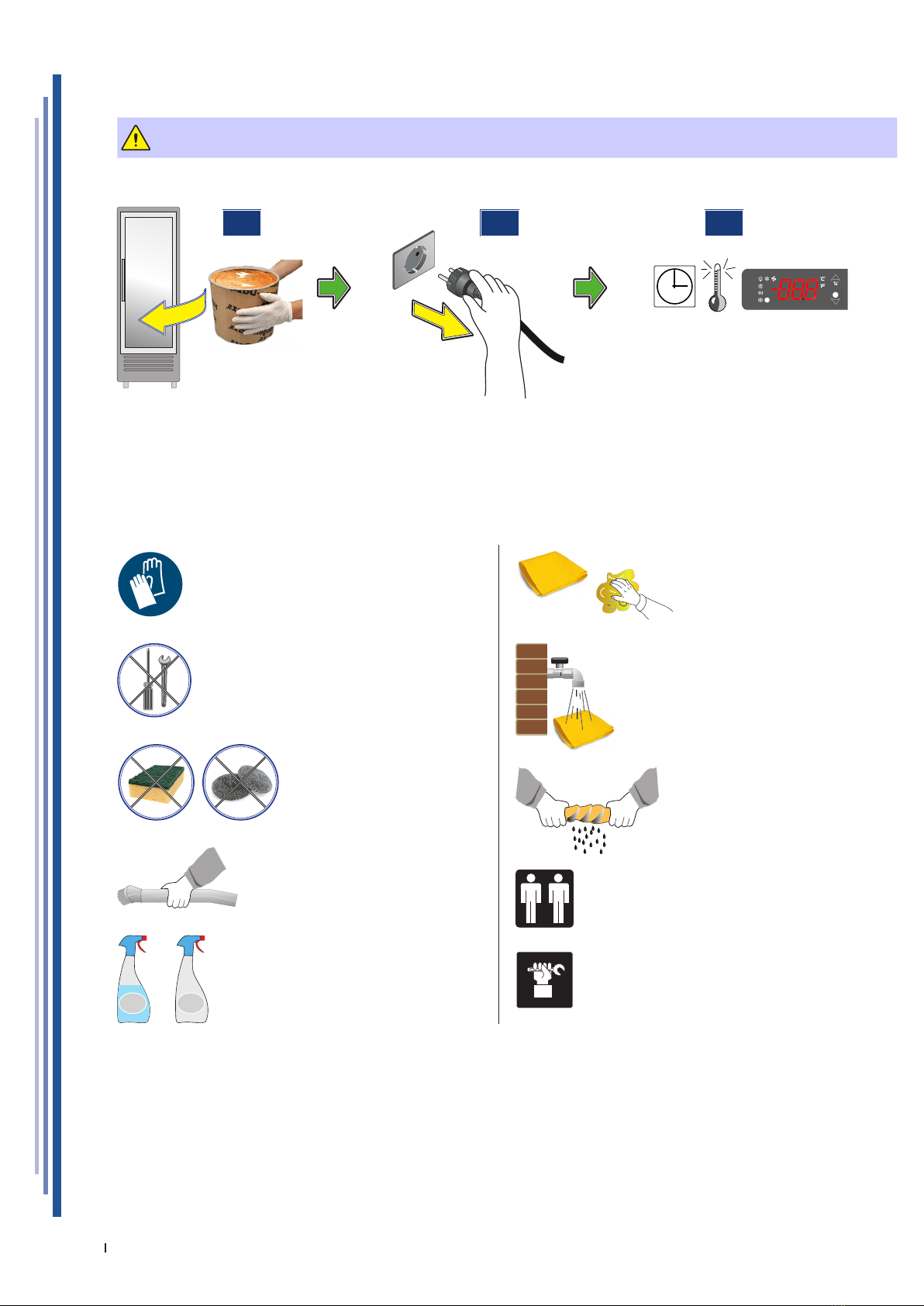

3. MAINTENANCE.....................................................................7

3.1 Before ordinary maintenance.................................................7

3.2 Information for ordinary maintenance ...................................7

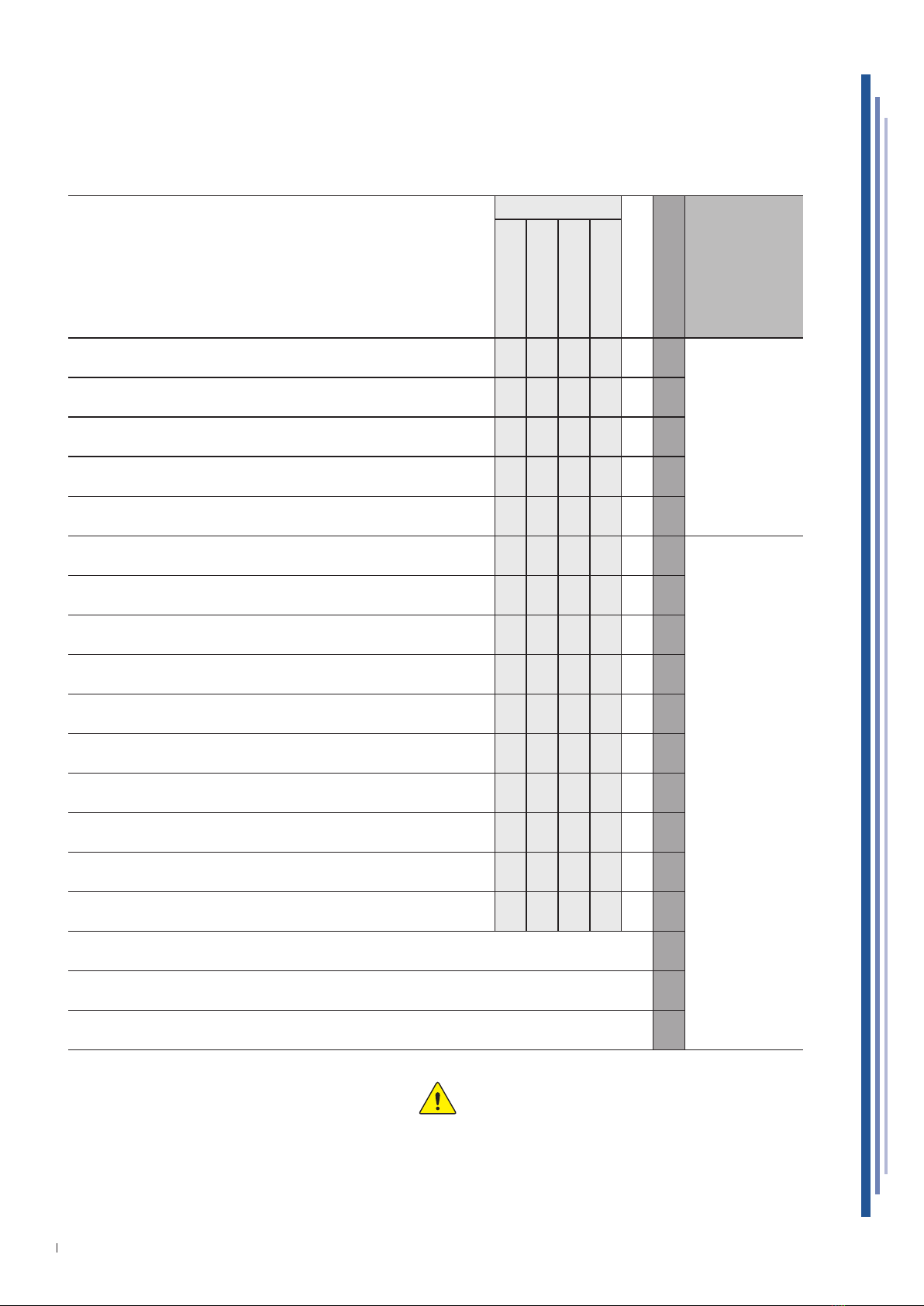

3.3 Maintenance table..................................................................8

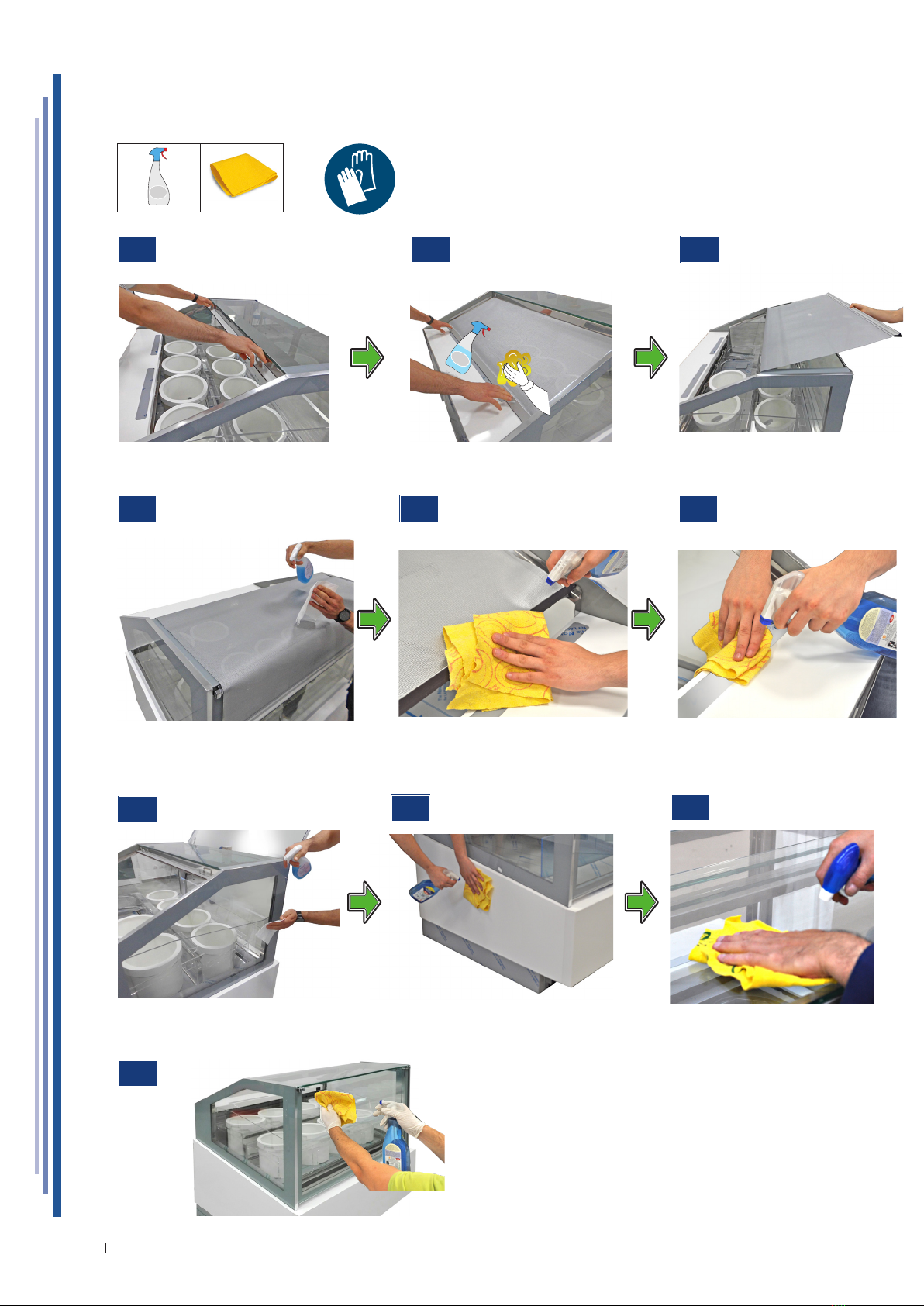

4. CLEANING ............................................................................9

4.1 Cleaning the blind ..................................................................9

4.2 External cleaning ...................................................................9

4.3 Internal cleaning...................................................................10

4.3.1 Front glass opening, closing..................................10

4.3.2 Removal of glass shelves......................................10

5. ICE CREAM TUB USE ........................................................ 11

5.1 Inserting the ice cream tub into the basket .......................... 11

5.1.1 Temperature conditions........................................................ 11

5.1.2 Load the baskets correctly ...................................................12

5.2 Removing the ice cream tub from the basket ......................13

6. FLAVOUR CARDS USE......................................................14

6.1 Insertingtheavourcards....................................................14

6.2 Installingtheavourcardholder ..........................................14

7. CLEANING (Internal).........................................................15

7.1 Removing the internal parts .................................................15

8. CLEANING (Internal evaporator) .....................................16

8.1 Cleaning the evaporator.......................................................16

9. CLEANING DUST FILTER .................................................17

10. CLEANING THE CONDENSER .........................................18

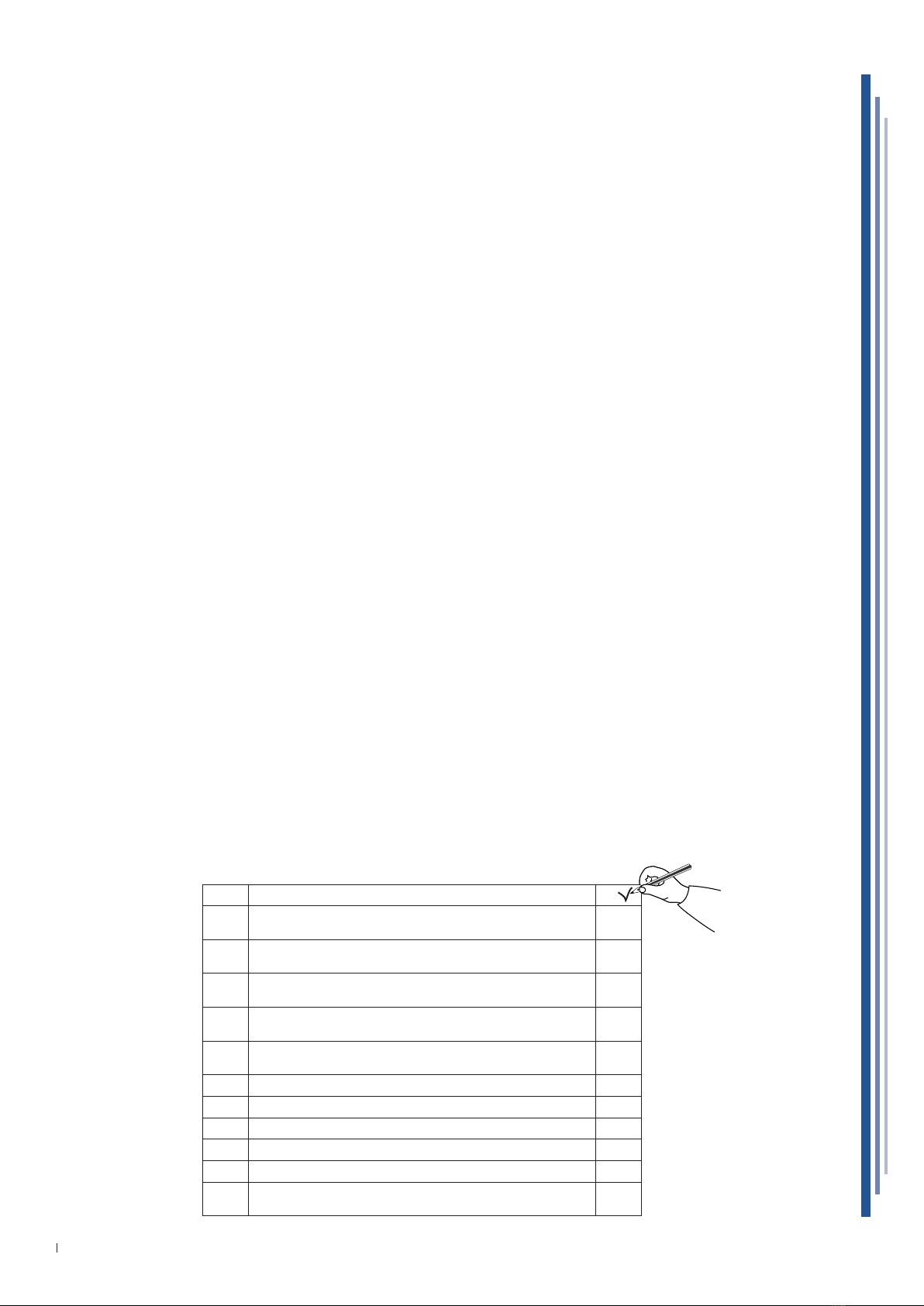

1Isthecabinetinplaceandreadyrstart-up?

2Istheelectricalpowersupplycorrect?20Ampcircuit

breaker_208Volts

3Are there any HVAC vents located above or behind the case that

willintroduceairintothecabinet?

4Is the cabinet located close to door ways, drive thru windows or

draftswhichcouldintroduceairintothecabinet?

5Is the overall placement of the cabinet acceptable, not exposed

tosourcesofheatordirectsunlight?

6Hastheupdateddefrostparametersbeenconrmed?(askyour

service agent)

7Hasthetemperaturebeensettothecorrentsetting?

8Hasthecabinetreachedsetpointandcycledo?

9Isthesightglassfull?

10 Areallthelightson?

11 Isthecondenserairwayunobstructedandairlterinplace?

12 Is the owners manual with 1 spare light and compressor fuse

withthecabinet?

When doing a start-up, please ensure the supplied checklist has been

completed and also check the following